ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

ARTES-5.1 â ESA Telecom Technology Workplan ... - Emits - ESA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

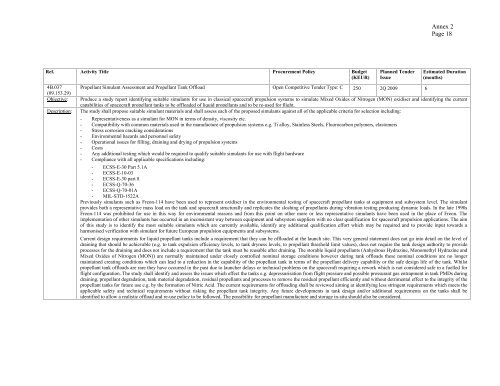

Annex 2Page 18Ref. Activity Title Procurement Policy Budget(KEUR)4B.037(09.153.29)Objective:Description:Planned TenderIssuePropellant Simulant Assessment and Propellant Tank Offload Open Competitive Tender Type: C 250 2Q 2009 6Estimated Duration(months)Produce a study report identifying suitable simulants for use in classical spacecraft propulsion systems to simulate Mixed Oxides of Nitrogen (MON) oxidiser and identifying the currentcapabilities of spacecraft propellant tanks to be offloaded of liquid propellants and to be re-used for flight.The study shall propose suitable simulant materials and shall assess each of the proposed simulants against all of the applicable criteria for selection including:- Representativeness as a simulant for MON in terms of density, viscosity etc.- Compatibility with common materials used in the manufacture of propulsion systems e.g. Ti alloy, Stainless Steels, Fluorocarbon polymers, elastomers- Stress corrosion cracking considerations- Environmental hazards and personnel safety- Operational issues for filling, draining and drying of propulsion systems- Costs- Any additional testing which would be required to qualify suitable simulants for use with flight hardware- Compliance with all applicable specifications including:- ECSS-E-30 Part <strong>5.1</strong>A- ECSS-E-10-03- ECSS-E-30 part 8- ECSS-Q-70-36- ECSS-Q-70-01A- MIL-STD-1522APreviously simulants such as Freon-114 have been used to represent oxidiser in the environmental testing of spacecraft propellant tanks at equipment and subsystem level. The simulantprovides both a representative mass load on the tank and spacecraft structurally and replicates the sloshing of propellants during vibration testing producing dynamic loads. In the late 1990sFreon-114 was prohibited for use in this way for environmental reasons and from this point on other more or less representative simulants have been used in the place of Freon. Theimplementation of other simulants has occurred in an inconsistent way between equipment and subsystem suppliers with no clear qualification for spacecraft propulsion applications. The aimof this study is to identify the most suitable simulants which are currently available, identify any additional qualification effort which may be required and to provide input towards aharmonised verification with simulant for future European propulsion equipments and subsystems.Current design requirements for liquid propellant tanks include a requirement that they can be offloaded at the launch site. This very general statement does not go into detail on the level ofdraining that should be achievable (e.g. to tank expulsion efficiency levels, to tank dryness levels, to propellant threshold limit values), does not require the tank design authority to provideprocesses for the draining and does not include a requirement that the tank must be reusable after draining. The storable liquid propellants (Anhydrous Hydrazine, Monomethyl Hydrazine andMixed Oxides of Nitrogen (MON)) are normally maintained under closely controlled nominal storage conditions however during tank offloads these nominal conditions are no longermaintained creating conditions which can lead to a reduction in the capability of the propellant tank in terms of the propellant delivery capability or the safe design life of the tank. Whilstpropellant tank offloads are rare they have occurred in the past due to launcher delays or technical problems on the spacecraft requiring a rework which is not considered safe in a fuelled forflight configuration. The study shall identify and assess the issues which effect the tanks e.g. depressurisation from flight pressure and possible pressurant gas entrapment in tank PMDs duringdraining, propellant degradation, tank material degradation, residual propellants and processes to remove the residual propellant efficiently and without detrimental effect to the integrity of thepropellant tanks for future use e.g. by the formation of Nitric Acid. The current requirements for offloading shall be reviewed aiming at identifying less stringent requirements which meets theapplicable safety and technical requirements without risking the propellant tank integrity. Any future developments in tank design and/or additional requirements on the tanks shall beidentified to allow a realistic offload and re-use policy to be followed. The possibility for propellant manufacture and storage in-situ should also be considered.