MAINTENANCE MANUAL - Stemme AG

MAINTENANCE MANUAL - Stemme AG

MAINTENANCE MANUAL - Stemme AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A4010022_B12_97.doc-0/04.12.07 16:33/05.12.07 08:57<br />

<strong>Stemme</strong> <strong>AG</strong> – Flugplatzstrasse F2 Nr. 7 - Germany-15344 Strausberg<br />

<strong>MAINTENANCE</strong> <strong>MANUAL</strong><br />

for the powered sailplane STEMME S 10<br />

Document No. A40-10-022<br />

Date of Issue: October 1, 1990<br />

The pages forming the Airworthiness Limitations Section have been approved by the<br />

Luftfahrt-Bundesamt, FRG. They are marked "LBA approved" and held in yellow colour.<br />

................................................ (Signature)<br />

(Stamp)<br />

................................................ (Original date of approval)<br />

This Maintenance Manual is based on the original in the German language. It comprises<br />

some deviations due to specific FAA requirements and unique U.S. aircraft specification.<br />

Model: STEMME S 10 Serial number: 10-<br />

Type Certificate: EASA.A.054 (former LBA 846) / FAA No. G 58 EU Registration: N-<br />

Non-standard equipment or systems with effect to the contents of this manual, if installed, are entered in the table on page 1.<br />

Druck-Info: Datei enthält 68 Seiten gesamt

Maintenance Manual STEMME S 10 Date of Issue Oct. 1, 1990 page: 2-1<br />

0.1 Record of Amendments<br />

Amendment No.: 12 Date: Nov. 30. 2007<br />

Any amendment of the present manual must be recorded in the following table. Exempted are:<br />

Data relating to the installation of alternative equipment (page 1)<br />

Data relating to the installation of supplemental or additional equipment (page 51)<br />

Deletion of inapplicable text passages pursuant to the Service Bulletin A31-10-008.<br />

The list of amendments on this page and the list of effective pages on the next page are assigned to the<br />

serial number. The indicated revision no. in the headline of these pages does not change with later entries<br />

in the lists.<br />

Information as to which amendments must be included in the present Manual can be seen from the current<br />

"Record of Airworthiness Directives and Service Bulletins" (see Annex B, doc. no. A08-10-000).<br />

The new or amended text of the latest amendment will be marked on the revised page by a black vertical line<br />

on the right hand margin. Any Amendment Numbers applied to the specific page and the date of the most<br />

recent amendment is indicated on the right hand side in the headline of each page. In text passages<br />

concerned by the installation of alternative equipment, the text for both versions is included in [ ]; the text not<br />

applicable to the serial number concerned must be crossed out. For further information please refer to<br />

Section 9.3 or to the Service Bulletin A31-10-008.<br />

The inspector certifies by his signature at the same time the correct transfer of the information specific to the<br />

