- Page 1 and 2: 48 HOUR TURNAROUND ON CONNECTORSCON

- Page 3 and 4: WARRANTY & PRODUCT SAFETY INFORMATI

- Page 5 and 6: AMPHE-LITEAmphenol’s MIL-DTL-3899

- Page 7 and 8: 26482 Series 38999 SeriesPT/PTSE 62

- Page 9 and 10: TABLE OF CONTENTS97 Series5015 Seri

- Page 11 and 12: Amphenol 97 Series MIL-DTL-5015MATE

- Page 13 and 14: TECHNICALSPECIFICATIONSContact rete

- Page 15 and 16: 8S-110SL-3*10SL-4*12-512S-112S-212S

- Page 17 and 18: PLUG STYLES (BARREL ASSEMBLIES)97-3

- Page 19 and 20: MS3057-A CABLE CLAMPACCESSORIESSTAN

- Page 21 and 22: GASKETSACCESSORIESSynthetic rubber

- Page 23 and 24: Amphenol AIT/MS Series MIL-DTL-5015

- Page 25 and 26: TECHNICALSPECIFICATIONSMECHANICALWi

- Page 27 and 28: STEP 4: SELECT LAYOUTaSee pages 64-

- Page 29 and 30: ACCESSORIESInsert head first.Trim e

- Page 31 and 32: COAXCONTACT SIZE12COAXWIRE SIZERG16

- Page 33 and 34: ENDBELL STYLESSHELLSIZEAL 3XXDIMENS

- Page 35 and 36: DIMENSIONSSTYLE 6 RIGHT ANGLE ENDBE

- Page 37 and 38: PANEL CUTOUTSDimension J is flange

- Page 39 and 40: MS3057-A CABLE CLAMPMS3057-C WATERP

- Page 41 and 42: GASKETSACCESSORIESSynthetic rubber

- Page 43 and 44: CRIMP TOOL OPERATION (CONTINUED)CRI

- Page 45 and 46: MateswithAIT/MS SERIES CONNECTORSCO

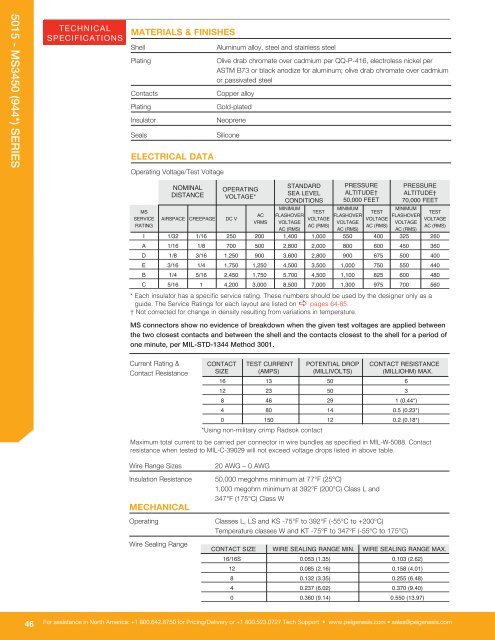

- Page 47: Amphenol MS3450 (Matrix ® ) Series

- Page 51 and 52: 8S-110S-210SL-310SL-412S-1*12S-2*12

- Page 53 and 54: RECEPTACLESSHELLSIZESIZE16&12CONTAC

- Page 55 and 56: PINSCONTACTSIZEHAND-CRIMPTOOLPOWER-

- Page 57 and 58: ACCESSORIESSTANDARD CABLE CLAMPSLig

- Page 59 and 60: COMMERCIAL &MILITARYAmphenol AIB/GT

- Page 61 and 62: TECHNICALSPECIFICATIONSELECTRICAL D

- Page 63 and 64: TECHNICALSPECIFICATIONSAIB/GT SERIE

- Page 65 and 66: TIP: Order connector, backshell and

- Page 67: CONTACT LEGEND =16 =12 =8 =4 =0 =2/

- Page 70 and 71: 5015 - AMPHENOL AIB/GT SERIES MIL-D

- Page 72: 5015 - AMPHENOL AIB/GT SERIES MIL-D

- Page 75 and 76: CONTACT LEGEND =16 =12 =8 =4 =0Mati

- Page 77 and 78: MATING-FACE VIEW OF PIN INSERTSLAYO

- Page 79 and 80: LAYOUTS BY SHELL SIZESERIES KEY: 97

- Page 81 and 82: LAYOUTS BY SHELL SIZESERIES KEY: 97

- Page 83 and 84: LAYOUTS BY SHELL SIZESERIES KEY: 97

- Page 85 and 86: LAYOUTS BY SHELL SIZESERIES KEY: 97

- Page 87 and 88: LAYOUTS BY SHELL SIZESERIES KEY: 97

- Page 89 and 90: ACCESSORIESCONTACTSIZE16S †16AF8W

- Page 91 and 92: COAXCONTACT SIZE12COAXWIRE SIZERG16

- Page 93 and 94: PRINTED CIRCUIT CONTACTSSHELLSIZESH

- Page 95 and 96: STYLE 0, 20, 30 RECEPTACLESL 2BTHRE

- Page 97 and 98: STYLE 1 CABLE RECEPTACLEB ThreadFK

- Page 99 and 100:

