ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

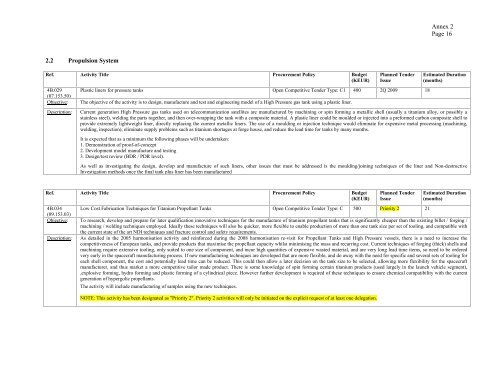

Annex 2Page 162.2 Propulsion SystemRef. Activity Title Procurement Policy Budget(KEUR)4B.029(07.153.50)Objective:Description:Planned TenderIssuePlastic liners for pressure tanks Open Competitive Tender Type: C1 400 2Q 2009 18The objective of the activity is to design, manufacture and test and engineering model of a High Pressure gas tank using a plastic liner.Estimated Duration(months)Current generation High Pressure gas tanks used on telecommunication satellites are manufactured by machining or spin forming a metallic shell (usually a titanium alloy, or possibly astainless steel), welding the parts together, and then over-wrapping the tank with a composite material. A plastic liner could be moulded or injected into a preformed carbon composite shell toprovide extremely lightweight liner, directly replacing the current metallic liners. The use of a moulding or injection technique would eliminate for expensive metal processing (machining,welding, inspection), eliminate supply problems such as titanium shortages at forge house, and reduce the lead time for tanks by many months.It is expected that as a minimum the following phases will be undertaken:1. Demonstration of proof-of-concept2. Development model manufacture and testing3. Design/test review (BDR / PDR level).As well as investigating the design, develop and manufacture of such liners, other issues that must be addressed is the moulding/joining techniques of the liner and Non-destructiveInvestigation methods once the final tank plus liner has been manufacturedRef. Activity Title Procurement Policy Budget(KEUR)Planned TenderIssueEstimated Duration(months)4B.034 Low Cost Fabrication Techniques for Titanium Propellant Tanks Open Competitive Tender Type: C 500 Priority 2 21(09.153.03)Objective: To research, develop and prepare for later qualification innovative techniques for the manufacture of titanium propellant tanks that is significantly cheaper than the existing billet / forging /machining / welding techniques employed. Ideally these techniques will also be quicker, more flexible to enable production of more than one tank size per set of tooling, and compatible withthe current state of the art NDI techniques and fracture control and safety requirements.Description: As detailed in the 2005 harmonisation activity and reinforced during the 2008 harmonisation re-visit for Propellant Tanks and High Pressure vessels, there is a need to increase thecompetitiveness of European tanks, and provide products that maximise the propellant capacity whilst minimising the mass and recurring cost. Current techniques of forging (thick) shells andmachining require extensive tooling, only suited to one size of component, and incur high quantities of expensive wasted material, and are very long lead time items, so need to be orderedvery early in the spacecraft manufacturing process. If new manufacturing techniques are developed that are more flexible, and do away with the need for specific and several sets of tooling foreach shell component, the cost and potentially lead time can be reduced. This could then allow a later decision on the tank size to be selected, allowing more flexibility for the spacecraftmanufacturer, and thus market a more competitive tailor made product. There is some knowledge of spin forming certain titanium products (used largely in the launch vehicle segment),,explosive forming, hydro forming and plastic forming of a cylindrical piece. However further development is required of these techniques to ensure chemical compatibility with the currentgeneration of hypergolic propellants.The activity will include manufacturing of samples using the new techniques.NOTE: This activity has been designated as "Priority 2". Priority 2 activities will only be initiated on the explicit request of at least one delegation.