3-layer coatings brochure - Hall Longmore

3-layer coatings brochure - Hall Longmore

3-layer coatings brochure - Hall Longmore

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3-Layer (Trilaminate)CoatingsOriginally developed for the oil and gas industry, 3-<strong>layer</strong> <strong>coatings</strong>have applications across the entire steel pipe corrosion protectionspectrum. 3-<strong>layer</strong> <strong>coatings</strong> provide a “belt and braces” solution tosteel pipe treatment by offering the enhanced corrosion protectionof the Fusion Bonded Epoxy (FBE) <strong>layer</strong> along with the robust,impact and mechanical resistance of the polyethylene top coat.The long term benefits include:High impact resistanceHigh corrosion resistance with cathodic protectionExcellent resistance to soil stressesHighly impermeable to water penetrationSuperior adhesion to steelGood flexibilityExcellent insulation properties with long termresistance to stray currentCan be customised to specific operating conditionsby varying the thickness of the coating in line withspecifications

3-Layer Coating<strong>Hall</strong> <strong>Longmore</strong> offers the following tests on all 3-<strong>layer</strong> <strong>coatings</strong>:1. Cathodic Disbondment (CD)2. Peel AdhesionCathodic disbondment3. Elongation4. Impact5. Dust and Debris6. EID (Holiday testing)Peel AdhesionThe above tests are generally performed in accordance with CSAZ245.20/21-02. Additional or enhanced testing as required byInstitutional / Client based Particular Specifications must beverified by <strong>Hall</strong> <strong>Longmore</strong>’s Quality-Assurance/Control department.Pipe inspections are performed at each stage to ensure complianceand minimize the risk of defects.3-Layer Polyethylene Coatings (3LPE) can be used in operatingconditions of up to 80ºC, making them suitable in most steel pipeapplications from water to gas transfer. However, for pipelines withoperating temperatures in excess of 80ºC, polypropylene and theassociated high temperature FBE and co-polymer adhesives arerequired – 3LPP.Elongation TestImpact TestPlease contact <strong>Hall</strong> <strong>Longmore</strong> for further information in this regard.Dust and Debris InspectionSample CutElectric Insulation Detection (EID)

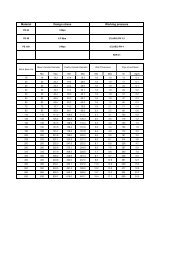

3-Layer Coatings: Technical DetailsTYPICAL TECHNICAL SPECIFICATION FOR 3-LAYER COATINGSSystem B1 : A coating that consists of a powdered epoxy primer (FBE) an extruded co-polymer adhesive(cohesive) and an extruded polyethylene outer <strong>layer</strong> (HDPE)Characteristic Test Criteria Component LayersStandard Clause Table FBE Layer Cohesive Layer HDPE LayerCompoundDescriptionCSAZ245.20-02CSAZ245.21-0233N/AN/AA thermosetting coatingmaterial based on epoxyresin.Polyethylene basedadhesiveA black high densitynatural resin polyethylenewith ultraviolet stabiliserand colourantCure time CSAZ245.20-02 12.1 1 Meets manufacturersspecificationThickness CSAZ245.21-20 N/A Table 6 0.12mm minimum 0.1mm minimum 0.45mm minimumOperating TemprangeManufacturersspecifications100ºC general140ºC spikesWater Absorption CSAZ245.20-02 12.3 1 0.50% maxDensityCSAZ245.20-02ASTM D 79212.5 1 1400g/lCSAZ245.21-20Table 3.915g/cm 3 _+ 1%.950g/cm 3 _+ 1%Impact Resistance CSAZ245.20-02 12.12 1 1.5J 3J / mm of actualthicknessBond strength /AdhesionCSAZ245.20-02 12.14 1 Rating 1-3 Peel: 150N min.Dialectric strength ASTM D 149.95 CSAZ245.21-20Section 7.4.2550v/mil10V / micron of thicknessup to 15000V max.Shore Hardness D ASTM D 224090 /=60Flow Rate ASTM D 1238 CSAZ245.21-20Table 21.5g/10min _+20% 0.4g/10min _+ 20%Softening Point ASTM D 1505 CSAZ245.21-20Table 2Tensile strengthat yieldASTM D 638 Manufacturers 1 /= 18MPa 17MPa min.specifications85ºCElongation /DuctilityASTM D 638Manufacturersspecifications1 300% min. 300% min.Environmental stresscracking resistanceCathodicDisbondmentFlexibilityASTM D 1693CSAZ245.21-20Table 3CSAZ245.20-02 12.8 1 7mm max.(24 hrs @ 3.5V; 65ºCaccelerate)CSAZ245.21-20Table 1_+1000hr1 Bend of 2.5º - 3.0º(R=22.42t)<strong>Hall</strong> <strong>Longmore</strong> reserves the right to change or amend the contents of this document at anytime without any notice with this document intendedfor general information only. Any specific information required about product specifications, applications, technical information, sales, conditions,warranties and guarantees as required for any design or installation should be obtained from <strong>Hall</strong> <strong>Longmore</strong>.JULY 2008