Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

Chapter 11 Production of Scotch and Irish whiskies: their history and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

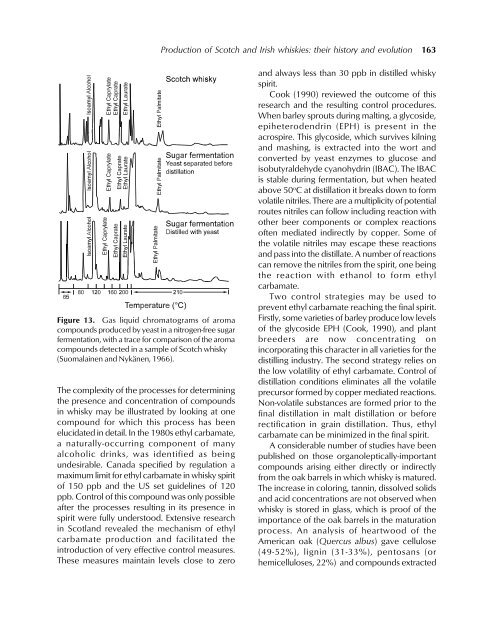

<strong>Production</strong> <strong>of</strong> <strong>Scotch</strong> <strong>and</strong> <strong>Irish</strong> <strong>whiskies</strong>: <strong>their</strong> <strong>history</strong> <strong>and</strong> evolution 163Figure 13. Gas liquid chromatograms <strong>of</strong> aromacompounds produced by yeast in a nitrogen-free sugarfermentation, with a trace for comparison <strong>of</strong> the aromacompounds detected in a sample <strong>of</strong> <strong>Scotch</strong> whisky(Suomalainen <strong>and</strong> Nykänen, 1966).The complexity <strong>of</strong> the processes for determiningthe presence <strong>and</strong> concentration <strong>of</strong> compoundsin whisky may be illustrated by looking at onecompound for which this process has beenelucidated in detail. In the 1980s ethyl carbamate,a naturally-occurring component <strong>of</strong> manyalcoholic drinks, was identified as beingundesirable. Canada specified by regulation amaximum limit for ethyl carbamate in whisky spirit<strong>of</strong> 150 ppb <strong>and</strong> the US set guidelines <strong>of</strong> 120ppb. Control <strong>of</strong> this compound was only possibleafter the processes resulting in its presence inspirit were fully understood. Extensive researchin Scotl<strong>and</strong> revealed the mechanism <strong>of</strong> ethylcarbamate production <strong>and</strong> facilitated theintroduction <strong>of</strong> very effective control measures.These measures maintain levels close to zero<strong>and</strong> always less than 30 ppb in distilled whiskyspirit.Cook (1990) reviewed the outcome <strong>of</strong> thisresearch <strong>and</strong> the resulting control procedures.When barley sprouts during malting, a glycoside,epiheterodendrin (EPH) is present in theacrospire. This glycoside, which survives kilning<strong>and</strong> mashing, is extracted into the wort <strong>and</strong>converted by yeast enzymes to glucose <strong>and</strong>isobutyraldehyde cyanohydrin (IBAC). The IBACis stable during fermentation, but when heatedabove 50 o C at distillation it breaks down to formvolatile nitriles. There are a multiplicity <strong>of</strong> potentialroutes nitriles can follow including reaction withother beer components or complex reactions<strong>of</strong>ten mediated indirectly by copper. Some <strong>of</strong>the volatile nitriles may escape these reactions<strong>and</strong> pass into the distillate. A number <strong>of</strong> reactionscan remove the nitriles from the spirit, one beingthe reaction with ethanol to form ethylcarbamate.Two control strategies may be used toprevent ethyl carbamate reaching the final spirit.Firstly, some varieties <strong>of</strong> barley produce low levels<strong>of</strong> the glycoside EPH (Cook, 1990), <strong>and</strong> plantbreeders are now concentrating onincorporating this character in all varieties for thedistilling industry. The second strategy relies onthe low volatility <strong>of</strong> ethyl carbamate. Control <strong>of</strong>distillation conditions eliminates all the volatileprecursor formed by copper mediated reactions.Non-volatile substances are formed prior to thefinal distillation in malt distillation or beforerectification in grain distillation. Thus, ethylcarbamate can be minimized in the final spirit.A considerable number <strong>of</strong> studies have beenpublished on those organoleptically-importantcompounds arising either directly or indirectlyfrom the oak barrels in which whisky is matured.The increase in coloring, tannin, dissolved solids<strong>and</strong> acid concentrations are not observed whenwhisky is stored in glass, which is pro<strong>of</strong> <strong>of</strong> theimportance <strong>of</strong> the oak barrels in the maturationprocess. An analysis <strong>of</strong> heartwood <strong>of</strong> theAmerican oak (Quercus albus) gave cellulose(49-52%), lignin (31-33%), pentosans (orhemicelluloses, 22%) <strong>and</strong> compounds extracted