SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

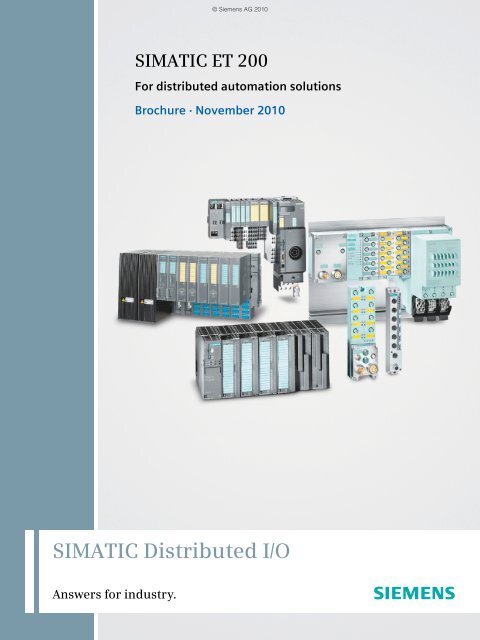

© Siemens AG 2010<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong><strong>For</strong> <strong>distributed</strong> <strong>automation</strong> <strong>solutions</strong>Brochure · <strong>November</strong> 2010<strong>SIMATIC</strong> Distributed I/OAnswers for industry.

© Siemens AG 2010ContentsTo be able to respond to the increasing internationalcompetitive pressure, it is more important than ever toconsistently make full use of the potential for optimization– over the complete lifecycle of a machine orplant.Optimized processes reduce the total cost of ownership,shorten the time to market, and improve quality.This perfect balance between quality, time, and costs isnow, more than ever, the decisive success factor in industry.Totally Integrated Automation is optimally aligned to allrequirements and open for international standards andthird-party systems. With its six characteristic systemfeatures, Totally Integrated Automation supports thecomplete lifecycle of a machine or plant. The completesystem architecture offers holistic <strong>solutions</strong> for every<strong>automation</strong> segment on the basis of a comprehensiverange of products.<strong>SIMATIC</strong>: more efficient and systematic <strong>automation</strong><strong>SIMATIC</strong>, a core component of Totally Integrated Automation,includes a variety of standardized, flexible, andscalable products – such as the <strong>distributed</strong> I/O devicesof the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> portfolio presented in this brochure.<strong>SIMATIC</strong> is currently considered to be the global numberone in <strong>automation</strong>. One of the decisive reasons forthis is that <strong>SIMATIC</strong> exhibits the six system features ofTotally Integrated Automation:• Engineering• Communication• Diagnostics• Safety• Security• RobustnessIn addition, <strong>SIMATIC</strong> features two additional systemfeatures:• Technology• High availabilityAs an integral part of the <strong>SIMATIC</strong> range, the <strong>SIMATIC</strong><strong>ET</strong> <strong>200</strong> <strong>distributed</strong> I/O system can offer you a host ofbenefits that are described in detail on the followingpages.Totally Integrated System Automation features 5

© Siemens AG 2010System featuresThe overviewEngineeringMaximum engineering efficiency –in all phases of the lifecycle of the machine and plantWith <strong>SIMATIC</strong> you rely on an integrated engineering environment. Efficient software supportsyou over the complete lifecycle of your machine or plant – from the planning and designstages through configuring and programming as far as commissioning, operation and upgrading.With its integration capability and harmonized interfaces, <strong>SIMATIC</strong> software supportsa high degree of data consistency – throughout the entire engineering process.CommunicationsMaximum data transparency on all <strong>automation</strong> levels –based on proven standards<strong>SIMATIC</strong> creates the foundations for unlimited integration in communication – and thus formaximum transparency on all levels, from the field and control level to the operations managementlevel all they way up to the corporate management level. <strong>SIMATIC</strong> relies on international,cross-vendor standards which can be combined flexibly: PROFIN<strong>ET</strong>, the leading IndustrialEthernet standard and PROFIBUS, the global No. 1 fieldbus.DiagnosticsMinimization of downtimes –through efficient diagnostic conceptsAll <strong>SIMATIC</strong> products feature integrated diagnostic functions with which a fault can be identifiedand eliminated to provide increased system availability.Even with larger plants, the Maintenance Station provides you with a uniform view of themaintenance-relevant information of all <strong>automation</strong> components.SafetyProtection of personnel and machines –within the framework of an integrated complete system<strong>SIMATIC</strong> Safety Integrated offers TÜV-certified products, which facilitate compliance with relevantstandards: IEC 62061 up to SIL 3, EN ISO 13849-1 up to PL e, as well as EN 954-1. Due tothe integration of safety technology in standard technology, only one controller, one I/O, oneengineering, and one bus system are required. Thus the system advantages and comprehensivefunctionality of <strong>SIMATIC</strong> are also available for fail-safe applications.6 System features

© Siemens AG 2010Data security in the networked world – through harmonized, scalablesecurity systemsWith <strong>SIMATIC</strong> you can use all the advantages that result as the worlds of <strong>automation</strong> and officegrow together more and more: Seamless exchange of data across all levels (CollaborativeManufacturing), or access to production data via the Internet from any location. In order tomeet the resulting increased security requirements, <strong>SIMATIC</strong> offers you IT Security for the protectionof production and data, e.g. by means of firewall functions, access protection, encryption,and Virtual Private Networks.SecurityMaximum industrial suitability – through increased robustnessEach standard product from the <strong>SIMATIC</strong> range is characterized by the highest quality and robustnessand is perfect for use in industrial environments. Specific system tests ensure theplanned and required quality. <strong>SIMATIC</strong> components meet all relevant international standardsand are certified accordingly. Temperature and shock resistance are defined in the <strong>SIMATIC</strong>quality guidelines, as are vibration resistance or electromagnetic compatibility.<strong>For</strong> demanding to extreme rated conditions, special versions such as SIPLUS extreme or specialversions of <strong>SIMATIC</strong> <strong>ET</strong><strong>200</strong> are available. These include an increased degree of protection,extended temperature ranges, and exceptional environmental stress.RobustnessMore possibilities, less complexity –through integrated technology functionalityCounting and measuring, cam control, closed-loop control, or motion control: You can integratetechnological tasks in many different combinations and with various degrees of complexitywithout a system changeover into the world of <strong>SIMATIC</strong> – easily, conveniently, consistently.Parameter assignment and programming are implemented in the familiar STEP 7environment.TechnologyMaximum availability –with integrated high availability conceptsSiemens offers a comprehensive high availability concept to ensure high availability for theentire plant: from the field level to the control level all the way up to the management level.<strong>For</strong> example, field-tested controllers ensure high availability through bumpless switching withautomatic event synchronization.High availabilitywww.siemens.com/simatic-system-featuresSystem features 7

© Siemens AG 2010EngineeringMaximum engineering efficiency –in all phases of the lifecycle of the machine and plantStandardized design and engineering …… for all <strong>automation</strong> componentsOperationsmanagement levelEngineering Station<strong>SIMATIC</strong> WinCCControl levelPROFIN<strong>ET</strong>Industrial EthernetProject databaseDigital Engineering• <strong>SIMATIC</strong> Automation DesignerEngineering Software• <strong>SIMATIC</strong> STEP 7• <strong>SIMATIC</strong> WinCC / WinCC flexibleField levelHMIPROFIBUSControllerDrivesDistributed IOWith <strong>SIMATIC</strong> you rely on an integrated engineering environment.Efficient software supports you over thecomplete lifecycle of your machine or plant – from theplanning and design stages through configuring andprogramming as far as commissioning, operation andupgrading.With its integration capability and harmonized interfaces,<strong>SIMATIC</strong> software permits a high degree of dataconsistency – throughout the entire engineering process.Data consistency in the entire project• Variables only have to be entered and configured inone editor• Project-wide synchronizationModularity through blocks• Program sections and user interfaces can be createdmodularly as reusable blocks• Program modules can be loaded into the <strong>automation</strong>system during operation• In addition, expansions and changes to the hardwareconfiguration are possible during operationShared configuration for the complete <strong>automation</strong>hardware• Shared hardware configuration• Shared network configurationOpen data interfaces• Third-party components can be incorporated basedon GSD/EDD• Import/export interfaces permit data exchange withthird-party software (MS Excel)• Data transfer from planning software – e.g. fromelectrical engineering department (CAE)• Ability to incorporate Visual Basic scripts for furtherprocessingData archiving• All data, hardware configuration data, programs,user interfaces are saved and archived in one projectMultilingual/internationality• The user interface of many software packages isavailable in six or more languages• The interfaces of the HMI devices (operator panels)can be created in various languages, even duringoperation – as can the program comments within<strong>SIMATIC</strong> STEP 7Standard programming languages• Six PLCopen or IEC 61131-3-compliant programminglanguages• PLCopen-certified motion control blocks8 System features

