SIMOVERT MV Medium-Voltage Drives 660 kVA to 9100 ... - Industry

SIMOVERT MV Medium-Voltage Drives 660 kVA to 9100 ... - Industry

SIMOVERT MV Medium-Voltage Drives 660 kVA to 9100 ... - Industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Siemens DA 63 · 20040/3

0/4 Siemens DA 63 · 2004

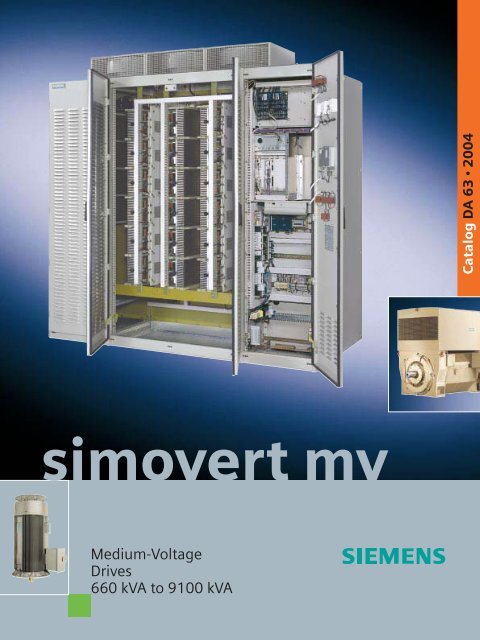

<strong>SIMOVERT</strong> <strong>MV</strong>Overview11/2 Applications1/2 ¦ Innovative standard solutionsfor all applications¦ <strong>SIMOVERT</strong> <strong>MV</strong>: The flexible, modularand high-performance solution¦ <strong>SIMOVERT</strong> <strong>MV</strong>: The all-rounder1/3 ¦ <strong>SIMOVERT</strong> <strong>MV</strong>: The international solution¦ Focus on cus<strong>to</strong>mer benefits¦ <strong>SIMOVERT</strong> <strong>MV</strong>: Quality and environmentalresponsibility1/4 ¦ <strong>SIMOVERT</strong> <strong>MV</strong> drive convertersand H-compact, H-compact PLUShigh-voltage mo<strong>to</strong>rs:Optimally harmonized with one another1/5 Examples of order numbers1/5 <strong>SIMOVERT</strong> <strong>MV</strong> drive converter1/5 H-compact mo<strong>to</strong>rs1/6 H-compact PLUS mo<strong>to</strong>rsSiemens DA 63 · 2004 1/1

1<strong>SIMOVERT</strong> <strong>MV</strong>OverviewApplicationsInnovative standard solutionsfor all applications<strong>SIMOVERT</strong> <strong>MV</strong> ® are voltagesourceDC link drive convertersusing three-level technology.They convert the three-phasesystem line supply with fixedvoltage and fixed frequency, in<strong>to</strong>a three-phase system withvariable voltage and variablefrequency. The fully-digital,open-loop control technologyand the high-performance Vec<strong>to</strong>rControl with the innovativepower semiconduc<strong>to</strong>rs HV-IGBT (High-<strong>Voltage</strong> InsulatedGate Bipolar Transis<strong>to</strong>r) on theinverter side and a twelve-pulsediode rectifier on the line side inthe standard version guaranteehigh reliability, flexibility, securityof investment for the future,low harmonics fed back in<strong>to</strong> theline supply and low mo<strong>to</strong>rstressing.<strong>SIMOVERT</strong> <strong>MV</strong>The flexible, modular andhigh-performance solutionThe design of this standardseries is consistently modular.Thanks <strong>to</strong> its flexibility, it fulfillsalmost every cus<strong>to</strong>mer requirement.<strong>SIMOVERT</strong> <strong>MV</strong> is availablefor the most importantstandard mo<strong>to</strong>r voltages,2.3 kV, 3.3 kV, 4.16 kV, 6 kVand 6.6 kV. The standardizedoutput range extends from0.66 <strong>MV</strong>A <strong>to</strong> 9.1 <strong>MV</strong>A(dependent on the rated mo<strong>to</strong>rvoltage) with air and water cooling– higher outputs are availableon request.<strong>SIMOVERT</strong> <strong>MV</strong>: The all-rounder<strong>SIMOVERT</strong> <strong>MV</strong> can be usedfor an extremely wide range ofapplications.In waterworks, district heatingstations and water treatmentplants:Pumps for drinking water recoveryand distribution, pumpsfor heating circuits, slurrypumps.In the oil and natural gasindustry:Pumps and compressorsIn machinery construction:Fans, pumps and constant<strong>to</strong>rquedrivesIn the foodstuff industry:Centrifugal drives (e.g. in thesugar industry), pumps, kneaders,mixers, mills, extrudersIn marine engineering:Propeller drives, bow thrusters,lateral thrustersIn the cement industry:Conveyor belts, blowers andcrushersIn open-pit mining:Conveyor belt systems, vibra<strong>to</strong>rs,excava<strong>to</strong>rs, crushersIn wire and fine rolling mills:Wire-drawing drivesIn power utilities:Pumps, blowers, coal crushersIn the paper industry:Refiners, pumpsFig. 1/1Innovative HV-IGBT power semiconduc<strong>to</strong>r(High-<strong>Voltage</strong> Insulated Gate Bipolar Transis<strong>to</strong>r)Fig. 1/2Service-friendly using a modular design: Easily replaceable Power-Cards1/2 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>Overview 1Applications<strong>SIMOVERT</strong> <strong>MV</strong>: The international solution<strong>SIMOVERT</strong> <strong>MV</strong> is not only availablefor the most importantinternational medium-voltagelevels, but also for the mostimportant international standards,such as:Further, <strong>SIMOVERT</strong> <strong>MV</strong> isoptionally available for marineapplications according <strong>to</strong> therequirements of the followingclassification societies (withcertificate, if desired):¦ IEC¦ American Bureau of¦ ENShipping¦ DIN VDE¦ Bureau Veritas¦ Det Norske Veritas¦ Germanischer Lloyd¦ Lloyds Register of Shipping¦ Chinese ClassificationSocietyFocus on cus<strong>to</strong>merbenefitsWith the <strong>SIMOVERT</strong> <strong>MV</strong> drivesystem, the main focus is oncus<strong>to</strong>mer benefits. The optimumdrive solution can alwaysbe found as a result of standardizedtechnology, a perfectlyharmonized system comprising<strong>SIMOVERT</strong> <strong>MV</strong> and theH-compact and H-compact-PLUS mo<strong>to</strong>rs and an extremelycomprehensive range of accessories.<strong>SIMOVERT</strong> <strong>MV</strong>:Quality and environmentalresponsibility<strong>SIMOVERT</strong> <strong>MV</strong> drive convertersare manufactured according <strong>to</strong>the highest quality standards.The complete manufacturingprocess, i.e. development,mechanical design, production,contract administration andlogistics supply center andsales/marketing have been certifiedfrom an independent bodyaccording <strong>to</strong> DIN ISO 9001.It goes without saying that<strong>SIMOVERT</strong> <strong>MV</strong> fulfills all of theimportant criteria for environmentalprotection.Fig. 1/3Mounting rack of the Vec<strong>to</strong>r ControlFig. 1/4Optional single-phase uninterruptible power supply (UPS) withMASTERGUARD (option L17)Siemens DA 63 · 2004 1/3

1<strong>SIMOVERT</strong> <strong>MV</strong>OverviewApplications<strong>SIMOVERT</strong> <strong>MV</strong> drive converters and H-compact, H-compact PLUS high-voltage mo<strong>to</strong>rs:Optimally harmonized with one anotherThe <strong>SIMOVERT</strong> <strong>MV</strong> drive The self-ventilated, rib-cooledconverters <strong>to</strong>gether with the mo<strong>to</strong>rs H-compact (1LA4) arewell-proven H-compact and available in an output rangeH-compact PLUS high-voltage from 0.8 MW <strong>to</strong> 3.6 MW. Theymo<strong>to</strong>rs form a high-performancedrive package over a applications where highoffer significant advantages forwide output and speed range. <strong>to</strong>rques are demanded even atDuring development, the drive low speeds. If the requirementsconverter and mo<strong>to</strong>r were alwaysconsidered as a single en-the force-ventilated versionare even more stringent, thentity, and were harmonized with (1PQ4) provides <strong>to</strong>rques whichone another both from the perspectiveof cost-effectiveness rated mo<strong>to</strong>r <strong>to</strong>rque over a wideare almost the same as theas well as technically. This is the speed control range.reason why a filter is not requiredbetween the drive converterand the mo<strong>to</strong>r. The mo<strong>to</strong>rsare extremely rugged,which means that they can besimply operated under even the<strong>to</strong>ughest application conditions.H-compact PLUS high-voltagemo<strong>to</strong>rs (shaft height from450 mm <strong>to</strong> 630 mm) cover anoutput range from 0.7 MW <strong>to</strong>7 MW. The mo<strong>to</strong>rs have a modulardesign and are availablewith three cooling types:¦ open-circuit cooling (1RA4),¦ air-<strong>to</strong>-water cooling (1RN4)and¦ air-<strong>to</strong>-air cooling (1RQ4).As a result of this variable coolingconcept, the drives can beintegrated in<strong>to</strong> any plant orsystem configuration.The mo<strong>to</strong>rs are characterizedby superb output, reliability andefficiency. This is mainlyachieved as follows:¦ Excellent operating data,expecially when it comes <strong>to</strong>efficiency and power fac<strong>to</strong>r¦ High power density¦ Compact type ofconstruction¦ Stiff rugged enclosure andbearing endshields manufacturedout of cast iron¦ All parts are providedwith long-term corrosionprotection¦ MICALASTIC high voltageinsulation using VPItechnology (VacuumPressure Impregnation)1/4 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>Overview 1Examples of order numbers<strong>SIMOVERT</strong> <strong>MV</strong> drive converter6SE80 <strong>SIMOVERT</strong> <strong>MV</strong> drive converterOutput in 100 <strong>kVA</strong>Cooling type1 Air cooling2 Water coolingRated supply voltageA 2.3 kVB3.3 kVC 4.16 kVD6.0 kVE 6.6 kVVersionA Drive converter with 12-pulse diode inputFunction releaseClosed-loop control related versionOptionsAll of the options provided in the drive converter are listed here and specifiedwith a supplementary code; options may have <strong>to</strong> be specified in plain texte.g. 6 S E 8 0 1 5 – 1 B A 0 1 – ZH-compact mo<strong>to</strong>rsH-compact mo<strong>to</strong>rs1LA4 self-ventilated1PQ4 force-ventilatedFrame size, coded (shaft height, output stage)No. of poles (2, 4, 6, 8)Ro<strong>to</strong>r version<strong>SIMOVERT</strong> <strong>MV</strong> drive convertere.g. 1 L A 4 4 5 0 – 2 C V 0 0 – Z<strong>Voltage</strong> code0 2.3 kV / 50 Hz1 2.3 kV / 60 Hz2 3.3 kV / 50 Hz3 3.3 kV / 60 Hz4 4.16 kV / 50 Hz5 4.16 kV / 60 HzType of construction code0 IM B34 IM V1 with protective roof assembly8 IM V1 without protective roof assemblySpecial versionsSpecify a code and, if required, describe in plain textSiemens DA 63 · 2004 1/5

