CONCURRENT SESSION ABSTRACTSFriday, March 15 3:00 PM–6:00 PMNautilusSynthetic BiologyCo-chairs: Nancy Keller and Peter PuntEngineering Aspergillus oryzae for high level production of L-malic acid. Debbie S Yaver 1 , S. Brown 2 , A. Berry 2 . 1) Expression Technology, Novozymes, Inc.,Davis, CA; 2) Microbial Physiology, Novozymes, Inc., Davis, CA.In the last decade, there has been widespread interest and investment in developing processes for the production of bulk and specialty chemicals fromrenewable feedstocks by fermentation. During this period, Novozymes has successfully developed technology for production of a specialty molecule(hyaluronic acid) by Bacillus fermentation and has been very active in developing technologies for the production of bulk chemicals by metabolicengineering and fermentation using several different microorganisms. An example of the latter is L-malic acid. In the literature it is reported that somewild-type Aspergillus strains produce high levels of malic acid under specific cultivation conditions. Concentrations up to 113 g/L malate (94% w/w fromglucose) reported for A. flavus in fed-batch fermentations (Battat, et. al., 1991. Biotechnol. Bioeng. 37:1108-1116). The goal of our work was to improvemalic acid production in the natural malic acid producing filamentous fungus Aspergillus oryzae NRRL 3488 by overexpression of cloned genes and classicalmutagenesis. More than 75 different recombinant strains were tested containing combinations of overexpression of genes as well as deletions. A highthrough put screen was developed and used to screen mutagenized strains. Combined genetic engineering and mutagenesis/HTS was used to increase themalic acid production rate of A. oryzae NRRL3488 by 4-fold with final C4 acid totals of 340 g/l at 8 days in lab scale fermentations.When synthetic biology meets metabolic engineering: in vivo pathway assembly in Saccharomyces cerevisiae. Niels Kuijpers 1,2 , Daniel Solis Escalante 1,2 ,Jack T. Pronk 1,2,3 , Jean-Marc Daran 1,2,3 , Pascale Daran-Lapujade 1,2 . 1) Department of Biotechnology, Delft University of Technology, Julianalaan 67, 2628 BCDelft, The Netherlands; 2) Kluyver Centre for Genomics of Industrial Fermentation, PO Box 5057, 2600 GA Delft, The Netherlands; 3) Platform GreenSynthetic Biology, Julianalaan 67, 2628 BC Delft, The Netherlands.The yeast Saccharomyces cerevisiae is a powerful and versatile workhorse intensively exploited for a wide range of biotechnological applications. Besidesthe large scale production of endogenous products, such as the biofuel ethanol, S. cerevisiae has been genetically engineered to produce manyheterologous compounds, including half of the worldwide insulin market. The past decade has been marked by the conversion of S. cerevisiae into acomplex cell factory with remarkable new capabilities such as the production of the anti-malaria drug precursor artemisinic acid. The ever-increasingdemand for cheap and sustainable production of complex molecules combined with its attractiveness as a host for pathway engineering will inevitablyintensify the exploitation of S. cerevisiae as cell factory in the future. Even in the genetically accessible bakers yeast, expression of dozen of genes is stilllargely based on laborious classical techniques involving successive restrictions and ligations, complemented with the creative application of PCR.However, the increasing size and complexity