Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

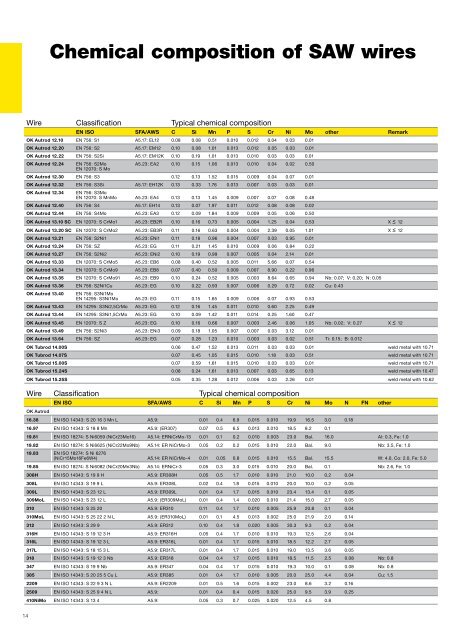

Chemical composition of SAW wiresWire Classification Typical chemical compositionEN ISO SFA/AWS C Si Mn P S Cr Ni Mo other RemarkOK Autrod 12.10 EN 756: S1 A5.17: EL12 0.08 0.08 0.51 0.010 0.012 0.04 0.03 0.01OK Autrod 12.20 EN 756: S2 A5.17: EM12 0.10 0.08 1.01 0.013 0.012 0.05 0.03 0.01OK Autrod 12.22 EN 756: S2Si A5.17: EM12K 0.10 0.19 1.01 0.013 0.010 0.03 0.03 0.01OK Autrod 12.24 EN 756: S2MoA5.23: EA2 0.10 0.15 1.06 0.013 0.010 0.04 0.02 0.50EN 12070: S MoOK Autrod 12.30 EN 756: S3 0.12 0.13 1.52 0.015 0.009 0.04 0.07 0.01OK Autrod 12.32 EN 756: S3Si A5.17: EH12K 0.13 0.33 1.76 0.013 0.007 0.03 0.03 0.01OK Autrod 12.34 EN 756: S3MoEN 12070: S MnMo A5.23: EA4 0.13 0.13 1.45 0.009 0.007 0.07 0.08 0.48OK Autrod 12.40 EN 756: S4 A5.17: EH14 0.13 0.07 1.97 0.011 0.012 0.08 0.08 0.02OK Autrod 12.44 EN 756: S4Mo A5.23: EA3 0.12 0.09 1.84 0.009 0.009 0.05 0.06 0.50OK Autrod 13.10 SC EN 12070: S CrMo1 A5.23: EB2R 0.10 0.16 0.73 0.005 0.004 1.25 0.04 0.53 X ≤ 12OK Autrod 13.20 SC EN 12070: S CrMo2 A5.23: EB3R 0.11 0.16 0.63 0.004 0.004 2.39 0.05 1.01 X ≤ 12OK Autrod 13.21 EN 756: S2Ni1 A5.23: ENi1 0.11 0.18 0.96 0.004 0.007 0.03 0.95 0.01OK Autrod 13.24 EN 756: SZ A5.23: EG 0.11 0.21 1.45 0.010 0.009 0.06 0.84 0.22OK Autrod 13.27 EN 756: S2Ni2 A5.23: ENi2 0.10 0.19 0.99 0.007 0.005 0.04 2.14 0.01OK Autrod 13.33 EN 12070: S CrMo5 A5.23: EB6 0.08 0.40 0.52 0.005 0.011 5.66 0.07 0.54OK Autrod 13.34 EN 12070: S CrMo9 A5.23: EB8 0.07 0.40 0.50 0.009 0.007 8.90 0.22 0.96OK Autrod 13.35 EN 12070: S CrMo91 A5.23: EB9 0.10 0.24 0.52 0.005 0.003 8.64 0.65 0.94 Nb: 0.07; V: 0.20; N: 0.05OK Autrod 13.36 EN 756: S2Ni1Cu A5.23: EG 0.10 0.22 0.93 0.007 0.006 0.29 0.72 0.02 Cu: 0.43OK Autrod 13.40 EN 756: S3Ni1MoEN 14295: S3Ni1Mo A5.23: EG 0.11 0.15 1.65 0.009 0.006 0.07 0.93 0.53OK Autrod 13.43 EN 14295: S3Ni2,5CrMo A5.23: EG 0.12 0.16 1.45 0.011 0.010 0.60 2.25 0.49OK Autrod 13.44 EN 14295: S3Ni1,5CrMo A5.23: EG 0.10 0.09 1.42 0.011 0.014 0.25 1.60 0.47OK Autrod 13.45 EN 12070: S Z A5.23: EG 0.10 0.16 0.66 0.007 0.003 2.46 0.06 1.05 Nb: 0.02; V: 0.27 X ≤ 12OK Autrod 13.49 EN 756: S2Ni3 A5.23: ENi3 0.09 0.18 1.05 0.007 0.007 0.03 3.12 0.01OK Autrod 13.64 EN 756: SZ A5.23: EG 0.07 0.28 1.23 0.010 0.003 0.03 0.02 0.51 Ti: 0.15; B: 0.012OK Tubrod 14.00S 0.06 0.47 1.52 0.013 0.011 0.03 0.03 0.01 weld metal with 10.71OK Tubrod 