AL400G Alkalinity Meter - Illawarra Industrial Instrumentation

AL400G Alkalinity Meter - Illawarra Industrial Instrumentation

AL400G Alkalinity Meter - Illawarra Industrial Instrumentation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

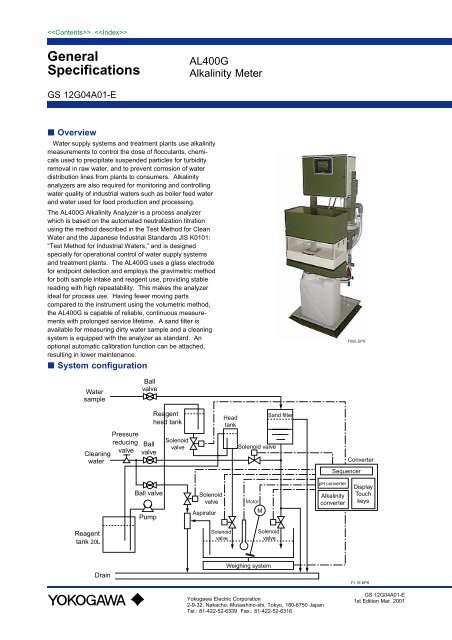

GeneralSpecifications<strong>AL400G</strong><strong>Alkalinity</strong> <strong>Meter</strong>GS 12G04A01-E OverviewWater supply systems and treatment plants use alkalinitymeasurements to control the dose of flocculants, chemicalsused to precipitate suspended particles for turbidityremoval in raw water, and to prevent corrosion of waterdistribution lines from plants to consumers. <strong>Alkalinity</strong>analyzers are also required for monitoring and controllingwater quality of industrial waters such as boiler feed waterand water used for food production and processing.The <strong>AL400G</strong> <strong>Alkalinity</strong> Analyzer is a process analyzerwhich is based on the automated neutralization titrationusing the method described in the Test Method for CleanWater and the Japanese <strong>Industrial</strong> Standards JIS K0101:“Test Method for <strong>Industrial</strong> Waters,” and is designedspecially for operational control of water supply systemsand treatment plants. The <strong>AL400G</strong> uses a glass electrodefor endpoint detection and employs the gravimetric methodfor both sample intake and reagent use, providing stablereading with high repeatability. This makes the analyzerideal for process use. Having fewer moving partscompared to the instrument using the volumetric method,the <strong>AL400G</strong> is capable of reliable, continuous measurementswith prolonged service lifetime. A sand filter isavailable for measuring dirty water sample and a cleaningsystem is equipped with the analyzer as standard. Anoptional automatic calibration function can be attached,resulting in lower maintenance. System configurationF00E.EPSWatersampleBallvalveCleaningwaterPressurereducingvalveBallvalveReagenthesd tankSolenoidvalveHeadtankSolenoid valveSand filterSequencerConverterBall valvePumpSolenoidvalveAspiratorMotorMpH converter<strong>Alkalinity</strong>converterDisplayTouchkeysReagenttank 20LSolenoidvalveSolenoidvalveDrainWeighing systemYokogawa Electric Corporation2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 JapanTel.: 81-422-52-6339 Fax.: 81-422-52-6316F1.1E.EPSGS 12G04A01-E1st Edition Mar. 2001