serial number (deletion of inapplicable text passages).<br />

Am.<br />

No.<br />

Affected<br />

Sections<br />

Removed Pages included Pages<br />

Amendment<br />

Date<br />

Date of<br />

inclusion<br />

Signature<br />

1 0, 4 4, 21 4, 21 Aug. 15, 1991 Aug. 15, 1991 ex works<br />

2 0, 4 4, 21, 22 4, 21, 22 March 1, 1993 March 1, 1993 ex works<br />

3 0, 9, 10, 11, 12,<br />

13<br />

1, 2, 3, 5, 51, 53,<br />

54, 55, 56<br />

4 3, 12 14, 15, 47*,<br />

Fig. 3.3.2.a * ,<br />

Fig. 3.6.b*<br />

Title p., 1, 2, 3, 5,<br />

51, 53 to 56,<br />

Cover p. Annex A,<br />

B, and C<br />

14, 15, 47*,<br />

Fig. 3.3.2.a*,<br />

Fig. 3.6.b*<br />

5 not issued<br />

6 3, 4, 10, 12 13, 25, 55,<br />

Fig. 3.2.b<br />

7 3, 5, 12 4, 13, 14, 24 ··· 26,<br />

Fig. 3.2.a ··· g,<br />

Fig. 6.4.1.a<br />

13, 25, 55,<br />

Fig. 3.2.b<br />

4, 13, 14, 24 ··· 26,<br />

Fig. 3.2.a ··· g,<br />

Fig. 6.4.1.a<br />

July 1, 1993 July 1, 1993 ex works<br />

May 26, 1993 May 26, 1993 ex works<br />

Feb. 10, 1994 Feb. 10, 1994 ex works<br />

Dec. 05, 1994 Dec. 05, 1994 ex works<br />

8 0, 5 2 ··· 5, 26 ··· 30 2 ··· 5, 26 ··· 30 Aug. 8, 1996 Aug. 8, 1996 ex works<br />

9 3, 5, 6, 7, 8 2...5, 19 ,28, 29, 33,<br />

42, 44, 45, 48<br />

2...5, 19 ,28, 29, 33,<br />

42, 44, 45, 48<br />

10 0,4 2, 3, 21, 22 2, 3, 21, 22-1, 22-2 March 16, 2005<br />

11 0,3,4,5,7,9 2..5, 18, 21, 22-1,<br />

22-2, 27...30, 36,<br />

38, 51..54<br />

2..5, 18, 21, 22-1,<br />

22-2, 27...30, 36,<br />

38, 51..53, 54-1,<br />

54-2<br />

April 19, 1999 April 19, 1999<br />

May 25. 2005<br />

*<br />

These pages may only be incorporated with the quoted amendment number if the alternative equipment<br />

item requiring the amendment is installed in the individual aircraft - please check the entries on page 1 for<br />

the corresponding SB. Amendment no. 4 is mandatory for U.S.A.<br />

A4010022_B12_97.doc-2/04.12.07 16:33/05.12.07 08:58 Doc. No. A40-10-022

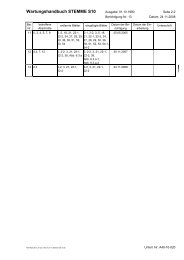

Maintenance Manual STEMME S 10 Date of Issue Oct. 1, 1990 page: 2-2<br />

Am.<br />

No.<br />

Affected<br />

Sections<br />

12 0, 7, 4, 12 Title, 2, 3, 21, 22-1,<br />

22-1, 38, Fig. 6.3.a,<br />

Removed Pages included Pages<br />

Title, 2-1, 2-2, 3, 21,<br />

22-1, 22-1, 38, Fig.<br />

6.3.a-1, Fig. 6.3.a-2<br />

Amendment No.: 12 Date: Nov 30. 2007<br />

Amendment<br />

Date<br />

Nov 30. 2007<br />

Date of<br />

inclusion<br />

Signature<br />

A4010022_B12_97.doc-3/04.12.07 16:33/05.12.07 08:57 Doc. No. A40-10-022

Maintenance Manual STEMME S 10 Date of Issue Oct. 1, 1990 page: 3<br />

0.2 List of effective pages<br />

Amendment No.: 12 Date: Nov. 30. 2007<br />

This record is valid only for the Serial No. specified on the title page. Any amendment is contained ex works<br />

that is effective for this Maintenance Manual at Aug. 08, 1996 (amendment status 08). Related to alternative<br />

equipment, only those amendments is provided for that correspond to the entries on page 1, amendments<br />