1<strong>SIMOVERT</strong> <strong>MV</strong>OverviewExamples of order numbersH-compact PLUS mo<strong>to</strong>rse.g. 1 R A 4 5 6 0 – 8 H V 2 0 – ZH-compact PLUS mo<strong>to</strong>rs1RA4 open-circuit ventilated1RN4 with air/water cooler1RQ4 with air/air coolerFrame size, coded (shaft height, output stage)No. of poles (4, 6, 8)Cooling typeF Version with separately-driven fanIP55/IC86W (1RN4)H Basic version with shaft-mounted fanIP23/IC01 (1RA4) and IP55/IC81W (1RN4)J Basic version with shaft-mounted fan, internal and externalIP55/IC611 (1RQ4)<strong>SIMOVERT</strong> <strong>MV</strong> drive converter<strong>Voltage</strong> code0 2.3 kV / 50 Hz1 2.3 kV / 60 Hz2 3.3 kV / 50 Hz3 3.3 kV / 60 Hz4 4.16 kV / 50 Hz5 4.16 kV / 60 HzType of construction code0 IM B34 IM V1 with protective roof assembly (1RQ4)8 IM V1 without protective roof assembly (1RA4/1RN4)Special versionsSpecify a code and, if required, describe in plain text1/6 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>Systemdescription2/2 Technical features2/2 ¦ Line supply¦ Incoming transformer2/3 ¦ Drive converter– Innovative HV-IGBT power semiconduc<strong>to</strong>rs– Opera<strong>to</strong>r control of the drive converter– Power section design2/4 – Low mo<strong>to</strong>r stressing using athree-level circuit design¦ Mo<strong>to</strong>rs22/6 Open and closed-loop control functions2/6 ¦ Closed-loop control features¦ Software functions2/7 Opera<strong>to</strong>r control and diagnostics2/7 ¦ OP7 opera<strong>to</strong>r panel¦ Control terminal strip¦ PROFIBUS DP2/8 ¦ Integration of drives in<strong>to</strong> SIMATIC ® S7with Drive ES– Drive ES Basic features– Functions of the blocks from Drive ES SIMATIC– Overview “Software environment for<strong>SIMOVERT</strong> <strong>MV</strong>”Siemens DA 63 · 2004 2/1

2<strong>SIMOVERT</strong> <strong>MV</strong>System descriptionTechnical featuresLine supply Incoming transformer Drive converter<strong>SIMOVERT</strong> <strong>MV</strong> drives keep theline supply stressing low:The <strong>SIMOVERT</strong> <strong>MV</strong> drive converteris connected <strong>to</strong> the¦ The starting current is limited medium-voltage line supply<strong>to</strong> the rated currentthrough a drive converter transformer.For the standard¦ There is only a low harmonic12-pulse DFE, a three-windingcomponent in the line currenttransformer is required, anddue <strong>to</strong> the 12-pulse diodeone five-winding transformer orrectifier DFE (Diode Fronttwo three-winding transformersEnd) used as standardfor the optional 24-pulse DFE(see Page 6/17).¦ Low reactive power drawn(cos j 1 > 0.96)¦ Optional 24-pulse diode rectifierfor applications wherethe harmonics fed back in<strong>to</strong>the line supply must be keptas low as possibleThe <strong>SIMOVERT</strong> <strong>MV</strong> drive (driveconverter and mo<strong>to</strong>r) is decoupledfrom the line supplythrough a transformer, resultingin:¦ Defined short-circuit power¦ Floating mo<strong>to</strong>r operationpossible¦ Low harmonics as a result ofthe 12-pulse DFE.¦ Output range:– for air cooling<strong>660</strong> <strong>to</strong> 7200 <strong>kVA</strong>;– for water cooling:1000 <strong>to</strong> <strong>9100</strong> <strong>kVA</strong>– higher outputs on request¦ Available for standardizedmedium voltage levels of2.3 kV, 3.3 kV, 4.16 kV, 6 kVand 6.6 kV¦ Ready-<strong>to</strong>-connect cabinetunit with degree of protectionIP21¦ Compact, modular design,hence extremely reliable andeasy <strong>to</strong> service¦ Standardized output rangefor air- and water cooling¦ The open-loop and closedlooppower supply is electricallyisolated from the powersection¦ Short-circuit proof driveconverter output (withoutsupplementary measures)¦ Fully-digital open- andclosed-loop control using afast signal processor¦ Vec<strong>to</strong>r Control with excellentcontrol performance¦ Frequency and speed controlrange up <strong>to</strong> 1:1000 (withencoder)¦ Speed resolution in the permille range (with encoder)¦ The drive is operated andmoni<strong>to</strong>red via the localopera<strong>to</strong>r panel, via a PC withthe engineering system<strong>Drives</strong> ES, via the controlterminal strip from a centralcontrol room or viaPROFIBUS DP from a higherlevelsupervisory processcontrol system¦ Opera<strong>to</strong>r prompting andmessages from the driveconverter are displayed inplain text on the opera<strong>to</strong>rpanel¦ Communications-capable inthe au<strong>to</strong>mation environmentvia PROFIBUS DP¦ The circuit-breaker iscontrolled from the driveconverter.6 kV / 6.6 kV<strong>660</strong> <strong>kVA</strong> 2000 <strong>kVA</strong>4.16 kV1300 <strong>kVA</strong> 7200 <strong>kVA</strong>3.3 kV1000 <strong>kVA</strong> 3100 <strong>kVA</strong>2.3 kV800 <strong>kVA</strong> 2400 <strong>kVA</strong>Air cooling4.16 kV1700 <strong>kVA</strong> <strong>9100</strong> <strong>kVA</strong>3.3 kV1300 <strong>kVA</strong> 4000 <strong>kVA</strong>2.3 kV1000 <strong>kVA</strong> 2600 <strong>kVA</strong>Water coolingFig. 2/1<strong>SIMOVERT</strong> <strong>MV</strong> drive converter output range2/2 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>System descriptionTechnical featuresInnovative HV-IGBTpower semiconduc<strong>to</strong>rsThe IGBT (Insulated GateBipolar Transis<strong>to</strong>r) has establisheditself as a standard inlow-voltage drive technology.A new generation has beencreated by consequentiallydeveloping the device for ahigher blocking capability and ahigher current-carrying capacity:The HV-IGBT (High-<strong>Voltage</strong>-IGBT).Advantages of HV-IGBT devicesover conventional IGCTthyris<strong>to</strong>rs (Integrated GateCommutated Thyris<strong>to</strong>r):¦ The HV-IGBT can be controlledby just using the voltageapplied <strong>to</strong> the gate¦ Together with the gating circuit,current and voltage transientscan be influencedduring turn-on and turn-off.¦ Overvoltages caused by parasiticleakage inductanceswhen the HV-IGBT is turnedoff are limited by the HV-IGBTin conjunction with the gatingcircuit¦ The turn-on characteristics ofthe HV-IGBT can be optimallyadapted <strong>to</strong> the free-wheelingdiode: the diode turns off inthe safe operating range¦ The HV-IGBT does notrequire any snubber circuitry,thus resulting in a simpledesign, high utilization leveland a high degree of reliabilityof the drive converter¦ The required gating power islow¦ HV-IGBTs limit, <strong>to</strong>gether withthe gating circuit, short-circuitcurrents without anyother circuitry required.This means that the<strong>SIMOVERT</strong> <strong>MV</strong> drive converterhas a short-circuitproof output.Opera<strong>to</strong>r controlof the drive converterThe important control elements<strong>to</strong> operate the drive converteras well as measured value andstatus displays are combined inthe OP7 opera<strong>to</strong>r panel.With the help of the optionalsoftware Drive ES (Drive EngineeringSystem), parameterizationbecomes particularly easyand user-friendly.Installed <strong>to</strong> a standard hardwareplatform (PC or programmingunit PG), Drive ES alsoguarantees permanent provisionof au<strong>to</strong>mation and drivedata of a project in the STEP 7Manager.Further, the drive converter andthe drive can be centrally controlledfrom a control room.A control terminal strip is providedfor this purpose. All of therequired control- and measuredvalue signals can beconnected here or retrievedfrom here.Beyond this, the drive convertercan be integrated in<strong>to</strong> a higherlevelsupervisory process controlsystem. Communicationsbetween the external controland drive converter are realizedvia the serial PROFIBUS DPinterface.Power section designThe power section of the<strong>SIMOVERT</strong> <strong>MV</strong> drive converterconsists, as standard of the following:¦ 12-pulse diode rectifier (DFE)¦ Three-level voltage DC linkwith capaci<strong>to</strong>rs and crowbarthyris<strong>to</strong>r¦ Three-level inverter with threephase unitsThe power section design utilizingthree-level technology hasmany advantages:¦ The HV-IGBTs are onlystressed with half of the DClink voltage¦ For the same quality of theoutput current, the switchingfrequency is only approximately1/4 of that required for2-level technology; thus, theHV-IGBT losses are lowerand the efficiency isincreased¦ Improved output currentcharacteristic in comparison<strong>to</strong> two-level designs: Thelosses in the mo<strong>to</strong>r and thesound pressure level arelower.2IncomingrectifierDC voltagelinkThree-levelinverterFig. 2/2Power section block diagramSiemens DA 63 · 2004 2/3

<strong>SIMOVERT</strong> <strong>MV</strong>System descriptionTechnical featuresPower section design (continued)2Fig. 2/3Modular and service-friendly:Air-cooled HV-IGBT Power-Cardof the mo<strong>to</strong>r-side drive converterFig. 2/4Modular and service-friendly:Water-cooled HV-IGBT Power-Cardof the mo<strong>to</strong>r-side drive converterLoad currentLow mo<strong>to</strong>r stressing using athree-level circuit designThe mo<strong>to</strong>r-side inverter utilizesa three-level circuit design. Thisresults, <strong>to</strong>gether with the propertiesof the HV-IGBT, in anessentially sine-wave outputcurrent. The low harmoniccomponent guarantees an excellentconstant <strong>to</strong>rque with respect<strong>to</strong> time over the completespeed control range and lowmo<strong>to</strong>r losses. Fig. 2/5<strong>SIMOVERT</strong> <strong>MV</strong> output current (current fundamental fac<strong>to</strong>r, typical g = 99%)Mo<strong>to</strong>rsWhen developing the<strong>SIMOVERT</strong> <strong>MV</strong> drive system,the mo<strong>to</strong>rs were involved in theoverall design concept rightfrom the very start. Thus, the<strong>SIMOVERT</strong> <strong>MV</strong> drive convertersand the Siemens standardH-compact and H-compactPLUS mo<strong>to</strong>rs are optimally harmonizedwith one another, bothfrom the economic and technicalperspectives. They do notrequire a special output filter foran optimum cost-effective solution.With output frequencies of up<strong>to</strong> 100 Hz (higher frequencieson request), the drive convertersare also suitable for feedingfast directly-coupled drives.Using an IHV-filter or theoptional output filter the<strong>SIMOVERT</strong> <strong>MV</strong> drive converterscan feed any other mediumvoltage,third-party inductionmo<strong>to</strong>r:This means that fixed-speedmedium-voltage mo<strong>to</strong>rs can beretrofitted <strong>to</strong> become variablespeeddrives using a<strong>SIMOVERT</strong> <strong>MV</strong> drive converter.2/4 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>System descriptionTechnical featuresLine supplyCircuit-breaker<strong>Medium</strong>-voltage circuit-breaker,converter-controlledDrive converter transformerThree-winding transformer <strong>to</strong> adapt the voltage<strong>to</strong> the medium-voltage line supply. It provides twovoltage systems, rotated through 30° electrical for12-pulse line-side operation and less harmonic effectson the supply2Line-side drive converterSeries circuit of 2 uncontrolled diode rectifiers in a threephasebridge circuit configuration <strong>to</strong> generate the DC linkvoltageDC link capaci<strong>to</strong>rsMaintenance-free and self-healing MKK capaci<strong>to</strong>rs ina parallel circuit configuration <strong>to</strong> smooth the DC linkvoltage. The number of capaci<strong>to</strong>rs depends on the driveconverter outputDC link DC voltage PTPT <strong>to</strong> sense the actual DC link voltageMo<strong>to</strong>r-side inverter3-phase units comprising the HV-IGBT anddiode Power-Cards.Combined electronic PT and CT on the mo<strong>to</strong>r sideCT/PT <strong>to</strong> sense the actual output voltages and mo<strong>to</strong>rcurrents Mo<strong>to</strong>rSquirrel-cage induction mo<strong>to</strong>r with a medium-voltagewindingFig. 2/6Block diagram of a <strong>SIMOVERT</strong> <strong>MV</strong> driveSiemens DA 63 · 2004 2/5