© Siemens AG 2010CommunicationsMaximum data transparency on all <strong>automation</strong> levels –based on proven standardsCorporate management level/Production management levelControl levelEthernetOperations management levelPROFIN<strong>ET</strong>IWLANInternet<strong>SIMATIC</strong>WinCCSwitchIndustrial EthernetControllerControllerHMIField levelDistributedI/ODistributedI/OIWLANPROFIBUSAS-InterfaceDrivesDrivesWith <strong>SIMATIC</strong> you create the prerequisite for full integrationof communication – and thus for maximumtransparency from the field and control level via theoperations management level all the way up to the corporatemanagement level. <strong>SIMATIC</strong> relies on international,cross-vendor standards which can be combinedflexibly: PROFIN<strong>ET</strong>, the leading Industrial Ethernet standardand PROFIBUS, the global No. 1 fieldbus.With <strong>SIMATIC</strong>, relevant information is thus available atany time throughout the plant. This enormously simplifiescommissioning, diagnostics, and maintenance –even wirelessly or over the Internet. It is also possibleto access the components from anywhere in order tointervene in the process if necessary.Plant-wide or company-wide data access• Integrated communications options via all <strong>automation</strong>levels- Management level- Operations management level- Control level- Field levelCombinable bus systems• Existing communications structures can be integratedand/or retained with the CP/Link communicationsprocessors (PROFIN<strong>ET</strong>, PROFIBUS, AS-Interface, etc.)Wireless communication• Support for wireless communication based on IndustrialWireless LAN – even safety functionality is implementedthrough IWLAN communicationRouting function• System-wide access to all components – for facilitatedcommissioning, diagnostics, and remote maintenanceIntegration in office applications• OPC and OPC XML for the connection of office applications• Web server functionality for access to device information(z. B. diagnostic buffer) from every InternetreadyPCFlexibility and scalability• Flexible combination options of the communicationstandard – without affecting the performance of asystem (safety, diagnostics, etc.)• Implementation of time-critical applications up toisochronous modeSystem features 9

© Siemens AG 2010DiagnosticsMinimization of downtimes –through efficient diagnostic conceptsOperations management level<strong>SIMATIC</strong> WinCC Maintenance StationPlant-wide diagnosticsTransfer of configuration from STEP 7Control levelPROFIN<strong>ET</strong>Industrial EthernetEngineering<strong>SIMATIC</strong>STEP 7Line-width displayof informationPROFIBUSDiagnosticsenablingHMIControllerDetectionof faultField levelDrivesDistributedI/OAll <strong>SIMATIC</strong> products feature integrated diagnosticfunctions with which a fault can be detected and eliminatedefficiently to provide increased system availability.Even with larger plants, the Maintenance Stationprovides you with a uniform view of the maintenancerelevantinformation of all <strong>automation</strong> components.This increases Overall Equipment Efficiency (OEE), minimizesdowntimes, and saves costs.Integrated diagnostics• Totally Integrated Automation offers products andmodules with integrated diagnostic function• Plant-wide system diagnostics for detection and automaticsignaling of faults• Additional messages for monitoring the application/process (process diagnostics) are easy to configureand can be generated automaticallyDiagnostics can be activated, no programming is required• The diagnostic function of the modules is easily activatedin <strong>SIMATIC</strong> STEP 7• Message texts are available in five languages• Predefined message windows/views for visualizationon the HMI deviceConsistent diagnostics from the field level to themanagement level• System states (module and network status, systemerror messages) are available plant-wide with consistentdisplay.• Diagnostics displays with different degrees of detail(hierarchy) are automatically generated from configurationdata (HW Config)Diagnostics with display of relevant information• Error text information• Unique module identification (number)• Address/slot information• Chronological time stamp10 System features

© Siemens AG 2010SafetyProtection of personnel and machines –within the framework of an integrated complete systemPreviously: Standard and safety <strong>automation</strong> – divided into two systemsEmergency stopEmergency stopStandardControllerStandardI/OFail-safeControllerPROFIBUSEmergency stopSafety busNew: standard and safety <strong>automation</strong> – integrated in one systemEmergency stopEmergency stopFail-safe<strong>SIMATIC</strong>ControllerStandard andfail-safe I/OEmergency stopPROFIN<strong>ET</strong>/PROFIsafePROFIBUS/PROFIsafeAs a machine builder and plant constructor and operator,you are obliged by law to ensure the safety of personneland the environment. With Safety Integrated,Siemens offers TÜV-certified products to meet theseguidelines and that simplify compliance withrelevant standards: IEC 62061 up to SIL 3, EN ISO13849-1 up to PL e, as well as EN 954-1 up to Cat. 4.In the spirit of Totally Integrated Automation, safety-relatedfunctions are integrated into standard <strong>automation</strong>with Safety Integrated. Thus Siemens offers a completeand integrated safety program – from detection to evaluationto reaction.One of the cornerstones is <strong>SIMATIC</strong> Safety Integrated –the fail-safe control system. By integrating safety intostandard technology, only one controller, one I/O, oneengineering, and one bus system are required. Thus thesystem benefits and comprehensive functionality of<strong>SIMATIC</strong> are also available for fail-safe applications.The result: A significant reduction in engineering overheadand the number of hardware components.One controller for Standard and Safety• Comprehensive self-tests and self-diagnostics of thefail-safe <strong>SIMATIC</strong> Controllers• Simultaneous processing of the standard and safetyprogram on one controllerMixed configuration of I/O• Space-saving setup thanks to the combination of failsafemodules and standard modules in one stationUniform engineering• All programming (standard and safety) is implementedin the proven STEP 7 environment• Programming as needed with ready-made, TÜV-certified,or user-created blocksFail-safe communication• Fail-safe communication over the global proven communicationstandards PROFIN<strong>ET</strong> or PROFIBUS, withthe PROFIsafe profile• Innovative approaches such as wireless fail-safe communicationover IWLAN (Industrial Wireless LAN) andPROFIN<strong>ET</strong> – e.g. using the <strong>SIMATIC</strong> Mobile Panel277F IWLAN with integrated safety functionDiagnostic function• Identical system diagnostics of safety modules andstandard components: Uniform function, display, parameterizationas well as easy activation of the diagnosticfunction without programmingSystem features 11

© Siemens AG 2010SecurityData security in the networked world –through matched, scalable security conceptsCorporate management,production management, andoperations management -levelControl andfield levelPROFIN<strong>ET</strong>Industrial EthernetServerEngineering <strong>SIMATIC</strong> STEP 7/WinCC flexibleSwitch<strong>SIMATIC</strong> STEP 7/Project dataSecuritymoduleLogfileSecuritymoduleLogfileWith <strong>SIMATIC</strong> you can use all the advantages that resultas the worlds of <strong>automation</strong> and office grow togethermore and more: Seamless exchange of data across alllevels (Collaborative Manufacturing), or access to productiondata via the Internet from any location. In orderto meet the resulting increased security requirements,<strong>SIMATIC</strong> offers you IT Security for the protection of productionand data.With the SCALANCE S device family or the SOFTN<strong>ET</strong> SecurityClient, firewall functions, access protection, encryption,VPNs, etc. can be implemented very easily –to protect plants and machinery. With <strong>SIMATIC</strong> Logon,the engineering or control system is extended with auser administration function, with which plant personnelcan be assigned role-based access rights to controlmachinery or plants.Total protection of plants, machinery, and expertise:• Low administrative effort without IT expertise• Support for relevant IT security standards such asfirewalls, VPN, WEP, WPASecurity architecture on every level:Defense in Depth• Physical separation and access protection• Levels can function autonomously• Clearly defined and monitored access points betweenlevelsUniform user administration (Single Logon)• Uniform user management for secure authenticationof the user12 System features