that are included later must be entered by hand.<br />

Section Page Am. No. Date<br />

-- Title 12 Nov. 30, 07<br />

-- 1 3 July 1, 93<br />

0.1 2-1 12 Nov. 30, 07<br />

0.1 2-2 12 Nov. 30, 07<br />

0.2 3 12 Nov. 30, 07<br />

0.3 4 11 May 25. 05<br />

0.3 5 11 May 25. 05<br />

res. 6 Oct. 1, 90<br />

1 7 Oct. 1, 90<br />

res. 8 Oct. 1, 90<br />

2 9 Oct. 1, 90<br />

2 10 Oct. 1, 90<br />

res. 11 Oct. 1, 90<br />

3.1 12 Oct. 1, 90<br />

3.1/3.2 13 6, 7 Dec. 5, 94<br />

3.3 14 4, 7 Dec. 5, 94<br />

3.3 15 4 May 26, 93<br />

3.3 16 Oct. 1, 90<br />

3.4 17 Oct. 1, 90<br />

3.5/3.6 18 11 May 25. 05<br />

3.7/3.8 19 9 Apr. 19, 99<br />

res. 20 Oct. 1, 90<br />

4 21 12 Nov. 30, 07<br />

4 22-1 12 Nov. 30, 07<br />

4 22-2 12 Nov. 30, 07<br />

5.1/5.2 23 Oct. 1, 90<br />

5.2 24 7 Dec. 5, 94<br />

5.2 25 6, 7 Dec. 5, 94<br />

5.2 26 7, 8 Aug. 8, 96<br />

5.2 27 11 May 25. 05<br />

5.2 28 11 May 25. 05<br />

5.2 29 11 May 25. 05<br />

Section Page Am. No. Date<br />

5.3 30 11 May 25. 05<br />

6.1/6.3 31 Oct. 1, 90<br />

6.4/6.5 32 Oct. 1, 90<br />

6.6 33 9 Apr. 19, 99<br />

res. 34 Oct. 1, 90<br />

7.1/7.3 35 Oct. 1, 90<br />

7.3 36 11 May 25. 05<br />

7.3 37 Oct. 1, 90<br />

7.3/7.4 38 12 Nov. 30, 07<br />

7.4 39 Oct. 1, 90<br />

7.4 40 Oct. 1, 90<br />

7.4/7.6 41 Oct. 1, 90<br />

7.7/7.8 42 9 Apr. 19, 99<br />

res. 43 Oct. 1, 90<br />

8 44 9 Apr. 19, 99<br />

8 45 9 Apr. 19, 99<br />

8 46 Oct. 1, 90<br />

8 47 4 May 26, 93<br />

8 48 9 Apr. 19, 99<br />

8 49 Oct. 1, 90<br />

res. 50 Oct. 1, 90<br />

9.1 51 11 May 25. 05<br />

9.2, 9.3 52 11 May 25. 05<br />

9.3 53 11 May 25. 05<br />

9.3 54-1 11 May 25. 05<br />

9.3 54-2 11 May 25. 05<br />

10, 11 55 3, 6 Feb.10, 94<br />

12 56 3 July 1, 93<br />

Figure to<br />

Section<br />

Am. No. Am. Date<br />

2.a Oct. 1, 90<br />

3.2.a 7 Dec. 5, 94<br />

3.2.b 7 Dec. 5, 94<br />

3.2.c 7 Dec. 5, 94<br />

3.2.d 7 Dec. 5, 94<br />

3.2.e 7 Dec. 5, 94<br />

3.2.f 7 Dec. 5, 94<br />

3.2.g 7 Dec. 5, 94<br />

3.3.a Oct. 1, 90<br />

3.3.2.a 4 May 26, 93<br />

