Chemwatch MSDS Print - FUJIFILM Australia

Chemwatch MSDS Print - FUJIFILM Australia

Chemwatch MSDS Print - FUJIFILM Australia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

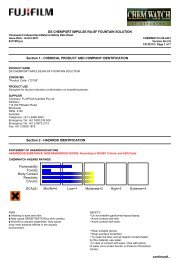

Fujifilm Inkjet For RTR - CI00E<strong>Chemwatch</strong> Material Safety Data SheetIssue Date: 1-Feb-2012 CHEMWATCH 30-06309317SPVersion No:2.0Page 3 of 8Section 5 - FIRE FIGHTING MEASURES• Prevent, by any means available, spillage from entering drains or water course.FIRE/EXPLOSION HAZARD• Non combustible.• Not considered a significant fire risk, however containers may burn.Decomposition may produce toxic fumes of: carbon dioxide (CO2), nitrogen oxides (NOx), phosphorus oxides (POx), other pyrolysisproducts typical of burning organic material.May emit poisonous fumes.May emit corrosive fumes.FIRE INCOMPATIBILITY• Avoid contamination with oxidising agents i.e. nitrates, oxidising acids, chlorine bleaches, pool chlorine etc. as ignition mayresult.HAZCHEMNoneSection 6 - ACCIDENTAL RELEASE MEASURESMINOR SPILLS• Clean up all spills immediately.• Avoid breathing vapours and contact with skin and eyes.• Control personal contact with the substance, by using protective equipment.• Contain and absorb spill with sand, earth, inert material or vermiculite.MAJOR SPILLS■ Moderate hazard.• Clear area of personnel and move upwind.• Alert Fire Brigade and tell them location and nature of hazard.• Wear breathing apparatus plus protective gloves.• Prevent, by any means available, spillage from entering drains or water course.Personal Protective Equipment advice is contained in Section 8 of the <strong>MSDS</strong>.Section 7 - HANDLING AND STORAGEPROCEDURE FOR HANDLING• Most acrylic monomers have low viscosity therefore pouring, material transfer and processing of these materials do notnecessitate heating.• Viscous monomers may require heating to facilitate handling. To facilitate product transfer from original containers, productmust be heated to no more than 60 deg. C. (140 F.), for not more than 24 hours.• Do NOT use localised heat sources such as band heaters to heat/ melt product.• Do NOT use steam .• DO NOT allow clothing wet with material to stay in contact with skin.• Avoid all personal contact, including inhalation.• Wear protective clothing when risk of exposure occurs.• Use in a well-ventilated area.• Avoid contact with moisture.SUITABLE CONTAINER• Polyethylene or polypropylene container.• Packing as recommended by manufacturer.• Check all containers are clearly labelled and free from leaks.STORAGE INCOMPATIBILITY■ for multifunctional acrylates:• Avoid exposure to free radical initiators (peroxides, persulfates) , iron, rust, oxidisers, and strong acids and strong bases.• Avoid heat, flame, sunlight, X-rays or ultra-violet radiation.• Storage beyond expiration date, may initiate polymerisation. Polymerisation of large quantities may be violent (even explosive).STORAGE REQUIREMENTS• Store in original containers.• Keep containers securely sealed.• Store in a cool, dry, well-ventilated area.continued...