<strong>SIMOVERT</strong> <strong>MV</strong>System descriptionOpen- and closed-loop control functions2The field-oriented Vec<strong>to</strong>r Controlis used for the mo<strong>to</strong>r-sideclosed-loop control of the<strong>SIMOVERT</strong> <strong>MV</strong> voltage DC linkdrive converter.The Vec<strong>to</strong>r Control can eitherbe operated as closed-loopfrequency, speed or <strong>to</strong>rquecontrol.The Vec<strong>to</strong>r Control achievesthe same dynamic performanceas that of a DC drive.This is made possible by thefact that the <strong>to</strong>rque- and fluxgeneratingcurrent componentsare precisely controlled,independently of one another.Specified <strong>to</strong>rques can be preciselymaintained and limitedusing this vec<strong>to</strong>r control.In the speed control range 1:10,the field-oriented control of the<strong>SIMOVERT</strong> <strong>MV</strong> does not requirea speed encoder and isessentially independent of themo<strong>to</strong>r parameters.A speed encoder is required forthe following <strong>SIMOVERT</strong> <strong>MV</strong>applications:¦ High requirements are placedon the dynamic performance¦ Closed-loop <strong>to</strong>rque control/constant-<strong>to</strong>rque drives with acontrol range > 1:10¦ Lowest speeds¦ Highest speed accuracy.The various control versions arelisted in detail on Page 6/9.Closed-loop control features¦ Message system where plaintext messages are output onthe OP7 opera<strong>to</strong>r panel¦ Self-diagnostics of the controlhardware, e.g. memorytest¦ Multi-channel fast tracememory <strong>to</strong> record currentsand voltages for drive diagnostics¦ Non-volatile memory for reliablediagnostics, even if thepower supply fails¦ HV-IGBT modules are moni<strong>to</strong>redwith an individual signalfor mounting slot¦ Comfortable local opera<strong>to</strong>rcontrol via the OP7 opera<strong>to</strong>rpanel¦ Highly accurate and stableactual value sensing usingthe innovative sigma-deltatechnique for reliable driveconverter actual values (refer<strong>to</strong> Fig. 2/7).Fig. 2/7Actual mo<strong>to</strong>r currents and output voltages are precisely sensedusing a special, patented sigma-delta techniqueSoftware functionsThe basic software includes abroad scope of standard functions.These functions offermaximum ease of use and outstandingflexibility. Also, theyensure universal operatingconditions and a high degree ofoperational reliability andsafety.Setpoint inputSetpoints can be entered as thesum of main- and supplementarysetpoints as follows:¦ Internally: as fixed, mo<strong>to</strong>rizedpotentiometer- or jog setpoint¦ Externally: via the analoginputs, the serial interfaces orthe option modules.The fixed internal setpoints andthe mo<strong>to</strong>rized potentiometersetpoint can be changed-overor set from any of the interfacesvia control commands.Au<strong>to</strong>matic restart(option L32)This function au<strong>to</strong>maticallyrestarts a drive converter whenthe power returns after a shutdown due <strong>to</strong> power failure.Restart-on-the-fly circuit(option L31)The restart-on-the-fly circuitallows the drive converter <strong>to</strong> beswitched <strong>to</strong> a mo<strong>to</strong>r which isstill rotating.2/6 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>System descriptionOpera<strong>to</strong>r control and diagnostics<strong>SIMOVERT</strong> <strong>MV</strong> drives can becontrolled and visualized at thedrive converter itself, or alsoexternally.OP7 opera<strong>to</strong>r panelThe <strong>SIMOVERT</strong> <strong>MV</strong> drive canbe locally controlled and moni<strong>to</strong>redusing the opera<strong>to</strong>r panelin the cabinet door.The assignment of the keys isdefined by the drive converter’ssoftware for open-loop andclosed-loop control. The followingfunctions can be selected:¦ Display drive actual values¦ Enter speed setpoints usingthe numerical keys¦ Read and delete messages¦ Preset two mo<strong>to</strong>r and setpointdata records¦ Preset jog setpoints¦ Menue-assisted functions forservice and commissioning.At the unit via¦ the standard OP7 opera<strong>to</strong>rpanel¦ a PC with the Drive ES engineeringsystemBy entering the necessaryparameters, the control modecan be set from remote <strong>to</strong>direct.The following actual values canbe displayed:¦ Speed¦ Mo<strong>to</strong>r voltage¦ Mo<strong>to</strong>r current¦ Mo<strong>to</strong>r output¦ cos j of the mo<strong>to</strong>r¦ DC link voltage¦ Operating timeThe messages and actual valuesare displayed on a liquidcrystaldisplay with 4 x 20digits. The plain-text display isin one of the following languages(as standard):¦ German¦ EnglishRemote control via¦ the control terminal strip¦ PROFIBUS DPFig. 2/8OP7 Opera<strong>to</strong>r panel2Control terminal stripThe drive converter includes acontrol terminal strip <strong>to</strong> controland moni<strong>to</strong>r the<strong>SIMOVERT</strong> <strong>MV</strong> drive from acontrol room. Both analog aswell as digital inputs andoutputs are available at thiscontrol terminal strip (refer <strong>to</strong>Page 6/10).PROFIBUS DP<strong>SIMOVERT</strong> <strong>MV</strong> is equipped asstandard with a PROFIBUS DPinterface <strong>to</strong> establish the couplingbetween the drive and thehigher-level au<strong>to</strong>mation system.Today, PROFIBUS DP isthe standard bus system forSiemens drive technology for allapplications at the field level.PROFIBUS DP is specified inthe European StandardEN 50170, Volume 2, andpermits cyclic data transferbetween the <strong>SIMOVERT</strong> <strong>MV</strong>units and the higher-levelsystem.In order that the drive can fulfillthe specific process task, itsparameters must be individuallyadapted during the commissioningphase. The Drive ESBasic engineering <strong>to</strong>ol is usedfor this purpose. The programallows the drive parameters<strong>to</strong> be handled in a structuredfashion when commissioningthe drive and when service isrequired. Drive ES communicatesdirectly with the<strong>SIMOVERT</strong> <strong>MV</strong> via theconnected PROFIBUS DP.Fig. 2/9Mounting rack with vec<strong>to</strong>r controlSiemens DA 63 · 2004 2/7

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive Converters3/2 Design3/2 General technical data3/3 Rated data3/4 Air-cooled drive converters for 6.0 kV and 6.6 kV3/6 Water-cooled <strong>SIMOVERT</strong> <strong>MV</strong> drive converters3/8 Selection and ordering data3/8 <strong>SIMOVERT</strong> <strong>MV</strong> air-cooled drive converterswith 12-pulse diode input circuit (DFE)for constant and square-law load <strong>to</strong>rque3/10 <strong>SIMOVERT</strong> <strong>MV</strong> air-cooled drive converterswith 12-pulse diode input circuit (DFE)with sine-wave EMC output filter (option Y15)for square-law load <strong>to</strong>rque3/12 <strong>SIMOVERT</strong> <strong>MV</strong> air-cooled drive converterswith 12-pulse diode input circuit (DFE)for 6.0 and 6.6 kV with integrated high voltagefilter (IHV filter) for square-law load <strong>to</strong>rque3/14 <strong>SIMOVERT</strong> <strong>MV</strong> water-cooled drive converterswith 12-pulse diode inpyut circuit (DFE)for constant and square-law load <strong>to</strong>rque3/16 <strong>SIMOVERT</strong> <strong>MV</strong> water-cooled drive converterswith 12-pulse diode input circuit (DFE)with sine-wave EMC output filter (option Y15)for square-law load <strong>to</strong>rque33/18 Options3/18 Description of the optionsSiemens DA 63 · 2004 3/1