3.4.1.a Oct. 1, 90<br />

3.5.a Oct. 1, 90<br />

3.5.b Oct. 1, 90<br />

3.6 Oct. 1, 90<br />

3.6.a-1 12 Nov. 30, 07<br />

3.6.a-2 12 Nov. 30, 07<br />

3.6.b Oct. 1, 90<br />

3.6.c Oct. 1, 90<br />

3.6.d Oct. 1, 90<br />

3.6.e Oct. 1, 90<br />

3.6.f Oct. 1, 90<br />

6.3.a Oct. 1, 90<br />

6.3.b Oct. 1, 90<br />

6.4.1.a 7 Dec. 5, 94<br />

6.4.2.a Oct. 1, 90<br />

7.4.1.a Oct. 1, 90<br />

Annex A<br />

(Cover Page)<br />

Annex B<br />

(Cover Page)<br />

Annex C<br />

(Cover Page)<br />

3 July 1,1993<br />

3 July 1,1993<br />

3 July 1,1993<br />

A4010022_B12_97.doc-3/05.12.07 09:00/05.12.07 09:00 Doc. No. A40-10-022

Maintenance Manual STEMME S10 Date of Issue: Oct. 1, 1990 page: 21<br />

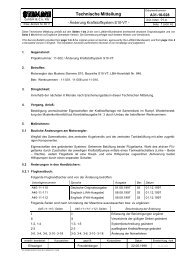

4. Airworthiness Limitations Section<br />

Amendment No.: 12 Date: Nov 30. 2007<br />

LBA approved<br />

This section is FAA-approved for U.S. registered powered sailplanes in accordance with the provisions of<br />

14 CFR Section 21.29. In addition, this section is required by FAA Type Certificate No. G 58 EU and it<br />

specifies maintenance required under 14 CFR Sections 43.16 and 91.163 unless an alternative program has<br />

been FAA-approved.<br />

The permissible operating times of all parts, components and assemblies assigned for installation - in series<br />

or optional - in the powered sailplane STEMME S10 and subject to service life limitations, are notified by the<br />

Service Bulletin no. A31-10-001. When the limitation of at least one item changes, this SB will be reissued in<br />

a revised version. The document no. will be maintained in this case, the amendment no. will be advanced<br />

(the letter in the amendment index is for internal use only).<br />

The pages of this section are printed on yellow paper for better discernment. They may not be revised without<br />

FAA engineering approval. Regulations upon keeping of service records must be observed.<br />

Excerpt of Service Bulletin A31-10-001 Amendment-No: 12.a: Review of permissible operating times:<br />

