S type - Kitagawa Europe

S type - Kitagawa Europe

S type - Kitagawa Europe

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

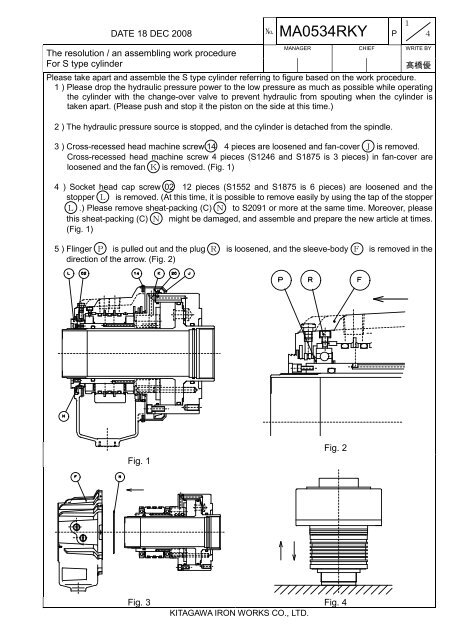

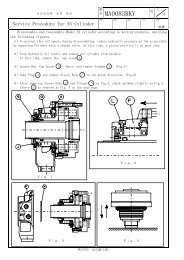

DATE 18 DEC 2008 № MA0534RKY P14The resolution / an assembling work procedureFor S <strong>type</strong> cylinderMANAGER CHIEF WRITE BY高 橋 優Please take apart and assemble the S <strong>type</strong> cylinder referring to figure based on the work procedure.1 ) Please drop the hydraulic pressure power to the low pressure as much as possible while operatingthe cylinder with the change-over valve to prevent hydraulic from spouting when the cylinder istaken apart. (Please push and stop it the piston on the side at this time.)2 ) The hydraulic pressure source is stopped, and the cylinder is detached from the spindle.3 ) Cross-recessed head machine screw 14 4 pieces are loosened and fan-cover J is removed.Cross-recessed head machine screw 4 pieces (S1246 and S1875 is 3 pieces) in fan-cover areloosened and the fan K is removed. (Fig. 1)4 ) Socket head cap screw 02 12 pieces (S1552 and S1875 is 6 pieces) are loosened and thestopper L is removed. (At this time, it is possible to remove easily by using the tap of the stopperL .) Please remove sheat-packing (C) N to S2091 or more at the same time. Moreover, pleasethis sheat-packing (C) N might be damaged, and assemble and prepare the new article at times.(Fig. 1)5 ) Flinger P is pulled out and the plug R is loosened, and the sleeve-body F is removed in thedirection of the arrow. (Fig. 2)Fig. 1Fig. 2Fig. 3 Fig. 4KITAGAWA IRON WORKS CO., LTD.