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersDesignGeneral technical dataPower componentsLine-side drive converter¦ Standard¦ OptionMo<strong>to</strong>r-side drive converterClosed-loop controlDrive quadrants¦ 12/24-pulse DFE¦ with the braking chopper and external brake resis<strong>to</strong>roptionDiodes / HV-IGBT12-pulse diode rectifier (DFE, Diode Front End)24-pulse diode rectifier (DFE)3-level drive converterVec<strong>to</strong>r Control, fully-digital with signal processor2 directions of rotation, mo<strong>to</strong>ring (2 quadrant)2 directions of rotation, mo<strong>to</strong>ring and braking (4 quadrant)3Electrical isolation of the power section– open- and closed-loop controlFiber-optic cableAuxiliary supply 3-ph./N/380 V/AC ±10%, 50/60 Hz ± 3%3-ph./N/400 V/AC ±10%, 50/60 Hz ± 3%3-ph./N/415 V/AC +6% –10%, 50/60 Hz ± 3%Optional: Auxiliary supply without loadable N conduc<strong>to</strong>r (Y75).Optional: Other auxiliary voltages (Y75).Air coolingPermissible ambient- andcoolant temperature and humidity rating¦ in operation¦ during s<strong>to</strong>rage¦ during transportWater coolingPermissible ambient temperature and humidity rating¦ in operation¦ during s<strong>to</strong>rage (without de-ionized water)¦ during transport (without de-ionized water)Permissible coolant temperature(raw, unconditioned water)¦ inlet¦ outletInstallation altitudeForced air cooling using integrated fans0 °C <strong>to</strong> +40 °C: 100% load capacity, relative air humidity ˆ 85% (moisture condensationis not permissible), otherwise corresponds <strong>to</strong> 3K3 acc. <strong>to</strong> IEC 60721-3-3+40 °C <strong>to</strong> +45 °C: current de-rating, refer <strong>to</strong> Fig. 6/3–25 °C <strong>to</strong> +55 °C: relative air humidity ˆ 95%, otherwise corresponds <strong>to</strong>1K2 acc. <strong>to</strong> IEC 60721-3-1–25 °C <strong>to</strong> +70 °C: relative air humidity ˆ 95%, otherwise corresponds <strong>to</strong>2K2 acc. <strong>to</strong> IEC 60721-3-2With integrated water-<strong>to</strong>-water cooling unit+5 °C <strong>to</strong> +40 °C: 100% load capacity, relative air humidity ˆ 85% (moisture condensationis not permissible), otherwise corresponds <strong>to</strong> 3K3 acc. <strong>to</strong> IEC 60721-3-3-25 °C <strong>to</strong> +55 °C: relative air humidity ˆ 95%, otherwise corresponds <strong>to</strong>1K2 acc. <strong>to</strong> IEC 60721-3-1-25 °C <strong>to</strong> +70 °C: relative air humidity ˆ 95%, otherwise corresponds <strong>to</strong>2K2 acc. <strong>to</strong> IEC 60721-3-2+5 °C <strong>to</strong> +35 °Cmax. +40 °Cˆ 1000 m above sea level: 100% load capability> 1000 m <strong>to</strong> 5000 m above sea level: Current de-rating, refer <strong>to</strong> Fig. 6/4> 2000 m <strong>to</strong> 5000 m above sea level: additional voltage de-rating, refer <strong>to</strong> Fig. 6/5Insulation Degree of pollution 2 acc. <strong>to</strong> DIN VDE 0110, Part 1Moisture condensation is not permissibleDegree of protection¦ Standard¦ OptionsAcc. <strong>to</strong> DIN VDE 0470, IEC 60 529, EN 60 529IP21 (air cooling), IP23 (water cooling)Refer <strong>to</strong> Page 3/19Protective class Class 1 in accordance with DIN VDE 0106, Part 1Shock hazard protection Acc. <strong>to</strong> DIN VDE 0106 Part 100 (VGB 4) and DIN VDE 0113 Part 1Radio interference suppression acc. <strong>to</strong> EN 61 800-3No radio interference suppressionPaint finish/color For indoor use/gray RAL 7032Mechanical strengthStandardFor stationary applications¦ deflection¦ accelerationDuring transport¦ deflection¦ accelerationAcc. <strong>to</strong> DIN IEC 60 068-2-60.075 mm in the frequency range 10 Hz <strong>to</strong> 58 Hz9.8 ms -2 (1 x g) in the frequency range > 58 Hz <strong>to</strong> 500 Hz3.5 mm in the frequency range 5 Hz <strong>to</strong> 9 Hz9.8 ms -2 (1 x g) in the frequency range > 9 Hz <strong>to</strong> 500 HzIncreased strength for option M66:Suitable for marine duty3/2 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersDesignGeneral technical dataThe <strong>SIMOVERT</strong> <strong>MV</strong> voltagesourceDC link drive convertershave rated outputs from <strong>660</strong> <strong>to</strong><strong>9100</strong> <strong>kVA</strong> and are available asready-<strong>to</strong>-connect cabinet unitswith degree of protection IP21(air cooling) or IP23 (watercooling).The modular design not onlymakes <strong>SIMOVERT</strong> <strong>MV</strong> extremelycompact, but alsoextremely service-friendly andenhances its availability. Componentsand parts are replacedin just a few minutes.When designing the equipment,special significance wasplaced on the modular design.For that reason, the <strong>SIMOVERT</strong><strong>MV</strong> converter can be easilyadapted for various requirementsand allows for inexpensive,cus<strong>to</strong>mized drive solutions.3Fig. 3/1Air-cooled drive converter <strong>SIMOVERT</strong> <strong>MV</strong> 6SE80Rated dataRated mo<strong>to</strong>r voltage 2.3 kV 3.3 kV 4.16 kV 6 kV 6.6 kVDrive convertersupply voltage 1 )2 × 1.2 kV 2 × 1.7 kV 2 × 2.2 kV 3 ) 2 × 1.2 kV 2 × 1.2 kVSupply voltage <strong>to</strong>lerance 2 ) – 10% – 10% – 10% – 10% – 10%Line supply frequency 50/60 Hz – 3% 50/60 Hz – 3% 50/60 Hz – 3% 50/60 Hz – 3% 50/60 Hz – 3%Line supply power fac<strong>to</strong>r,basic fundamental > 0.96 > 0.96 > 0.96 > 0.96 > 0.96Max. output frequency (standard)Higher frequencies, optional100 Hzup <strong>to</strong> 125 Hz100 Hzup <strong>to</strong> 125 Hz100 Hzup <strong>to</strong> 125 Hz66 Hz–66 Hz–Closed-loop control related properties (typical values)Speed accuracy 4 )n > 10%n < 5%in the field-weakening rangeTorque accuracyin the constant flux rangein the field-weakening rangeTorque rise time0.4 × f slipf slipf max /f rated × f slip /32.5%for n > 10 %5%approx. 5 msfor n >10%0.4 × f slipf slipf max /f rated × f slip /32.5%for n > 10%5%approx. 5 msfor n >10%0.4 × f slipf slipf max /f rated × f slip /32.5%for n > 10%5%approx. 5 msfor n >10%0.4 × f slipf slip–2.5%for n > 10%–approx. 8 msfor n >10%Torque ripple 2% 2% 2% 2% 2%0.4 × f slipf slip–2.5%for n > 10%–approx. 8 msfor n >10%1) The drive converter supplyvoltage corresponds <strong>to</strong> thesecondary no-load voltage ofthe transformer.2) –20% <strong>to</strong>lerance of the driveconverter input voltage in accordancewith the de-rated output.3) Outputs > 4000 <strong>kVA</strong>require 2 × 2 × 2.2 kV infeeds.4) These values are valid withoutspeed encoder and over anaverage of 10 s.Siemens DA 63 · 2004 3/3

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersDesignAir-cooled drive converters for 6.0 kV and 6.6 kV (continued)This has the followingbenefits:Retrofit applicationsExisting fixed speed mo<strong>to</strong>rsturn <strong>to</strong> variable-speed driveswhen converters are added:¦ The existing mo<strong>to</strong>r is suitablefor converter-fed operationwithout derating, because there is no additional loss inthe mo<strong>to</strong>r.¦ No mechanical changeoverat the driven machine isnecessary, e.g. adjustment ofthe shaft height, of thefoundation, of the coupling,the cooling system etc.¦ The existing mo<strong>to</strong>r cablesare preserved; no changesnecessary.¦ No supplementary outputchokes are necessary with long mo<strong>to</strong>r cables.New configurationsFig. 3/3Output voltage and current of the 6.0 and 6.6 kV <strong>SIMOVERT</strong> <strong>MV</strong> drive converter¦ Standard medium-voltagedrives can be put <strong>to</strong> usewithout extra measures andwithout derating.¦ It is possible <strong>to</strong> use standardpower cables for connectingthe mo<strong>to</strong>r.¦ No supplementary outputchokes are necessary withlong mo<strong>to</strong>r cables.Please refer <strong>to</strong> the notes onPage 6/13 for configuration of6.0kV/6.6kV drives.3Siemens DA 63 · 2004 3/5

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersDesign3Water-cooled drive convertersA water-<strong>to</strong>-water cooling unitis an integral part of the watercooled<strong>SIMOVERT</strong> <strong>MV</strong> driveconverter.The cooling unit is used <strong>to</strong> dissipatethe power loss from thedrive converter. It has an innerand an outer water circuit.The water of the outer circuitcools the inner circuit via theheat exchanger.The closed and vented innerwater circuit is filled with finewater. Fine water is de-ionizedwater with a very low conductivity.The water’s conductivitymust be low since the heat sink,through which the water flows,is on the same voltage level asthe HV-IGBT, and thus on thesame level as the DC link.Intake and outlet pipes are fittedbetween each phase stack.Cold water coming from thecooling unit flows in<strong>to</strong> the inletpipe, is heated-up by the powerloss in the HV-IGBT and thenreturns <strong>to</strong> the cooling unit viathe outlet pipe (see Fig. 3/7).A floor-mounted pan is installedin the drive converter cabinet inwhich, if there is a leak, the wateris collected. A leakage watermoni<strong>to</strong>ring function allows theleak <strong>to</strong> be quickly found if coolingwater is lost.Fig. 3/4<strong>SIMOVERT</strong> <strong>MV</strong> with water cooling (without cooling unit)Fig. 3/5Cooling unit (closed and open), in a special version with option W01 and stainless steel piping3/6 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersDesignThe water-cooled Power-Cardis a plug-in module just like theair-cooled Power-Card. If thePower-Card is <strong>to</strong> be replaced,the water circuit must beopened. This would mean thatair would enter the water circuitwhich would have <strong>to</strong> be subsequentlyvented. In order <strong>to</strong>avoid this, the Power-Cards areequipped with special connec<strong>to</strong>rs.These connec<strong>to</strong>rs preventair from entering the system.Thus, it is no longer necessary<strong>to</strong> subsequently vent thesystem, i.e. the drive converteris quickly operational again.3Fig. 3/6Water-cooled Power-Card with pipe connectionsRectifierInverterIntakeDischargeLeakage water moni<strong>to</strong>ringin the floor panelFig. 3/7Cooling of the drive converter power sectionSiemens DA 63 · 2004 3/7

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataAir-cooled <strong>SIMOVERT</strong> <strong>MV</strong> drive converters with 12-pulse diode input circuit (DFE)for constant and square-law load <strong>to</strong>rqueRated drive Rated output Order No. Rated Base load Short- Input current Input Power loss 1 ) Efficiency 1 )converter at the mo<strong>to</strong>r output current 4 ) time at rated operatingvoltage at 50/60 Hz at 50/60 Hzoutput drive shaft current current 4 ) point3P N P , N , 0 , K , e V e P V h<strong>kVA</strong> kW A A A A kV kW %Rated mo<strong>to</strong>r voltage 2.3 kV800 640 6SE8008-1AA01 200 150 226 204 2 x 1.2 12 98.51000 810 6SE8010-1AA01 250 188 283 256 2 x 1.2 15 98.51200 980 6SE8012-1AA01 300 225 339 306 2 x 1.2 18 98.51400 1160 6SE8014-1AA01 350 263 396 360 2 x 1.2 20 98.61600 1320 6SE8016-1AA01 400 300 452 410 2 x 1.2 22 98.61800 1490 6SE8018-1AA01 450 338 509 460 2 x 1.2 25 98.72000 1<strong>660</strong> 6SE8020-1AA01 500 375 565 510 2 x 1.2 27 98.72200 1870 6SE8022-1AA01 550 413 622 560 2 x 1.2 29 98.72400 2040 6SE8024-1AA01 600 450 678 610 2 x 1.2 31 98.7Rated mo<strong>to</strong>r voltage 3.3 kV1000 810 6SE8010-1BA01 175 140 210 178 2 x 1.7 15 98.51300 1060 6SE8013-1BA01 230 184 276 235 2 x 1.7 20 98.51500 1240 6SE8015-1BA01 260 208 312 266 2 x 1.7 23 98.51800 1490 6SE8018-1BA01 315 252 378 320 2 x 1.7 27 98.62100 1730 6SE8021-1BA01 370 296 444 375 2 x 1.7 30 98.62300 1890 6SE8023-1BA01 400 320 480 408 2 x 1.7 33 98.62600 2150 6SE8026-1BA01 460 368 552 465 2 x 1.7 37 98.62900 2310 6SE8028-1BA01 510 408 612 515 2 x 1.7 41 98.63100 2560 6SE8031-1BA01 550 440 <strong>660</strong> 560 2 x 1.7 42 98.7Rated mo<strong>to</strong>r voltage 4.16 kV1300 1070 6SE8013-1CA01 180 135 203 184 2 x 2.2 20 98.51700 1410 6SE8017-1CA01 240 180 270 243 2 x 2.2 26 98.52000 1640 6SE8020-1CA01 280 210 316 284 2 x 2.2 30 98.52300 1890 6SE8023-1CA01 320 240 362 325 2 x 2.2 34 98.62600 2150 6SE8026-1CA01 360 270 407 370 2 x 2.2 37 98.62900 2400 6SE8028-1CA01 400 300 452 410 2 x 2.2 40 98.63300 2730 6SE8033-1CA01 460 345 520 470 2 x 2.2 46 98.63700 3060 6SE8037-1CA01 510 383 576 520 2 x 2.2 49 98.74000 3320 6SE8040-1CA01 550 413 622 562 2 x 2.2 51 98.7Rated mo<strong>to</strong>r voltage 2 x 4.16 kV 3 )4700 3900 6SE8047-1CA01 2 x 325 2 x 244 2 x 370 2 x 335 2 x 2 x 2.2 2 x 37 98.45200 4300 6SE8052-1CA01 2 x 360 2 x 270 2 x 410 2 x 370 2 x 2 x 2.2 2 x 40 98.55900 4900 6SE8058-1CA01 2 x 415 2 x 310 2 x 470 2 x 425 2 x 2 x 2.2 2 x 46 98.56700 5500 6SE8067-1CA01 2 x 460 2 x 345 2 x 520 2 x 470 2 x 2 x 2.2 2 x 49 98.67200 6000 6SE8072-1CA01 2 x 495 2 x 370 2 x 560 2 x 505 2 x 2 x 2.2 2 x 51 98.61) Without cooling system.2) Plus 18 A pre-charging current for 20 s.3) Drive converter with power section in parallel connection.4) Data valid for a load cycle with short time current 60 s, base load current500 s, with short time current/base load current = 150% / 100%.3/8 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataAuxiliarypower req.[3/AC/N/400 V] 2 )Dimensions(with panels and doors)DimensiondrawingNo.WeightCoolingair req.Measuringsurfacesound press.levelMeasuringsurfacelevelCable cross-sectionfor line and mo<strong>to</strong>rsides max.Width Depth Height L pA L sA mm mm mm Page kg m 3 /s dB (A) dB (A) mm 2 per phase10 1818 1259 2570 7/2 1200 1.36 79 18 2 x 18510 2418 1259 2570 7/3 1750 1.66 79 18 2 x 18510 2418 1259 2570 7/3 1750 1.66 79 18 2 x 18510 2418 1259 2570 7/3 1800 1.66 79 18 2 x 18510 2418 1259 2570 7/3 1800 1.66 79 18 2 x 18510 2418 1259 2570 7/3 1850 1.66 79 18 3 x 18510 2418 1259 2570 7/3 1850 1.66 79 18 3 x 18514 2418 1259 2570 7/3 1900 1.79 80 18 3 x 18514 2418 1259 2570 7/3 1900 1.79 80 18 3 x 185314 1818 1259 2570 7/4 1500 1.90 81 18 2 x 18510 2418 1259 2570 7/5 2050 2.07 79 18 2 x 18514 2418 1259 2570 7/5 2050 2.63 80 18 2 x 18514 2418 1259 2570 7/5 2100 2.63 80 18 2 x 18514 2418 1259 2570 7/5 2100 2.63 80 18 2 x 18514 2418 1259 2570 7/5 2150 2.63 80 18 3 x 18514 2418 1259 2570 7/5 2150 2.63 80 18 3 x 18514 2418 1259 2570 7/5 2200 2.63 80 18 3 x 18514 2418 1259 2570 7/5 2200 2.63 80 18 3 x 18514 1818 1259 2570 7/4 1500 1.90 81 18 2 x 18510 2418 1259 2570 7/5 2050 2.07 79 18 2 x 18514 2418 1259 2570 7/5 2050 2.63 80 18 2 x 18514 2418 1259 2570 7/5 2100 2.63 80 18 2 x 18514 2418 1259 2570 7/5 2100 2.63 80 18 2 x 18514 2418 1259 2570 7/5 2150 2.63 80 18 3 x 18514 2418 1259 2570 7/5 2150 2.63 80 18 3 x 18520 2418 1259 2570 7/5 2200 2.90 83 18 3 x 18520 2418 1259 2570 7/5 2200 2.90 83 18 3 x 18538 4218 1259 2570 7/6 3600 5.80 86 19 3 x 18538 4218 1259 2570 7/6 3650 5.80 86 19 3 x 18538 4218 1259 2570 7/6 3650 5.80 86 19 3 x 18538 4218 1259 2570 7/6 3700 5.80 86 19 3 x 18538 4218 1259 2570 7/6 3700 5.80 86 19 3 x 185Siemens DA 63 · 2004 3/9