© Siemens AG 2010RobustnessMaximum industrial suitability – through increased robustnessSystem/device levelShock/vibration resistanceShielding for EMCTemperature range +5 to +45 °CDrive andstation levelShock/vibration resistanceCoated modulesPositive ConnectionsHot swappingShielding for EMCModule/submodule levelReplaceable terminal boxCoding of connecting terminalsGold-plated pinsShielding for EMCConnection levelRJ45 connector in industrial designShielding for EMCWith any standard product from the <strong>SIMATIC</strong> range, yourely on maximum quality and robustness – perfect foruse in industrial environments. Specific system testsensure the planned and required quality of each individualcomponent. <strong>For</strong> example, <strong>SIMATIC</strong> IPCs undergomore than 50 tests to ensure industrial compatibility.Of course, <strong>SIMATIC</strong> components meet all relevant internationalstandards and are certified accordingly. Sensitivityto temperature, shock and vibration are definedin the <strong>SIMATIC</strong> Quality Guidelines as well as EMC resistanceand versions for use in hazardous areas.The <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> range also includes standard productswith IP67 degree of protection which are dustproofand protected from temporary submersion.Suitable for industry – even under difficult operatingconditions• An integrated range of products for all industrialapplication areas and extremely rough conditions• Maximum robustness at all levels of <strong>automation</strong> andfor all applications: from field devices to control unitsto operator panels• Can be used direct on the machine or close to theprocess – even without a control cabinet, i.e. withoutrequiring installation and wiringSIPLUS extreme modules from the <strong>SIMATIC</strong> spectrum,e.g. <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> in special design, are available forindustrial applications with difficult to extreme operatingconditions. SIPLUS extreme components aresuitable for use in expanded range of ambient temperatureas well as in corrosive environmental conditions,salty ambient air, condensation and deposits of conductivedust.This enables their use in harsh industrial environmentsor outdoors, without the need for additional precautionssuch as enclosures or air conditioning.System features 13

© Siemens AG 2010TechnologyMore possibilities, less complexity –through integrated technology functionalityOPPCTechnology CPUS7-300S7-<strong>200</strong> <strong>ET</strong> <strong>200</strong>SPROFIBUS DP (DRIVE)IsochronousMICRO-MASTERSIMODRIVESensorSIMO-DRIVEMASTERDRIVESSINAMICS SCounting and measuring, cam control, closed-loop control,or motion control: You can integrate technologicaltasks in many different combinations and with variousdegrees of complexity without a system changeoverinto the world of <strong>SIMATIC</strong> – easily, conveniently, consistently.Thanks to maximum freedom and scalability whenchoosing a software or hardware-based solution,<strong>SIMATIC</strong> Technology allows the effective implementationof technological functions at an excellent priceperformanceratio. Parameter assignment and programmingare implemented in the familiar STEP 7environment.<strong>For</strong> example, in technology controllers, the PLCopencertifiedmotion control modules are integrated in astandard S7-300 CPU. They are therefore especiallysuited for coupled motion sequences of multiple axes.The isochronous PROFIBUS ensures maximum precisionof fast processing operations.Integrated technology functions• CPU/STEP 7-integrated functions – for compact machineswith few axes and counter/control channels• Loadable, software-based function blocks – for flexibleimplementation on almost all <strong>SIMATIC</strong> hardwareplatforms• <strong>ET</strong> <strong>200</strong>S modules – <strong>distributed</strong> <strong>solutions</strong> through intelligentI/O modules• Parameterizable function modules – for high demandson accuracy and dynamic response• Technology controllers – Solution to comprehensivemotion control tasks with high performance• Freely-configurable application modules and closedloopcontrol systems – for very complex technologytasks with highest performance14 System features

© Siemens AG 2010High availabilityMaximum availability – with integrated high availability conceptsRedundant controller<strong>SIMATIC</strong> S7-400HSwitched,<strong>distributed</strong> I/O,e.g. <strong>ET</strong> <strong>200</strong>MPROFIBUSDP/PA linkor Y linkPROFIBUS PADowntimes in <strong>automation</strong> systems can lead to complicatedre-start procedures, which cripple entire processesand production sequences and can result in veryhigh costs – in any industry. Risk factors such as poweroutages, water damage, fire outbreaks, or lightningstrikes, but also system failures or operator errors, cansignificantly affect the operation of a plant.<strong>For</strong> high plant availability, Siemens offers a comprehensivehigh availability concept for the whole plant andon all levels of <strong>automation</strong>. This helps prevent the highcost of downtime. <strong>For</strong> example, field-tested controllersensure high availability through bumpless switchingwith automatic event synchronization. Where necessary,the controllers can even be up to 10 km apart.High availability options• Interruption-free operation due to redundant controllers• Redundant I/O – for a loss-free signal transfer fromthe field devices to the control system• Redundant servers – for complete integrity of plantdata; redundant archive servers can also be implemented• Fault-tolerant fieldbuses – for reliable communicationfrom the field devices to the controller via <strong>distributed</strong>I/OEfficient programming and configuring of scalable<strong>solutions</strong>• Highly efficient <strong>solutions</strong> – with scalable performanceand flexibly adjustable degree of high availability• Easy integration of safety functions• Simple programming and configuration in the familiarSTEP 7 engineering environmentAdvantages in operation• Problem-free exchange of all components duringoperation• Changes to configuration during operation• Highest system availability with early fault detectionand integrated diagnostic capabilities• No data loss in the event of failure – thanks to theevent-driven synchronization of the controllers andredundant serversSystem features 15

© Siemens AG 2010Distributed <strong>automation</strong>The right solution for any requirementYou are constantly on the look out for possibilities of optimizingproduction and reducing costs? With increasing competitionit is essential to provide individual machinery and plantsas fast and cost-effectively as possible? This starts with thedesign of your machine and continues through installation,commissioning and normal operation right up to maintenance.Uniform engineering, comprehensive functionality, simple installationand high-precision diagnostics from any point in theplant are essential – and it all needs to be based on internationalstandards.Ahead of the competition thanks to consistentdecentralizationFlexible, <strong>distributed</strong> <strong>solutions</strong> are an essential part of modern<strong>automation</strong> – <strong>solutions</strong> that are tailored to your requirementsand permit significant cost savings. Whether compact ormodular, purely digital I/O interfaces or complete <strong>distributed</strong>systems with drive technology, installed in the control cabinetor directly in harsh industrial environments.<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> – the right solution for every applicationWith <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> a wide range of <strong>distributed</strong> I/O systemsis available – for <strong>solutions</strong> in the control cabinet or without acontrol cabinet directly at the machine, as well as for applicationsin hazardous areas. <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> systems for cabinetfreeconfigurations are installed in a rugged, fiber-glass reinforcedplastic enclosure, making them resistant to shock anddirt, as well as watertight. Furthermore, you need fewer additionalcomponents, save on cabling, and profit from extremelyfast response times.The modular design makes it possible to scale and expand the<strong>ET</strong> <strong>200</strong> systems simply and in small stages. Already integratedadd-on modules reduce costs, and at the same time offer awidely diverse range of possible applications. You can choosefrom many different combination options: digital and analoginputs/outputs, intelligent modules with CPU functionality,safety engineering, motor starters, pneumatic systems, frequencyconverters, and diverse technology modules.Communication over PROFIN<strong>ET</strong> and PROFIBUS, uniform engineering,transparent diagnostic possibilities as well as optimalinterfacing to <strong>SIMATIC</strong> controllers and HMI units prove theunique integration of Totally Integrated Automation.In a control cabinet (IP20)Without control cabinet (IP65/67)MultifunctionalCompact andexpandableBlockMultifunctional Block Block<strong>ET</strong> <strong>200</strong>S <strong>ET</strong> <strong>200</strong>S COMPACT <strong>ET</strong> <strong>200</strong>L<strong>ET</strong> <strong>200</strong>pro <strong>ET</strong> <strong>200</strong>eco PN <strong>ET</strong> <strong>200</strong>ecoModularIntrinsically-safeRobot<strong>ET</strong> <strong>200</strong>M<strong>ET</strong> <strong>200</strong>iSP<strong>ET</strong> <strong>200</strong>R16Distributed <strong>automation</strong>

© Siemens AG 2010Distributed fieldbus systems are elementary componentsof the <strong>automation</strong> landscape Communication is performedat the field level with PROFIN<strong>ET</strong> and PROFIBUS –these systems ensure rapid data transfer between thecomponents and consistent decentralization of the <strong>automation</strong>solution.In addition to the fieldbus systems, the point-to-point connectionI/O-Link is also available for intelligent connectionof sensors and actuators.The use of open communication standards offers flexible connectionpossibilities – whichever system you decide on. Youalso have flexibility with the <strong>ET</strong><strong>200</strong> systems – most systemscommunicate both over PROFIN<strong>ET</strong> and PROFIBUS.Distributed fieldbus systemsManagement levelOffice environmentCell levelField levelPROFIN<strong>ET</strong>PROFIBUSIntelligent sensor/actuatorinterfacing with IO-LinkPROFIN<strong>ET</strong>With 2.1 million nodes installed, PROFIN<strong>ET</strong> is the world'sleading Industrial Ethernet standard. The forecast annualgrowth of more than 30% emphasizes the strong position.Company-wide <strong>automation</strong> with PROFIN<strong>ET</strong>:PROFIN<strong>ET</strong> – the open Industrial Ethernet Standard for <strong>automation</strong>– ensures integrated communication.Existing fieldbus systems can be easily integrated. This protectsyour investments for the future. With PROFIN<strong>ET</strong>, theestablished IT services (e.g. web services, remote services,TCP/IP communication) can be used easily. PROFIN<strong>ET</strong> offersinnovative diagnostics options, new functions such asShared Service, I-Device, MRP (Media Redundant Protocol),and high performance. This enables new, user-friendlyapplications, such as wireless, high-precision <strong>automation</strong>with Industrial Wireless LAN.PROFIBUSPROFIBUS is the No. 1 fieldbus – the proof lies in the 31.4million nodes installed worldwide.PROFIBUS is not only implemented in the manufacturingarea, but it can also be used throughout the process industry– even in hazardous areas. Standard interfaces supportquick and easy connection of the I/O to your systems andtherefore integrated communication from the cell leveldown to the field level.IO-LinkIO-Link is the smart concept for the standardized linking ofsensors and switching devices to the control level by meansof an economical point-to-point connection. This new communicationsstandard below the fieldbus level allows centralfault diagnosis and location as far as the sensor/actuatorlevel and simplifies commissioning and maintenance byallowing the parameter data to be modified dynamically,direct from the application.Distributed <strong>automation</strong> 17

