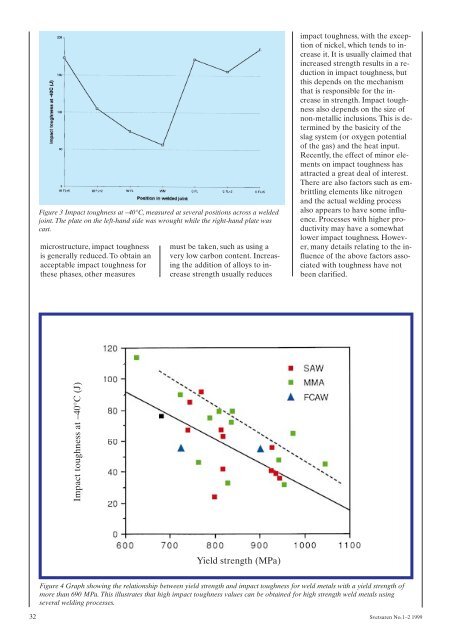

Figure 3 Impact toughness at –40°C, measured at several positions across a weldedjoint. The plate on the left-hand side was wrought while the right-hand plate wascast.microstructure, impact toughnessis generally reduced. To obtain anacceptable impact toughness forthese phases, other measuresmust be taken, such as using avery low carbon content. Increasingthe addition <strong>of</strong> alloys to increasestrength usually reducesimpact toughness, with the exception<strong>of</strong> nickel, which tends to increaseit. It is usually claimed thatincreased strength results in a reductionin impact toughness, butthis depends on the mechanismthat is responsible for the increasein strength. Impact toughnessalso depends on the size <strong>of</strong>non-metallic inclusions. This is determinedby the basicity <strong>of</strong> theslag system (or oxygen potential<strong>of</strong> the gas) and the heat input.Recently, the effect <strong>of</strong> minor elementson impact toughness hasattracted a great deal <strong>of</strong> interest.There are also factors such as embrittlingelements like nitrogenand the actual welding processalso appears to have some influence.Processes with higher productivitymay have a somewhatlower impact toughness. However,many details relating to the influence<strong>of</strong> the above factors associatedwith toughness have notbeen clarified.Impact toughness at –40°C (J)Yield strength (MPa)Figure 4 Graph showing the relationship between yield strength and impact toughness for weld metals with a yield strength <strong>of</strong>more than 690 MPa. This illustrates that high impact toughness values can be obtained for high strength weld metals usingseveral welding processes.32 <strong>Svetsaren</strong> No.1–2 1999

In very rough terms, it can beassumed that a weld metal likethe one in Figure 1a has an impacttoughness at –40°C <strong>of</strong> 150 J,the one in Figure 1b 100 J andthe one in Figure 1c 50 J. Due tothe greater homogeneity <strong>of</strong> themicrostructure <strong>of</strong> the higher alloyedweld metals, they have farless scatter in terms <strong>of</strong> impacttoughness.Welding steels with ayield strength <strong>of</strong> 690 MPaIn this section, consumables forwelding steels with a yieldstrength <strong>of</strong> 690 MPa will be presented.Some results from differentwelding procedures will alsobe shown.Table 1 gives details <strong>of</strong> theEsab range <strong>of</strong> consumables forwelding high strength steels. Thechemical compositions and mechanicalproperties relate to allweld metal. It should be notedthat the two last consumables aredesigned for welding steels <strong>of</strong>even higher strength.A number <strong>of</strong> welding proceduresin which these consumableshave been used are presented inTable 2, together with the results<strong>of</strong> mechanical testing. As can beseen, the welding proceduresspan quite a large field, in terms<strong>of</strong> both heat input and platethickness. A parameter which isnot given in Table 2 but is still importantis the preheating andinterpass temperatures used duringwelding. A preheating temperature<strong>of</strong> 100–150°C was generallyused for all thicknesses. Thisprevented hydrogen cracking. Inthe case <strong>of</strong> modern quenched andtempered steels with a low carboncontent, the main risk whenit comes to hydrogen cracking liesin the weld metal. So the choice<strong>of</strong> preheating temperature shouldnot be based on the composition<strong>of</strong> the steel. Unfortunately, thereare as yet no formulae or graphicalmethods that provide reliableguidelines for the avoidance <strong>of</strong>weld metal hydrogen cracking. Inorder to find suitable preheatingtemperatures, more elaboratemethods, such as a Tekken test,should be used.As can be seen from Table 2,high tensile strengths were foundin the weld procedures. In