Growth of plasma-polymerized thin films by PECVD method and ...

Growth of plasma-polymerized thin films by PECVD method and ...

Growth of plasma-polymerized thin films by PECVD method and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

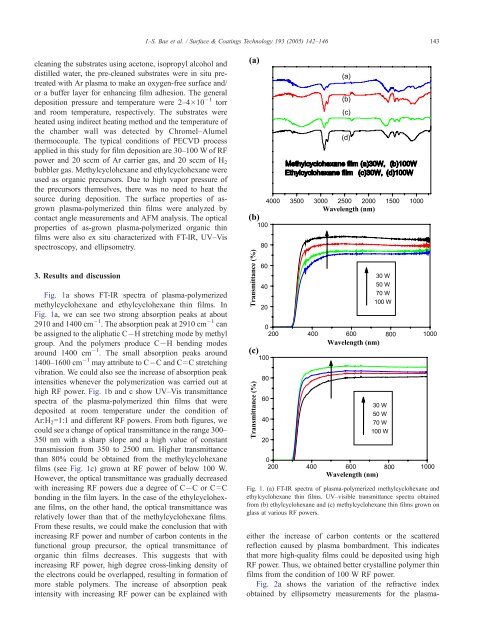

I.-S. Bae et al. / Surface & Coatings Technology 193 (2005) 142–146 143cleaning the substrates using acetone, isopropyl alcohol <strong>and</strong>distilled water, the pre-cleaned substrates were in situ pretreatedwith Ar <strong>plasma</strong> to make an oxygen-free surface <strong>and</strong>/or a buffer layer for enhancing film adhesion. The generaldeposition pressure <strong>and</strong> temperature were 2–410 1 torr<strong>and</strong> room temperature, respectively. The substrates wereheated using indirect heating <strong>method</strong> <strong>and</strong> the temperature <strong>of</strong>the chamber wall was detected <strong>by</strong> Chromel–Alumelthermocouple. The typical conditions <strong>of</strong> <strong>PECVD</strong> processapplied in this study for film deposition are 30–100 W <strong>of</strong> RFpower <strong>and</strong> 20 sccm <strong>of</strong> Ar carrier gas, <strong>and</strong> 20 sccm <strong>of</strong> H 2bubbler gas. Methylcyclohexane <strong>and</strong> ethylcyclohexane wereused as organic precursors. Due to high vapor pressure <strong>of</strong>the precursors themselves, there was no need to heat thesource during deposition. The surface properties <strong>of</strong> asgrown<strong>plasma</strong>-<strong>polymerized</strong> <strong>thin</strong> <strong>films</strong> were analyzed <strong>by</strong>contact angle measurements <strong>and</strong> AFM analysis. The opticalproperties <strong>of</strong> as-grown <strong>plasma</strong>-<strong>polymerized</strong> organic <strong>thin</strong><strong>films</strong> were also ex situ characterized with FT-IR, UV–Visspectroscopy, <strong>and</strong> ellipsometry.3. Results <strong>and</strong> discussionFig. 1a shows FT-IR spectra <strong>of</strong> <strong>plasma</strong>-<strong>polymerized</strong>methylcyclohexane <strong>and</strong> ethylcyclohexane <strong>thin</strong> <strong>films</strong>. InFig. 1a, we can see two strong absorption peaks at about2910 <strong>and</strong> 1400 cm 1 . The absorption peak at 2910 cm 1 canbe assigned to the aliphatic CUH stretching mode <strong>by</strong> methylgroup. And the polymers produce CUH bending modesaround 1400 cm 1 . The small absorption peaks around1400–1600 cm 1 may attribute to CUC <strong>and</strong> CMC stretchingvibration. We could also see the increase <strong>of</strong> absorption peakintensities whenever the polymerization was carried out athigh RF power. Fig. 1b <strong>and</strong> c show UV–Vis transmittancespectra <strong>of</strong> the <strong>plasma</strong>-<strong>polymerized</strong> <strong>thin</strong> <strong>films</strong> that weredeposited at room temperature under the condition <strong>of</strong>Ar:H 2 =1:1 <strong>and</strong> different RF powers. From both figures, wecould see a change <strong>of</strong> optical transmittance in the range 300–350 nm with a sharp slope <strong>and</strong> a high value <strong>of</strong> constanttransmission from 350 to 2500 nm. Higher transmittancethan 80% could be obtained from the methylcyclohexane<strong>films</strong> (see Fig. 1c) grown at RF power <strong>of</strong> below 100 W.However, the optical transmittance was gradually decreasedwith increasing RF powers due a degree <strong>of</strong> CUC orCMCbonding in the film layers. In the case <strong>of</strong> the ethylcyclohexane<strong>films</strong>, on the other h<strong>and</strong>, the optical transmittance wasrelatively lower than that <strong>of</strong> the methylcyclohexane <strong>films</strong>.From these results, we could make the conclusion that wi<strong>thin</strong>creasing RF power <strong>and</strong> number <strong>of</strong> carbon contents in thefunctional group precursor, the optical transmittance <strong>of</strong>organic <strong>thin</strong> <strong>films</strong> decreases. This suggests that wi<strong>thin</strong>creasing RF power, high degree cross-linking density <strong>of</strong>the electrons could be overlapped, resulting in formation <strong>of</strong>more stable polymers. The increase <strong>of</strong> absorption peakintensity with increasing RF power can be explained withFig. 1. (a) FT-IR spectra <strong>of</strong> <strong>plasma</strong>-<strong>polymerized</strong> methylcyclohexane <strong>and</strong>ethylcyclohexane <strong>thin</strong> <strong>films</strong>. UV–visible transmittance spectra obtainedfrom (b) ethylcyclohexane <strong>and</strong> (c) methylcyclohexane <strong>thin</strong> <strong>films</strong> grown onglass at various RF powers.either the increase <strong>of</strong> carbon contents or the scatteredreflection caused <strong>by</strong> <strong>plasma</strong> bombardment. This indicatesthat more high-quality <strong>films</strong> could be deposited using highRF power. Thus, we obtained better crystalline polymer <strong>thin</strong><strong>films</strong> from the condition <strong>of</strong> 100 W RF power.Fig. 2a shows the variation <strong>of</strong> the refractive indexobtained <strong>by</strong> ellipsometry measurements for the <strong>plasma</strong>-