NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

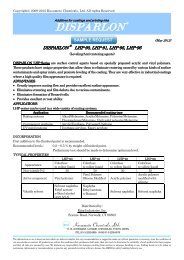

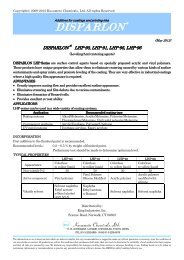

K-CORR 1031 and<strong>NA</strong>-<strong>LUBE</strong> ADTC SynergyC 4 H 9 SN CC 4 H 9 S CH 2SCS<strong>NA</strong>-<strong>LUBE</strong> ADTCNC 4 H 9C 4 H 9At various additive treat levels in an ISO VG 32paraffinic oil, K-CORR 1031 improves the lowload antiwear performance of an additive normallychosen for high load extreme pressure effectiveness.The graph to the right shows an example of theantiwear synergism of K-CORR 1031 with theextreme pressure agent <strong>NA</strong>-<strong>LUBE</strong> ADTC (anashless dialkyldithiocarbamate).K-CORR 1031 Industrial Lubricant PerformanceK-CORR 1031 imparts outstanding steel corrosion protection and demulsibility to formulated fluids.The table below shows the typical performance of K-CORR 1031 in an oil containing a dimercaptothiadiazolederivative.TestsBase Oil0.35% K-CORR NF-410 0.35% K-CORR NF-4100.06% K-CORR 1031ParaffinicISO VG 32ParaffinicISO VG 320.35% K-CORR NF-4100.25% K-CORR 1031ParaffinicISO VG 32Steel Corrosion(ASTM D 665, DIN 51 585) A & B Fail Pass PassDemulsibility(ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (minutes)Copper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100°C24 hours, 100°C3 hours, 135°C42-38-0101a1a1aASTM D 4172 Four Ball Wear Test0.843-37-015FZG A/8.3/90 (DIN 51 354 Part 2)Damage Load Stage 9 9 91b1b1b41-39-015Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.75 0.76 0.61Average Scar Diameter (mm)0.60.40.20Without K-CORRWith 0.25% K-CORR 10310.0 0.5 1.0 1.5 2.0Weight % <strong>NA</strong>- <strong>LUBE</strong> ADTC1a1a1aK-CORR ® Ashless Rust & Corrosion InhibitorsK-CORR 1031 at 0.06% in this base oil passes the standard steel corrosion tests without detractingfrom other test requirements. At an increased level of 0.25% K-CORR 1031, improvement in theFour Ball Wear performance, similar to that shown on the previous page, is demonstrated.Additive CompatibilityA concern exists regarding the compatibility of ashless and metal-containing (primarily zinc)lubricants and functional fluids. Formulations containing K-CORR 100 Series rust inhibitors,particularly K-CORR 1031, are tolerant of contamination with zinc dithiophosphate-based fluids.Studies showing this behavior are available.Pages 33-34