Growth of plasma-polymerized thin films by PECVD method and ...

Growth of plasma-polymerized thin films by PECVD method and ...

Growth of plasma-polymerized thin films by PECVD method and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

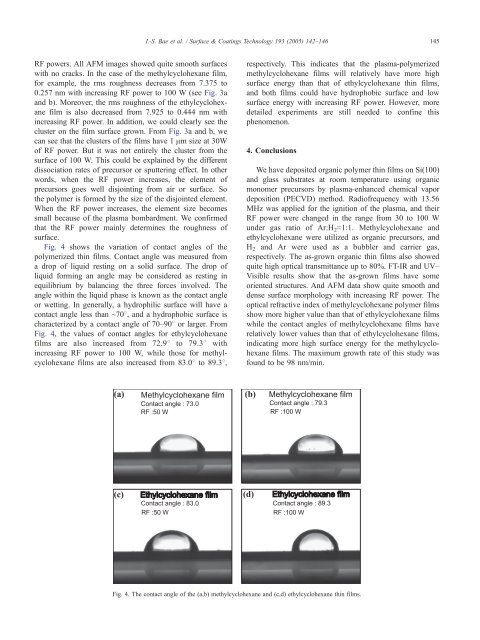

I.-S. Bae et al. / Surface & Coatings Technology 193 (2005) 142–146 145RF powers. All AFM images showed quite smooth surfaceswith no cracks. In the case <strong>of</strong> the methylcyclohexane film,for example, the rms roughness decreases from 7.375 to0.257 nm with increasing RF power to 100 W (see Fig. 3a<strong>and</strong> b). Moreover, the rms roughness <strong>of</strong> the ethylcyclohexanefilm is also decreased from 7.925 to 0.444 nm wi<strong>thin</strong>creasing RF power. In addition, we could clearly see thecluster on the film surface grown. From Fig. 3a <strong>and</strong> b, wecan see that the clusters <strong>of</strong> the <strong>films</strong> have 1 Am size at 30W<strong>of</strong> RF power. But it was not entirely the cluster from thesurface <strong>of</strong> 100 W. This could be explained <strong>by</strong> the differentdissociation rates <strong>of</strong> precursor or sputtering effect. In otherwords, when the RF power increases, the element <strong>of</strong>precursors goes well disjointing from air or surface. Sothe polymer is formed <strong>by</strong> the size <strong>of</strong> the disjointed element.When the RF power increases, the element size becomessmall because <strong>of</strong> the <strong>plasma</strong> bombardment. We confirmedthat the RF power mainly determines the roughness <strong>of</strong>surface.Fig. 4 shows the variation <strong>of</strong> contact angles <strong>of</strong> the<strong>polymerized</strong> <strong>thin</strong> <strong>films</strong>. Contact angle was measured froma drop <strong>of</strong> liquid resting on a solid surface. The drop <strong>of</strong>liquid forming an angle may be considered as resting inequilibrium <strong>by</strong> balancing the three forces involved. Theangle wi<strong>thin</strong> the liquid phase is known as the contact angleor wetting. In generally, a hydrophilic surface will have acontact angle less than ~708, <strong>and</strong> a hydrophobic surface ischaracterized <strong>by</strong> a contact angle <strong>of</strong> 70–908 or larger. FromFig. 4, the values <strong>of</strong> contact angles for ethylcyclohexane<strong>films</strong> are also increased from 72.98 to 79.38 wi<strong>thin</strong>creasing RF power to 100 W, while those for methylcyclohexane<strong>films</strong> are also increased from 83.08 to 89.38,respectively. This indicates that the <strong>plasma</strong>-<strong>polymerized</strong>methylcyclohexane <strong>films</strong> will relatively have more highsurface energy than that <strong>of</strong> ethylcyclohexane <strong>thin</strong> <strong>films</strong>,<strong>and</strong> both <strong>films</strong> could have hydrophobic surface <strong>and</strong> lowsurface energy with increasing RF power. However, moredetailed experiments are still needed to confine thisphenomenon.4. ConclusionsWe have deposited organic polymer <strong>thin</strong> <strong>films</strong> on Si(100)<strong>and</strong> glass substrates at room temperature using organicmonomer precursors <strong>by</strong> <strong>plasma</strong>-enhanced chemical vapordeposition (<strong>PECVD</strong>) <strong>method</strong>. Radi<strong>of</strong>requency with 13.56MHz was applied for the ignition <strong>of</strong> the <strong>plasma</strong>, <strong>and</strong> theirRF power were changed in the range from 30 to 100 Wunder gas ratio <strong>of</strong> Ar:H 2 =1:1. Methylcyclohexane <strong>and</strong>ethylcyclohexane were utilized as organic precursors, <strong>and</strong>H 2 <strong>and</strong> Ar were used as a bubbler <strong>and</strong> carrier gas,respectively. The as-grown organic <strong>thin</strong> <strong>films</strong> also showedquite high optical transmittance up to 80%. FT-IR <strong>and</strong> UV–Visible results show that the as-grown <strong>films</strong> have someoriented structures. And AFM data show quite smooth <strong>and</strong>dense surface morphology with increasing RF power. Theoptical refractive index <strong>of</strong> methylcyclohexane polymer <strong>films</strong>show more higher value than that <strong>of</strong> ethylcyclohexane <strong>films</strong>while the contact angles <strong>of</strong> methylcyclohexane <strong>films</strong> haverelatively lower values than that <strong>of</strong> ethylcyclohexane <strong>films</strong>,indicating more high surface energy for the methylcyclohexane<strong>films</strong>. The maximum growth rate <strong>of</strong> this study wasfound to be 98 nm/min.Fig. 4. The contact angle <strong>of</strong> the (a,b) methylcyclohexane <strong>and</strong> (c,d) ethylcyclohexane <strong>thin</strong> <strong>films</strong>.