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataAir-cooled <strong>SIMOVERT</strong> <strong>MV</strong> drive converters with 12-pulse diode input circuit (DFE)with sine-wave EMC output filter (option Y15) for square-law load <strong>to</strong>rqueRated drive Rated output Order No. Rated Input current Input Power loss 1 ) Efficiency 1 )converter at the mo<strong>to</strong>r with Order code +Y15 output current at rated voltage at 50/60 Hz at 50/60 Hzoutputdrive shaf<strong>to</strong>perating point3P N P , N , e V e P V h<strong>kVA</strong> kW A A kV kW %Rated mo<strong>to</strong>r voltage 2.3 kV<strong>660</strong> 550 6SE8008-1AA01-Z 165 169 2 x 1.2 16 97.6830 690 6SE8010-1AA01-Z 208 212 2 x 1.2 19 97.71000 830 6SE8012-1AA01-Z 250 256 2 x 1.2 22 97.81160 960 6SE8014-1AA01-Z 290 296 2 x 1.2 25 97.81330 1100 6SE8016-1AA01-Z 334 340 2 x 1.2 27 98.01500 1240 6SE8018-1AA01-Z 377 383 2 x 1.2 29 98.11<strong>660</strong> 1380 6SE8020-1AA01-Z 417 424 2 x 1.2 31 98.11830 1520 6SE8022-1AA01-Z 460 467 2 x 1.2 34 98.12000 1<strong>660</strong> 6SE8024-1AA01-Z 500 510 2 x 1.2 36 98.2Rated mo<strong>to</strong>r voltage 3.3 kV910 750 6SE8010-1BA01-Z 160 163 2 x 1.7 19 97.91180 980 6SE8013-1BA01-Z 206 210 2 x 1.7 24 98.01365 1130 6SE8015-1BA01-Z 239 243 2 x 1.7 28 97.91640 1360 6SE8018-1BA01-Z 287 292 2 x 1.7 32 98.01910 1590 6SE8021-1BA01-Z 334 340 2 x 1.7 35 98.22100 1740 6SE8023-1BA01-Z 367 373 2 x 1.7 38 98.22370 1970 6SE8026-1BA01-Z 415 422 2 x 1.7 41 98.32640 2190 6SE8028-1BA01-Z 462 470 2 x 1.7 46 98.32820 2340 6SE8031-1BA01-Z 493 500 2 x 1.7 47 98.3Rated mo<strong>to</strong>r voltage 4.16 kV1180 980 6SE8013-1CA01-Z 164 167 2 x 2.2 25 97.91550 1290 6SE8017-1CA01-Z 215 219 2 x 2.2 32 97.91820 1510 6SE8020-1CA01-Z 252 257 2 x 2.2 37 98.02090 1730 6SE8023-1CA01-Z 290 295 2 x 2.2 41 98.02370 1970 6SE8026-1CA01-Z 330 335 2 x 2.2 45 98.12640 2190 6SE8028-1CA01-Z 366 372 2 x 2.2 48 98.23000 2490 6SE8033-1CA01-Z 416 424 2 x 2.2 54 98.23370 2800 6SE8037-1CA01-Z 468 475 2 x 2.2 58 98.33640 3020 6SE8040-1CA01-Z 505 513 2 x 2.2 59 98.41) Without cooling system.2) Plus 18 A pre-charging current for 20 s.Note:Modifications of the Technical Data result in deviating rating data for mo<strong>to</strong>rand drive converter. When ordering, the plain text should include the ratedmo<strong>to</strong>r current, the mo<strong>to</strong>r current in the rated operating point and the mo<strong>to</strong>rno-load current.3/10 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataAuxiliarypower req.[3/AC/N/400 V] 2 )Dimensions(with panels and doors)DimensiondrawingNo.WeightCoolingair req.Measuringsurfacesound press.levelMeasuringsurfacelevelCable cross-sectionfor line and mo<strong>to</strong>rsides max.Width Depth Height L pA L sA mm mm mm Page kg m 3 /s dB (A) dB (A) mm 2 per phase10 2718 1259 2570 7/2+7/10 2300 1.6 79 19 2 x 18510 3318 1259 2570 7/3+7/10 2850 1.9 79 19 2 x 18510 3318 1259 2570 7/3+7/10 3100 1.9 79 19 2 x 18510 3318 1259 2570 7/3+7/10 3150 1.9 79 19 2 x 18510 3318 1259 2570 7/3+7/10 3220 1.9 79 19 2 x 18510 3318 1259 2570 7/3+7/10 3270 1.9 79 19 3 x 18510 3318 1259 2570 7/3+7/10 3550 1.9 79 19 3 x 18514 3318 1259 2570 7/3+7/10 3600 2.1 80 19 3 x 18514 3318 1259 2570 7/3+7/10 3700 2.1 80 19 3 x 185314 2718 1259 2570 7/4+7/10 2850 2.2 81 19 2 x 18510 3318 1259 2570 7/5+7/10 3400 2.3 79 19 2 x 18514 3318 1259 2570 7/5+7/10 3450 2.9 80 19 2 x 18514 3318 1259 2570 7/5+7/10 3500 2.9 80 19 2 x 18514 3318 1259 2570 7/5+7/10 3730 2.9 80 19 2 x 18514 3318 1259 2570 7/5+7/10 3780 2.9 80 19 3 x 18514 3318 1259 2570 7/5+7/10 3990 2.9 80 19 3 x 18514 3318 1259 2570 7/5+7/10 4040 2.9 80 19 3 x 18514 3318 1259 2570 7/5+7/10 4100 2.9 80 19 3 x 18514 2718 1259 2570 7/4+7/10 3100 2.2 81 19 2 x 18510 3618 1259 2570 7/5+7/10 3690 2.3 79 19 2 x 18514 3618 1259 2570 7/5+7/10 3690 3.1 80 19 2 x 18514 3618 1259 2570 7/5+7/10 3740 3.1 80 19 2 x 18514 3618 1259 2570 7/5+7/10 4150 3.1 80 19 2 x 18514 3618 1259 2570 7/5+7/10 4200 3.1 80 19 3 x 18514 3618 1259 2570 7/5+7/10 4550 3.1 80 19 3 x 18520 3618 1259 2570 7/5+7/10 4600 3.1 83 19 3 x 18520 3618 1259 2570 7/5+7/10 4800 3.1 83 19 3 x 185Siemens DA 63 · 2004 3/11