© Siemens AG 2010Product range at a glanceSolutions in a control cabinet (IP20)<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S –the all-rounder with a comprehensive range of functions■ Discretely modular configuration with multi-conductor connection■ Multifunctional thanks to a wide range of modules: motor starters, frequency converters,safety technology, technology modules, <strong>distributed</strong> intelligence, as well as IO-Link modules■ Use in hazardous area (Zone 2)■ Also available as a high-speed (HS) version for high performance and maximum precision■ Also available as expandable block version with integral DI/DO: <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S COMPACT<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>M –the multi-channel S7-300■ Modular design using standard <strong>SIMATIC</strong> S7-300 modules; redundant design also possible■ Fail-safe I/O modules■ High channel density with up to 64 channels per module■ <strong>For</strong> use in hazardous areas up to Zone 2, sensors and actuators up to Zone 1.■ High plant availability thanks to redundancy, hot swapping, and configuration changesduring operation<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>L –digital block I/O■■■Low-cost digital block I/ODigital electronic blocks of up to 32 channelsSimple configuration and design<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>iSP –the intrinsically-safe version for hazardous areas■■■■■Modular design, also available with redundancyRugged, intrinsically-safe designFail-safe I/O modulesUse in hazardous areas up to Zone 1/21, sensors and actuators may even be located inZone 0/20High plant availability thanks to redundancy, hot swapping, and configuration changesduring operation18Product range at a glance

© Siemens AG 2010Solutions without a control cabinet (IP65/67)<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>pro –modular and multi-functional■■■■■Modular design with an extremely compact enclosureEasy installationMultifunctional thanks to a wide range of modules – from simple inputs and outputs throughsafety systems, motor starters and frequency converters to the MOBY identification systemHigh plant availability thanks to hot swapping and permanent wiringExtensive diagnostics<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>eco PN –Block I/O with PROFIN<strong>ET</strong> connectionNEW■■■■■Low-cost, space-saving block I/OsDigital modules with up to 16 channels (can also be parameterized)Analog modules, IO-Link Master and load voltage distributorPROFIN<strong>ET</strong> connection with 2-port switch in each moduleCan be flexibly <strong>distributed</strong> in the plant via PROFIN<strong>ET</strong> in a line and/or star topology<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>eco –digital block I/O■■■■Low-cost digital block I/OFlexible connection optionsFail-safe modulesHigh plant availability – the electronic block can be easily replaced during operation withoutany interruption in bus communication or power supply<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>R –the solution for robots■■■Specially for use on robots, e.g. in body-in-white assembly in the automotive industryMounted directly on the chassisResistant to weld spatter thanks to heavy-duty metal enclosureProduct range at a glance 19

© Siemens AG 2010Product overview■ <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> for the control cabinetI/O system <strong>ET</strong> <strong>200</strong>S <strong>ET</strong> <strong>200</strong>M <strong>ET</strong> <strong>200</strong>L <strong>ET</strong> <strong>200</strong>iSPSpecial applicationsConfigurationDegree of protection IP20 IP20 IP20 IP30Construction typeBit-modular,Modular Block Modularexpandable blockMounting DIN rail Mounting rail DIN rail Mounting railConnection system for sensors/actuators Multi-conductor connectionSingle-conductorconnectionMulti-conductorconnectionMulti-conductorconnectionSpring-loaded/screwtype,Fast ConnectSpring-loaded/screwtype,Fast Connect,Top ConnectSpring-loaded/screw-typeSpring-loaded/screw-typeSafety technology n n n<strong>For</strong> use in hazardous areas Zones 2, 22 Zones 2, 22 Zone 1, 21Increased availability Switched, redundant Switched, redundantTemperature range 0 °C … +60 °C 1) 0 °C … +60 °C 1) 0 °C … +60 °C 1) -20 °C to +70 °CVibration resistance (continuous) 2 g 1 g 1 g 1 gCommunicationPROFIN<strong>ET</strong> (copper/fiber-optic) n / n n / -PROFIBUS (copper/fiber-optic) 12 Mbit/s / 12 Mbit/s 12 Mbit/s / - 1.5 Mbit/s / - 1.5 Mbit/s / -System functionsPermanent wiring n n n nHot swapping n n (with active backplanenbus)Isochronous mode, e.g. for high-speed control n nExpansion/configuration during operation n / - n / n n / nHigh-speed modules n nDiagnostics (module-dependent) Channel-discrete Channel-discrete Submodule-discrete Channel-discreteFunctionsDigital channels n n n nAnalog channelsincl. HARTnnnnnMotor starters / frequency convertersn / nPneumatic interface n 2) n 2)Technological functionsCounting/measuring,positioning,Counting/measuring,positioning, camCounting,frequency measuringweighingcontrol, closed-loopcontrol, weighingIntegrated CPU functionality/I-Device n / n n / n(via S7-300 CPUs)Shared Device 3) n nMRP 3) n nOptions handlingnSensor technology (IO-Link)nn applicable / available- not applicable / not available1) Also available as SIPLUS component for expandedtemperature range -25 °C … +60/70°C and corrosive atmosphere/condensation (exact details atwww.siemens.com/siplus)2) You can find additional information on thesupplemental products atwww.siemens.com/simatic-et<strong>200</strong>3) Available for PROFIN<strong>ET</strong> versions20Product overview

© Siemens AG 2010■ <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> without control cabinetI/O system <strong>ET</strong> <strong>200</strong>pro <strong>ET</strong> <strong>200</strong>eco PN <strong>ET</strong> <strong>200</strong>eco <strong>ET</strong> <strong>200</strong>RConfigurationDegree of protection IP65/66/67 IP65/67 IP65/67 IP65Construction type Modular Block Block BlockMounting Mounting rail Direct mounting Direct mounting Direct mountingConnection system for sensors/actuators M8, M12, M23 M12 M12 M12Special applicationsSafety technology n n<strong>For</strong> use in hazardous areasIncreased availability1Temperature range -25 °C ... +55 °C(0 °C ... +55 °C) 1) -25 °C to +60 °C 0 °C to +55 °C 0 °C to +55 °CVibration resistance (continuous) 5 g (module-dependent) 20 g 5 g 5 gCommunicationPROFIN<strong>ET</strong> (copper/fiber-optic) n / n n / -PROFIBUS (copper/fiber-optic) 12 Mbit/s / 12 Mbit/s 12 Mbit/s / - 12 Mbit/s / -System functionsPermanent wiringnHot swappingnIsochronous modeExpansion/configuration during operationHigh-speed modulesDiagnostics (module-dependent) Channel-discrete Channel-discrete Submodule-discrete Group-discreteFunctionsDigital channels n n 2) n nAnalog channelsnnincl. HARTMotor starters / frequency convertersn / nPneumatic interface n 3)Technological functionsIntegrated CPU functionality/I-Devicen / nShared device 4)nMRP 4) n nOptions handlingnSensor technology (IO-Link)nn applicable / available- not applicable / not available1) In parenthesis: Temperature range of the frequency converter2) also parameterizable3) You can find additional information on the supplemental products atwww.siemens.de/simatic-et<strong>200</strong>4) Available for PROFIN<strong>ET</strong> versionsProduct overview 21