of today’s constructs in metabolic engineering has made design and construction of plasmids by theseclassical techniques increasingly complicated and time consuming. Although uncovered nearly three decades ago, the high efficiency of S. cerevisiaehomologous recombination is only beginning to reveal its full potential for the assembly of large DNA constructs (Gibson et al., 2008). In vivo assembly inyeast is predicted to have a large impact on laboratory practices, ranging from simple plasmid construction to engineering of complex pathways viaautomated high-throughput strain construction. Despite those promising prospects, in vivo assembly has not yet become a standard technique in mostacademic laboratories. This offers unique possibilities for standardization and, simultaneously, for further optimization. In the present work we describe anapproach designed to improve the efficiency of in vivo assembly and to make a robust, versatile in vivo assembly strategy for multi-component plasmids.As a proof of principle, the method was used to assemble a 21 kb plasmid from 9 overlapping fragments, using only PCR and yeast transformation. GibsonD.G. et al. (2008), Science, 319, 1215-1220.Analysis of the intracellular galactoglycom of Trichoderma reesei grown on lactose. Levente Karaffa 1 , Leon Coulier 2 , Erzsébet Fekete 1 , Karin M.Overkamp 2 , Irina S. Druzhinina 3 , Marianna Mikus 3 , Bernhard Seiboth 3 , Levente Novák 4 , Peter J. Punt 2 , Christian P. Kubicek 3 . 1) Department of BiochemicalEngineering, University of Debrecen, H-4032, Debrecen, Hungary; 2) TNO, P.O. Box 360, 3700 AJ Zeist, The Netherlands; 3) Research Area Biotechnologyand Microbiology, Institute of Chemical Engineering, TU Wien, Gumpendorferstrasse 1a, A-1060 Wien, Austria; 4) Department of Colloid andEnvironmental Chemistry, Faculty of Science and Technology, University of Debrecen, H-4032, Debrecen, Hungary.Lactose (1,4-0-b-D-galactopyranosyl-D-glucose) is used as a soluble carbon source for the production of cellulases and hemicellulases for - among otherpurposes - in the biofuel and biorefinery industries. However, the mechanism how lactose induces cellulase formation in T. reesei is still enigmatic.Previous results raised the hypothesis that intermediates from the two D-galactose catabolic pathway may give rise to the accumulation of intracellularoligogalactosides that could act as inducer. We have therefore used HPAEC-MS to study the intracellular galactoglycome of T. reesei during growth onlactose, in T. reesei mutants impaired in galactose catabolism, and in strains with different cellulase productivity. Lactose, allo-lactose and lactulose weredetected in the highest amounts in all strains, and two trisaccharides (Gal-b-1,6-Gal-b-1,4-Glc/Fru; and Gal-b-1,4-Gal-b-1,4-Glc/Fru) also accumulated tosignificant levels. D-Glucose and D-galactose, as well as two further oligosaccharides (Gal-b-1,3/1,4-Gal; Gal-b-1,2/1,3-Glc) were only detected in minoramounts, In addition, one unknown disaccharide and four trisaccharides were also detected. The unknown hexose disaccharide to correlate with cellulaseformation in the improved mutant strains as well as the galactose pathway mutants, and Gal-b-1,4-Gal-b-1,4-Glc and two other unknown hexosetrisaccharides to correlate with cellulase production only in the pathway mutants, suggesting that these compounds could be involved in cellulaseinduction by lactose.78