Fujifilm Inkjet For RTR - CI00E<strong>Chemwatch</strong> Material Safety Data SheetIssue Date: 1-Feb-2012 CHEMWATCH 30-06309317SPVersion No:2.0Page 4 of 8Section 7 - HANDLING AND STORAGE• Store away from incompatible materials and foodstuff containers.Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTIONEXPOSURE CONTROLSThe following materials had no OELs on our records• N- vinylcaprolactam: CAS:2235- 00- 9• diphenyl(2, 4, 6- trimethylbenzoyl)phosphine: CAS:75980- 60- 8 CAS:596818- 40- 5• trimethylolpropane triacrylate, ethoxylated: CAS:28961- 43- 5 CAS:75577- 70- 7• ethoxylated, propoxylated phosphate: CAS:37280- 82- 3MATERIAL DATADIPHENYL(2,4,6-TRIMETHYLBENZOYL)PHOSPHINE:N-VINYLCAPROLACTAM:■ It is the goal of the ACGIH (and other Agencies) to recommend TLVs (or their equivalent) for all substances for which thereis evidence of health effects at airborne concentrations encountered in the workplace.At this time no TLV has been established, even though this material may produce adverse health effects (as evidenced in animalexperiments or clinical experience).NOTE: The ACGIH occupational exposure standard for Particles Not Otherwise Specified (P.N.O.S) does NOT apply.<strong>FUJIFILM</strong> INKJET FOR RTR - CI00E:TRIMETHYLOLPROPANE TRIACRYLATE, ETHOXYLATED:■ CEL TWA: 1 mg/m3 [compare WEEL-TWA* for multifunctional acrylates (MFAs)]Exposure to MFAs has been reported to cause contact dermatitis in humans and serious eye injury in laboratory animals.Exposure to some MFA-resin containing aerosols has also been reported to cause dermatitis.N-VINYLCAPROLACTAM:■ Sensory irritants are chemicals that produce temporary and undesirable side-effects on the eyes, nose or throat.Historically occupational exposure standards for these irritants have been based on observation of workers' responses to variousairborne concentrations.TRIMETHYLOLPROPANE TRIACRYLATE, ETHOXYLATED:■ For 4-methoxyphenol (MEHQ)MEHQ has caused ocular toxicity in animals and skin depigmentation in rodents and workers. The recommendation for the TLV-TWAarises from documented eye and skin toxicities and by analogy with hydroquinone.ETHOXYLATED, PROPOXYLATED PHOSPHATE:■ No exposure limits set by NOHSC or ACGIH.PERSONAL PROTECTIONRESPIRATOR•Type A-P Filter of sufficient capacity. (AS/NZS 1716 & 1715, EN 143:2000 & 149:2001, ANSI Z88 or national equivalent)EYE• Safety glasses with side shields.• Chemical goggles.• Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A written policy document,describing the wearing of lens or restrictions on use, should be created for each workplace or task. This should include areview of lens absorption and adsorption for the class of chemicals in use and an account of injury experience. Medical andfirst-aid personnel should be trained in their removal and suitable equipment should be readily available. In the event ofchemical exposure, begin eye irrigation immediately and remove contact lens as soon as practicable. Lens should be removed atthe first signs of eye redness or irritation - lens should be removed in a clean environment only after workers have washedhands thoroughly. [CDC NIOSH Current Intelligence Bulletin 59], [AS/NZS 1336 or national equivalent].HANDS/FEET■ NOTE:• The material may produce skin sensitisation in predisposed individuals. Care must be taken, when removing gloves and otherprotective equipment, to avoid all possible skin contact.• Contaminated leather items, such as shoes, belts and watch-bands should be removed and destroyed.continued...

Fujifilm Inkjet For RTR - CI00E<strong>Chemwatch</strong> Material Safety Data SheetIssue Date: 1-Feb-2012 CHEMWATCH 30-06309317SPVersion No:2.0Page 5 of 8Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTIONSuitability and durability of glove type is dependent on usage. Important factors in the selection of gloves include:• frequency and duration of contact,• chemical resistance of glove material,• glove thickness and• dexterity.General warning: Do NOT use latex gloves! Use only recommended gloves - using the wrong gloves may increase the risk:Exposure condition Short time use; (few minutesless than 0.5 hour) Little physical stressExposure condition Medium time use; less than 4hours Physical stress (opening drums, usingtools, etc.)Exposure condition Long time CleaningoperationsUse of thin nitrile rubber gloves: Nitrilerubber (0.1 mm) Excellent tactibility (" feel"), powder- free Disposable Inexpensive Giveadequate protection to low molecular weighacrylic monomersUse of medium thick nitrile rubber glovesNitrile rubber, NRL (latex) free; 0.56 mm lowtactibility (" feel" ), powder free High priceGives adequate protection for most acrylates incombination with commonly used solvents up to 8hours Do NOT give adequate protection to lowmolecular weight monomers at exposures longerthan 1 hour Avoid use of ketones and acetatesin wash- up solutions..OTHER• Overalls.• P.V.C. apron.• Barrier cream.• Skin cleansing cream.ENGINEERING CONTROLS■ Engineering controls are used to remove a hazard or place a barrier between the worker and the hazard. Well-designedengineering controls can be highly effective in protecting workers and will typically be independent of worker interactions toprovide this high level of protection.The basic types of engineering controls are:Process controls which involve changing the way a job activity or process is done to reduce the risk.Enclosure and/or isolation of emission source which keeps a selected hazard "physically" away from the worker and ventilationthat strategically "adds" and "removes" air in the work environment.Section 9 - PHYSICAL AND CHEMICAL PROPERTIESAPPEARANCEColoured liquid with a characteristic odour; does not mix with water.PHYSICAL PROPERTIESLiquid.Does not mix with water.Sinks in water.State Liquid Molecular Weight Not ApplicableMelting Range (°C) Not Available Viscosity Not AvailableBoiling Range (°C) 111 Solubility in water (g/L) ImmiscibleFlash Point (°C) Not Applicable pH (1% solution) Not AvailableDecomposition Temp (°C) Not Available pH (as supplied) Not AvailableAutoignition Temp (°C) Not Applicable Vapour Pressure (kPa) Not AvailableUpper Explosive Limit (%) Not Applicable Specific Gravity (water=1) 1.15Lower Explosive Limit (%) Not Applicable Relative Vapour Density Not Available(air=1)Volatile Component (%vol) Not Available Evaporation Rate Not Availablecontinued...