© Siemens AG 2010<strong>ET</strong> <strong>200</strong> – featuresSimple configuration and increased plant availabilitySimple configurationIntegral plug-in connections make installation quick and easyand therefore reduce the costs. In the case of modular systems,mounting is on a rail. The modules are snapped ontothe rail and plugged into each other.The sensors and actuators can be easily connected to a bussystem without the need to use an array of single wires withcable distributors and cable racks. This makes the wiring simpleand transparent, less error-prone and therefore low-cost.Self-assembling backplane busPermanent wiringDue to the separation of mechanics and electronics, permanentwiring is possible, i.e. the station can be prewired beforeinstallation or start-up. Prewiring can therefore be inspectedwithout the electronics modules which prevents damage tosensitive components. The start-up time is thereforereduced. In addition, the modules can also be replaced in theevent of a fault without time-consuming rewiring.Permanent wiring: connections and electronics are separate from oneanotherHot swappingIn the event of a fault, electronic modules are easily replacedduring operation with the equipment live (hot swapping).The station remains functional, and the plant therefore remainsavailable – there is no need for costly shutting downand starting up of the plant. While the components are beingreplaced, the wiring remains intact.Hot swapping: Module replacement during operationConfiguration in Run (CiR)Changes or expansions are required even during active operationof a (sub-) system. Possible applications are due to nonstoprequirements, that is, in continuous processes in processengineering that cannot be shut down or whose productioncannot be interrupted.Changes to the hardware configuration in RUN are possiblewhen <strong>distributed</strong> I/Os are connected to the S7-400:• Stations can be added and removed,e.g. for configuring a new process line• I/O modules can be added and removed,e.g. for implementing additional sensors• I/O modules can be reparameterized,e.g. for replacement partsChanges to the configuration are possible during normal operation22<strong>ET</strong> <strong>200</strong> – features

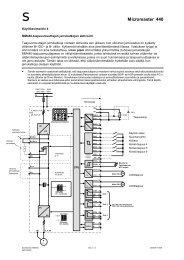

© Siemens AG 2010Use in hazardous areasIn many industries, the manufacture, processing, transportor storage of combustible materials results in the creationor release of gases, vapors or mist into theenvironment. Other processes create combustible dust. Incombination with oxygen in the air, a potentially explosiveatmosphere can occur that will result in an explosion if ignited.Special properties must be exhibited by the equipmentused in these environments, and they must becertified. <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong> is equipped for this, and includesa corresponding range of products.The <strong>ET</strong> <strong>200</strong> systems can be used in different zones – either inZones 2 and 1 in the case of gaseous atmospheres, or in Zones22 and 21 in the case of dusty atmospheres.The sensors and actuators linked to the I/Os can even be inZone 0 or Zone 20.A manufacturer's declaration (compliance of the control cabinetwith the ATEX directive) is necessary for installation inZone 2/22. Certification of the control cabinet for the gas/dustarea must be procured for installation in Zone 1/21.Data communication takes place as usual over PROFIBUS. Ifcommunication is continued over PROFIBUS stations in Zone1 or for other reasons over intrinsically safe PROFIBUS stations,the PROFIBUS is made intrinsically safe by an intermediatefieldbus isolating transformer. This limits the ignition energyto the permissible level and the intrinsically safe PROFIBUS isrouted to the hazardous area.Industrial EthernetControl systemDUSTFM/ULATEXFM/ULATEXClass I Zone 2 Class I Zone 1 Class I Zone 0Zone 2 Zone 1 Zone 0Class II Zone 2 Class II Zone 1 Class II Zone 0Zone 22Zone 21Zone 202)S7-400DP/PA-Link2Fieldbusisolating transformer<strong>ET</strong> <strong>200</strong>S<strong>ET</strong> <strong>200</strong>M1)1)1)1)SITRANS FHARTPROFIBUS DP-iSPROFIBUS PAHazardous areaSITRANS P1 0Ex i, Ex eActuators/sensorsActuators/sensors<strong>ET</strong> <strong>200</strong>iSP1) 3)Ex iAFDiSHARTActuators/sensorsActuators/sensorsG_ST70_XX_00674<strong>ET</strong> <strong>200</strong> in hazardous gas and dust atmospheres 1) Dust atmospheres: installation of components always in an enclosure withIP6x degree of protection.2)With 10 A DC standard power supply3)Installation of the station complies with FM/UL up to Class I, Division 2; connectedsensors and actuators even up to Class I, Division 1 or installation ofstation and sensors/actuators according to FM/UL up to Class II/III, Division 1<strong>ET</strong> <strong>200</strong> – features 23

© Siemens AG 2010PROFIN<strong>ET</strong> innovationsNEWPROFIN<strong>ET</strong> has been expanded by a number of innovativefeatures. These simplify system configuration in fail-safeapplications, for example, and they allow a leaner andmore versatile topology in many different scenarios.<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>proTwo controllers can access the same PROFIN<strong>ET</strong> IO-Device,such as a <strong>distributed</strong> <strong>ET</strong> <strong>200</strong>, using the function Shared Device.Since fewer remote devices have to be installed in thefield, engineering, cabling and installation costs are reduced.In addition, the modules can be flexibly assigned to one of thetwo CPUs.<strong>SIMATIC</strong> S7-300Ring(MRP)<strong>SIMATIC</strong> S7-400IO-Controller 1IO-Controller 2PROFIN<strong>ET</strong>Industrial Ethernet<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>Ring topology with Media Redundancy Protocol (MRP)PROFIN<strong>ET</strong>Industrial EthernetGreater plant availability can be achieved with the help of aring topology and the Media Redundancy Protocol (MRP).This runs direct via the integral PROFIN<strong>ET</strong> port to <strong>SIMATIC</strong> controllersand <strong>ET</strong> <strong>200</strong> IO stations and can be used with or withoutIE switches.IO-DeviceWith the Shared Device function, two different IO controllers can access thesame IO device simultaneouslyThe function I-Device (intelligent IO-Device) enables simpleand fast controller-controller communication through directaccess to the IO address image with PROFIN<strong>ET</strong> IO protocol.Local controllers, such as the <strong>ET</strong> <strong>200</strong>S CPU, can be more easilyintegrated into modular machines or safety applications, forexample.PROFIN<strong>ET</strong> systems with the innovative PROFIenergy profileare able to control energy consumption. They can be configuredin such a way that they can be disconnected automaticallyand in a coordinated way during breaks in production, andthen connected again when production starts up again – inthe correct order, at the correct intervals, reliably and plantwide.Additional expanded functionsThe <strong>ET</strong> <strong>200</strong>S supports the Options handling function. Withthis, an application can be subdivided into several modules orsub-tasks (e.g. bottling, labeling, packaging), without theneed to manage several projects for different machine constellations.In the <strong>ET</strong> <strong>200</strong>S station, the input/output modulesare assigned to the appropriate sub-tasks. The actually availablemachine modules or the input/output modules of the<strong>ET</strong> <strong>200</strong> station required for this are selected and activated atcommissioning.PROFIN<strong>ET</strong> IRT and isochronous mode allow high-speed anddeterministic communication in which the different cycles ofa system (input, remote station, network, CPU processing andoutput) are synchronized even in the case of parallel TCP/IPtraffic. High-precision and dynamic applications can thus beimplemented using <strong>SIMATIC</strong>.24<strong>ET</strong> <strong>200</strong> – features

© Siemens AG 2010<strong>SIMATIC</strong> Selection ToolJust a mouse click away from a tailor-made I/O station:with the <strong>SIMATIC</strong> Selection ToolWith the <strong>SIMATIC</strong> Selection Tool, you get first class supportwith assembling your overall <strong>automation</strong> system (<strong>SIMATIC</strong> S7,<strong>ET</strong> <strong>200</strong> station). The software tool guides you comfortably,easily and conveniently through the configuration and createsautomatic ordering lists for you including accessories. It alsosupports you with compliance with limitations, for example,for load currents, slot rules or parameters.The configuration generated in the <strong>SIMATIC</strong> Selection Tool canbe imported easily into STEP 7. This reduces the engineeringoverhead and avoids double entries.The software tool is structured clearly: Six configuration viewsmake working easy and convenient.• General: General station data as well as a graphical presentationof the configured station• Module selection: Guided selection of modules by meansof module suggestions• Limits: Display of station size, weight, number of modules,load voltage, parameters, etc.• Accessories: Guided selection of the required accessories(module-specific or station-wide)• Potential distribution: Graphical presentation of the potentialswithin a station• Parts list: Automatic generation of a transparent parts listmakes ordering easierStandards and approvalsStandards and approvalsPROFIBUS EN 50 170, Volume 2PROFIN<strong>ET</strong> IEC 61158IEC 1131 IEC 1131, Part 2ULacc. to UL508 standard, File No.E 116536/E 75310 (AC modules)CSA acc. to standard C22.2 No. 142.File No. LR 48323/LR 44226 (ACmodules)cULus(for hazardous locations)acc. to UL 508 standardFile No. E 116536acc. to hazardous locationsUL 1604File no. E 222109acc. to CSA C22.2 standardNo. 142FM Standard Class No. 3611,Class I Div. 2, Group A, B, C, DClass I, Zone 2, Group IIC(without motor starter)ShipbuildingAmerican Bureau of ShippingBureau VeritasDet Norske VeritasGermanischer LloydLloyds Register of ShippingNippon Kaiji KyokaiEx approval Cat. 3EN 50 021(for Zone 2 acc. to ATEX-100a)ISASafetyISA-S71.04Severity Level G1, G2, G3(for <strong>ET</strong> <strong>200</strong>S, <strong>ET</strong> <strong>200</strong>M, <strong>ET</strong> <strong>200</strong>iSP)IEC 62061 up to SIL3,EN ISO 13849-1 up to PLe, as wellas EN 954-1 up to Cat. 4The <strong>SIMATIC</strong> Selection Tool can be found on the Internet atwww.siemens.com/et<strong>200</strong>or in the Industry Mall and also in the Catalog CA01 on DVDConfiguration made easy with the <strong>SIMATIC</strong> Selection Tool<strong>ET</strong> <strong>200</strong> – features 25

