Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

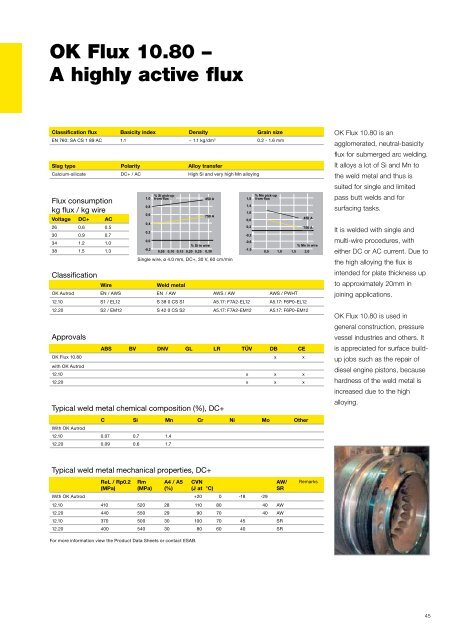

OK Flux 10.80 –A highly active fluxClassification flux Basicity index Density Grain sizeEN 760: SA CS 1 89 AC 1.1 ~ 1.1 kg/dm 3 0.2 - 1.6 mmSlag type Polarity Alloy transferCalcium-silicate DC+ / AC High Si and very high Mn alloyingFlux consumptionkg flux / kg wireVoltage DC+ AC26 0.6 0.530 0.9 0.734 1.2 1.038 1.5 1.3Classification1,00,80,60,40,20,0-0,2% Si pick-upfrom flux450 A750 A% Si in wire0,05 0,10 0,15 0,20 0,25 0,30Single wire, ø 4.0 mm, DC+, 30 V, 60 cm/min1,81,41,00,60,2-0,2-0,6-1,0% Mn pick-upfrom flux450 A750 A% Mn in wire0,5 1,0 1,5 2,0WireWeld metalOK Autrod EN / AWS EN / AW AWS / AW AWS / PWHT12.10 S1 / EL12 S 38 0 CS S1 A5.17: F7A2-EL12 A5.17: F6P0-EL1212.20 S2 / EM12 S 42 0 CS S2 A5.17: F7A2-EM12 A5.17: F6P0-EM12ApprovalsABS BV DNV GL LR TÜV DB CEOK Flux 10.80 x xwith OK Autrod12.10 x x x12.20 x x xTypical weld metal chemical composition (%), DC+OK Flux 10.80 is anagglomerated, neutral-basicityflux for submerged arc welding.It alloys a lot of Si and Mn tothe weld metal and thus issuited for single and limitedpass butt welds and forsurfacing tasks.It is welded with single andmulti-wire procedures, witheither DC or AC current. Due tothe high alloying the flux isintended for plate thickness upto approximately 20mm injoining applications.OK Flux 10.80 is used ingeneral construction, pressurevessel industries and others. Itis appreciated for surface buildupjobs such as the repair ofdiesel engine pistons, becausehardness of the weld metal isincreased due to the highalloying.C Si Mn Cr Ni Mo OtherWith OK Autrod12.10 0.07 0.7 1.412.20 0.09 0.6 1.7Typical weld metal mechanical properties, DC+ReL / Rp0.2(MPa)Rm(MPa)A4 / A5(%)CVN(J at °C)With OK Autrod +20 0 -18 -2912.10 410 520 28 110 80 40 AW12.20 440 550 29 90 70 40 AW12.10 370 500 30 100 70 45 SR12.20 400 540 30 80 60 40 SRAW/SRRemarksFor more information view the Product Data Sheets or contact ESAB.45