No.<br />

S10<br />

Model Permissible op. time by<br />

S10-V<br />

S10-VT<br />

Part/Assembly/<br />

Equipment<br />

1 X X X Airframe<br />

(Composite structure)<br />

2 X X Limbach Engine<br />

Manufacturer,<br />

Type<br />

Part No.<br />

(STEMME)<br />

Overhaul<br />

(TBO)<br />

Replaceme<br />

nt<br />

NOTES<br />

STEMME sundry 6000 h 6000 h (1)<br />

Limbach<br />

L 2400 EB 1.D<br />

L 2400 EB 1.AD<br />

10AM-MOL (2)<br />

3 X X Magneto for Limbach Slick 4230 (from Limbach) (2)<br />

4 X Rotax Engine<br />

5 X<br />

Propeller<br />

(fixed pitch)<br />

ROTAX 914<br />

F2/S1<br />

11AM-M<br />

1200 h<br />

(12 years)<br />

(5)(8)<br />

STEMME 10AP-N 400 h (3)(4)<br />

6 X Lateral parts STEMME<br />

10AP-N01<br />

10AP-N11<br />

1000h (4)<br />

7 X Fix-Pitch Propeller STEMME 10AP-F 400 h (3) (4)<br />

8 X Centre Part STEMME 10AP-F01 2000 h (4)<br />

9 X Variable pitch propeller STEMME 10AP-V<br />

200 h<br />

(5 years)<br />

(3)(4)(10)<br />

10 X Variable pitch propeller STEMME 11AP-V<br />

200 h<br />

(5 years)<br />

(3)(4)(10)<br />

11 X X Propeller hub STEMME 10AP-V01 2000h (4)<br />

12 X<br />

Propeller fork and<br />

X<br />

its fastening<br />

STEMME<br />

10AP-V88,<br />

-V77, -V78, -VU<br />

400h (3)(4)<br />

13 X X<br />

Reduction Gear<br />

(vee-belts)<br />

STEMME 10<strong>AG</strong> 400 h (3)(4)<br />

14<br />

Reduction Gear<br />

X<br />

(cog wheels)<br />

STEMME 11<strong>AG</strong> 1000 h (3)(4)<br />

15 X Gear suspension STEMME 10AA<br />

1000 h<br />

(12 years)<br />

(4)(11)<br />

16 X Gear suspension STEMME 14AA<br />

1000 h<br />

(12 years)<br />

(4)(11)<br />

17 X Gear suspension STEMME 11AA<br />

1000 h<br />

(12 years)<br />

(4)(11)<br />

18 X X<br />

Flywheel clutch<br />

(2 flyweights)<br />

STEMME 10AK 400 h (3)(4)<br />

A4010022_B12_97.doc-21/04.12.07 16:25/04.12.07 16:28 Doc. No: A40-10-022

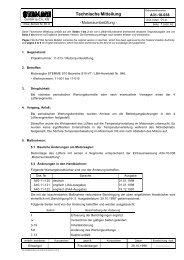

Maintenance Manual STEMME S10 Date of Issue: Oct. 1, 1990 page: 22-1<br />

No.<br />

S10<br />

Amendment No.: 12 Date: Nov 30. 2007<br />

LBA approved<br />

Model Permissible op. time by<br />

S10-V<br />

S10-VT<br />

Part/Assembly/<br />

Equipment<br />

Manufacturer,<br />

Type<br />

Part No.<br />

(STEMME)<br />

Overhaul<br />

(TBO)<br />

Replaceme<br />

nt<br />

NOTES<br />

19<br />

Flywheel clutch<br />

X<br />

(3 flyweights)<br />

STEMME 11AK 400 h (3)(4)<br />

20 X X Driveshaft<br />

Ciba-Geigy<br />

(without P/N ref.)<br />

10AS-07 800 h (3)(4)(9)<br />

21 X X X Driveshaft<br />

Glaenzer-Spicer<br />

19.01.01.xxx<br />

10AS-07 800 h (3)(4)(9)<br />

22 X X X Driveshaft<br />

MAN Techn. <strong>AG</strong><br />

95.0700.00.000<br />

10AS-W 800 h (3)(4)(9)<br />

23 X X X Driveshaft STEMME 10AS-F 800 h (3)(4)(9)<br />

24<br />

rubber parts of the<br />

X<br />

engine<br />

Rotax sundry 5 years (7)<br />

25 X X<br />

Rubber parts of the<br />

clutch<br />

STEMME<br />

10AK-43<br />

10AK-48<br />

12 years<br />

26 X X<br />

flexible disk of the drive<br />

shaft system<br />

STEMME 10AS-09 12 years<br />

27<br />

flexible disk of the drive<br />

X<br />

shaft system<br />

STEMME 11AS-09 12 years<br />

28 X X Fuel Hoses STEMME 10AB-... - 5 years<br />

29 X X Fuel hoses STEMME HZ-KSL014 - 5 years<br />

30 X X X Fuel Hoses STEMME HZ-KSL010 - 5 years<br />

31 X X Lubrication Hoses STEMME 10AM-KÖS / ~T - 5 years<br />

32 X Lubrication Hoses STEMME 11AM-O... - 5 years<br />

33 X Coolant Hoses STEMME 11AM-W... - 5 years<br />

34 X X X Brake Hoses sundry 10FO-B06 - 10 years<br />

35 X X X Safety Harnesses sundry 10C-08/-09 - 12 years (6)<br />

36 X X<br />

Control Rod<br />

X<br />

Connectors<br />

L'Hotellier 10M-098/-099 (2)<br />

37 X fuel check valve <strong>Stemme</strong> 11AB-M03 5 years 10 years (12)<br />

On expiry of a part’s permissible operating times the affected part has to be sent to the manufacturer or to a<br />

from the manufacturer approved repair/overhaul workshop for inspection. The organisation has to decide if<br />

further use is possible after the inspection, or if an replacement or overhaul or repair is necessary.<br />

If the limitation is given in operating hours and in a calendar period (year), the first occurring case applies.<br />

