Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

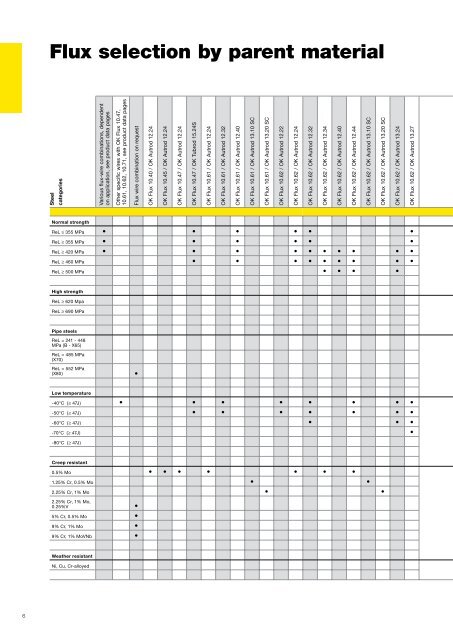

Flux selection by parent materialSteelcategoriesVarious flux-wire combinations, dependenton application, see product data pagesOther specific wires with OK Flux 10.47,10.61, 10.62, 10.71, see product data pagesFlux wire combination on requestOK Flux 10.40 / OK Autrod 12.24OK Flux 10.45 / OK Autrod 12.24OK Flux 10.47 / OK Autrod 12.24OK Flux 10.47 / OK Tubrod 15.24SOK Flux 10.61 / OK Autrod 12.24OK Flux 10.61 / OK Autrod 12.32OK Flux 10.61 / OK Autrod 12.40OK Flux 10.61 / OK Autrod 13.10 SCOK Flux 10.61 / OK Autrod 13.20 SCOK Flux 10.62 / OK Autrod 12.22OK Flux 10.62 / OK Autrod 12.24OK Flux 10.62 / OK Autrod 12.32OK Flux 10.62 / OK Autrod 12.34OK Flux 10.62 / OK Autrod 12.40OK Flux 10.62 / OK Autrod 12.44OK Flux 10.62 / OK Autrod 13.10 SCOK Flux 10.62 / OK Autrod 13.20 SCOK Flux 10.62 / OK Autrod 13.24OK Flux 10.62 / OK Autrod 13.27Normal strengthReL 355 MPa ReL 355 MPa ReL 420 MPa ReL 460 MPa ReL 500 MPa High strengthReL 620 MpaReL 690 MPaPipe steelsReL = 241 - 448MPa (B - X65)ReL = 485 MPa(X70)ReL = 552 MPa(X80)Low temperature-40°C ( 47J) -50°C ( 47J) -60°C ( 47J) -70°C ( 47J)-80°C ( 47J)Creep resistant0.5% Mo 1.25% Cr, 0.5% Mo 2.25% Cr, 1% Mo 2.25% Cr, 1% Mo,0.25%V5% Cr, 0.5% Mo 9% Cr, 1% Mo 9% Cr, 1% MoVNb Weather resistantNi, Cu, Cr-alloyed6