Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

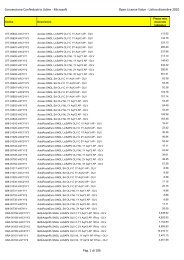

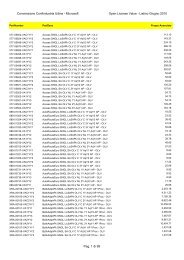

<strong>TRUCK</strong> <strong>MIXERS</strong>INNOVATIVEAESTHETICS OFTHE DRUM WITHGREATER CAPACITYThe L&T Truck Mixers are a realsystem for concrete mixing andtransport according to high qualityand functional standards. Eachtechnical detail has been conceived,designed and realized in order to makethe mixers work in perfect harmonywith the truck chassis destined for theirtransport. A wide range of capacitiesfrom 4 to 12 m 3 of vibrated concretealways guarantees low tares andoptimised carrying capacities.All L&T Truck Mixers are equippedwith hydraulic transmissions andgearboxes that allow to reachthe maximum rotation speed ofthe mixing drum when the vehicle isat 1500 revolutions/1’ (in comparisonwith the usual 1800 revolutions/1’).Such a characteristic allowsto diminish the fuel consumption,to reduce the wear and tear andto respect the environment (thanksto the low sound emissions) and toincrease the service life of the engine.TECHNICALDATAAxlesNominalCapacityGeometricalVolumeWaterVolumeMax Req.PowerMin. Lenght(H)Min. Lenght(D)Min. Width(H)Min. Width(D)HeightWeight(H)Weight(D)m 3m 3m 3kWmmmmmmmmmmKg.Kg.LT3.74x23 (4)6,7484,043354500451023002300230226503050LT4.74x248,5844,910354772500923002300237828003250LT5.76x459,4405,568404990525823002300243629003350LT6.76x4610,8546,688465249554923002300253331003600LT7.76x47 (8)12,7668,279525872607223002300266533503850LT7.7C6x4712,7667,875525853605323002500258133503850LT8.76x48 (9)13,8689,011586135673923002500273535504050LT8XL.76x48,5 (9,5)14,0149,580585135673923002500273536504150LT9.78x49 (10)16,14310,024706558728525002500273342004700LT10.78x410 (11)17,64811,241776901762825002500279344004900LT12.78x41219,62812,304777365814625002500280548005400LT14.710x51422,80014,4007785489145250025002856520060008 9

<strong>TRUCK</strong> <strong>MIXERS</strong>TECHNICALCHARACTERISTICSFLIP-OVER CHUTEIts ergonomy allows a practical and safe usethanks to the anti- trapping and anti-shear device(available in various lengths).IN CAB CONTROLSFor managing the drum form the cabin.ELECTRIC CONTROL WITH CSD SYSTEMFor a constant speed of rotation of the mixingdrum regardless of the speed of the vehiclemotor, the IMER Group truck mixers can befitted with the CSD device integrated in thecontrol panel for the electro-hydraulic controls(option).REAR WORKING LIGHTThe rear area of all truck mixers is the mostdifficult to control. The installation of the rearworking light guarantees their perfect visibilityin all operating conditions.DRUM SAFETY LOCKAll the IMER Group truck mixers areprovided with a special antirotationmechanical locking device. This mechanism,essential and easy to use, ensures theabsolute safety of all maintenanceoperations inside the mixing drum.10 11

<strong>TRUCK</strong> <strong>MIXERS</strong>PRESSURE GAUGEIt is mounted on the rear part of the truckmixers and makes the charging and themixing phases easier to manage it allowsthe control of plasticity of the concrete.SINGLE CHUTE ARM WITHOPTIMISED BRAKEThe single chute support features better availabilityfor roller greasing and access to the drum rotationblock. The handwheel offers a more ergonomic gripand makes the chute “braking” operation quickerand easier.ERGONOMIC SHAPE OF THE CASTLEIt is compact and easy to clean.MANHOLE CONFIGURATIONWITH NEW SEALThe new type of oval manhole is very linearin appearance because there are no protrusionswhere the material can pile up and it hasa perfect seal due to the use of a thick,oval-shaped gasket.MECHANICAL GEARBOX TO MEETYOUR NEEDSIt is oversized to meet the high torque demandedby the concrete drum.HYDRAULIC PUMP SUPPORTThe innovative support is bolted onto thesubframe in an intermediate position tocover almost all the PTO pump positions,resulting in a great advantage for ourfitters.12 13

