Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

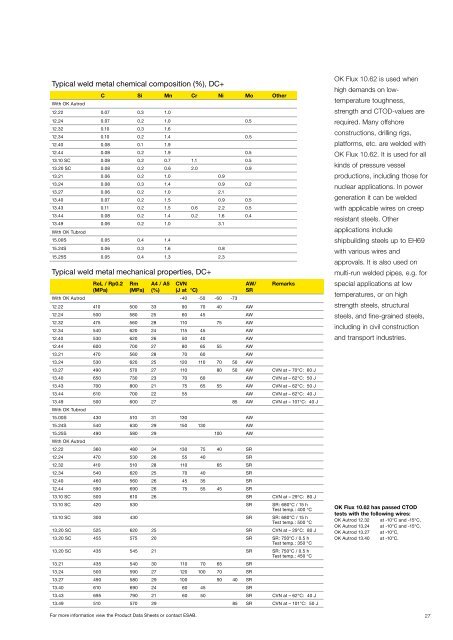

Typical weld metal chemical composition (%), DC+C Si Mn Cr Ni Mo OtherWith OK Autrod12.22 0.07 0.3 1.012.24 0.07 0.2 1.0 0.512.32 0.10 0.3 1.612.34 0.10 0.2 1.4 0.512.40 0.08 0.1 1.912.44 0.08 0.2 1.9 0.513.10 SC 0.08 0.2 0.7 1.1 0.513.20 SC 0.08 0.2 0.6 2.0 0.913.21 0.06 0.2 1.0 0.913.24 0.08 0.3 1.4 0.9 0.213.27 0.06 0.2 1.0 2.113.40 0.07 0.2 1.5 0.9 0.513.43 0.11 0.2 1.5 0.6 2.2 0.513.44 0.08 0.2 1.4 0.2 1.6 0.413.49 0.06 0.2 1.0 3.1With OK Tubrod15.00S 0.05 0.4 1.415.24S 0.06 0.3 1.6 0.815.25S 0.05 0.4 1.3 2.3Typical weld metal mechanical properties, DC+ReL / Rp0.2(MPa)Rm(MPa)A4 / A5(%)CVN(J at °C)With OK Autrod -40 -50 -60 -73AW/SRRemarks12.22 410 500 33 90 70 40 AW12.24 500 580 25 60 45 AW12.32 475 560 28 110 75 AW12.34 540 620 24 115 45 AW12.40 530 620 26 50 40 AW12.44 600 700 27 80 65 55 AW13.21 470 560 28 70 60 AW13.24 530 620 25 120 110 70 50 AW13.27 490 570 27 110 80 50 AW CVN at – 70°C: 60 J13.40 650 730 23 70 60 AW CVN at – 62°C: 50 J13.43 700 800 21 75 65 55 AW CVN at – 62°C: 50 J13.44 610 700 22 55 AW CVN at – 62°C: 40 J13.49 500 600 27 85 AW CVN at – 101°C: 40 JWith OK Tubrod15.00S 430 510 31 130 AW15.24S 540 630 29 150 130 AW15.25S 490 580 29 100 AWWith OK Autrod12.22 360 480 34 130 75 40 SR12.24 470 530 26 55 40 SR12.32 410 510 28 110 65 SR12.34 540 620 25 70 40 SR12.40 460 560 26 45 35 SR12.44 590 690 26 75 55 45 SR13.10 SC 500 610 26 SR CVN at – 29°C: 80 J13.10 SC 420 530 SR SR: 680°C / 15 hTest temp.: 400 °C13.10 SC 300 430 SR SR: 680°C / 15 hTest temp.: 500 °C13.20 SC 525 620 25 SR CVN at – 29°C: 80 J13.20 SC 455 575 20 SR SR: 750°C / 0.5 hTest temp.: 350 °C13.20 SC 435 545 21 SR SR: 750°C / 0.5 hTest temp.: 450 °C13.21 435 540 30 110 70 65 SR13.24 500 590 27 120 100 70 SR13.27 490 580 29 100 90 40 SR13.40 610 690 24 60 45 SR13.43 695 790 21 60 50 SR CVN at – 62°C: 40 J13.49 510 570 29 85 SR CVN at – 101°C: 50 JFor more information view the Product Data Sheets or contact ESAB.OK Flux 10.62 is used whenhigh demands on lowtemperaturetoughness,strength and CTOD-values arerequired. Many offshoreconstructions, drilling rigs,platforms, etc. are welded withOK Flux 10.62. It is used for allkinds of pressure vesselproductions, including those fornuclear applications. In powergeneration it can be weldedwith applicable wires on creepresistant steels. Otherapplications includeshipbuilding steels up to EH69with various wires andapprovals. It is also used onmulti-run welded pipes, e.g. forspecial applications at lowtemperatures, or on highstrength steels, structuralsteels, and fine-grained steels,including in civil constructionand transport industries.OK Flux 10.62 has passed CTODtests with the following wires:OK Autrod 12.32 at -10°C and -15°C,OK Autrod 13.24 at -10°C and -15°C,OK Autrod 13.27 at -10°C,OK Autrod 13.40 at -10°C.27