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataAir-cooled <strong>SIMOVERT</strong> <strong>MV</strong> drive converters with 12-pulse diode input circuit (DFE)with Integrated High <strong>Voltage</strong> filter (IHV filter) for square-law load <strong>to</strong>rqueRated drive Rated output Order No. Rated Input current InputPower loss 1 ) Efficiency 1 )converter at the mo<strong>to</strong>r output current at rated voltage at 50/60 Hz at 50/60 Hzoutputdrive shaf<strong>to</strong>perating point3P N P , N , e V e P V h<strong>kVA</strong> kW A A kV kW %Rated mo<strong>to</strong>r voltage 6.0 kV<strong>660</strong> 550 6SE8008-1DA01 65 170 2 x 1.2 17 97.51000 810 6SE8010-1DA01 95 257 2 x 1.2 25 97.61200 980 6SE8012-1DA01 115 310 2 x 1.2 30 97.61300 1080 6SE8013-1DA01 125 335 2 x 1.2 34 97.51500 1240 6SE8015-1DA01 145 387 2 x 1.2 39 97.51800 1490 6SE8018-1DA01 175 465 2 x 1.2 45 97.62000 1640 6SE8020-1DA01 190 515 2 x 1.2 50 97.6Rated mo<strong>to</strong>r voltage 6.6 kV<strong>660</strong> 550 6SE8008-1EA01 60 170 2 x 1.2 17 97.51000 810 6SE8010-1EA01 90 257 2 x 1.2 25 97.61200 980 6SE8012-1EA01 105 308 2 x 1.2 29 97.61300 1080 6SE8013-1EA01 116 335 2 x 1.2 33 97.51500 1240 6SE8015-1EA01 130 386 2 x 1.2 39 97.51800 1490 6SE8018-1EA01 160 463 2 x 1.2 44 97.62000 1640 6SE8020-1EA01 175 514 2 x 1.2 49 97.61) Without cooling system.2) Plus 18 A pre-charging current for 20 s.Note:Modifications of the Technical Data result in deviating rating data for mo<strong>to</strong>rand drive converter. When ordering, the plain text should include the ratedmo<strong>to</strong>r current, the mo<strong>to</strong>r current in the rated operating point and the mo<strong>to</strong>rno-load current.3/12 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataAuxiliarypower req.[3/AC/N/400 V] 2 )Dimensions(with panels and doors)DimensiondrawingNo.WeightCoolingair req.Measuringsurfacesound press.levelMeasuringsurfacelevelCable cross-sectionfor line and mo<strong>to</strong>rsides max.Width Depth Height L pA L sA mm mm mm Page kg m 3 /s dB (A) dB (A) mm 2 per phase12 3018 1259 2570 7/7 4550 1.9 79 19 2 x 18512 3618 1259 2570 7/8 5500 2.2 79 19 2 x 18512 3618 1259 2570 7/8 5500 2.2 79 19 2 x 18512 3918 1259 2570 7/8 5600 2.2 79 19 2 x 18512 3918 1259 2570 7/8 5600 2.2 79 19 2 x 18512 4218 1259 2570 7/8 6450 3.2 81 19 3 x 18512 4218 1259 2570 7/8 6500 3.2 81 19 3 x 185312 3018 1259 2570 7/7 4550 1.9 79 19 2 x 18512 3618 1259 2570 7/8 5500 2.2 79 19 2 x 18512 3618 1259 2570 7/8 5500 2.2 79 19 2 x 18512 3918 1259 2570 7/8 5600 2.2 79 19 2 x 18512 3918 1259 2570 7/8 5600 2.2 79 19 2 x 18512 4218 1259 2570 7/8 6450 3.2 81 19 3 x 18512 4218 1259 2570 7/8 6500 3.2 81 19 3 x 185Siemens DA 63 · 2004 3/13

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataWater-cooled <strong>SIMOVERT</strong> <strong>MV</strong> drive converters with 12-pulse diode input circuit (DFE)for constant and square-law load <strong>to</strong>rqueRated drive Rated output Order No. Rated Base load Short- Input current Input Power loss 1 ) Efficiency 1 )converter at the mo<strong>to</strong>r output current 5 ) time at rated operatingvoltage at 50/60 Hz at 50/60 Hzoutput drive shaft current current 5 ) point3P N P , N , 0 , K , e V e P V h<strong>kVA</strong> kW A A A A kV kW %Rated mo<strong>to</strong>r voltage 2.3 kV1000 810 6SE8010-2AA01 250 188 283 256 2 x 1.2 15 98.51200 980 6SE8012-2AA01 300 225 339 306 2 x 1.2 18 98.51400 1160 6SE8014-2AA01 350 263 396 360 2 x 1.2 20 98.61600 1320 6SE8016-2AA01 400 300 452 410 2 x 1.2 22 98.61800 1490 6SE8018-2AA01 450 338 509 460 2 x 1.2 25 98.72000 1<strong>660</strong> 6SE8020-2AA01 500 375 565 510 2 x 1.2 27 98.72200 1870 6SE8022-2AA01 550 413 622 560 2 x 1.2 29 98.72400 2040 6SE8024-2AA01 600 450 678 610 2 x 1.2 31 98.72600 2200 6SE8026-2AA01 650 467 700 662 2 x 1.2 34 98.7Rated mo<strong>to</strong>r voltage 3.3 kV1300 1060 6SE8013-2BA01 230 184 276 235 2 x 1.7 20 98.51500 1240 6SE8015-2BA01 260 208 312 266 2 x 1.7 23 98.51800 1490 6SE8018-2BA01 315 252 378 320 2 x 1.7 27 98.62100 1730 6SE8021-2BA01 370 296 444 375 2 x 1.7 30 98.62300 1890 6SE8023-2BA01 400 320 480 408 2 x 1.7 33 98.62600 2150 6SE8026-2BA01 460 368 552 465 2 x 1.7 37 98.62900 2310 6SE8028-2BA01 510 408 612 515 2 x 1.7 41 98.63100 2560 6SE8031-2BA01 550 440 <strong>660</strong> 560 2 x 1.7 42 98.73600 2950 6SE8036-2BA01 630 467 700 640 2 x 1.7 48 98.74000 3320 6SE8040-2BA01 700 467 700 710 2 x 1.7 54 98.7Rated mo<strong>to</strong>r voltage 4.16 kV1700 1410 6SE8017-2CA01 240 180 270 243 2 x 2.2 26 98.52000 1640 6SE8020-2CA01 280 210 316 284 2 x 2.2 30 98.52300 1890 6SE8023-2CA01 320 240 362 325 2 x 2.2 34 98.62600 2150 6SE8026-2CA01 360 270 407 370 2 x 2.2 37 98.62900 2400 6SE8028-2CA01 400 300 452 410 2 x 2.2 40 98.63300 2730 6SE8033-2CA01 460 345 520 470 2 x 2.2 46 98.63700 3060 6SE8037-2CA01 510 383 576 520 2 x 2.2 49 98.74000 3320 6SE8040-2CA01 550 413 622 562 2 x 2.2 51 98.74500 3700 6SE8045-2CA01 625 467 700 635 2 x 2.2 58 98.75000 4100 6SE8050-2CA01 700 467 700 710 2 x 2.2 65 98.7Rated mo<strong>to</strong>r voltage 2 x 4.16 kV 3 )5900 4900 6SE8058-2CA01 2 x 415 2 x 310 2 x 470 2 x 425 2 x 2 x 2.2 2 x 46 98.56700 5500 6SE8067-2CA01 2 x 460 2 x 345 2 x 520 2 x 470 2 x 2 x 2.2 2 x 49 98.67200 6000 6SE8072-2CA01 2 x 495 2 x 370 2 x 560 2 x 505 2 x 2 x 2.2 2 x 51 98.68000 6500 6SE8080-2CA01 2 x 555 2 x 420 2 x 630 2 x 565 2 x 2 x 2.2 2 x 58 98.6<strong>9100</strong> 7500 6SE8091-2CA01 2 x 630 2 x 420 2 x 630 2 x 640 2 x 2 x 2.2 2 x 65 98.71) Without cooling system.2) Plus 18 A pre-charging current for 20 s.3) Drive converter with power section in parallel connection.4) Raw water.5) Data valid for a load cycle with short time current 60 s, base load current500 s, with short time current/base load current = 150% / 100%.3/14 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataLoss <strong>to</strong> theenvironmentAuxiliarypower req.[3/AC/N/400 V] 2 )Dimensions(with panels and doors)DimensiondrawingNo.WeightCoolingwaterrequired 4 )Measuringsurfacesoundpress. levelMeasuringsurfacelevelCable crosssectionfor lineand mo<strong>to</strong>r sidesmax.Width Depth Height L pA L skW A mm mm mm Page kg m 3 /h dB (A) dB (A) mm 2 per phase2.8 14 3018 1259 2280 7/11 2450 5.5 73 18 2 x 1853.1 14 3018 1259 2280 7/11 2450 5.8 73 18 2 x 1853.4 14 3018 1259 2280 7/11 2500 5.9 73 18 2 x 1853.7 14 3018 1259 2280 7/11 2500 6.1 73 18 2 x 1854.1 14 3018 1259 2280 7/11 2550 6.2 73 18 3 x 1854.5 14 3018 1259 2280 7/11 2550 6.4 73 18 3 x 1854.9 14 3018 1259 2280 7/11 2600 6.5 73 18 3 x 1855.4 14 3018 1259 2280 7/11 2600 6.7 73 18 3 x 1855.9 14 3018 1259 2280 7/11 2600 7.2 73 18 3 x 18532.8 14 3418 1259 2280 7/12 2800 8.7 73 18 2 x 1852.9 14 3418 1259 2280 7/12 2800 8.9 73 18 2 x 1853.2 14 3418 1259 2280 7/12 2850 9.2 73 18 2 x 1853.6 14 3418 1259 2280 7/12 2850 9.5 73 18 2 x 1853.8 14 3418 1259 2280 7/12 2900 9.7 73 18 3 x 1854.2 14 3418 1259 2280 7/12 2900 10.1 73 18 3 x 1854.7 14 3418 1259 2280 7/12 2950 10.3 73 18 3 x 1855.0 14 3418 1259 2280 7/12 2950 10.4 73 18 3 x 1855.8 14 3418 1259 2280 7/12 2950 10.8 73 18 3 x 1856.4 14 3418 1259 2280 7/12 2950 10.8 73 18 3 x 1853.2 14 3418 1259 2280 7/12 3000 9.2 73 18 2 x 1853.4 14 3418 1259 2280 7/12 3000 9.5 73 18 2 x 1853.8 14 3418 1259 2280 7/12 3050 9.8 73 18 2 x 1854.3 14 3418 1259 2280 7/12 3050 10.1 73 18 2 x 1854.5 14 3418 1259 2280 7/12 3100 10.3 73 18 3 x 1855.1 14 3418 1259 2280 7/12 3100 10.7 73 18 3 x 1855.6 14 3418 1259 2280 7/12 3150 11.0 73 18 3 x 1855.9 14 3418 1259 2280 7/12 3150 11.1 73 18 3 x 1856.7 14 3418 1259 2280 7/12 3150 11.9 73 18 3 x 1857.5 14 3418 1259 2280 7/12 3150 12.4 73 18 3 x 18510.1 20 5218 1259 2280 7/13 4450 21.4 76 19 3 x 18511.1 20 5218 1259 2280 7/13 4500 22.0 76 19 3 x 18511.8 20 5218 1259 2280 7/13 4500 22.3 76 19 3 x 18513.2 20 5218 1259 2280 7/13 4500 23.8 76 19 3 x 18515.0 20 5218 1259 2280 7/13 4500 24.8 76 19 3 x 185Siemens DA 63 · 2004 3/15