<strong>TRUCK</strong> <strong>MIXERS</strong>SAFETY GRIDFor the safe inspection of the charginghopper.TRIGGER TYPE CONTROLS (JOY)AND EMERGENCY STOPMUD FLAPSMUDGUARDSThey are available in steel or alluminium(for the superlight version).WATER TANKAll IMER Group truck mixers areprovided, in the standard version,with a 650 l water tank, and foroption available in different size,stainless steel or pressurized systems.NEW FALL-PREVENTION SYSTEMThe new fall-prevention system has beenengineered to keep within the machineclearance and to avoid taking the righthandoff when going up to the platform.The system is operated directly by theoperator when he is on the platform.14 15

<strong>TRUCK</strong> <strong>MIXERS</strong>REAR BUMPERThe rear bumper (also availablein retractable and fixed version) isextremely safe, practical to useand very flexibile on site.SUPERLIGHT EXTENSION CHUTESThe standard supply includes two“superlight” polystone extension chutes.Their lightness (only 7 kg) makes themextremely easy to handle, cutting downthe risk of accidents to a minimum.SIDE ALUMINIUM CYCLIST BARRIERSSpecial “anticatch” barriers ensure safetyon the road and in the working site duringthe usual operations of the truck mixer.ERGONOMIC LADDERThe slip proof steps and thelarger platform allow a perfectvisual of the concrete in safety.16 17

<strong>TRUCK</strong> <strong>MIXERS</strong>OPTIONALSTOOL BOX“A place for everything, everything in its place”.Sometimes wasting time, or even losing tools alongthe way, can be not only costly but also extremelydangerous.ADDITIVE TANKThe stainless-steel pressure tank for additivesis provided with a pressure-control safetysystem and a level control for perfect metering.The corrosion-resistant tank is fitted with alarge safety cap for fast and easy filling.CLOSING FLAPThe simple and practical closing flap stands outfor its cost efficiency in preventing the spills ofgrouts and concrete residues during the movementsof the discharge chute, avoiding pollutionto the environment in the vicinity of the castingoperation.VIBRATOR ON DISCHARGE CHUTEThis dispositive allows, during the discharge,an optimum flow even in presence of specialconcrete.SIDE PROTECTION GUARDSTheir function is to protect the vehicle fromthe eventual corrosive action of the specialconcrete and demoulding chemicals.HYDRAULIC HALF PLUGTo carry particularly fluid material on roughor steep terrain, it becomes necessary toinstall the hydraulic half plug to preventspills of polluting material during thejourney or inside the work yard.ECOLOGICAL HYDRAULIC PLUGThe charging of dry material in thebatching plant and the following mixing inthe drum mixer are a cause of dust spillsfrom the drum: this closing device definitelysolves this problem. Adapting the L&Ttruck mixers to a philosophy of respect forhealth and the environment is fast andconvenient.LT555 TELESCOPIC CHUTEThe LT 555 telescopic chute is animportant accessory designed to increasethe versatility of the L&T truck mixer.The LT 555 telescopic chute, extendingto 4.5 metres in length (5.5 metres withthe funnel end), can be ordered in allmodels. Reliable and safe, with a stainlesssteelconstruction: it is light, strong andextremely manoeuvrable, both verticallyand radially.18 19

<strong>TRUCK</strong> <strong>MIXERS</strong>20 21

<strong>TRUCK</strong> <strong>MIXERS</strong>ARTICSEMI-TRAILER<strong>MIXERS</strong>These special truck mixers are installedon large building sites and are able totransport up to 14 m 3 of concrete. Theyare usually installed on large buildingsites, so the truck is immediately freeand can be used for other operations.This mixer is absolutely independentfrom the truck and it is a stock ofconcrete ready to be used on site.It is available with 2 or 3 axlesdepending on the local regulations orthe number of the axles of the truck.22 23

<strong>TRUCK</strong> <strong>MIXERS</strong>SL SUPERLIGHT<strong>TRUCK</strong> <strong>MIXERS</strong>The new range of SUPER LIGHTtruck mixers has been completelyredesigned to guarantee maximumpayload, in full compliance with theweight limits of the traffic regulations.Thanks to the special IMER WEARsteel, it is superlight and much morewear resistant.The mixing drum is realized inspecial IMER WEAR steel havingmechanical characteristics superiorto the materials utilized so far forconstructing truck mixers. The wearresistance of the IMER WEAR steelallows to reduce the steel sheetthickness up to 3 mm, keeping, orbetter, increasing, its life.24 25