CONCURRENT SESSION ABSTRACTSNovel transcriptomics approaches for metabolic pathway engineering target identification in Aspergillus. Peter J. Punt, Martien Caspers, MarvinSteijaert, Eric Schoen, Machtelt Braaksma. Microbiology, TNO, Zeist, Netherlands.Among filamentous fungi Aspergillus sp. are well known production host for several organic acids. These acids, traditionally being food ingredients, morerecently have gained attention as platform or building-block chemicals. These chemicals, currently mostly produced based on petrochemistry, are thestarting point for the production of a wide variety of materials, such as resins, plastics, etc. Production of these compounds via biobased routes will be amajor contribution towards a Biobased Economy. For the production of these bulk compounds robust host organisms are required, suitable for using lowcost lignocellulose-based feedstocks, resistant against adverse conditions due to inhibitory feedstock compounds and capable of coping with high productconcentrations. A. niger was shown to fulfill most of these prerequisites (Rumbold et al., 2009).Based on the extended molecular genetic toolkit systemsbiology approaches were developed for A. niger and other fungi (e.g. Braaksma et al., 2010). These approaches were followed towards production of theseplatform chemicals in A. niger, as demonstrated by the example of itaconic acid (Li et al., 2011, 2012). The recent development of novel high throughputsequence methods has led to new much more efficient transcriptomics approaches such as RNAseq. Combination of these approaches with novelexperimental design and statistical methods for targetgene identification in metabolic pathway engineering will be illustrated. Rumbold, K., van Buijsen,H.J.J., Overkamp, K.M., van Groenestijn, J.W., Punt, P.J., Werf, M.J.V.D. (2009) Microbial production host selection for converting second-generationfeedstocks into bioproducts. Microbial Cell Factories 8, art. no. 64 Braaksma, M., van den Berg, R.A., van der Werf, M.J., Punt, P.J. (2010) A Top-DownSystems Biology Approach for the Identification of Targets for <strong>Fungal</strong> Strain and Process Development. In: Cellular and Molecular Biology of FilamentousFungi. Eds: K.A. Borkovich & D.J. Ebbole ASM Press, Washington DC. pp. 25-35 Li, A., van Luijk, N., ter Beek, M., Caspers, M., Punt, P., van der Werf, M.(2011) A clone-based transcriptomics approach for the identification of genes relevant for itaconic acid production in Aspergillus. <strong>Fungal</strong> <strong>Genetics</strong> andBiology 48 (6), pp. 602-611.A new method for gene mining and enzyme discovery. Y. Huang 1,2,3 , P. Busk 1 , M. Grell 1 , H. Zhao 2,3 , L. Lange 1 . 1) Section for Sustainable Biotechnology,Department of Biotechnology, Chemistry and Environmental Engineering, Aalborg University Copenhagen, Denmark; 2) Environmental Microbiology KeyLaboratory of Sichuan Province, Chengdu Institute of Biology, Chinese Academy of Sciences, Chengdu, Sichuan 610041, PR China; 3) University of theChinese Academy of Sciences, Beijing 100049, PR China.Peptide pattern recognition (PPR) is a non-alignment based sequence analysis principle and methodological approach, which can simultaneouslycompare multiple sequences and find characteristic features. This method has improved the understanding of structure/function relationship for enzymeswithin the CAZY families, which would make it easier to predict the potential function of novel enzymes, creating bigger promises for industrial purposes.Mucor circinelloides, member of the former subdivision Zygomycota, can utilize complex polysaccharides such as wheat bran, corncob, xylan, CMC andavicel as substrate to produce plant cell wall degrading enzymes. Although the genome of M. circinelloides has been sequenced, only few plant cell walldegrading enzymes are annotated in this species. In the present project, PPR was applied to analyze glycoside hydrolase families (GH family) and miningfor new GH genes in M. circinellolides genome. We found 19 different genes encoding GH3, GH5, GH6, GH7, GH9, GH16, GH38, GH43, GH47 and GH125 inthe genome. Of the three GH3 encoding genes found, one was predicted by PPR to encode a b-glucosidase. We expressed this gene in Pichia pastoris andfound that the recombinant protein has high b-glucosidase activity (4884 U/mL). In this work, PPR provided targeted short cut to discovery of enzymeswith a specific activity. Not only could PPR pinpoint genes belonging to different GH families but it did also predict the enzymatic function of the genes.Increased production of fatty acids and triglycerides in Aspergillus oryzae by modifying fatty acid metabolism. Koichi Tamano 1 , Kenneth Bruno 2 , TomokoIshii 1 , Sue Karagiosis 2 , David Culley 2 , Shuang Deng 2 , James Collet 2 , Myco Umemura 1 , Hideaki Koike 1 , Scott Baker 2 , Masayuki Machida 1 . 1) National Instituteof Advanced Industrial Science and Technology (AIST); 2) Pacific Northwest National Laboratory (PNNL).Biofuels are attractive substitutes for petroleum based fuels. Biofuels are considered they do not contribute to global warming in the sense they arecarbon-neutral and do not increase carbons on the globe. Hydrocarbons that are synthesized by microorganisms have potential of being used as biofuelsor the source compounds. In the hydrocarbon compounds synthesized by A. oryzae, fatty acids and triglycerides are the source compounds of biodieselthat is fatty acid methyl ester. We have increased the production by modifying fatty acid metabolism with genetic engineering in A. oryzae. Firstly,enhanced-expression strategy was used for the increase. For four enzyme genes related to the synthesis of palmitic acid [C16:0-fatty acid], the individualenhanced-expression mutants were made. And the fatty acids and triglycerides in cytosol were assayed by enzyme assay kits, respectively. As a result,both fatty acids and triglycerides were most synthesized in the enhanced-expression mutant of fatty acid synthase gene at 2.1-fold and 2.2-fold more thanthe wild-type strain, respectively. Secondly, gene disruption strategy was used for the increase. Disruptants of several enzyme genes related to long-chainfatty acid synthesis were made individually. And one of them showed drastic increase in fatty acid synthesis. In the future, further increase in the synthesisis expected by utilizing genetic engineering in A. oryzae.<strong>27th</strong> <strong>Fungal</strong> <strong>Genetics</strong> <strong>Conference</strong> | 79