Features• Proven measuring system based on neutralizationtitration gravimetric analysis• Reducing the reagent consumption to 1/6 comparedto the previous models• Compact, easy-to-operate design, allowing simplerinstallation with minimum space requirements• Enhanced self-diagnostics, including check forreagent shortage General SpecificationsMeasured object: M alkalinity of clean or raw water(CaCO 3equivalent: Equivalence point pH 4.8)Measurement principle: Neutralization titration gravimetricanalysis using glass pH electrodeMeasurement interval: Continuous measurement, fixedperiod (previous value held).Interval: 10 min. + hold time (arbitrary setting inrange 0.0 to 24 hrs)Measurement ranges:Low range: 0 to 50 mg/lMedium range: 0 to 100 mg/lHigh range: 0 to 200 mg/lOutput ranges: ProgrammableMinimum range: 0 to 50 mg/lMaximum range: Measurement rangeOutput signal:Two outputs (<strong>Alkalinity</strong>, pH)Note: pH output is valid during measurement.4 to 20 mA DC (max. load resistance: 600 )Burnout upscale/downscale selectable in range2.0 to 22.0 mAOutput hold during maintenance: selectable aslast value or fixed valueDisplay: Digital (0.0 to 200.0).Contact output:Output type: concentration high or low limit alarm,auto-cleaning/auto-calibration cycle,in-maintenancestatus signal, instrument fail.Contact operation: On or Off outputContact type: relay contact output (voltage-free contact)Contact rating:Max. open/closed voltage: 100-240 V AC or 24 V DC(resistance load)Max. voltage across load: 264 V AC or 125 V DCMax. current: 2 A, AC or DC (resistance load)Max. power switched: 120 V A or 48 W (resistanceload)Contact status:Contacts Power offPower OnNo alarm AlarmAll Open Open Closed(Note) Same output for power off as for instrument failure.T01E.EPSContact input :contact types : Remote measurement start,remote cleaning start, remote calibration start(only available when specified)Contact type : Voltage-free contactContact operation: ON input resistance; 200 or lessOFF input resistance; 100 k or greaterAuto-clean function:Measurement tank: Water or acid cleaningselectableHead tank/Sand filter: back-flush washAuto-calibration function (optional ):<strong>Alkalinity</strong> span calibration with standard solutionDiagnostic functions:Measurement out of range, pH abnormal(calibration fail), converter abnormal, titrationabnormal, sample solution interrupt, reagent low,calibration solution low.Materials:Converter case; Carbon steel plateDetector case; Stainless steelMeasurement tank; Acrylic resinWetted parts; Polyethylene,polypropylene, PVC,TeflonStanchion; Carbon steel or stainless steel(specified by model/suffix code)Reagent tank: PolyethyleneReagent level detector: PolypropyleneFinish:Converter case; Baked polyurethane resinDetector; Case Baked polyurethane resinStanchion; Baked polyurethane resinColors:Converter case; Munsell 0.6GY3.1/2.0 andMunsell 2.5Y8.4/1.2Detector; Munsell 0.6GY3.1/2.0 andMunsell 2.5Y8.4/1.2Stanchion; Munsell 0.6GY3.1/2.0Ambient temperature: 0 to 40°CAmbient humidity: 5 to 95% RH (non-condensing)Storage temperature: -30 to 70°CInstallation location: Indoors (rainproof shelter required ifmounted outdoors)Mounting: Secured by anchor boltsPiping connection:Water sample, cleaning water: VP16Drain: VP40Air: Rc1/4Sample conditions:Temperature: 0 to 40°C.Flow rate : 1 to 3 l/min or less (approx. 50 gsample water per analysis)Pressure: 20 to 500 kPa2All Rights Reserved. Copyright © 2000, Yokogawa Electric CorporationGS 12G04A01-E1st Edition Feb.26.2001-00

Reagent:Solution: Diluted sulfuric acid (H 2SO 4)Concentrations:Low range: 0.005 mol/lMedium range: 0.01 mol/lHigh range: 0.02 mol/lConsumption: Max. 5 ml per analysisCleaning water:Water quality: Clean water equivalent (chlorinecontainingwater with turbidity 1 mg/1 or less).Temperature: 0 to 50°CPressure: 100 to 500 kPaConsumption: approx. 50 l/dayNote: Reagent is used if acid cleaning is selected bymaintenance panel.Standard solution (for autocalibration):Solution: Potassium bicarbonate (KHCO3)aqueous solution as alkalinity equivalent to 80%of measuring rangeAir purge (using instrument air):Note : Be sure to perform air purge.Supply pressure; 140 kPaAir supply; approx. 5 l/minPower supply: 100, 110, 200 or 220 V AC, 50/60 HzPower consumption: Approx. 150 VA or lessWeight: With sampling equipment; approx. 70 kgCharacteristics:Repeatability; within 2% of full scaleLinearity; within 3% of full scale3 Model and Suffix CodesModel Suffix Code Option Code Specifications<strong>AL400G</strong>ApplicationRangePower supplySampling equipmentAutocalibrationOption-1-2-L-M-H-1-3-5-7-NN-AD-AB-SD-SB-NN-A3/AP/SCT<strong>Alkalinity</strong> <strong>Meter</strong>Clean waterRaw waterLow range (0 to 50 mg/l)Medium range (0 to 100 mg/l)High range (0 to 200 mg/l)200V AC, 50/60 Hz220V AC, 50/60 Hz100V AC, 50/60 Hz110V AC, 50/60 HzAlways -NNIncluded, base mountingIncluded, rear mountingIncluded, base mounting,with stainless steel stanchionIncluded, rear mounting,With stainless steel stanchionWithout autocalibrationWith autocalibrationWith air purge pumpWith stainless tag plateT02E.EPS AccessoriesName Qty DescriptionpH4 buffer solutionpH7 buffer solutionPolyethylene bottleWash bottlePotassium bicarbonateSyringeFittingTube11212112m12 packs, each for 500ml preparation12 packs, each for 500ml preparation500ml for pH standard solution500ml Polyethylene0.8 g20ml3 -way jointPolyethylene tubeT03E.EPSAll Rights Reserved. Copyright © 2000, Yokogawa Electric Corporation GS 12G04A01-E 1st Edition Feb.26.2001-00