© Siemens AG 2010<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>SThe all-rounder with the comprehensive range of modules<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S is the multifunctional, highly modular I/Osystem with IP20 degree of protection that can be exactlytailored to the <strong>automation</strong> task. Thanks to its rugged construction,it can also be used under conditions of high mechanicalstress.Various interface modules are available for interfacing to thePROFIN<strong>ET</strong> and/or PROFIBUS bus systems. Interface moduleswith an integral CPU transfer the computing power of anS7300 CPU directly into the I/O device and constitute a localcontroller. They therefore offload the central PLC, and permitrapid responses to time-critical signals.Interface modules with integrated CPU and PROFIN<strong>ET</strong>/PROFIBUS connection are available – both in standard andsafety-related designs. The PROFIN<strong>ET</strong> version of the <strong>ET</strong> <strong>200</strong>Salso offers the following new functions:• I-Device• Shared Device• MRPNew high feature interface modules, fast I/O modules, isochronousmode and an extremely fast internal data transportincrease the performance of the <strong>ET</strong> <strong>200</strong>S and permits the useeven with extremely fast closed-loop controls.With the 8-channel digital input and output modules, the bitmodular<strong>ET</strong> <strong>200</strong>S is even more compact. They are perfectlysuited for configurations with many channels and a spacesavingand cost-saving configuration is demanded. The8-channel module permits the connection of 2-wire sensorsand they offer a simultaneity factor of 100% (that is, 4 A summationcurrent with 8 outputs with 0.5 A each).Distributed <strong>automation</strong> <strong>solutions</strong> increasingly involve not justdigital and analog signals, but also technological functions,motor starters, frequency converters or a pneumatic interface.The bit-modular <strong>ET</strong> <strong>200</strong>S offers a comprehensive modulerange to implement the tasks:• Technology modules are available e.g. for counting and positioningtasks, for cam control or for closed-loop controltasks.• Using the motor starters/soft starters, any three-phaseloads up to 7.5 kW can be connected. Motor starters areavailable in several designs, including a fail-safe design.• Frequency converters (also with integral safety technology)provide stepless speed control for asynchronous motors upto 4 kW.• Pneumatic interfacing using modules from Bürkert.• I/O-Link modules support the connection of intelligent sensorssuch as sonar BEROs.<strong>ET</strong> <strong>200</strong>S with PROFIN<strong>ET</strong> connection, I/O modules, motor starters andfrequency converters• CANopen module from HMS• PROFIenergy power modules• Failsafe I/O modules permit the integration in safetyrelatedplants with <strong>SIMATIC</strong> Safety Integrated.• SIPLUS components allow for operation also in the expandedtemperature range -25 °C ... +60 °C and incorrosive atmospheres or under condensation(Exact details at www.siemens.com/siplus).Diagnostics functions and hot swapping of modules increaseplant availability:• Comprehensive diagnostic interrupts indicate the modulestatus on the one hand and channel-specific informationon the other hand.• Electronic modules, motor starters and frequency converterscan be replaced during normal operation without theneed for tools and with the equipment live (hot swapping).During replacement of a module, the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S cancontinue to operate and the application will continue tofunction properly. If motor starters and frequency convertersare used, even the otherwise obligatory isolation of thesystem can be avoided.The <strong>SIMATIC</strong> Selection Tool can be found on the Internet atwww.siemens.com/et<strong>200</strong>or in the Industry Mall and also in the Catalog CA01 on DVD26<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S

© Siemens AG 2010Bit-modular economical design with multi-conductor connectionIn addition to the extremely low space requirements, the<strong>ET</strong> <strong>200</strong>S results in savings in wiring of up to 80% in comparisonto conventional <strong>solutions</strong>.The reasons for this are:• The backplane bus is built up automatically.• All supply terminals have the characteristics of terminalblocks, allowing signal leads and motor cables to be directlyconnected to the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S without the needfor intermediate terminals.• The integral safety system is a system component – an additionalsafety bus can therefore be omitted.• Reserve modules can be used to reserve module slots forfuture use.• Permanent wiring• Considerably less cross-wiring thanks to the self-assemblingvoltage busses – this reduces the testing outlay andpossible sources of error.• The module labeling is not covered by the wiring when themodule is installed.• Easy configuration of an <strong>ET</strong> <strong>200</strong>S station with the<strong>SIMATIC</strong> Selection ToolFast ConnectThe insulation displacementmethod Fast Connect offerseven more benefits for installationof the electronic andpower modules.With this new method, thestandard conductor crosssectionsfrom 0.34 to1.5 mm² can be connected.No preparation is required forinstallation:• Time savings of up to 60 %for installation as comparedto the conventional Fast connection systemconnection methods• No stripping or crimping necessary• Simple and safe installation with a screwdriver. Reductionof error ratio during installation• The stripped length does not have to be determinedPower module PM-EElectronic moduleInterface moduleIM 151Power modulePM-DMotor starterBus terminationmoduleTerminal modulesTerminal modules TM-D withintegrated energy busPE/N moduleBit-modular design of <strong>ET</strong> <strong>200</strong>S<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S 27

© Siemens AG 2010Interface modules for bus connection<strong>ET</strong> <strong>200</strong> S is connected to the bus system via the interface module– either to the field-proven PROFIN<strong>ET</strong> or to PROFIBUS, the openIndustrial Ethernet standard. Various interface modules canbe chosen, which all provide for channel-discrete diagnostics:Interface modules without CPU functionalityIM 151-1 BASICIM 151-1 COMPACTIM 151-1 5)Standard/Standard FOIM 151-1 5)High Feature (HF)IM 151-3 PN 5)IM 151-3 PN HFIM 151-3 PN FOIM 151-3 PN HSPROFIBUS Copper Copper/FOC 1) CopperPROFIN<strong>ET</strong> Copper Copper/FOC 1) Copper 6)2-port switch 4) n n nNumber of modules12 63 63 63 63 32Station width 2 m 1 m/2 m 2 m 2 m 2 m 0.5 mFail-safety n nIsochronousn n 6)modePROFIenergy n / -Shared device n n nMRP n n / -Electronicrating plate 2) n n n n nFirmware update Bus n Bus/MicroMemory CardOrder No. group6ES7 151-Bus/MicroMemory Card1CA. 1AA. / 1AB. 1BA. 3AA. 3BA. 3BA6-.Bus/MicroMemory CardInterface module IM 151-3 PN HFfor PROFIN<strong>ET</strong> with standard cableInterface module IM 151-3 PN FOwith fiber optic cableInterface modules with CPU functionality 3)IM 151-7 CPU/CPU FO 5)IM 151-7 5)F-CPUIM 151-8 5)PN/DP CPUIM 151-8F 5)PN/DP CPUPROFIBUS Copper/FOC 1) Copper n 3) n 3)PROFIN<strong>ET</strong> Copper Copper2-port switch 4) n 7) n 7)Number of 63 63 63 63modulesStation width 2 m 2 m 2 m 2 mFail-safety n nIsochronousmodePROFIenergynI-Device n nShared device n nMRP n nElectronicn nrating plate 2)Firmware update MicroMemory CardMicroMemory CardBus, MicroMemory CardBus, MicroMemory CardOrder No. group6ES7 151-7AA. / 7AB. 7FA. 8AB. 8FB.1)Plastic, polymer-cladded fiber (PCF)2)The electronic rating plate contains identification data savedin a module, e.g. order number, product version, installationdate, plant identification, which unequivocally identify themodule and are available online, e.g. in order to simplify troubleshooting.3)Additional PROFIBUS line with master module6ES7 138-4HA.4)The integral 2-port switch of the IM 151-3 now also easily permitsa linear configuration in addition to the star topology.5)Also available as SIPLUS component for expandedtemperature range -25 °C … +60/70 °C and corrosive atmosphere/condensation(exact details atwww.siemens.com/siplus).6)Available with SIMOTION controller as of V4.1 SP1 andPROFIN<strong>ET</strong> with IRT.7)3 port-switch28<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S