14.07S 0.07 0.45 1.05 0.015 0.010 1.18 0.03 0.51 weld metal with 10.71OK Tubrod 15.00S 0.07 0.59 1.61 0.015 0.010 0.03 0.03 0.01 weld metal with 10.71OK Tubrod 15.24S 0.08 0.24 1.61 0.013 0.007 0.03 0.65 0.13 weld metal with 10.47OK Tubrod 15.25S 0.05 0.35 1.28 0.012 0.006 0.03 2.26 0.01 weld metal with 10.62Wire Classification Typical chemical compositionEN ISO SFA/AWS C Si Mn P S Cr Ni Mo N FN otherOK Autrod16.38 EN ISO 14343: S 20 16 3 Mn L A5.9: 0.01 0.4 6.9 0.015 0.010 19.9 16.5 3.0 0.1816.97 EN ISO 14343: S 18 8 Mn A5.9: (ER307) 0.07 0.5 6.5 0.013 0.010 18.5 8.2 0.119.81 EN ISO 18274: S Ni6059 (NiCr23Mo16) A5.14: ERNiCrMo-13 0.01 0.1 0.2 0.010 0.003 23.0 Bal. 16.0 Al: 0.3, Fe: 1.019.82 EN ISO 18274: S Ni6625 (NiCr22Mo9Nb) A5.14: ER NiCrMo-3 0.05 0.2 0.2 0.015 0.010 22.0 Bal. 9.0 Nb: 3.5, Fe: 1.019.83 EN ISO 18274: S Ni 6276(NiCr15Mo16Fe6W4) A5.14: ER NiCrMo-4 0.01 0.05 0.8 0.015 0.010 15.5 Bal. 15.5 W: 4.0, Co: 2.0, Fe: 5.019.85 EN ISO 18274: S Ni6082 (NiCr20Mn3Nb) A5.14: ERNiCr-3 0.05 0.3 3.0 0.015 0.010 20.0 Bal. 0.1 Nb: 2.6, Fe: 1.0308H EN ISO 14343: S 19 9 H A5.9: ER308H 0.05 0.5 1.7 0.010 0.010 21.0 10.0 0.2 0.04308L EN ISO 14343: S 19 9 L A5.9: ER308L 0.02 0.4 1.8 0.015 0.010 20.0 10.0 0.2 0.05309L EN ISO 14343: S 23 12 L A5.9: ER309L 0.01 0.4 1.7 0.015 0.010 23.4 13.4 0.1 0.05309MoL EN ISO 14343: S 23 12 L A5.9: (ER309MoL) 0.01 0.4 1.4 0.020 0.010 21.4 15.0 2.7 0.05310 EN ISO 14343: S 25 20 A5.9: ER310 0.11 0.4 1.7 0.010 0.005 25.9 20.8 0.1 0.04310MoL EN ISO 14343: S 25 22 2 N L A5.9: (ER310MoL) 0.01 0.1 4.5 0.013 0.002 25.0 21.9 2.0 0.14312 EN ISO 14343: S 29 9 A5.9: ER312 0.10 0.4 1.8 0.020 0.005 30.3 9.3 0.2 0.04316H EN ISO 14343: S 19 12 3 H A5.9: ER316H 0.05 0.4 1.7 0.010 0.010 19.3 12.5 2.6 0.04316L EN ISO 14343: S 19 12 3 L A5.9: ER316L 0.01 0.4 1.7 0.015 0.010 18.5 12.2 2.7 0.05317L EN ISO 14343: S 18 15 3 L A5.9: ER317L 0.01 0.4 1.7 0.015 0.010 19.0 13.5 3.6 0.05318 EN ISO 14343: S 19 12 3 Nb A5.9: ER318 0.04 0.4 1.7 0.015 0.010 18.5 11.5 2.5 0.08 Nb: 0.8347 EN ISO 14343: S 19 9 Nb A5.9: ER347 0.04 0.4 1.7 0.015 0.010 19.3 10.0 0.1 0.08 Nb: 0.8385 EN ISO 14343: S 20 25 5 Cu L A5.9: ER385 0.01 0.4 1.7 0.010 0.005 20.0 25.0 4.4 0.04 Cu: 1.52209 EN ISO 14343: S 22 9 3 N L A5.9: ER2209 0.01 0.5 1.6 0.015 0.002 23.0 8.6 3.2 0.162509 EN ISO 14343: S 25 9 4 N L A5.9: 0.01 0.4 0.4 0.015 0.020 25.0 9.5 3.9 0.25410NiMo EN ISO 14343: S 13 4 A5.9: 0.05 0.3 0.7 0.025 0.020 12.5 4.5 0.814