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataWater-cooled <strong>SIMOVERT</strong> <strong>MV</strong> drive converters with 12-pulse diode input circuit (DFE)with sine-wave EMC output filter (option Y15) for square-law load <strong>to</strong>rqueRated drive Rated output Order No. Rated Input current Input Power loss 1 ) Efficiency 1 )converter at the mo<strong>to</strong>r with Order code +Y15 output current at rated voltage at 50/60 Hz at 50/60 Hzoutputdrive shaf<strong>to</strong>perating point3P N P , N , e V e P V h<strong>kVA</strong> kW A A kV kW %Rated mo<strong>to</strong>r voltage 2.3 kV1000 810 6SE8010-2AA01-Z 250 256 2 x 1.2 21 97.61200 980 6SE8012-2AA01-Z 300 306 2 x 1.2 25 97.91400 1160 6SE8014-2AA01-Z 350 360 2 x 1.2 28 98.01600 1320 6SE8016-2AA01-Z 400 410 2 x 1.2 31 98.11800 1490 6SE8018-2AA01-Z 450 460 2 x 1.2 33 98.22000 1<strong>660</strong> 6SE8020-2AA01-Z 500 510 2 x 1.2 36 98.22200 1870 6SE8022-2AA01-Z 550 560 2 x 1.2 39 98.22400 2040 6SE8024-2AA01-Z 600 610 2 x 1.2 41 98.3Rated mo<strong>to</strong>r voltage 3.3 kV1300 1060 6SE8013-2BA01-Z 230 235 2 x 1.7 27 97.91500 1240 6SE8015-2BA01-Z 260 267 2 x 1.7 31 97.91800 1490 6SE8018-2BA01-Z 315 320 2 x 1.7 35 98.12100 1730 6SE8021-2BA01-Z 370 375 2 x 1.7 39 98.12300 1890 6SE8023-2BA01-Z 400 410 2 x 1.7 43 98.12600 2150 6SE8026-2BA01-Z 460 465 2 x 1.7 46 98.22900 2310 6SE8028-2BA01-Z 510 516 2 x 1.7 51 98.23100 2560 6SE8031-2BA01-Z 550 560 2 x 1.7 54 98.3Rated mo<strong>to</strong>r voltage 4.16 kV1700 1410 6SE8017-2CA01-Z 240 243 2 x 2.2 35 97.92000 1640 6SE8020-2CA01-Z 280 284 2 x 2.2 41 98.02300 1890 6SE8023-2CA01-Z 320 325 2 x 2.2 45 98.02600 2150 6SE8026-2CA01-Z 360 370 2 x 2.2 49 98.12900 2400 6SE8028-2CA01-Z 400 410 2 x 2.2 53 98.23300 2730 6SE8033-2CA01-Z 460 470 2 x 2.2 60 98.23700 3060 6SE8037-2CA01-Z 510 522 2 x 2.2 64 98.34000 3320 6SE8040-2CA01-Z 550 565 2 x 2.2 66 98.41) Without cooling system.2) Plus 18 A pre-charging current for 20 s.3) Raw water.Note:Modifications of the Technical Data result in deviating rating data for mo<strong>to</strong>rand drive converter. When ordering, the plain text should include the ratedmo<strong>to</strong>r current, the mo<strong>to</strong>r current in the rated operating point and the mo<strong>to</strong>rno-load current.3/16 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersSelection and ordering dataLoss <strong>to</strong> theenvironmentAuxiliary Dimensionspower req.[3/AC/N/400 V] 2 )(with panels and doors)DimensiondrawingNo.WeightCoolingwaterrequired 3 )Measuringsurfacesound press.levelMeasuringsurfacelevelCable crosssectionfor lineand mo<strong>to</strong>r sidesmax.Width Depth Height L pA L skW A mm mm mm Page kg m 3 /h dB (A) dB (A) mm 2 per phase6.6 14 3918 1259 2280 7/11+7/15 3550 5.5 73 19 2 x 1857.0 14 3918 1259 2280 7/11+7/15 3800 5.8 73 19 2 x 1858.2 14 3918 1259 2280 7/11+7/15 3850 5.9 73 19 2 x 1858.9 14 3918 1259 2280 7/11+7/15 3920 6.1 73 19 2 x 1859.0 14 3918 1259 2280 7/11+7/15 3970 6.2 73 19 3 x 1859.1 14 3918 1259 2280 7/11+7/15 4250 6.4 73 19 3 x 1859.7 14 3918 1259 2280 7/11+7/15 4300 6.5 73 19 3 x 18510.5 14 3918 1259 2280 7/11+7/15 4400 6.7 73 19 3 x 18537.1 14 4318 1259 2280 7/12+7/15 4150 8.7 73 19 2 x 1857.4 14 4318 1259 2280 7/12+7/15 4200 8.9 73 19 2 x 1857.7 14 4318 1259 2280 7/12+7/15 4250 9.2 73 19 2 x 1858.8 14 4318 1259 2280 7/12+7/15 4480 9.5 73 19 2 x 1859.0 14 4318 1259 2280 7/12+7/15 4530 9.7 73 19 3 x 1859.1 14 4318 1259 2280 7/12+7/15 4740 10.1 73 19 3 x 1859.3 14 4318 1259 2280 7/12+7/15 4790 10.3 73 19 3 x 18510.0 14 4318 1259 2280 7/12+7/15 4850 10.4 73 19 3 x 1853.2 14 4618 1259 2280 7/12+7/15 4640 9.2 73 19 2 x 1859.0 14 4618 1259 2280 7/12+7/15 4640 9.5 73 19 2 x 18510.5 14 4618 1259 2280 7/12+7/15 4690 9.8 73 19 2 x 18510.9 14 4618 1259 2280 7/12+7/15 5100 10.1 73 19 2 x 18511.8 14 4618 1259 2280 7/12+7/15 5150 10.3 73 19 3 x 18512.0 14 4618 1259 2280 7/12+7/15 5500 10.7 73 19 3 x 18514.0 14 4618 1259 2280 7/12+7/15 5550 11.0 73 19 3 x 18514.5 14 4618 1259 2280 7/12+7/15 5750 11.1 73 19 3 x 185Siemens DA 63 · 2004 3/17

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersOptionsDescription of the optionsDescription of the option Comment Use with <strong>SIMOVERT</strong> <strong>MV</strong> in versionOrderCode2.3 kV3.3 kV4.16 kVair-cooled2 x 4.16 kVair-cooled6.0 kV6.6 kVair-cooled2 x 4.16 kV2.3 kV3.3 kV4.16 kVwatercooledwatercooled3Circuit versions / special optionsL01 24-pulse diode rectifierA 24-pulse diode rectifier can be used if harmonics fedback in<strong>to</strong> the line supply are <strong>to</strong> be kept <strong>to</strong> a minimum.Drive converters with a power section connected inparallel can also be operated as 24-pulse system usingthis option (refer <strong>to</strong> the engineering information andinstructions, Page 6/17).For 6SE8008-..., 6SE8010-_BA.. and 6SE8013-_CA..drive converter types, option L01 results in the cabinetwidth being increased by 1200 mm, or 600 mm for allother types.L03L72Grounding switch for DC link1 grounding switch for grounding the DC link, mechanicallyoperated. It must only be operated when the DClink is discharged. Auxiliary contacts of the groundingswitch are connected in the circuit-breaker controlcircuit for interlocking. The cabinet width increases by600 mm (except in conjunction with L08).Braking chopperA braking chopper is available so that drives usingdiode rectifiers can be braked.For 6SE8008-..., 6SE8010-_BA.. and 6SE8013-_CA..drive converter types option L72 does not result in thecabinet width being increased, but results in the cabinetwidth being increased by 600 mm 1 ) for all othertypes.For power data refer <strong>to</strong> page 6/18Water-cooled versionPlate-type heat exchanger with stainless steel platesW01 Water-<strong>to</strong>-water cooling unit with redundant pumps anda stainless steel plate-type heat exchanger.Option W01 results in the cabinet width beingincreased (refer <strong>to</strong> the dimension drawings).W02Water-<strong>to</strong>-water cooling unit with redundant pumps andredundant stainless steel plate-type heat exchanger.The pumps and heat-exchanger can be replaced whilethe drive is operational.Option W02 results in the cabinet width beingincreased (refer <strong>to</strong> the dimension drawings).Plate-type heat exchanger with titanium platesW10 Water-<strong>to</strong>-water cooling unit, non-redundant, with atitanium plate-type heat exchanger (without titaniumpiping on the raw-water side).Application: For aggressive raw water supplies, suchas salt waterW11W12OthersW50Water-<strong>to</strong>-water cooling unit with redundant pumpsand a titanium plate heat exchanger (without titaniumpiping on the raw-water side).Application: For aggressive raw water supplies, suchas salt water.Option W11 results in the cabinet width beingincreased (refer <strong>to</strong> the dimension drawings).Water-<strong>to</strong>-water cooling unit with redundant pumpsand a redundant titanium plate-type heat exchanger(without titanium piping on the raw-water side).Application: For aggressive raw water supplies, suchas salt water.Option W12 results in the cabinet width beingincreased (refer <strong>to</strong> the dimension drawings).3-way valve <strong>to</strong> control the de-ionized watertemperaturePartiallyredundantFullyredundantNonredundantPartiallyredundantFullyredundant¦ –Refer <strong>to</strong>the informationonPage 6/17¦ ¦ –Refer <strong>to</strong>theinformationon Page6/17¦ ¦ ¦ ¦ ¦■ ■ ■ ■ ■– – – ¦ ¦– – – ¦ ¦– – – ¦ ¦– – – ¦ ¦– – – ¦ ¦See Page 6/7 – – – ¦ ¦½ Option possible ■ On request – Not available1) The required brake resis<strong>to</strong>r is not included in the scope of supply.3/18 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersOptionsOrderCodeDescription of the option Comment Use with <strong>SIMOVERT</strong> <strong>MV</strong> in version2.3 kV3.3 kV4.16 kVair-cooled2 x 4.16 kVair-cooled6.0 kV6.6 kVair-cooled2 x 4.16 kV2.3 kV3.3 kV4.16 kVwatercooledwatercooledMechanical versionsM11M23Dust protectionDoors with filter elements. Front-mounted so that thefilter element can be replaced with the doors closedand the drive converter operational.Caution: When filter elements are used, the outputmust be limited <strong>to</strong> 98% of the rated output.Degree of protection IP23With fan cover, corresponding <strong>to</strong> IP23.Caution: Cubicle depth increases by 50 mm.¦ ¦ ¦ – –¦ ¦ ¦ Standard Standard3M41M43Degree of protection IP41Wire-mesh doors (1 mm) and fan coverDegree of protection IP43With coverFan coveronly IP21With L08 orY15:Fan coversonly IP23¦ ¦ ¦ – –– – – ¦ ¦To achieve with M23 and M41M57Degree of protection IP54Cabinet with internal air-<strong>to</strong>-water cooler.Not available<strong>to</strong>gether withoption L17– – – ■ ■M59M60Cabinet doors without air intake openingsAir intake from below through floor panelswith cut-outs.LocksDoors can be locked using integrated safety locks.Caution:please notethe informationon page 6/6¦ ¦ – – –¦ ¦ ¦ ¦ ¦M65M66Emergency operation in the event of fan failureOperation can be continued at a lower output(emergency operation) when a fan fails.Refer <strong>to</strong> Page 6/6 for specifications.Suitable for marine applicationsAccording <strong>to</strong> the requirements of themarine classification societies:Lloyds Register of Shipping, American Bureau ofShipping, Germanischer Lloyd, Bureau Veritas,Det Norske VeritasChinese Classification SocietyY09 Special paint finish according <strong>to</strong> RAL ...Deviating from the standard RAL 7032RAL No. must be specified in plain text.Only appliesfor the maindrive converterfansIncludes theoptions Y09,L33, and L55.Not withoption L17Fans alwaysRAL 7032¦ – – – –– – – ¦ ¦¦ ¦ ¦ ¦ ¦Marine version with individual certificateV10 Individual certificate fromGermanische Lloyd (GL)for non-essential servicesV20V30V50V60V70Individual certificate fromLloyds Register of Shipping (LRS)for non-essential servicesIndividual certificate fromBureau Veritas (BV)for non-essential servicesIndividual certificate fromDet Norske Veritas (DNV)for non-essential servicesIndividual certificate fromAmerican Bureau of Shipping (ABS)for non-essential servicesIndividual certificate fromChinese Classification Society (CCS)for non-essential servicesIncludes M66 – – – ¦ ¦Includes M66and L86Includes M66and Y75– – – ¦ ¦– – – ¦ ¦Includes M66 – – – ¦ ¦Includes M66 – – – ¦ ¦Includes M66and coremarkings– – – ¦ ¦½ Option possible ■ On request – Not availableSiemens DA 63 · 2004 3/19