© Siemens AG 2010Distributed intelligenceThe interface modules withintegrated CPU can be usedboth in stand-alone modeand for <strong>distributed</strong> <strong>automation</strong><strong>solutions</strong> with a medium-sizedprogram. Theycorrespond to a CPU 314and enable <strong>distributed</strong>preprocessing of the productiondata locally – evenin the failsafe version. Dependingon the version,IM151-8 PN/DP CPUcommunication can take place via MPI/PROFIBUS and/orPROFIN<strong>ET</strong>. This has the following advantages:• Relieves the central control unit• Reduction in the response times to critical local signals• More transparent and shorter programs• Easier trouble-shooting• Less load on the bus system• Modularization of the system structure and precommissioning– also at different sitesAdditional PROFIBUS lineThe DP master module forthe interface module withintegrated CPU is used toexpand the <strong>ET</strong> <strong>200</strong>S as masterwith an integrated DPmaster interface. A lowerlevelPROFIBUS line canthen be configured withfurther <strong>distributed</strong> I/O.Options handlingWith the use of options handling with <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S, theentire station including all options is configured. Modules forunnecessary options are either replaced by reserve modulesor can be completely eliminated. Optional functions are activatedduring operation without new configuration.Options handling is available in two versions:Interface module IM 151-7: withintegral CPU (also as F version)and master moduleWith reserve modulesIn this case, the station is configured with all options.I/O modules that are not required are replaced by cost-effectivereserve modules. Later, they can be exchanged for theconfigured modules without new configuration, even duringongoing operation.Without reserve modulesIn this case, the station is configured with all options, however,only the necessary modules (terminal and I/O modules) areplugged in. The modules which are not plugged in can be laterretrofitted as required without new configuration.Options handling is available for interface modules withPROFIN<strong>ET</strong> interface and for those with PROFIBUS interface.<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S COMPACT –The block I/O featuring bit-modular expansion<strong>ET</strong> <strong>200</strong>S COMPACTexpandable block<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S COMPACT isthe new interface for the bitmodular<strong>ET</strong> <strong>200</strong>S I/O system.The new IM 151-1 COMPACTinterface module expandsthe well-known range ofproven <strong>ET</strong> <strong>200</strong>S modules andpermits use as a block I/O.The functionality is based onthe IM 151-1 BASIC and comprisesan interface moduleand 32 channels in oneblock. Two different variants of the <strong>ET</strong> <strong>200</strong>S COMPACT are offered– either a station with 32 digital inputs or mixed with16 digital inputs and 16 digital outputs.By expanding the block with <strong>ET</strong> <strong>200</strong>S modules (up to 12 modules),a total of 128 channels can be connected to the <strong>SIMATIC</strong><strong>ET</strong> <strong>200</strong>S COMPACT. Thus frequently required inputs/outputs inblock form can be combined with bit-modular specialist modulessuch as motor starters, frequency converters, pneumatics,etc.<strong>ET</strong> <strong>200</strong>S COMPACT withexpansionsExpansions with the8-channel modules supportan extremely high packingdensity. As a result, one terminalbox can accommodatemore components or a smallerterminal box can be used.<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S 29

© Siemens AG 2010Motor starters for any applicationThe <strong>ET</strong> <strong>200</strong>S motor starters can be used to protect andswitch any three-phase load. The completely prewireddevices are available in different performance classes asdirect, reversing or soft-starters up to an output of 7.5 kW.The terminal module contains the self-assembling energy busand the terminals for direct connection of the motor cable.A motor starter can be removed and inserted without theneed to isolate the system.Standard motor starters• Circuit-breaker and contactor combination up to 5.5 kW• Direct-on-line or reversing starters• Optional safety systemHigh Feature motor starters• Combination of starter circuit-breaker, electronic overloadrelay and contactor or soft starter up to 7.5 kW• Comprehensive diagnostics messages, e.g. actual currentvalue• Statistical data, e.g. current for the last overload trip, canbe read out using the service and commissioning softwareMotorstarter ES• Parameterization over the bus• Only two current setting ranges up to 7.5 kW• Safety technology integratedFail-safe motor starterAs soon as more complex or widely <strong>distributed</strong> safety applicationsare implemented, the Failsafe motor starter in combinationwith the PM-D F PROFIsafe power module is the optimizedsolution. Signals from safe sensors are read in through safe inputsat any required point in a plant and transferred to the failsafeprogrammable controller via PROFIBUS by means of thePROFIsafe message frame. In the application program they arelinked to the Failsafe motor starters or the associated powermodule.These motor starters based on the High Feature motor starteroffer a completely new patented technique for safety shutdown:Whereas under normal operation the contactor isresponsible for shutdown, in the event of a fault, e.g. weldedcontactor contacts, the integral dual processor monitoring alsotrips the circuit-breaker. This ensures that each individual motorstarter achieves Category 4 or SIL 3 without additionalredundancy contactors.The fail-safe motor startermonitors the function of thecontactor regardless ofwhether the application issafety-related or not, sothese devices are also suitablefor use in high-availabilityprocesses.Further characteristics thatsupport high availability are:• Type of coordination 2over the complete power range up to 7.5 kW• The emergency start function allows important processesto be continued to completion despite a reason for shutdown,e.g. overload.Advantages of fail-safe motor starters over conventionalsafety systems• Significantly fewer components, therefore less complexconfigurations and considerably less HW engineering andwiring overhead• Rapid installation thanks to simple plug-in technology• Motor starters are fault tolerant and failsafe• High degree of flexibility thanks to assignment to switchoffgroups in software• When the safety application changes, there is less overheadbecause the wiring is retainedTwo alternatives are available:Motor starter for failsafe<strong>ET</strong> <strong>200</strong>SSolution local• Used for locally restricted safety applications• <strong>For</strong> group deactivation of Standard, High-Feature or Failsafemotor starters without complex wiring for conventionalsafety systems• <strong>For</strong> local evaluation of EMERGENCY STOP circuits withautomatic or monitored starting• Cascading of the shutdown groups• Can also be used in combination with external safetycircuitsSolution PROFIsafe• <strong>For</strong> usage with safety-related applications that are complexand interconnected• The logic of the safety functions (safe sensors can befreely assigned to Failsafe motor starters) is implementedwith software and thanks to safety-related communication(PROFIsafe)• Safety module PM-DF PROFIsafe forms 6 shutdowngroups• Selective and autonomous shutdown of the fail-safemotor starter for any safety function• Also for controlling external safety systems through F-CMcontact multiplier30<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S

© Siemens AG 2010Frequency converter for stepless speed controlWhen stepless speed control of induction motors up to 4kW is required, the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S FC frequency converteropens up new applications for the <strong>ET</strong> <strong>200</strong>S I/O system inthe field of drive technology.The frequency converter is of a modular design: Apart from aclosed-loop control module, one from three possible powersections is snapped onto purely mechanical components(terminal modules).Advantages of the frequency converters• No tools needed for installation• Self-assembling communication and power busses• Permanent wiring• Pulling and plugging in of the control module andpower unit during operation• Complete parameter settings on optional Micro MemoryCard for servicing requirements• Energy efficiency in many applications• Communication via PROFIN<strong>ET</strong> or PROFIBUSRegenerative feedback function includedLine-commutated feedback of power into the supply systemwithout he need for a chopper module or braking resistance isunique in this class.The power loss of the overall system is reduced – which reducesthe thermal load on the station and supports the use ofsmaller control cabinets. And what is more, the power fedback into the system when braking is available to other loadsfree-of-charge.The new concept of the frequency converter also makes externalline reactors superfluous. This saves additional installationspace as well as procurement and installation costs.<strong>For</strong> applications that are particularly sensitive to EMC, anexternal EMC filter is available that is connected in the infeedof the power bus.Frequency converters in size A(0.75 kW)Wide range of applications• Simple drive tasks• Conveyor system applications such as driving and liftinggear and winding and unwinding drives• Closed-loop control with motor encoder for extremelyprecise speed and torque control• Unwinding units, lowering of loads with hoisting gear, orelectric braking of large centrifugal masses when makinguse of line-commutated energy recoveryFail-safe frequency converterThe integrated safety functions of the failsafe version of thefrequency converter support simple drive <strong>solutions</strong> in plantsections which pose a potential danger. In combination withthe PM-D F PROFIsafe power module, the frequency converterin the failsafe version offers comprehensive integrated safetyfunctions:• Safe Torque Off, STO – the drive is prevented from startingup purely electronically, and therefore without contact.• Safe Stop 1, SS1 – shutdown of the drive is monitored withouta motor encoder or other encoder.• Safely Limited Speed, SLS – the violation of a reduced motorspeed is monitored without a motor encoder or otherencoder.Frequency converter with savings effectFailsafe frequency converter in sizeB (2.2 to 4.0 kW)Energy, and thus money, can be saved in many applicationswith frequency converters. <strong>For</strong> example, in pump and ventilationapplications, power costs can be reduced by up to 70% bymeans of variable-speed operation instead of fixed-speed concepts.In the case of hoisting applications and centrifuges, forexample, the frequency converter with power recovery capabilitycan save up to 50% of the energy by recoving the brakingenergy.<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S 31