STYLE 4 RUBBER-COVERED PLUGSL 2BTHR

- Page 101 and 102:

DIMENSIONSSTYLE 6, 6HD PLUGSB Threa

- Page 103 and 104:

6B PANEL PLUGQS RLSRPTDIMENSIONSSTY

- Page 105 and 106:

PANEL CUTOUTSDim. J-flange in front

- Page 107 and 108:

MS3420 TELESCOPING BUSHINGSSIZE1ST

- Page 109 and 110:

SOLDER CONTACTSSTEP 1: Slidethe rea

- Page 111 and 112:

INSERTION OF CONTACTS (CONTINUED)UN

- Page 113 and 114:

AIBC/ACA-B SERIES CONNECTORSSERIESA

- Page 115 and 116:

AMPHENOL HOW TO ORDER GUIDEVG95234

- Page 117 and 118:

Amphenol PT/PT-SE MIL-DTL-26482 Ser

- Page 119 and 120:

TECHNICALSPECIFICATIONSInsulation S

- Page 121 and 122:

STEP 3: SELECT LAYOUTCONTACTSROTATI

- Page 123 and 124:

STEP 3: SELECT LAYOUTCONTACTSINSERT

- Page 125 and 126:

CONTACT LEGEND = 20 =16 =HV =12 =co

- Page 127 and 128:

WIRE HOLE FILLERPIN & SOCKET CRIMP

- Page 129 and 130:

PIN & SOCKET SE CRIMP COAX CONTACTS

- Page 131 and 132:

PRINTED CIRCUIT BOARDHOW-TO-ORDER P

- Page 133 and 134:

ENDBELL STYLESL1DIMENSIONSA E F/SR

- Page 135 and 136:

DIMENSIONSSTRAIGHT PLUGSRIGHT ANGLE

- Page 137 and 138:

MS3057-C WATERPROOF CABLE CLAMPGASK

- Page 139 and 140:

INSERTION OF CONTACTSSTEP 1: Slide

- Page 141 and 142:

Amphenol 62GB SeriesMIL-DTL-26482 P

- Page 143 and 144:

TECHNICALSPECIFICATIONSInsulation S

- Page 145 and 146:

STEP 2: SELECT LAYOUTINSERT SERVICE

- Page 147 and 148:

SHELL†CHOOSE KEYWAY ORIENTATIONSV

- Page 149 and 150:

ENDBELL STYLES62GB10A62GB11ADIMENSI

- Page 151 and 152:

STRAIGHT PLUG STYLES62GB16P62GB16JD

- Page 154 and 155:

26482 - AMPHENOL 62GB SERIESRECEPTA

- Page 156 and 157:

26482 - AMPHENOL 62GB SERIESPINSCRI

- Page 158 and 159:

26482 - AMPHENOL 62GB SERIESSTEP 1:

- Page 160 and 161:

26482 - AMPHENOL 62GB SERIESINSERTI

- Page 162 and 163:

26482 - AMPHENOL MIL-DTL-26482 SERI

- Page 164 and 165:

26482 - AMPHENOL MIL-DTL-26482 SERI

- Page 166 and 167:

26482 - AMPHENOL MIL-DTL-26482 SERI

- Page 168 and 169:

26482 - AMPHENOL MIL-DTL-26482 SERI

- Page 170 and 171:

26482 - AMPHENOL MIL-DTL-26482 SERI

- Page 172 and 173:

26482 - AMPHENOL MIL-DTL-26482 SERI

- Page 174 and 175:

38999 - LJT MIL-DTL-38999 SERIES IT

- Page 176 and 177:

38999 - LJT MIL-DTL-38999 SERIES IC

- Page 178 and 179:

38999 - LJT MIL-DTL-38999 SERIES IH

- Page 180 and 181:

38999 - LJT MIL-DTL-38999 SERIES IV

- Page 182 and 183:

38999 - LJT MIL-DTL-38999 SERIES IV

- Page 184 and 185:

38999 - LJT MIL-DTL-38999 SERIES IP

- Page 186 and 187:

38999 - LJT MIL-DTL-38999 SERIES IC

- Page 188 and 189:

38999 - LJT MIL-DTL-38999 SERIES IR

- Page 190 and 191:

38999 - LJT MIL-DTL-38999 SERIES IA

- Page 192 and 193:

38999 - LJT MIL-DTL-38999 SERIES IW

- Page 194 and 195:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 196 and 197:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 198 and 199:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 200 and 201:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 202 and 203:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 204 and 205:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 206 and 207:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 208 and 209:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 210 and 211:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 212 and 213:

38999 -AMPHENOL JT MIL-DTL-38999 SE

- Page 214 and 215:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 216 and 217:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 218 and 219:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 220 and 221:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 222 and 223:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 224 and 225:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 226 and 227:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 228 and 229:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 230 and 231:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 232 and 233:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 234 and 235:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 236 and 237:

38999 - AMPHENOL TV-CTV TRI-START M

- Page 238 and 239:

38999 - AMPHE-LITE D38999 SERIES II

- Page 240 and 241:

38999 - AMPHE-LITE D38999 SERIES II

- Page 242 and 243:

38999 - AMPHE-LITE D38999 SERIES II

- Page 244 and 245:

38999 - AMPHE-LITE D38999 SERIES II

- Page 246 and 247:

38999 - AMPHE-LITE D38999 SERIES II

- Page 248 and 249:

38999 - AMPHE-LITE D38999 SERIES II

- Page 250 and 251:

38999 - AMPHE-LITE D38999 SERIES II

- Page 252 and 253:

38999 - AMPHE-LITE D38999 SERIES II

- Page 254 and 255:

38999 - AMPHE-LITE D38999 SERIES II

- Page 256 and 257:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 258 and 259:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 260 and 261:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 262 and 263:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 264 and 265:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 266 and 267:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 268 and 269:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 270 and 271:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 272 and 273:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 274 and 275:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 276 and 277:

38999 - AMPHENOL SJT MIL-DTL-38999

- Page 278 and 279:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 280 and 281:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 282 and 283:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 284 and 285:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 286 and 287:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 288 and 289:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 290 and 291:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 292 and 293:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 294 and 295:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 296 and 297:

AMPHENOL AMPHE-EX EXPLOSION PROOF S

- Page 298 and 299:

AMPHENOL SCE2/TERRAPIN SERIESRECEPT

- Page 300 and 301:

AMPHENOL SCE2/TERRAPIN SERIESINSERT

- Page 302 and 303:

AMPHENOL SCE2/TERRAPIN SERIESDIMENS

- Page 304 and 305:

AMPHENOL SCE2/TERRAPIN SERIESDIMENS

- Page 306 and 307:

AMPHENOL SCE2/TERRAPIN SERIESRECOMM

- Page 308 and 309:

2M SERIESTECHNICALSPECIFICATIONSMAT

- Page 310 and 311:

2M SERIESLAYOUTS BY NUMBER OF CONTA

- Page 312 and 313:

2M SERIESCREATE YOUR PART NUMBER 2M

- Page 314 and 315:

2M SERIESPLUGMASTERKEYB THREAD2M801

- Page 316 and 317:

2M SERIESSQUARE FLANGED GASKETSE RA

- Page 318 and 319:

2M SERIESCREATE YOUR PART NUMBER 2M

- Page 320 and 321:

2M SERIESPLUG2M803 DIMENSIONS BAYON

- Page 322 and 323:

2M SERIES2 HOLE FLANGED GASKETSC MA

- Page 324 and 325:

2M SERIESCREATE YOUR PART NUMBER 2M

- Page 326 and 327:

2M SERIESPLUGKEYA DIA.2M804 DIMENSI

- Page 328 and 329:

2M SERIES2M804 ACCESSORIESSHRINK BO

- Page 330 and 331:

2M SERIESCREATE YOUR PART NUMBER 2M

- Page 332 and 333:

2M SERIESPLUG2M805 DIMENSIONS2M805-

- Page 334 and 335:

2M SERIESSQUARE FLANGED GASKETSE RA

- Page 336 and 337:

2M SERIESPINSCONTACT TOOLSInsert he

- Page 338 and 339:

2M SERIESTURNAROUND ON CONNECTORS

- Page 340 and 341:

RJ FIELD SERIESRJF RB - REVERSE BAY

- Page 342 and 343:

RJ FIELD SERIESRJF 544 SERIESMAIN C

- Page 344 and 345:

RJ FIELD SERIESRJFMAIN CHARACTERIST

- Page 346 and 347:

RJRJ FIELD SERIESPLUGRJF 6Plug with

- Page 348 and 349:

RJ FIELD SERIESRJFTVMAIN CHARACTERI

- Page 350 and 351:

RJ FIELD SERIESPLUGRJF TV 6Plug wit

- Page 352 and 353:

RJ FIELD SERIESRJFTV - WITH 360° E

- Page 354 and 355:

RJ FIELD SERIESUSBFTV - USB-AMAIN C

- Page 356 and 357:

RJ FIELD SERIESPLUGUSBFTV 6USBFTV U

- Page 358 and 359:

RJ FIELD SERIESUSBBFTV - USB-BMAIN

- Page 360 and 361:

RJ FIELD SERIESUSBFTV SC - SPRING-L

- Page 362 and 363:

RJ FIELD SERIESREINFORCED USBFTVENV

- Page 364 and 365:

44 SERIESAmphenol-Tuchel Electronic

- Page 366 and 367:

ECO-MATEAmphenol EcomateEXCELLENT F

- Page 368 and 369:

ACCESSORIESSEALING SCREWSSealing sc

- Page 370 and 371:

ACCESSORIESRIGHT ANGLE HEAT SHRINK

- Page 372 and 373:

ACCESSORIESPOTTING SYSTEMACCESSORIE

- Page 374:

ACCESSORIESPMAFLEX PCSACCESSORIESPM