If further equipment subject to service life limitations is installed, the overhaul intervals and service life limits<br />

prescribed by the respective manufacturer must be observed. The item has to be entered in the form Review<br />

of Operating times.<br />

A4010022_B12_97.doc-21/04.12.07 16:25/04.12.07 16:28 Doc. No: A40-10-022

Maintenance Manual STEMME S10 Date of Issue: Oct. 1, 1990 page: 22-2<br />

NOTES:<br />

Amendment No.: 12 Date: Nov 30. 2007<br />

LBA approved<br />

(1) Extension of service life exceeding 6000 h can be achieved only for individual airplanes after a comprehensive<br />

inspection of the airframe carried out by the manufacturer according to an approved program.<br />

(2) Please refer to the actual issue of the appropriate manufacturer's Service Bulletin. Maintenance Manuals<br />

or Instructions of the manufacturer must be strictly adhered to (for L'Hotellier Ball and Swivel Joints contained<br />

in the Annex to the Maintenance Manual).<br />

(3) The stated times are provisional within the TBO development programs. Based on sufficient operating<br />

experience they may be further raised or reduced if necessary (extension of TBO and/or service life is<br />

intended) and will be notified by a new issue of this Service Bulletin.<br />

(4) The TBO expires in each case of:<br />

• impact stop (possible ground touch of the propeller);<br />

• Non-observance of the periodical inspections as they are fixed in the Maintenance Manual;<br />

• replacement of essential parts.<br />

Damaging by ground contact, bird strike, stone strike or similar which require a „large repair“, the<br />

manufacturer decides which parts of the complete drive system are affected and if a repair may be<br />

practicable or if an overhaul or replacement have to be performed.<br />

(5) see also ROTAX SB 914-027 “Extension of the Time Between Overhaul (TBO)“.<br />

For Engines ROTAX 914F2/S1 up to S/N: 4.420.313 after performing of the ROTAX SB 914-027, for all other<br />

engines from S/N: 4.420.314 without any more actions.<br />

(6) Replacement required after heavy overloadings (e.g. due to an accident); hereto refer also to the<br />

operating instructions of the manufacturer.<br />

(7) All rubber parts of the engine Rotax 914 F2/S1 must be renewed. Subject to this action are: the<br />

carburetor venting hoses (between airbox-carburetor float chambers-fuel pressure control and pressure<br />

sensor), the air hoses between Turbo Charger-Intercooler-Airbox, the connecting hoses on the compensating<br />

tube, the V-belt, all rubber hoses of the cooling system, and the rubber diaphragms and the rubber flange on<br />

both carburetors.<br />

(8) For the STEMME supported model of the engine type Rotax 914, the TBO is established by this SB on<br />

the basis of that published by Rotax, and in general it will not differ. Overhaul of engines model<br />

Rotax 914 F2/S1 must be carried out by a workshop that is authorized by STEMME in accordance with<br />

Rotax.<br />

(9) The drive shaft cannot be overhauled. Instead of an overhaul it will be checked by a load test at<br />

STEMME.<br />

(10) After 5 years the variable pitch propellers 10AP-V and 11AP-V will not be overhauled. The propeller will<br />

be inspected only. During the inspection the propeller will be disassembled, inspected and reassembled.<br />

(11) During the overhaul of the gear suspensions 10AA, 14AA and 11AA all rubber parts are replaced<br />

(overhaul program: D40-10AA; D40-14AA or D40-11AA). The metal parts will be used again.<br />

(12) The fuel check valves can not be overhauled. The check valves will be checked visually after 5 years.<br />

Indications of a brittleness or change of the original colour must be specially observed. The parts must be<br />

untimely replaced if such a indication were found.<br />

A4010022_B12_97.doc-21/04.12.07 16:25/04.12.07 16:28 Doc. No: A40-10-022

Maintenance Manual STEMME S10 Date of Issue: Oct. 1, 1990 page: 38<br />

7.3.10 Drivetrain System<br />

Adjustment of the Belts on the Transmission Gear:<br />

Amendment No.: 12 Date: Nov 07. 2007<br />

Loosen the clamping screw on the left lower side of the transmission gear. Adjust the belt tension (per belt)<br />

by means of the setting screw on the left transmission gear side to 0.15 in. (3.7 mm) press-down depth<br />

halfway between the axes exerting a press-down force of 11.2 lbf. (50 N). Tighten the clamping screws.<br />

