Nya Svetsaren 1, 1999. - Luleå University of Technology

Nya Svetsaren 1, 1999. - Luleå University of Technology

Nya Svetsaren 1, 1999. - Luleå University of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

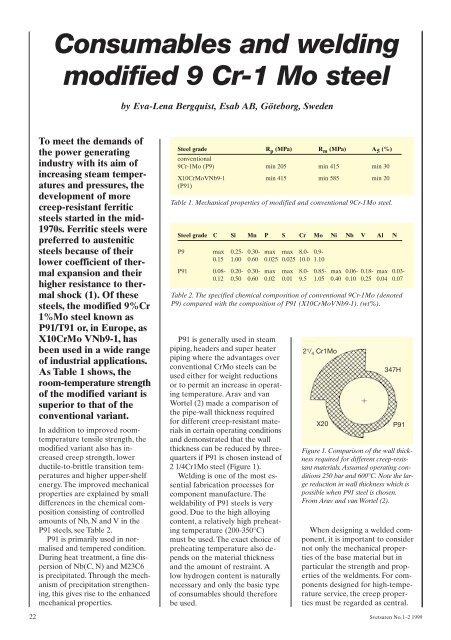

Consumables and weldingmodified 9 Cr-1 Mo steelby Eva-Lena Bergquist, Esab AB, Göteborg, SwedenTo meet the demands <strong>of</strong>the power generatingindustry with its aim <strong>of</strong>increasing steam temperaturesand pressures, thedevelopment <strong>of</strong> morecreep-resistant ferriticsteels started in the mid-1970s. Ferritic steels werepreferred to austeniticsteels because <strong>of</strong> theirlower coefficient <strong>of</strong> thermalexpansion and theirhigher resistance to thermalshock (1). Of thesesteels, the modified 9%Cr1%Mo steel known asP91/T91 or, in Europe, asX10CrMo VNb9-1, hasbeen used in a wide range<strong>of</strong> industrial applications.As Table 1 shows, theroom-temperature strength<strong>of</strong> the modified variant issuperior to that <strong>of</strong> theconventional variant.In addition to improved roomtemperaturetensile strength, themodified variant also has increasedcreep strength, lowerductile-to-brittle transition temperaturesand higher upper-shelfenergy. The improved mechanicalproperties are explained by smalldifferences in the chemical compositionconsisting <strong>of</strong> controlledamounts <strong>of</strong> Nb, N and V in theP91 steels, see Table 2.P91 is primarily used in normalisedand tempered condition.During heat treatment, a fine dispersion<strong>of</strong> Nb(C, N) and M23C6is precipitated. Through the mechanism<strong>of</strong> precipitation strengthening,this gives rise to the enhancedmechanical properties.Steel grade R p (MPa) R m (MPa) A 5 (%)conventional9Cr-1Mo (P9) min 205 min 415 min 30X10CrMoVNb9-1 min 415 min 585 min 20(P91)Table 1. Mechanical properties <strong>of</strong> modified and conventional 9Cr-1Mo steel.Steel grade C Si Mn P S Cr Mo Ni Nb V Al NP9 max 0.25- 0.30- max max 8.0- 0.9-0.15 1.00 0.60 0.025 0.025 10.0 1.10P91 0.08- 0.20- 0.30- max max 8.0- 0.85- max 0.06- 0.18- max 0.03-0.12 0.50 0.60 0.02 0.01 9.5 1.05 0.40 0.10 0.25 0.04 0.07Table 2. The specified chemical composition <strong>of</strong> conventional 9Cr-1Mo (denotedP9) compared with the composition <strong>of</strong> P91 (X10CrMoVNb9-1). (wt%).P91 is generally used in steampiping, headers and super heaterpiping where the advantages overconventional CrMo steels can beused either for weight reductionsor to permit an increase in operatingtemperature. Arav and vanWortel (2) made a comparison <strong>of</strong>the pipe-wall thickness requiredfor different creep-resistant materialsin certain operating conditionsand demonstrated that the wallthickness can be reduced by threequartersif P91 is chosen instead <strong>of</strong>2 1/4Cr1Mo steel (Figure 1).Welding is one <strong>of</strong> the most essentialfabrication processes forcomponent manufacture. Theweldability <strong>of</strong> P91 steels is verygood. Due to the high alloyingcontent, a relatively high preheatingtemperature (200-350°C)must be used. The exact choice <strong>of</strong>preheating temperature also dependson the material thicknessand the amount <strong>of</strong> restraint. Alow hydrogen content is naturallynecessary and only the basic type<strong>of</strong> consumables should thereforebe used.2 1 / 4 Cr1MoX20347HP91Figure 1. Comparison <strong>of</strong> the wall thicknessrequired for different creep-resistantmaterials. Assumed operating conditions250 bar and 600°C. Note the largereduction in wall thickness which ispossible when P91 steel is chosen.From Arav and van Wortel (2).When designing a welded component,it is important to considernot only the mechanical properties<strong>of</strong> the base material but inparticular the strength and properties<strong>of</strong> the weldments. For componentsdesigned for high-temperatureservice, the creep propertiesmust be regarded as central.22 <strong>Svetsaren</strong> No.1–2 1999