Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

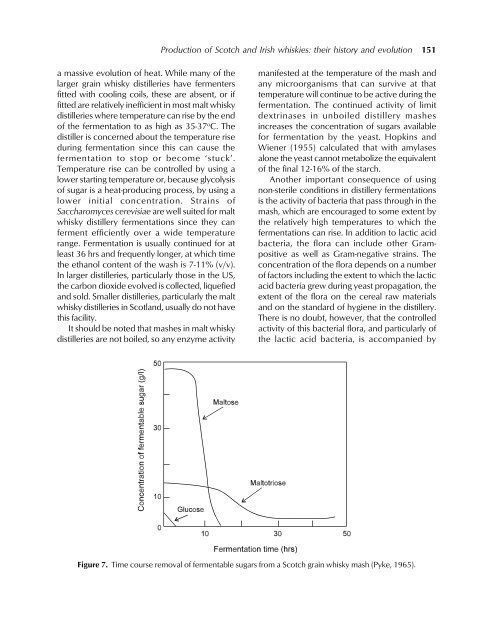

<strong>Production</strong> <strong>of</strong> <strong>Scotch</strong> <strong>and</strong> <strong>Irish</strong> <strong>whiskies</strong>: <strong>their</strong> <strong>history</strong> <strong>and</strong> evolution 151a massive evolution <strong>of</strong> heat. While many <strong>of</strong> thelarger grain whisky distilleries have fermentersfitted with cooling coils, these are absent, or iffitted are relatively inefficient in most malt whiskydistilleries where temperature can rise by the end<strong>of</strong> the fermentation to as high as 35-37 o C. Thedistiller is concerned about the temperature riseduring fermentation since this can cause thefermentation to stop or become ‘stuck’.Temperature rise can be controlled by using alower starting temperature or, because glycolysis<strong>of</strong> sugar is a heat-producing process, by using alower initial concentration. Strains <strong>of</strong>Saccharomyces cerevisiae are well suited for maltwhisky distillery fermentations since they canferment efficiently over a wide temperaturerange. Fermentation is usually continued for atleast 36 hrs <strong>and</strong> frequently longer, at which timethe ethanol content <strong>of</strong> the wash is 7-<strong>11</strong>% (v/v).In larger distilleries, particularly those in the US,the carbon dioxide evolved is collected, liquefied<strong>and</strong> sold. Smaller distilleries, particularly the maltwhisky distilleries in Scotl<strong>and</strong>, usually do not havethis facility.It should be noted that mashes in malt whiskydistilleries are not boiled, so any enzyme activitymanifested at the temperature <strong>of</strong> the mash <strong>and</strong>any microorganisms that can survive at thattemperature will continue to be active during thefermentation. The continued activity <strong>of</strong> limitdextrinases in unboiled distillery mashesincreases the concentration <strong>of</strong> sugars availablefor fermentation by the yeast. Hopkins <strong>and</strong>Wiener (1955) calculated that with amylasesalone the yeast cannot metabolize the equivalent<strong>of</strong> the final 12-16% <strong>of</strong> the starch.Another important consequence <strong>of</strong> usingnon-sterile conditions in distillery fermentationsis the activity <strong>of</strong> bacteria that pass through in themash, which are encouraged to some extent bythe relatively high temperatures to which thefermentations can rise. In addition to lactic acidbacteria, the flora can include other Grampositiveas well as Gram-negative strains. Theconcentration <strong>of</strong> the flora depends on a number<strong>of</strong> factors including the extent to which the lacticacid bacteria grew during yeast propagation, theextent <strong>of</strong> the flora on the cereal raw materials<strong>and</strong> on the st<strong>and</strong>ard <strong>of</strong> hygiene in the distillery.There is no doubt, however, that the controlledactivity <strong>of</strong> this bacterial flora, <strong>and</strong> particularly <strong>of</strong>the lactic acid bacteria, is accompanied byFigure 7. Time course removal <strong>of</strong> fermentable sugars from a <strong>Scotch</strong> grain whisky mash (Pyke, 1965).