Insufficient belt tension is indicated by slipping together with "squeaking" at full power or when the power<br />

lever is pushed forward suddenly.<br />

Removal:<br />

The propeller shaft can be removed together with transmission gear and the propeller in one step:<br />

− Remove the propeller dome: lift off left and right leg room coverings in the cockpit, Loosen clamping screw<br />

on the stay tube of the propeller dome, pull out locking screw, disconnect flexible hoses, disconnect the<br />

antenna connection to transponder/GPS, withdraw the dome to the front.<br />

− Disconnect the control cable of the propeller brake on the transmission gear.<br />

− Loosen four fastening screws on the transmission gear supports, loosen balancing spring on top of the<br />

transmission gear.<br />

− Pull out transmission gear with propeller shaft.<br />

− The engine side clutch remains on the engine. Removal by loosening of the attachment screws on the<br />

engine flange.<br />

Installation:<br />

− In the opposite order as removal. Attention: Clean and regrease splined sliding joint.<br />

− For tightening moments please refer to section.6.6, page 33.<br />

7.4 Landing Gear<br />

7.4.1 Main Landing Gear<br />

Check the main landing gear legs and the trailing arms for deformation and possible cracks as an result of<br />

overloads.<br />

Adjustment Data: see fig. 3.4.1.a<br />

Functional Check:<br />

Support the aircraft (clearance between the main wheels and the ground must be approximately 1.6 in. / 40<br />

mm), remove upper cowling of the central fuselage.<br />

Checking procedure:<br />

− Inspect screw joints (torque paint);<br />

− check wheels for smooth turning;<br />

− joint heads of the operating arms may not be jammed;<br />

− the articulations of the spindles and the operating arms must have play;<br />

− installation of the landing gear emergency release system without kinks/collisions;<br />

− landing gear stop switches on the operating arms: check for halfway position and proper functioning,<br />

inspect wiring / connection;<br />

A4010022_B12_97.doc-38/04.12.07 16:25/04.12.07 16:30 Doc. No: A40-10-022

Maintenance Manual STEMME S 10 Date of Issue Oct. 01, 1990 fig. 6.3.a-1<br />

Serial Number:<br />

-<br />

Registration:<br />

-<br />

Amendment No.: 12 Date: Nov. 30. 2007<br />

Relevant Equipment List:<br />

Order No.:<br />

This Weight and Balance Report was drawn up without weighing. Any weighing data have been taken from the<br />

Weight and Balance Report dated and if need be corrected according to point 4.2.<br />

Drawing Up Reason: Conformity Inspection<br />

Changes of Equipment<br />

Repair. Date of Findings Report:<br />

Other:<br />

1. Preparation and Conditions<br />

1.1 The fuselage weight must be determined including rudder, back rests with cushions or equivalent upholstery, seat cushions,<br />

canopy, standard tool kit in baggage compartment behind backrest, Logbook and Flight Manual. Replenish oil if necessary.<br />

Fixed ballast must be installed, loose ballast must be removed.<br />

1.2 Wing weight must be determined with bolts and 3 l / 0.66 imp. gal. fuel (unusable volume).<br />

1.3 Fixed supplementary equipment must be installed.<br />

1.4 Points 1.2 through 1.4 must be observed if an overall weighing of the powered glider is performed. The canopy has to be<br />

closed during weighing.<br />

1.5 If weight and moment arm of additionally installed or removed items is known exactly, the new CG may be determined<br />

numerically (see point 4.2)<br />

2. Overview of Component Weights and Weight Limits<br />

Component Weights from Separate<br />

Weighing<br />

[kg]<br />

[lbs] ***<br />

[kg]<br />

[lbs] ***<br />

Weight Limits [kg]<br />

Fig. 6.3.a Mass and Balance Sheet (Pattern; the complete form can be obtained from the<br />

