Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

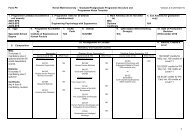

<strong>Production</strong> <strong>of</strong> <strong>Scotch</strong> <strong>and</strong> <strong>Irish</strong> <strong>whiskies</strong>: <strong>their</strong> <strong>history</strong> <strong>and</strong> evolution 143Table 1. Raw materials <strong>and</strong> unit processes used in the production <strong>of</strong> scotch <strong>and</strong> <strong>Irish</strong> <strong>whiskies</strong>.<strong>Scotch</strong> malt <strong>Scotch</strong> grain <strong>Irish</strong>Raw materials Peated <strong>and</strong> unpeated Wheat or corn <strong>and</strong> a small Unmalted barley <strong>and</strong> unpeated,malted barley proportion <strong>of</strong> malted barley malted barleyConversion Infusion mash Mash cook followed by Infusion mashconversion st<strong>and</strong>Fermentation Distillers yeast <strong>and</strong> Distillers yeast Distillers yeastbrewers yeastDistillation Two pot stills Continuous still Three pot stillsMaturation At 62 o GL in used charred Up to 67 o GL in used charred At 70 o GL in used charred oakoak bourbon whiskey oak bourbon whisky barrels bourbon whisky barrels or sherrybarrels or sherry casks or sherry casks for at least casks for at least three yearsfor at least three years three yearsspecific gravity <strong>of</strong> the fermented mash has usuallydropped to below 1.000. In pot still distilleries,the fermented mash or ‘wash’ (beer) is feddirectly to a still known as the wash still, fromwhich the distillates are redistilled in the secondor low wines still. In Irel<strong>and</strong>, <strong>and</strong> in one <strong>Scotch</strong>malt whisky distillery, a third distillation is carriedout. Finally, the freshly distilled whisky is storedin charred oak barrels for minimum periods <strong>of</strong>time that depend on the legislation in theproducing country (Table 1). <strong>Scotch</strong> malt <strong>and</strong><strong>Irish</strong> <strong>whiskies</strong> are customarily matured for muchlonger than the legal minimum period.Individual operationsRaw materialsMalted cerealsMalted barley is the principal malted cereal usedin whisky production. Like the brewer, the whiskydistiller uses barley cultivars <strong>of</strong> the speciesHordeum vulgare L. <strong>and</strong> Hordeum distichon(Hough et al., 1971). Malted barley is employedas a source <strong>of</strong> enzymes (principally amylolytic)that catalyze the hydrolysis <strong>of</strong> starches <strong>and</strong> insome instances serves as a source <strong>of</strong> starch thatis converted ultimately into ethanol. These twodem<strong>and</strong>s must be finely balanced. In themanufacture <strong>of</strong> <strong>Scotch</strong> malt whisky, where onlymalted barley is used, care must be taken whenthe grain is sprouting during the malting processto ensure that only a limited amount <strong>of</strong> enzymeactivity is produced. This is because enzyme isproduced at the expense <strong>of</strong> the fermentablematerials in the grain (referred to as ‘extract’).However in the manufacture <strong>of</strong> other types <strong>of</strong>whisky, malted barley is <strong>of</strong>ten used as the onlysource <strong>of</strong> amylolytic enzyme in a mash bill thatcontains a high proportion <strong>of</strong> unmalted grain. Inthis type <strong>of</strong> whisky production the enzymeactivity <strong>of</strong> the malted barley must be greater thanthat used in <strong>Scotch</strong> malt whisky manufacture.Traditionally, barley used in the production <strong>of</strong><strong>Scotch</strong> malt whisky was malted on the distillerypremises using a floor malting system <strong>and</strong> driedover fires <strong>of</strong> coke <strong>and</strong> peat in the pagoda-shapedkilns which are still a feature <strong>of</strong> these distilleries.To a large extent, this system has beensuperseded by mechanical maltings, whichproduce malt for groups <strong>of</strong> distilleries. In ordernot to destroy the enzyme activity developedduring malting, a balance must be achieved inthe kiln between drying the green malt to a