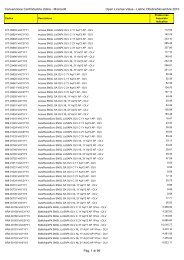

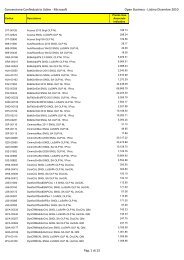

<strong>TRUCK</strong> <strong>MIXERS</strong>TECHNICALCHARACTERISTICSALUMINIUM WATER TANK ALUMINIUM MUDGUARDS LIGHTWEIGHT DISCHARGE CHUTEIN WEAR RESISTANT MATERIALSUPERLIGHT AND EXTREMELYRESISTANT DRUM IN IMER WEARSTEELSUPERLIGHT EXTENSION CHUTESTECHNICALDATAAxlesNominalCapacityGeometricalVolumeWaterVolumeMax Req.PowerMin. Lenght(H)Min. Lenght(D)Min. Width(H)Min. Width(D)HeightWeight(H SL)Weight(D SL)m 3m 3m 3kWmmmmmmmmmmKg.Kg.LT3.74x23 (4)6,7484,0433545004510230023002302LT4.74x248,5844,910354772500923002300237824052855LT5.76x459,4405,568404990525823002300243624862936LT6.76x4610,8546,688465249554923002300253326483148LT7.76x47 (8)12,7668,279525872607223002300266528553355LT7.7C6x4712,7667,875525853605323002500258128553355LT8.76x48 (9)13,8689,011586135673923002500273530323532LT8XL.76x48,5 (9,5)14,0149,580585135673923002500273530903590LT9.78x49 (10)16,14310,024706558728525002500273335994099LT10.78x410 (11)17,64811,241776901762825002500279338584358LT12.78x41219,62812,304777365814625002500280539744574LT14.710x51422,80014,40077854891452500250028564444524426 27

<strong>TRUCK</strong> <strong>MIXERS</strong>L&T DETACHABLES <strong>TRUCK</strong> <strong>MIXERS</strong>L&T truck mixer range also includes the detachables truck mixers. Theyare offered in two versions for the two categories of vehicles: thoseequipped with manual anchoring system and those with remote controlanchoring system (as following in the pictures).28 29

FOCUS TO THE CUSTOMERSERVICE TEAMSALES DEPARTMENTGianfranco Amaddeo: Sales Directorg.amaddeo@oru.itfaxph.+39.0432.562131+39.0432.563965ItalyAlfonso Sciandra: Area ManagerPaolo Berton: Area Managera.sciandra@oru.itp.berton@oru.itph.ph.+39.0432.563975+39.0432.563976ExportMichele Sebastiani: Export Area ManagerElia Vendramini: Export Area ManagerMassimo Grosso: Export Area ManagerMalvio Leita: Export Area Managerm.sebastiani@oru.ite.vendramini@oru.itm.grosso@oru.itm.leita@oru.itph.ph.ph.ph.+39.0432.563927+39.0432.563974+39.0432.563920+39.0432.563985MARKETING DEPARTMENTLoredana Viel: Marketing Managerl.viel@oru.itfaxph.+39.0432.562131+39.0432.563982TECHNICAL ASSISTANCEAND SPARE PARTS DEPARTMENTLorenzo Maestroni: After sales ManagerAndrea Carta: Sales of Spare PartsMario Cristin: Technical Assistanceastec@oru.itl.maestroni@oru.ita.carta@oru.itm.cristin@oru.itfaxph.ph.ph.+39.0432.563926+39.0432.563809+39.0432.563924+39.0432.563980CUSTOMER CARETamara Veniert.venier@oru.itph.+39.0432.563925ACCOUNTING DEPARTMENTMariolina Murianni: Accounting Managerm.murianni@oru.itfaxph.+39.0432.561463+39.0432.56395930 31

EDIZIONE 1/2007Le Officine Riunite - Udine S.p.A.Concrete Machinery DivisionVia Santa Caterina, 35 · 33030 Basaldella di Campoformido (Ud)Tel. +39 0432 563911 · Fax +39 0432 562131E-mail: oru@oru.it · www.imergroup.comLe Officine Riunite - Udine S.p.A. si riservano il diritto di variare senza preavviso i dati espostiquando vi siano giustificati motivi. I dati e le misure non sono quindi da ritenersi impegnativi.Le illustrazioni possono contenere accessori e quindi non conformi alle versioni standard delle macchine.Le Officine Riunite - Udine S.p.A. reserve the right to change the information contained herein withoutprior notice where they consider it justified. The data and dimensions are therefore not to be consideredas binding. The illustrations may include accessories and therefore they could be slightly different fromthe standard versions of the equipment.