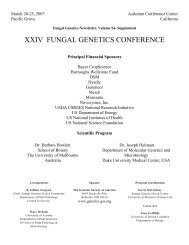

- Page 1:

Asilomar Conference GroundsMarch 12

- Page 7 and 8:

SCHEDULE OF EVENTSFriday, March 157

- Page 10 and 11:

EXHIBITSThe following companies hav

- Page 12 and 13:

CONCURRENT SESSIONS SCHEDULESWednes

- Page 14:

CONCURRENT SESSIONS SCHEDULESWednes

- Page 17 and 18:

CONCURRENT SESSIONS SCHEDULESThursd

- Page 19:

CONCURRENT SESSIONS SCHEDULESFriday

- Page 22 and 23:

CONCURRENT SESSIONS SCHEDULESSaturd

- Page 24:

CONCURRENT SESSIONS SCHEDULESSaturd

- Page 27 and 28:

PLENARY SESSION ABSTRACTSThursday,

- Page 29 and 30:

PLENARY SESSION ABSTRACTSFriday, Ma

- Page 31 and 32: PLENARY SESSION ABSTRACTSSaturday,

- Page 33 and 34: CONCURRENT SESSION ABSTRACTSWednesd

- Page 35 and 36: CONCURRENT SESSION ABSTRACTSUnravel

- Page 37 and 38: CONCURRENT SESSION ABSTRACTSSynergi

- Page 39 and 40: CONCURRENT SESSION ABSTRACTSWednesd

- Page 41 and 42: CONCURRENT SESSION ABSTRACTSWednesd

- Page 43 and 44: CONCURRENT SESSION ABSTRACTSWednesd

- Page 45 and 46: CONCURRENT SESSION ABSTRACTSA draft

- Page 47 and 48: CONCURRENT SESSION ABSTRACTSRegulat

- Page 49 and 50: CONCURRENT SESSION ABSTRACTSWednesd

- Page 51 and 52: CONCURRENT SESSION ABSTRACTSThursda

- Page 53 and 54: CONCURRENT SESSION ABSTRACTSThursda

- Page 55 and 56: CONCURRENT SESSION ABSTRACTSThursda

- Page 57 and 58: CONCURRENT SESSION ABSTRACTSThursda

- Page 59 and 60: CONCURRENT SESSION ABSTRACTSThursda

- Page 61 and 62: CONCURRENT SESSION ABSTRACTSThe mut

- Page 63 and 64: CONCURRENT SESSION ABSTRACTSInnate

- Page 65 and 66: CONCURRENT SESSION ABSTRACTSThursda

- Page 67 and 68: CONCURRENT SESSION ABSTRACTSGenome-

- Page 69 and 70: CONCURRENT SESSION ABSTRACTSIdentif

- Page 71 and 72: CONCURRENT SESSION ABSTRACTSFriday,

- Page 73 and 74: CONCURRENT SESSION ABSTRACTSFriday,

- Page 75 and 76: CONCURRENT SESSION ABSTRACTSThe Scl

- Page 77 and 78: CONCURRENT SESSION ABSTRACTSThe rol

- Page 79 and 80: CONCURRENT SESSION ABSTRACTSFriday,

- Page 81: CONCURRENT SESSION ABSTRACTSCompari

