ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

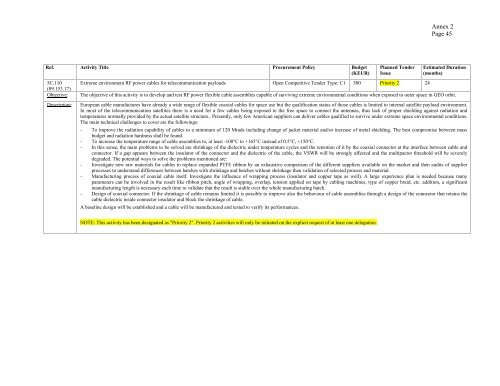

Annex 2Page 45Ref. Activity Title Procurement Policy Budget(KEUR)5C.110(09.153.17)Objective:Description:Planned TenderIssueExtreme environment RF power cables for telecommunication payloads Open Competitive Tender Type: C1 500 Priority 2 24Estimated Duration(months)The objective of this activity is to develop and test RF power flexible cable assemblies capable of surviving extreme environmental conditions when exposed to outer space in GEO orbit.European cable manufactures have already a wide range of flexible coaxial cables for space use but the qualification status of those cables is limited to internal satellite payload environment.In most of the telecommunication satellites there is a need for a few cables being exposed to the free space to connect the antennas, thus lack of proper shielding against radiation andtemperatures normally provided by the actual satellite structure.. Presently, only few American suppliers can deliver cables qualified to survive under extreme space environmental conditions.The main technical challenges to cover are the followings:- To improve the radiation capability of cables to a minimum of 120 Mrads including change of jacket material and/or increase of metal shielding. The best compromise between massbudget and radiation hardness shall be found.- To increase the temperature range of cable assemblies to, at least -100°C to +165°C instead of 0.5°C, +150°C.- In this sense, the main problems to be solved are shrinkage of the dielectric under temperature cycles and the retention of it by the coaxial connector at the interface between cable andconnector. If a gap appears between the insulator of the connector and the dielectric of the cable, the VSWR will be strongly affected and the multipactor threshold will be severelydegraded. The potential ways to solve the problems mentioned are:- Investigate new raw materials for cables to replace expanded PTFE ribbon by an exhaustive comparison of the different suppliers available on the market and then audits of supplierprocesses to understand differences between batches with shrinkage and batches without shrinkage then validation of selected process and material.- Manufacturing process of coaxial cable itself. Investigate the influence of wrapping process (insulator and copper tape as well). A large experience plan is needed because manyparameters can be involved in the result like ribbon pitch, angle of wrapping, overlap, tension applied on tape by cabling machines, type of copper braid, etc. addition, a significantmanufacturing length is necessary each time to validate that the result is stable over the whole manufacturing batch.- Design of coaxial connector: If the shrinkage of cable remains limited it is possible to improve also the behaviour of cable assemblies through a design of the connector that retains thecable dielectric inside connector insulator and block the shrinkage of cable.A baseline design will be established and a cable will be manufactured and tested to verify its performances.NOTE: This activity has been designated as "Priority 2". Priority 2 activities will only be initiated on the explicit request of at least one delegation.