4 Consumables• Auxiliary PartsName Part No. NotesQuantitiesReagentpH electrode (*3)pH4 buffer solutionpH7 buffer solutionSand granules (*5)Potassium bicarbonateSyringe (20 ml)K9049MPHA405-120K9020XAK9020XBK9720FZK9465RAL9827NJ0.5mol/l sulfuric acid, 3 500ml bottlesXerolyt pH electrode12 packs, each for 500ml preparation12 packs, each for 500ml preparation1L pack for sand filter2 packs (0.8 g)For standard solution6 sets / year (*2)1 unit / year1 box / year (*4)1 box / year (*4)1L / year2 sets / year (*6)1 bottle/ year*1: Required quantity is as referential and dependent on measurement conditions.*2: If sample is measured at 200 mg/l with 10-min cycle, maximum 1.5 bottles per month are required.*3: Once-a-year replacement recommended.*4: Required quantity for once-a-month calibration.*5: Once-a-year replacement recommended.*6: Required quantity for once-a-month calibration using auto-calibration.T04E.EPS• Limited-life partsName Part No. Recommendedreplacement interval (*1)Reagent pump (100 V) (*2 ) K9465JT 3 yearsAir pump (100 V) (*2 ) K9087XE 3 yearsSolenoid valve (SV1) K9465MC 5 yearsSolenoid valve (SV2) K9465MB 5 yearsSolenoid valves (SV3,SV5,SV7,SV8,SV9) K9465MD 5 yearsSolenoid valve (SV4) K9465ME 1 yearSolenoid valve (SV6) K9465MF 5 yearsMotor assembly (100 V) (*2) K9465CL 3 years*1: Recommended replacement interval is as referential and dependent on instrument.*2: Part numbers of items marked with *2 are for 100 V AC version. For other versions,refer to the Customer Maintenance Parts List.T04.2E.EPS Sampling Parts (for replacement)NameSand filter assembly for raw water applicationOverflow tank assembly for clean water applicationReagent head assemblyReagent tank assemblyReagent pump (for 100 V)Reagent pump (for 110 V)Reagent pump (for 200/220 V)Part No.K9465KFK9465KAK9465KVK9465KJK9465JTK9465JVK9465JWT05E.EPSAll Rights Reserved. Copyright © 2000, Yokogawa Electric CorporationGS 12G04A01-E1st Edition Feb.26.2001-00

6 External Wiring Diagram<strong>Alkalinity</strong>Analog outputpH analog output(for capturingtitration curve)61 +62 - (Common 1)63 G64 +65 - (Common 1)66 G717273747576Remote measurement startContact inputRemote cleaning startContact inputRemote calibration startContact input67687778LNPower inputGround(Common 2)(Common 2)(Common 2)(Common 2)8182838485868788Under-maintenanceContact outputFAIL contact outputHi / Lo alarm contact outputUnder auto clean, auto calibrationstatus contact outputNote : Contact outputs share common 2 ground,common 1 is isolated to common 2.F04E.EPS Flow DiagramSF(HP)RHTConverterAutocal.unit (-A3 version)KHCO3pH7pH4Water sample(VP16)V1SV6V3Rc1/4Rc1/4DetectorV5 V6 V7SV7 SV8 SV9Cleaningwater(VP16)V2PU1PRV4SV1Rc1/4Rc1/4HTSV3Rc1/4RTASPSV4SV2SV5ReagentRc3/8Rc1/4Air(Rc1/4)Drain(VP40)PU2(OPTIONAL)Rc1/4SF(HP) : Sand filter (raw water)or head tank (clean water)RHT : Reagent head tankRT : Reagent tankASP : Aspirator6/ 4 PE tube8/ 6 PE tube13/ 8 flexible wire-reinforced PVC tube22/ 15 flexible wire-reinforced PVC tube33/ 25 flexible wire-reinforced PVC tubeVP16 rigid PVC pipeVP40 rigid PVC pipeF05E.EPSAll Rights Reserved. Copyright © 2000, Yokogawa Electric CorporationGS 12G04A01-E1st Edition Feb.26.2001-00

Maintenance Space Requirements7Unit : mmApprox.500Approx.500Stanchion 600Approx.500350530FrontApprox.5004904- 15For anchor boltF06E.EPSAll Rights Reserved. Copyright © 2000, Yokogawa Electric Corporation GS 12G04A01-E 1st Edition Feb.26.2001-00

8All Rights Reserved. Copyright © 2000, Yokogawa Electric CorporationSubject to change without noticeGS 12G04A01-E1st Edition Feb.26.2001-00