© Siemens AG 2010I/O modules for simple applicationsModule type Information Order No. groupPower modules forelectronic modulesand motor startersTerminal modulesElectronic modules<strong>For</strong> supplying and monitoring the load voltage and encoder voltage;voltage and/or fuse failures; additional LEDs indicate the status of the voltage and thefuse; different function AC, DC, PROFIsafe and PROFIenergy.■ PM-E 24 V DC with diagnostics or PM-E 24 ... 48 V DC, with diagnostics and status■ PM-E 24 V DC to 230 V AC with diagnostics and fuse■ PM-E RO 24 V DC with diagnostics NEW■ PM-E F 24 V DC PROFIsafe for failsafe shutdown (max. Cat. 3) with standard modules■ PM-D F 24 V DC PROFIsafe for fail-safe motor starter and frequency converter<strong>For</strong> the electrical and mechanical connection of I/O modules and process wiring.Available with screw-type and spring-loaded terminals as well as the Fast Connectinsulation-piercing technique■ TM-P for power; TM-E for electronics■ TM-D for motor starters<strong>For</strong> supplying the <strong>ET</strong> <strong>200</strong>S with digital inputs and outputs; High Feature variants increasethe plant availability and offer additional functions and diagnostics.■ 6ES7 138-4CA. 1)■ 6ES7 138-4CB. 1)■ 6ES7 138-4CA.■ 6ES7 138-4CF.■ 3RK1 903-1.■ 6ES7193-4C. 1)■ 3RK1903-0A.Digital inputmodulesDigitaloutput modulesAnalog inputmodulesAnalogoutput modulesRelay moduleFail-safe modulesReserve modulesIO-Link■ 2-, 4- and 8-channel■ Available from 24 V DC to 230 V AC■ Different functionalities: Standard, High Featuresource input module 8 DI 24 V DC SRC■ 2-, 4- and 8-channel■ Available from 24 V DC to 230 V AC; 0.5 to 5 A■ Different functionalities: Standard, High Feature■ Electronics and relaysSink output modules4 DO 24 V DC/0.5 A8 DO 24 V DC/0.5 A■ 2- and 4-channel■ Current and voltage input, thermocouple and resistance measurement■ Functionalities: Standard, High Feature, High Speed■ 2-channel■ Current and voltage output■ Functionality: Standard, High Feature, High Speed■ 2-channel, 24 V DC or 24...230 V AC, 5A■ 2-channel, 24 V DC or 24...230 V AC, 5 A, can be switched channel-by-channel usingthe front switch■ Failsafe input module 4/8F-DI 24 V DC PROFIsafe■ Failsafe output module 4F-DO 24 V DC/2 A PROFIsafe■ Failsafe input/output module 4F-DI/3F-DO 24 V DC/2 A PROFIsafe■ Fail-safe relay module 1F-RO 24 V DC or 24 - 230 V AC, 5 AUsed as dummy modules for unused slots within an <strong>ET</strong> <strong>200</strong>SstationThe I/O-Link master module offers 4 I/O link channels with master functionality and enablesthe connection of intelligent IO-Link devices to the <strong>ET</strong><strong>200</strong>S. All IO-Link functions areprovided by <strong>ET</strong><strong>200</strong>S to PROFIBUS DP or PROFIN<strong>ET</strong> I/O master modules. Simple data handlingof IO-Link components is ensured via the configuration tool integrated in STEP 7.Up to 4 sensors, actuators or other IO-Link devices are each connected to a standard cable.In addition to the central parameterization, IO-Link in <strong>SIMATIC</strong> S7 also enables an expandeddiagnostics up to device level.■ 4-channelYou can find additional information on the IO-Link at www.siemens.de/IO-Link■ 6ES7131-4. 1)■ 6ES7132-4. 1)■ 6ES7134-4. 1)■ 6ES7135-4. 1)■ 6ES7132-4HB. 1)■ 6ES7138-4FA. 1)■ 6ES7138-4FB. 1)■ 6ES7138-4FC.■ 6ES7138-4FR.■ 6ES7138-4AA.■ 6ES7138-4GA.1)Also available as SIPLUS component for expanded temperature range-40/25 °C … +60/70 °C and corrosive atmosphere/condensation(exact details at www.siemens.com/siplus).32<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S

© Siemens AG 2010I/O modules for special applications, accessoriesModule type Information Order No. groupTechnology modules <strong>For</strong> the solution of technological tasks, high-performance function modules are availablethat perform these tasks largely autonomously and relieve the CPU significantly. Useddirectly on site; parameterization using STEP 7 or GSD file; serial interface■ 6ES7138-4DA. (24 V) 1)6ES7 138-4DE. (5 V)■ 6ES7138-4DB.■ 6ES7138-4DL.■ 6ES7138-4DC.Measuring modulesMotor starter(also with integratedsafety system)Frequency converter(also with integratedsafety system)Accessories■ High-speed counting and measuring tasks with 5 V or 24 V encoders Counter module:24 V DC / 100 kHz or 5 V DC / 500 kHz 1 COUNT■ Simple positioning tasks through position sensing with SSI encoders SSI module 1 SSI■ Controlled positioning of simple drives via digital outputs 1 POS U positioning module■ Positioning with stepper motors over a pulse/direction interface1 STEP stepper motor module■ Proportioning, resetting and controlling of actuators and valvespulse module (timer, pulse-width modulation, stepper motor) 2 PULSE■ Serial data exchange via point-to-point connection1 SI interface moduleSIWAREX CS is a compact electronic weighing system with calibration capability for the<strong>distributed</strong> I/O system <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S. The SIWAREX CS weighing module can be usedfor various different measuring tasks such as container weighing, fill-level measurement,platform weighing, crane weighing as well as the measuring of forces and torques.■ Uniform design and communication through integration in <strong>SIMATIC</strong> S7■ Use in <strong>distributed</strong> plant concept through connection to PROFIBUS DP via <strong>ET</strong> <strong>200</strong>S■ Measuring of weight or force with a resolution of 65,000 increments■ Calibration according to OIML R76■ A display with calibration capability can be connected■ Extensive diagnostics options■ Easy to parameterize using the SIWATOOL CS program■ Theoretical adjustment without adjustment weights■ Replacement of module without renewed adjustment of scale■ Use possible in Ex applicationsSIWAREX CF is a measuring module for connection of sensors operating according to thestrain gauge principle. The module can be used for various tasks, e.g. for measuringforces and torques.■ Uniform design technology and consistent communication thanks to integration into<strong>SIMATIC</strong> S7■ Use in <strong>distributed</strong> plant concept through connection to PROFIBUS DP via <strong>ET</strong> <strong>200</strong>S■ Measurement with a resolution of ± 16,000 parts, accuracy 0.15%■ Measurement rate 50 Hz■ Ready-to-use, free application software "Getting started"■ Direct, reversing and soft starters■ Functionality: Standard, High Feature, Failsafe■ Up to 7.5 kW■ Output up to 4.0 kW■ Regenerative feedback in generating mode■ Functionality: Standard and Failsafe■ Fail-safe functions certified in accordance with Cat. 3 according to EN 954-1 and SIL2 accordingto IEC 61508■ Integrated shield connection system for low-impedance connections of individuallengths. Space-saving, low-cost standard components with a simple plug-in techniqueare used for this purpose.■ Individual color-coded labels for terminals on the terminal modules; they are availablein different colors.■ Labeling plates for numbering the terminal modules: inscribed or blank.■ DIN A4 labeling sheets in different colors, pre-perforated; suitable for printing usinga laser printer. Information: www.s7-smartlabel.de1)Also available as SIPLUS component for expanded temperature range-40/25 °C … +60/70 °C and corrosive atmosphere/condensation(exact details at www.siemens.com/siplus).■ 6ES7138-4DD. 1)■ 6ES7 138-4DF. 1)■ 7MH4910-.■ 7MH4920-.■ 3RK1301-.■ 3RK1903-.■ 6SL3244-0S.■ 6ES7193-4.. 1)<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S 33