Fujifilm Inkjet For RTR - CI00E<strong>Chemwatch</strong> Material Safety Data SheetIssue Date: 1-Feb-2012 CHEMWATCH 30-06309317SPVersion No:2.0Page 6 of 8Section 10 - STABILITY AND REACTIVITYCONDITIONS CONTRIBUTING TO INSTABILITY• Presence of incompatible materials.• Product is considered stable.• Hazardous polymerisation will not occur.For incompatible materials - refer to Section 7 - Handling and Storage.Section 11 - TOXICOLOGICAL INFORMATIONPOTENTIAL HEALTH EFFECTSACUTE HEALTH EFFECTSSWALLOWED■ The material has NOT been classified by EC Directives or other classification systems as "harmful by ingestion". This isbecause of the lack of corroborating animal or human evidence. The material may still be damaging to the health of the individual,following ingestion, especially where pre-existing organ (eg. liver, kidney) damage is evident. Present definitions of harmful ortoxic substances are generally based on doses producing mortality rather than those producing morbidity (disease, ill-health).Gastrointestinal tract discomfort may produce nausea and vomiting. In an occupational setting however, ingestion of insignificantquantities is not thought to be cause for concern.EYE■ This material can cause eye irritation and damage in some persons.SKIN■ This material can cause inflammation of the skin oncontact in some persons.The material may accentuate any pre-existing dermatitis condition.Entry into the blood-stream, through, for example, cuts, abrasions or lesions, may produce systemic injury with harmful effects.Examine the skin prior to the use of the material and ensure that any external damage is suitably protected.INHALED■ The material can cause respiratory irritation in some persons. The body's response to such irritation can cause further lungdamage.CHRONIC HEALTH EFFECTS■ Skin contact with the material is more likely to cause a sensitisation reaction in some persons compared to the generalpopulation.Ample evidence from experiments exists that there is a suspicionthis material directly reduces fertility.Substance accumulation, in the human body, may occur and may cause some concern following repeated or long-term occupationalexposure.There is some evidence that inhaling this product is more likely to cause a sensitisation reaction in some persons compared tothe general population.Sensitisation may give severe responses to very low levels of exposure, i.e. hypersensitivity. Sensitised persons should not beallowed to work in situations where exposure may occur.TOXICITY AND IRRITATION■ Contact allergies quickly manifest themselves as contact eczema, more rarely as urticaria or Quincke's oedema. The pathogenesisof contact eczema involves a cell-mediated (T lymphocytes) immune reaction of the delayed type. Other allergic skin reactions,e.g. contact urticaria, involve antibody-mediated immune reactions. The significance of the contact allergen is not simplydetermined by its sensitisation potential: the distribution of the substance and the opportunities for contact with it areequally important. A weakly sensitising substance which is widely distributed can be a more important allergen than one withstronger sensitising potential with which few individuals come into contact. From a clinical point of view, substances arenoteworthy if they produce an allergic test reaction in more than 1% of the persons tested.Asthma-like symptoms may continue for months or even years after exposure to the material ceases. This may be due to a nonallergeniccondition known as reactive airways dysfunction syndrome (RADS) which can occur following exposure to high levels ofhighly irritating compound.No significant acute toxicological data identified in literature search.UV (ultraviolet)/ EB (electron beam) acrylates are generally of low toxicityUV/EB acrylates are divided into two groups; "stenomeric" and "eurymeric" acrylates.The first group consists of well-defined acrylates which can be described by a simple idealised chemical;they are low molecularweight species with a very narrow weight distribution profile.The eurymeric acrylates cannot be described by an idealised structure and may differ fundamentally between various suppliers;they are of relatively high molecular weigh and possess a wide weight distribution.Stenomeric acrylates are usually more hazardous than the eurymeric substances.Where no "official" classification for acrylates and methacrylates exists, there has been cautious attempts to createcontinued...