manufacturer)<br />

A4010022_B12_97.doc-1/04.12.07 16:33/05.12.07 08:41 Doc. No: A40-10-022<br />

[lbs] ***<br />

Central Wing Maximum All Up Weight (incl. Fuel) 850 (1874)<br />

Right Hand Outer Wing<br />

Left Hand Outer Wing<br />

Maximum Weight of Non-Lifting Parts<br />

GNTmax (incl. Load in Cockpit)<br />

Of that: Maximum Weight of Equipment on<br />

Instrument Panel, without engine instruments<br />

Fuselage Maximum Load (Max AUW - Empty Weight)<br />

Horizontal Tail<br />

Component Weight Sum<br />

Empty<br />

Weight*<br />

LNT**<br />

Max. Load in Cockpit<br />

(GNTmax - LNT**; maximum 202 kg / 445 lbs,<br />

of that max. 180 kg / 397 lbs in seats, max.<br />

110 kg / 243 lbs in each seat and max. 22 kg<br />

/ 48.5 lbs in baggage compartments)<br />

Cockpit load must be at least 7 kg / 15,43<br />

lbs less than maximum load!<br />

* cross-check: compare with empty weight from 3.; Divergence of 2 kg / 4.4 lbs due to measure error is allowable.<br />

** LNT: Empty weight of "Non Lifting Parts"<br />

*** Units: cross out if not applicable<br />

3. Determining of Empty Weight and Moment Arms<br />

Weights and Moment Arms ***:<br />

forward RH mr kg / lbs<br />

forward LH ml kg / lbs<br />

Tail Wheel ms kg / lbs<br />

Σ=Empty Weight me kg / lbs<br />

Moment Arm a mm / in.<br />

Moment Arm b mm / in.<br />

Datum level: Leading Edge of<br />

Central wing, vertical plane<br />

Pitch: wedge 1000:84 (4°50') on tail<br />

cone, upper edge horizontal<br />

570 (1257)<br />

10<br />

(22)

Maintenance Manual STEMME S 10 Date of Issue Oct. 01, 1990 fig. 6.3.a-2<br />

4. Determining of Empty Weight Center of Gravity<br />

4.1 After Weighing:<br />

x<br />

S<br />

mSb =<br />

m<br />

⋅<br />

+ [mm / in.]*** ⇒ x S =<br />

e<br />

a<br />

4.2 After Changes, without Weighing:<br />

Following changes have been made on the powered glider:<br />

Install. /<br />

Removal<br />

Amendment No.: 12 Date: Nov. 30. 2007<br />

Fig. 6.3.a Mass and Balance Sheet (Pattern; the complete form can be obtained from the<br />

manufacturer)<br />

A4010022_B12_97.doc-0/05.12.07/08:43<br />

Item<br />

⋅<br />

+<br />

Weight ( + /-)<br />

m = [kg / lbs]***<br />

Moment Arm ( + /-)<br />

x = [mm / in.]***<br />

Sum mzus= Sum Mzus=<br />

NOTE: Count weight installed positive, weights removed negative.<br />

Count moment arms aft of datum positive, in front of datum negative.<br />

x<br />

Sneu ,<br />

m ⋅ x + M<br />

=<br />

m<br />

alt alt zus<br />

neu<br />

[mm / in.] ⇒ x S , neu =<br />

5. Definition of Minimum Load Required<br />

⋅ +<br />

With Empty Weight determined: kg / lbs***<br />

and the empty weight CG aft of datum: mm / in. ***<br />

the Minimum Load Required is ****: kg / lbs***<br />

*** Units: cross out if not applicable<br />

****According to Maintenance Manual, Section 6.3<br />

= [mm / in.]***<br />

= mm / in. ***<br />

Site, Date Stamp Sign Job Leader<br />

Moment ( + /-)<br />

M =[mm kg / in. lbs]***<br />

Inspector Statement: All measured data are within the allowable ranges and correspond to the production and<br />

maintenance instructions of the type.<br />

Site, Date Stamp Sign Inspector