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersOptionsDescription of the options (continued)Description of the option Comment Use with <strong>SIMOVERT</strong> <strong>MV</strong> in versionOrderCode2.3 kV3.3 kV4.16 kVair-cooled2 x 4.16 kVair-cooled6.0 kV6.6 kVair-cooled2 x 4.16 kV2.3 kV3.3 kV4.16 kVwatercooledwatercooled3Electrical optionsL08 Output reac<strong>to</strong>rThis is required <strong>to</strong> limit the capacitive re-charging currentsof the mo<strong>to</strong>r feeder cables. Required for cables100 m and longer, so that operation is possible forlonger distances up <strong>to</strong> approx. 1000 m.The output reac<strong>to</strong>r is installed in a 600 mm widesupplementary cabinet.L17L33L34L50L54L55L56L70Y15Y75UPSThe uninterruptible power supply (UPS) buffers theelectronics power supply (1-ph. 230 V AC/N/PE) andprotects the open-loop and closed-loop control fromtemporary line faults (s<strong>to</strong>red energy time approx. 10min). The unit is integrated in the control cabinet.Internal cabinet lighting and socket connec<strong>to</strong>routlet 230 V, 1-phaseThis is triggered using a motion sensor,including protective contact socket outlet.Redundant fansThe drive converter can still be operated even when afan fails.Refer <strong>to</strong> Page 6/6 for specifications.Additional lights and switches5 signaling lights (LED): Off/Ready (green), On (white),Alarm (yellow), Fault (red), Local (white),1 Key switch Remote/LocalAnti-condensation heating 120 V ACThe rating is dependent on the cabinet size (a multipleof 90 W). External supply and on/off control with 1-ph.120 V AC.Anti-condensation heating 230 V ACThe rating is dependent on the cabinet size (a multipleof 90 W). External supply and on/off control with 1-ph.230 V AC.Control of anti-condensation heating forconverter and mo<strong>to</strong>rThe internal anti-condensation heating system (optionL55 or L54, not included) and any external anticondensationheating, e.g. on the mo<strong>to</strong>r, are switchedon by a contac<strong>to</strong>r when the converter is switched off.Current for external anti-condensation heating system:max. 10 AExternal supply with 230 V AC or 120 V AC.Analog display instruments3 supplementary measuring instruments in the door(96 x 96 mm) <strong>to</strong> display parameterizable signals, e.g.:¦ Speed¦ Mo<strong>to</strong>r voltage¦ Mo<strong>to</strong>r currentSine-wave EMC output filterFor 3rd-party and old mo<strong>to</strong>rs.Installed in 900 mm wide supplementary cabinet.With 4.16 kV, from 1700 <strong>kVA</strong>: installation in a 1200 mmwide supplementary cabinet.Please refer <strong>to</strong> explanations in Sect. 6, Page 6/19.Important:When ordering filters, the rated mo<strong>to</strong>r current, the mo<strong>to</strong>rcurrent at the rated operating point and the no-loadmo<strong>to</strong>r current must be specified in plain text.Auxiliary voltage other than 3ph/N/380...415 V ACor auxiliary supply without loadable N conduc<strong>to</strong>ror IT line supply <strong>Voltage</strong> should be quoted in plaintext. With Y75 the auxiliary voltage is wired via theControl Terminal Strip X860 (see Page 6/10):This option isalways aircooledwithfan cover IP23Not withoptions L33,M57, M66Not withoption L17Fans foroptions L08 orY15 are notredundantL54 and L55not includedMax. outputfrequency: 66 HzThis option isalways air-cooledwith fan coverIP21 or (optional)IP23¦ ¦ – ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ – – – –¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ – – ¦ –except followingtypes:6SE8026-2AA016SE8036-2BA016SE8040-2BA016SE8045-2CA016SE8050-2CA01¦ ¦ ¦ ¦ ¦½ Option possible ■ On request – Not available3/20 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersOptionsOrderCodeDescription of the option Comment Use with <strong>SIMOVERT</strong> <strong>MV</strong> in version2.3 kV3.3 kV4.16 kVair-cooled2 x 4.16 kVair-cooled6.0 kV6.6 kVair-cooled2 x 4.16 kV2.3 kV3.3 kV4.16 kVwatercooledwatercooledAnalog inputs and outputsStandard:2 Inputs 4 <strong>to</strong> 20 mA Q 130 ms cycle time4 Outputs 4 <strong>to</strong> 20 mA Q 4 ms cycle timeE74 Analog ± 10 V2 Inputs ± 10 V; Q 4 ms cycle time4 Outputs ± 10 V; Q 4 ms cycle timeE84E85E86Analog ± 20 mA2 Inputs ± 20 mA; Q 130 ms cycle time4 Outputs ± 20 mA; Q 4 ms cycle timeAnalog 4 ... 20 mA2 Inputs 4 ... 20 mA; Q 4 ms cycle time4 Outputs 4 ... 20 mA; Q 4 ms cycle timeIsolation amplifiers for analog inputs and outputsIsolation amplifiers decouple the different referencepotentials of the signals between the device electronicsand the higher-level controller. Six isolation amplifiersare installed (2 inputs, 4 outputs).The interfaces are adjustable(4 <strong>to</strong> 20 mA, 0 <strong>to</strong> 20 mA, ± 10 V).Note:The options E74, E84, E85 and E86 do not include any additional inputs, butinstead, specification changes.Important:Only one optionper convertercan be ordered!Cable length:200 m max¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦3Closed-loop control options (software)L31 Restart-on-the-flyThe drive converter is switched <strong>to</strong> a mo<strong>to</strong>r which iscoasting downL32L35Au<strong>to</strong>matic restartThe restart function au<strong>to</strong>matically powers up a driveconverter when power returns after it has been shutdown due <strong>to</strong> power failure.Condition:Synchronizing voltage from the medium-voltage leveland secure auxiliary infeed for open-loop and closedloopcontrol necessaryMax. output frequency > 100 HzExpansion of the closed-loop control for higher outputfrequencies up <strong>to</strong> max. 125 HzThermis<strong>to</strong>r mo<strong>to</strong>r protection devices, PT100 evaluationL81 Mo<strong>to</strong>r temperature shutdownThermis<strong>to</strong>r mo<strong>to</strong>r protection evaluation device3RN1013-1BW10 <strong>to</strong> evaluate the mo<strong>to</strong>r temperaturefor shutdown. The output contacts are connected inthe internal shutdown circuit of the unitL82L83L84Mo<strong>to</strong>r temperature alarmThermis<strong>to</strong>r mo<strong>to</strong>r protection evaluation device3RN1013-1BW10 <strong>to</strong> evaluate the mo<strong>to</strong>r temperaturefor alarm. The output contacts are connected in theinternal alarm circuit of the unitMo<strong>to</strong>r temperature alarm(for explosion-proof mo<strong>to</strong>rs)Thermis<strong>to</strong>r mo<strong>to</strong>r protection evaluation device3RN1013-1BW10 with PTB approval <strong>to</strong> evaluate themo<strong>to</strong>r temperature for alarm for explosion-proofmo<strong>to</strong>rs. The output contacts are connected in theinternal alarm circuit of the unitMo<strong>to</strong>r temperature shutdown(for explosion-proof mo<strong>to</strong>rs)Thermis<strong>to</strong>r mo<strong>to</strong>r protection evaluation device3RN1013-1BW10 with PTB approval <strong>to</strong> evaluate themo<strong>to</strong>r temperature for shutdown for explosion-proofmo<strong>to</strong>rs. The output contacts are connected in theinternal shutdown circuit of the deviceOption L31au<strong>to</strong>maticallyincludedNot availablewith optionY15¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ – ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦½ Option possible ■ On request – Not availableSiemens DA 63 · 2004 3/21

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersOptionsDescription of the options (continued)Description of the option Comment Use with <strong>SIMOVERT</strong> <strong>MV</strong> in versionOrderCode2.3 kV3.3 kV4.16 kVair-cooled2 x 4.16 kVair-cooled6.0 kV6.6 kVair-cooled2 x 4.16 kV2.3 kV3.3 kV4.16 kVwatercooledwatercooled3Thermis<strong>to</strong>r mo<strong>to</strong>r protection devices, PT100 evaluationL86 PT100 evaluation device, 6-channelPT100 evaluation device with two groups of threemeasuring channels each in two-wire circuit, with au<strong>to</strong>maticcable compensation when device is poweredon. Each measuring channel can be parameterizedindividually.L87L88L89PT100 evaluation device, 6-channel for explosionprotectionTemperature evaluation for 1 transformer2 thermis<strong>to</strong>r evaluation devices 3RN1013-1BW10 forevaluating the transformer temperature for shutdownand alarm. Output contacts wired <strong>to</strong> binary inputs forauxiliaries. Maximum cold resistance of thethermis<strong>to</strong>rs: 1.5 kohms per evaluation unit.Temperature evaluation for 2 transformers4 thermis<strong>to</strong>r evaluation devices 3RN1013-1BW10 forevaluating the transformer temperature for shutdownand alarm. Output contacts wired <strong>to</strong> binary inputs forauxiliaries. Maximum cold resistance of the thermis<strong>to</strong>rs:1.5 kohms per evaluation unit.DocumentationD15 Additional set of documentationOne additional copy each of the documentation in thelanguage selected; multiple orders possibleOn allconverterswith only onetransformerUseful especiallywithconverters 2 x4,16 kV or with24-pulserectifier(option L01)¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦D76 Documentation in English ¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦D77 Documentation in French Circuitdiagrams arein EnglishD78 Documentation in Spanish Circuitdiagrams arein EnglishY10Cus<strong>to</strong>mer-specific circuit diagramsThe cus<strong>to</strong>mer title block (max. 3 lines of 45 characterseach) is added <strong>to</strong> the standard converter circuit diagramsand <strong>to</strong> the ordered options. All references <strong>to</strong>non-ordered options are removed.Must be specified in plaintextSee Chapter 5for the standardscope ofsupply¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦½ Option possible ■ On request – Not available3/22 Siemens DA 63 · 2004

<strong>SIMOVERT</strong> <strong>MV</strong>6SE80 Drive ConvertersOptionsOrderCodeDescription of the option Comment Use with <strong>SIMOVERT</strong> <strong>MV</strong> in version2.3 kV3.3 kV4.16 kVair-cooled2 x 4.16 kVair-cooled6.0 kV6.6 kVair-cooled2 x 4.16 kV2.3 kV3.3 kV4.16 kVwatercooledwatercooledConverter acceptance test in the presence of the cus<strong>to</strong>merF03 Visual acceptance:¦ Degree of protection check¦ Device check (components)¦ Equipment identifier check¦ Check of air and creepage distances¦ Cable check¦ Cus<strong>to</strong>mer documentation check¦ Handover of acceptance pro<strong>to</strong>colThe tests are carried out with the converterde-energized.F73F77Functional acceptance of the converter withinductive load:¦ Visual check as described on option F03¦ Power supply check¦ Checking of the protection and moni<strong>to</strong>ring equipment(simulation)¦ Checking of the fans (or the cooling system in the caseof water cooling)¦ Pre-charging test¦ Function test with inductive load, rated voltage andrated current¦ Handover of acceptance pro<strong>to</strong>colFollowing the visual acceptance in a de-energizedstate, the converter is connected <strong>to</strong> the rated voltage.On the converter output side, the rated current flows inan inductive load at an output frequency of 5 Hz.Insulation test of the converter¦ High-voltage test¦ Measurement of the insulation resistanceF77 notincludedOnly in combinationwithF73.Cannot beordered alone¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦¦ ¦ ¦ ¦ ¦3F97Cus<strong>to</strong>mer-specific converter acceptance tests:If converter acceptance tests are desired that are notcovered by options F03, F73 and F77, cus<strong>to</strong>merspecificacceptance tests/supplementary tests can beordered using the short code F97 following requestand technical clarification. The scope of acceptancemust be described in a specification that has beencoordinated with the fac<strong>to</strong>ry.When ordering,referencemust be madein plaintext <strong>to</strong>the specification.■ ■ ■ ■ ■¦ Option possible ■ On request – Not availableSiemens DA 63 · 2004 3/23