Measuring Gas Velocity with the D-FL 100 Differential Pressure Bar

Measuring Gas Velocity with the D-FL 100 Differential Pressure Bar

Measuring Gas Velocity with the D-FL 100 Differential Pressure Bar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

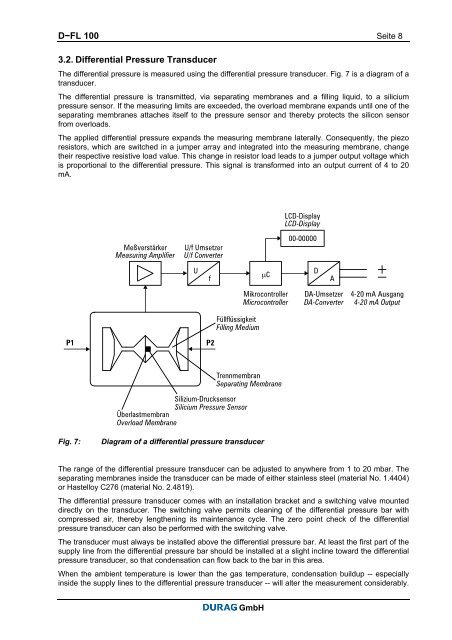

D−<strong>FL</strong> <strong>100</strong> Seite 83.2. <strong>Differential</strong> <strong>Pressure</strong> TransducerThe differential pressure is measured using <strong>the</strong> differential pressure transducer. Fig. 7 is a diagram of atransducer.The differential pressure is transmitted, via separating membranes and a filling liquid, to a siliciumpressure sensor. If <strong>the</strong> measuring limits are exceeded, <strong>the</strong> overload membrane expands until one of <strong>the</strong>separating membranes attaches itself to <strong>the</strong> pressure sensor and <strong>the</strong>reby protects <strong>the</strong> silicon sensorfrom overloads.The applied differential pressure expands <strong>the</strong> measuring membrane laterally. Consequently, <strong>the</strong> piezoresistors, which are switched in a jumper array and integrated into <strong>the</strong> measuring membrane, change<strong>the</strong>ir respective resistive load value. This change in resistor load leads to a jumper output voltage whichis proportional to <strong>the</strong> differential pressure. This signal is transformed into an output current of 4 to 20mA.Fig. 7:Diagram of a differential pressure transducerThe range of <strong>the</strong> differential pressure transducer can be adjusted to anywhere from 1 to 20 mbar. Theseparating membranes inside <strong>the</strong> transducer can be made of ei<strong>the</strong>r stainless steel (material No. 1.4404)or Hastelloy C276 (material No. 2.4819).The differential pressure transducer comes <strong>with</strong> an installation bracket and a switching valve mounteddirectly on <strong>the</strong> transducer. The switching valve permits cleaning of <strong>the</strong> differential pressure bar <strong>with</strong>compressed air, <strong>the</strong>reby leng<strong>the</strong>ning its maintenance cycle. The zero point check of <strong>the</strong> differentialpressure transducer can also be performed <strong>with</strong> <strong>the</strong> switching valve.The transducer must always be installed above <strong>the</strong> differential pressure bar. At least <strong>the</strong> first part of <strong>the</strong>supply line from <strong>the</strong> differential pressure bar should be installed at a slight incline toward <strong>the</strong> differentialpressure transducer, so that condensation can flow back to <strong>the</strong> bar in this area.When <strong>the</strong> ambient temperature is lower than <strong>the</strong> gas temperature, condensation buildup -- especiallyinside <strong>the</strong> supply lines to <strong>the</strong> differential pressure transducer -- will alter <strong>the</strong> measurement considerably.GmbH