Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

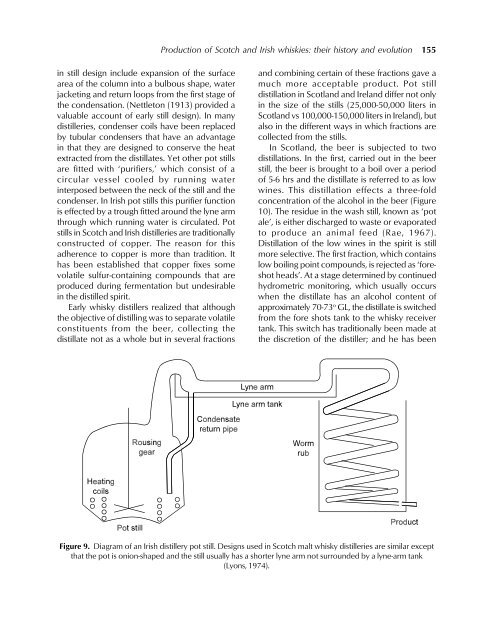

<strong>Production</strong> <strong>of</strong> <strong>Scotch</strong> <strong>and</strong> <strong>Irish</strong> <strong>whiskies</strong>: <strong>their</strong> <strong>history</strong> <strong>and</strong> evolution 155in still design include expansion <strong>of</strong> the surfacearea <strong>of</strong> the column into a bulbous shape, waterjacketing <strong>and</strong> return loops from the first stage <strong>of</strong>the condensation. (Nettleton (1913) provided avaluable account <strong>of</strong> early still design). In manydistilleries, condenser coils have been replacedby tubular condensers that have an advantagein that they are designed to conserve the heatextracted from the distillates. Yet other pot stillsare fitted with ‘purifiers,’ which consist <strong>of</strong> acircular vessel cooled by running waterinterposed between the neck <strong>of</strong> the still <strong>and</strong> thecondenser. In <strong>Irish</strong> pot stills this purifier functionis effected by a trough fitted around the lyne armthrough which running water is circulated. Potstills in <strong>Scotch</strong> <strong>and</strong> <strong>Irish</strong> distilleries are traditionallyconstructed <strong>of</strong> copper. The reason for thisadherence to copper is more than tradition. Ithas been established that copper fixes somevolatile sulfur-containing compounds that areproduced during fermentation but undesirablein the distilled spirit.Early whisky distillers realized that althoughthe objective <strong>of</strong> distilling was to separate volatileconstituents from the beer, collecting thedistillate not as a whole but in several fractions<strong>and</strong> combining certain <strong>of</strong> these fractions gave amuch more acceptable product. Pot stilldistillation in Scotl<strong>and</strong> <strong>and</strong> Irel<strong>and</strong> differ not onlyin the size <strong>of</strong> the stills (25,000-50,000 liters inScotl<strong>and</strong> vs 100,000-150,000 liters in Irel<strong>and</strong>), butalso in the different ways in which fractions arecollected from the stills.In Scotl<strong>and</strong>, the beer is subjected to twodistillations. In the first, carried out in the beerstill, the beer is brought to a boil over a period<strong>of</strong> 5-6 hrs <strong>and</strong> the distillate is referred to as lowwines. This distillation effects a three-foldconcentration <strong>of</strong> the alcohol in the beer (Figure10). The residue in the wash still, known as ‘potale’, is either discharged to waste or evaporatedto produce an animal feed (Rae, 1967).Distillation <strong>of</strong> the low wines in the spirit is stillmore selective. The first fraction, which containslow boiling point compounds, is rejected as ‘foreshotheads’. At a stage determined by continuedhydrometric monitoring, which usually occurswhen the distillate has an alcohol content <strong>of</strong>approximately 70-73 o GL, the distillate is switchedfrom the fore shots tank to the whisky receivertank. This switch has traditionally been made atthe discretion <strong>of</strong> the distiller; <strong>and</strong> he has beenFigure 9. Diagram <strong>of</strong> an <strong>Irish</strong> distillery pot still. Designs used in <strong>Scotch</strong> malt whisky distilleries are similar exceptthat the pot is onion-shaped <strong>and</strong> the still usually has a shorter lyne arm not surrounded by a lyne-arm tank(Lyons, 1974).