- Page 85 and 86: CONCURRENT SESSION ABSTRACTSFriday,

- Page 87 and 88: CONCURRENT SESSION ABSTRACTSEffect

- Page 89 and 90: CONCURRENT SESSION ABSTRACTSCommon

- Page 91 and 92: CONCURRENT SESSION ABSTRACTSSaturda

- Page 93 and 94: CONCURRENT SESSION ABSTRACTSSeconda

- Page 95 and 96: CONCURRENT SESSION ABSTRACTSSheddin

- Page 97 and 98: CONCURRENT SESSION ABSTRACTSSaturda

- Page 99 and 100: CONCURRENT SESSION ABSTRACTSSaturda

- Page 101 and 102: CONCURRENT SESSION ABSTRACTSSaturda

- Page 103 and 104: CONCURRENT SESSION ABSTRACTSprocess

- Page 105 and 106: CONCURRENT SESSION ABSTRACTSSpecifi

- Page 107 and 108: LISTING OF ALL POSTER ABSTRACTSBioc

- Page 109 and 110: LISTING OF ALL POSTER ABSTRACTS81.

- Page 111 and 112: LISTING OF ALL POSTER ABSTRACTS160.

- Page 113 and 114: LISTING OF ALL POSTER ABSTRACTS239.

- Page 115 and 116: LISTING OF ALL POSTER ABSTRACTS322.

- Page 117 and 118: LISTING OF ALL POSTER ABSTRACTS401.

- Page 119 and 120: LISTING OF ALL POSTER ABSTRACTSmedi

- Page 121 and 122: LISTING OF ALL POSTER ABSTRACTS558.

- Page 123 and 124: LISTING OF ALL POSTER ABSTRACTS640.

- Page 125 and 126: LISTING OF ALL POSTER ABSTRACTS723.

- Page 127 and 128: FULL POSTER SESSION ABSTRACTS5. Cha

- Page 129 and 130: FULL POSTER SESSION ABSTRACTS13. In

- Page 131 and 132: FULL POSTER SESSION ABSTRACTSbioche

- Page 133 and 134:

FULL POSTER SESSION ABSTRACTS30. Me

- Page 135 and 136:

FULL POSTER SESSION ABSTRACTS38. Me

- Page 137 and 138:

FULL POSTER SESSION ABSTRACTSidenti

- Page 139 and 140:

FULL POSTER SESSION ABSTRACTSsecret

- Page 141 and 142:

FULL POSTER SESSION ABSTRACTSinvolv

- Page 143 and 144:

FULL POSTER SESSION ABSTRACTSdiploi

- Page 145 and 146:

FULL POSTER SESSION ABSTRACTSSaccha

- Page 147 and 148:

FULL POSTER SESSION ABSTRACTSresist

- Page 149 and 150:

FULL POSTER SESSION ABSTRACTS96. Ce

- Page 151 and 152:

FULL POSTER SESSION ABSTRACTS104. M

- Page 153 and 154:

FULL POSTER SESSION ABSTRACTScan ex

- Page 155 and 156:

FULL POSTER SESSION ABSTRACTSturgor

- Page 157 and 158:

FULL POSTER SESSION ABSTRACTSlike p

- Page 159 and 160:

FULL POSTER SESSION ABSTRACTSIndoor

- Page 161 and 162:

FULL POSTER SESSION ABSTRACTSlength

- Page 163 and 164:

FULL POSTER SESSION ABSTRACTSA scre

- Page 165 and 166:

FULL POSTER SESSION ABSTRACTSthen q

- Page 167 and 168:

FULL POSTER SESSION ABSTRACTS170. S

- Page 169 and 170:

FULL POSTER SESSION ABSTRACTSof sup

- Page 171 and 172:

FULL POSTER SESSION ABSTRACTSis fzo

- Page 173 and 174:

FULL POSTER SESSION ABSTRACTSgrowth

- Page 175 and 176:

FULL POSTER SESSION ABSTRACTSSeq da

- Page 177 and 178:

FULL POSTER SESSION ABSTRACTS212. T

- Page 179 and 180:

FULL POSTER SESSION ABSTRACTSCompar

- Page 181 and 182:

FULL POSTER SESSION ABSTRACTSmore g

- Page 183 and 184:

FULL POSTER SESSION ABSTRACTSmolecu

- Page 185 and 186:

FULL POSTER SESSION ABSTRACTSunexpe

- Page 187 and 188:

FULL POSTER SESSION ABSTRACTSrapid

- Page 189 and 190:

FULL POSTER SESSION ABSTRACTS260. T

- Page 191 and 192:

FULL POSTER SESSION ABSTRACTSFusari

- Page 193 and 194:

FULL POSTER SESSION ABSTRACTSScienc

- Page 195 and 196:

FULL POSTER SESSION ABSTRACTS286. G

- Page 197 and 198:

FULL POSTER SESSION ABSTRACTSincomp

- Page 199 and 200:

FULL POSTER SESSION ABSTRACTSfound

- Page 201 and 202:

FULL POSTER SESSION ABSTRACTS312. I

- Page 203 and 204:

FULL POSTER SESSION ABSTRACTSall th

- Page 205 and 206:

FULL POSTER SESSION ABSTRACTSPia La

- Page 207 and 208:

FULL POSTER SESSION ABSTRACTS335. A

- Page 209 and 210:

FULL POSTER SESSION ABSTRACTS342. F

- Page 211 and 212:

FULL POSTER SESSION ABSTRACTSThis i

- Page 213 and 214:

FULL POSTER SESSION ABSTRACTSJacobs

- Page 215 and 216:

FULL POSTER SESSION ABSTRACTScalciu

- Page 217 and 218:

FULL POSTER SESSION ABSTRACTSThe ab

- Page 219 and 220:

FULL POSTER SESSION ABSTRACTSexpres

- Page 221 and 222:

FULL POSTER SESSION ABSTRACTS394. F

- Page 223 and 224:

FULL POSTER SESSION ABSTRACTS398. U

- Page 225 and 226:

FULL POSTER SESSION ABSTRACTSthe id

- Page 227 and 228:

FULL POSTER SESSION ABSTRACTS415. A

- Page 229 and 230:

FULL POSTER SESSION ABSTRACTSAcuM b

- Page 231 and 232:

FULL POSTER SESSION ABSTRACTSdiverg

- Page 233 and 234:

FULL POSTER SESSION ABSTRACTSBck1 f

- Page 235 and 236:

FULL POSTER SESSION ABSTRACTSin the

- Page 237 and 238:

FULL POSTER SESSION ABSTRACTS455. T

- Page 239 and 240:

FULL POSTER SESSION ABSTRACTSor hos

- Page 241 and 242:

FULL POSTER SESSION ABSTRACTSfragme

- Page 243 and 244:

FULL POSTER SESSION ABSTRACTSenhanc

- Page 245 and 246:

FULL POSTER SESSION ABSTRACTSassess

- Page 247 and 248:

FULL POSTER SESSION ABSTRACTSmating

- Page 249 and 250:

FULL POSTER SESSION ABSTRACTScommon

- Page 251 and 252:

FULL POSTER SESSION ABSTRACTSOne of

- Page 253 and 254:

FULL POSTER SESSION ABSTRACTScells

- Page 255 and 256:

FULL POSTER SESSION ABSTRACTSof Ave

- Page 257 and 258:

FULL POSTER SESSION ABSTRACTSascaro

- Page 259 and 260:

FULL POSTER SESSION ABSTRACTSis a n

- Page 261 and 262:

FULL POSTER SESSION ABSTRACTSand th

- Page 263 and 264:

FULL POSTER SESSION ABSTRACTSCiuffe

- Page 265 and 266:

FULL POSTER SESSION ABSTRACTSon oth

- Page 267 and 268:

FULL POSTER SESSION ABSTRACTScopies

- Page 269 and 270:

FULL POSTER SESSION ABSTRACTSChem.

- Page 271 and 272:

FULL POSTER SESSION ABSTRACTS593. C

- Page 273 and 274:

FULL POSTER SESSION ABSTRACTS601. P

- Page 275 and 276:

FULL POSTER SESSION ABSTRACTSE.elym

- Page 277 and 278:

FULL POSTER SESSION ABSTRACTSThe de

- Page 279 and 280:

FULL POSTER SESSION ABSTRACTSMicrob

- Page 281 and 282:

FULL POSTER SESSION ABSTRACTSchromo

- Page 283 and 284:

FULL POSTER SESSION ABSTRACTSmating

- Page 285 and 286:

FULL POSTER SESSION ABSTRACTSAt the

- Page 287 and 288:

FULL POSTER SESSION ABSTRACTSemerge

- Page 289 and 290:

FULL POSTER SESSION ABSTRACTS666. G

- Page 291 and 292:

FULL POSTER SESSION ABSTRACTSof che

- Page 293 and 294:

FULL POSTER SESSION ABSTRACTSthe lo

- Page 295 and 296:

FULL POSTER SESSION ABSTRACTSin the

- Page 297 and 298:

FULL POSTER SESSION ABSTRACTSpotent

- Page 299 and 300:

FULL POSTER SESSION ABSTRACTSpoint

- Page 301 and 302:

FULL POSTER SESSION ABSTRACTS716. p

- Page 303 and 304:

FULL POSTER SESSION ABSTRACTSnatura

- Page 305 and 306:

FULL POSTER SESSION ABSTRACTSelemen

- Page 307 and 308:

KEYWORD LISTABC proteins ..........

- Page 309 and 310:

KEYWORD LISThigh temperature growth

- Page 311 and 312:

AUTHOR LISTBolton, Melvin D. ......

- Page 313 and 314:

AUTHOR LISTFrancis, Martin ........

- Page 315 and 316:

AUTHOR LISTKawamoto, Susumu... 427,

- Page 317 and 318:

AUTHOR LISTNNadimi, Maryam ........

- Page 319 and 320:

AUTHOR LISTSenftleben, Dominik ....

- Page 321 and 322:

AUTHOR LISTYablonowski, Jacob .....

- Page 323 and 324:

LIST OF PARTICIPANTSLeslie G Beresf

- Page 325 and 326:

LIST OF PARTICIPANTSTim A DahlmannR

- Page 327 and 328:

LIST OF PARTICIPANTSIgor V Grigorie

- Page 329 and 330:

LIST OF PARTICIPANTSMasayuki KameiT

- Page 331 and 332:

LIST OF PARTICIPANTSGeorgiana MayUn

- Page 333 and 334:

LIST OF PARTICIPANTSNadia PontsINRA

- Page 335 and 336:

LIST OF PARTICIPANTSFrancis SmetUni

- Page 337 and 338:

LIST OF PARTICIPANTSAric E WiestUni