general,when it came to the transversetensile tests, fracture was found inthe base material. However, theremight be a problem in situationsin which the consumables onlygive a slight overmatching to 690MPa in an all weld metal test. Thereason for this is that the weldmetal, which is created by mixingthe consumable and the base materialunder the influence <strong>of</strong> thecooling conditions dictated by thewelding procedure, does not usuallyincrease very much instrength, unless large amounts <strong>of</strong>alloying elements are picked upfrom the base material. The basematerial, which has a specifiedminimum yield strength <strong>of</strong> 690MPa, has a much higher yieldstrength in practice. It is not uncommonfor the steel to have ayield strength which is 100–150MPa higher than the minimumspecified value. Naturally, thesesteels also have a higher ultimatetensile strength. So, even withweld metals which should nominallyovermatch the strength <strong>of</strong>the steel, fracture may take placein the weld metal in a transversetensile test.What is particularly encouragingwhen it comes to the weldingprocedures in Table 2 are thegood values for impact toughnesswhich were measured in the weldmetals. Figure 3 shows a plot <strong>of</strong>the impact toughness at –40°C forvarious positions across a weldmentin steels with a yieldstrength <strong>of</strong> 690 MPa. In this particularcase, which relates to theFCAW procedure using PZ 6148,the welding was done betweentwo plates, one rolled and onecast. As can be seen, there is a decreasein toughness from the basematerial via the HAZ to the weldmetal. This picture is <strong>of</strong>ten foundfor welds in 690 MPa steels, irrespective<strong>of</strong> the consumable orwelding procedure. The impacttoughness <strong>of</strong> the weld metal isgood, but it is slightly lower thanin the HAZ.A large number <strong>of</strong> test weldshave been prepared in order tostudy the connection between thestrength and impact toughness <strong>of</strong>weld metals. A summary <strong>of</strong> thisconnection is presented in Figure 4,which presents data for submergedarc, manual metal arc andflux cored arc weld metals. Theyield strength <strong>of</strong> the weld metalsvaried from about 650 MPa toabove 1,000 MPa. A clear trendcan be seen — an increase inyield strength produces a decreasein impact toughness. Ascan also be seen, weld metalsfrom manual metal arc weldinghave a slightly higher impacttoughness than submerged arcweld metals.ConclusionsWelding steels with a specifiedminimum yield strength <strong>of</strong> 690MPa is possible using most <strong>of</strong> thecommon arc welding processes.There are high productivity processesfor welding these steels,mainly cored wires and submergedarc welding. There is a range<strong>of</strong> consumables that will provideboth the strength and impacttoughness to match the base materialproperties. To avoid hydrogencracking in the weld metal, apreheating temperature <strong>of</strong>125–150°C should be used; thelower temperature is applicablefor thin plates and a low level <strong>of</strong>restraint. One particular problemis the actual yield strength <strong>of</strong> thedelivered base materials, which is<strong>of</strong>ten far higher than the specifiedminimum yield strength. The weldmetals normally overmatch thesteel, but, as the yield strength <strong>of</strong>the weld metal increases, a decreasein impact toughness isseen. This then indicates that aconsumable with slight overmatchingproperties should be selectedfor each case.About the authorLars-Erik Svensson, PhD, is manager<strong>of</strong> the Esab Central Laboratoriesin Gothenburg. He hasworked for more than 15 yearswith welding metallurgy, focusingprimarily on unalloyed and lowalloyedsteels. He has publishedone book and more than 25 paperson the microstructure and properties<strong>of</strong> welds.<strong>Svetsaren</strong> No.1 1999 33