Fujifilm Inkjet For RTR - CI00E<strong>Chemwatch</strong> Material Safety Data SheetIssue Date: 1-Feb-2012 CHEMWATCH 30-06309317SPVersion No:2.0Page 7 of 8Section 11 - TOXICOLOGICAL INFORMATIONclassifications in the absence of contrary evidence. For exampleMonalkyl or monoarylesters of acrylic acids should be classified as R36/37/38 and R51/53Monoalkyl or monoaryl esters of methacrylic acid should be classified as R36/37/38.Section 12 - ECOLOGICAL INFORMATIONNo dataEcotoxicityIngredient Persistence: Persistence: Air Bioaccumulation MobilityWater/SoilN- vinylcaprolactam LOW No Data LOW HIGHAvailablediphenyl(2, 4, 6- HIGH No Data LOW LOWtrimethylbenzoyl)phosphineAvailabletrimethylolpropane triacrylate, No Data No Dataethoxylated Available Availableethoxylated, propoxylated No Data No Dataphosphate Available AvailableSection 13 - DISPOSAL CONSIDERATIONS• Containers may still present a chemical hazard/ danger when empty.• Return to supplier for reuse/ recycling if possible.Otherwise:• If container can not be cleaned sufficiently well to ensure that residuals do not remain or if the container cannot be used tostore the same product, then puncture containers, to prevent re-use, and bury at an authorised landfill.• Where possible retain label warnings and <strong>MSDS</strong> and observe all notices pertaining to the product.Legislation addressing waste disposal requirements may differ by country, state and/ or territory. Each user must refer to lawsoperating in their area.A Hierarchy of Controls seems to be common - the user should investigate:• Reduction.• DO NOT allow wash water from cleaning or process equipment to enter drains.• It may be necessary to collect all wash water for treatment before disposal.• In all cases disposal to sewer may be subject to local laws and regulations and these should be considered first.• Where in doubt contact the responsible authority.• Recycle wherever possible.• Consult manufacturer for recycling options or consult local or regional waste management authority for disposal if no suitabletreatment or disposal facility can be identified.• Dispose of by: burial in a land-fill specifically licenced to accept chemical and / or pharmaceutical wastes or incineration ina licenced apparatus (after admixture with suitable combustible material).• Decontaminate empty containers. Observe all label safeguards until containers are cleaned and destroyed.Section 14 - TRANSPORTATION INFORMATIONHAZCHEM:None (ADG7)NOT REGULATED FOR TRANSPORT OF DANGEROUS GOODS: UN, IATA, IMDGSection 15 - REGULATORY INFORMATIONPOISONS SCHEDULENonecontinued...

Fujifilm Inkjet For RTR - CI00E<strong>Chemwatch</strong> Material Safety Data SheetIssue Date: 1-Feb-2012 CHEMWATCH 30-06309317SPVersion No:2.0Page 8 of 8Section 15 - REGULATORY INFORMATIONREGULATIONSRegulations for ingredientsN-vinylcaprolactam (CAS: 2235-00-9) is found on the following regulatory lists;"<strong>Australia</strong> Inventory of Chemical Substances (AICS)", "<strong>Australia</strong> National Pollutant Inventory", "OECD List of High ProductionVolume (HPV) Chemicals"diphenyl(2, 4, 6-trimethylbenzoyl)phosphine (CAS: 75980-60-8, 596818-40-5) is found on thefollowing regulatory lists;"<strong>Australia</strong> Inventory of Chemical Substances (AICS)", "<strong>Australia</strong> National Pollutant Inventory"trimethylolpropane triacrylate, ethoxylated (CAS: 28961-43-5, 75577-70-7) is found on thefollowing regulatory lists;"<strong>Australia</strong> Inventory of Chemical Substances (AICS)"ethoxylated, propoxylated phosphate (CAS: 37280-82-3) is found on the following regulatorylists;"<strong>Australia</strong> Inventory of Chemical Substances (AICS)"No data for Fujifilm Inkjet For RTR - CI00E (CW: 30-0630)Section 16 - OTHER INFORMATIONDenmark Advisory list for selfclassification of dangerous substancesSubstance CAS Suggested codesN- vinylcaprolactam 2235- 00- 9 Rep3; R63INGREDIENTS WITH MULTIPLE CAS NUMBERSIngredient NameCASdiphenyl(2,4,6-trimethylbenzoyl)phosphine 75980-60-8, 596818-40-5trimethylolpropane triacrylate, ethoxylated 28961-43-5, 75577-70-7■ Classification of the preparation and its individual components has drawn on official and authoritative sources as well asindependent review by the <strong>Chemwatch</strong> Classification committee using available literature references.A list of reference resources used to assist the committee may be found at:www.chemwatch.net/references.■ The (M)SDS is a Hazard Communication tool and should be used to assist in the Risk Assessment. Many factors determine whetherthe reported Hazards are Risks in the workplace or other settings.This document is copyright. Apart from any fair dealing for the purposes of private study, research, review orcriticism, as permitted under the Copyright Act, no part may be reproduced by any process without writtenpermission from CHEMWATCH. TEL (+61 3) 9572 4700.Issue Date: 1-Feb-2012<strong>Print</strong> Date: 4-May-2012This is the end of the <strong>MSDS</strong>.