- Page 2 and 3:

2 TABLE OF CONTENTSIntroductionGene

- Page 4 and 5:

4 INTRODUCTIONGeneral Product Infor

- Page 6 and 7:

6 INTRODUCTIONGuide to Catalog Symb

- Page 8 and 9:

8“The Original ” Dynafile ®Air

- Page 10 and 11:

10 ABRASIVE BELT TOOLSDynafile ®4"

- Page 12 and 13:

12.4 hp Dynafile ® IIAir-Powered A

- Page 14 and 15:

14 ABRASIVE BELT TOOLSDynafile ® I

- Page 16 and 17:

16Mini-Dynafile ® IIAir-Powered Ab

- Page 18 and 19:

18Dynafile ® IIIAir-Powered Abrasi

- Page 20 and 21:

20 ABRASIVE BELT TOOLSDynafile ® I

- Page 22 and 23:

22ABRASIVE BELT TOOLSDynabelter ®A

- Page 24 and 25:

24 ABRASIVE BELT TOOLSDynabelter ®

- Page 26 and 27:

26 ABRASIVE BELT TOOLSDynangle ® I

- Page 28 and 29:

Dynastraight ® ...................

- Page 30 and 31:

30ABRASIVE FINISHING TOOLSDynastrai

- Page 32 and 33:

32Dynastraight ®Air-Powered Abrasi

- Page 34 and 35:

34Dynastraight ®Air-Powered Abrasi

- Page 36 and 37:

36 ABRASIVE FINISHING TOOLSDynaRove

- Page 39 and 40:

ABRASIVE FINISHING TOOLSElectric Dy

- Page 41 and 42:

ABRASIVE FINISHING TOOLSLightweight

- Page 43 and 44:

Industrial DynaZipIndustrial-Qualit

- Page 45 and 46:

Dynorbital-Spirit ® & Dynorbital

- Page 47 and 48:

Dynorbital-Spirit ®Air-Powered Ran

- Page 49 and 50:

RANDOM ORBITAL SANDERSMesh Abrasive

- Page 51 and 52:

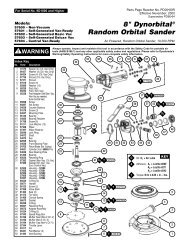

Dynorbital ®SupremeAir-Powered Ran

- Page 53 and 54:

Two-Hand Dynorbital ®Air-Powered R

- Page 55 and 56:

RANDOM ORBITAL SANDERS557° Offset

- Page 57 and 58:

RANDOM ORBITAL SANDERS57Right Angle

- Page 59 and 60:

RANDOM ORBITAL SANDERS11" Dia. Elec

- Page 61 and 62:

DynaLocke ®Air-Powered Dual-Action

- Page 63 and 64:

GEAR-DRIVEN AND FINISHING SANDERSGe

- Page 65 and 66:

“Backsplash ” SanderAir-Powered

- Page 67 and 68:

GEAR-DRIVEN AND FINISHING SANDERSDy

- Page 69 and 70:

Dynabug ® Orbital SanderAir-Powere

- Page 71 and 72:

GEAR-DRIVEN AND FINISHING SANDERSDy

- Page 73 and 74:

GEAR-DRIVEN AND FINISHING SANDERSDy

- Page 75 and 76:

Wet Dynorbital ® Supreme .........

- Page 77 and 78:

Wet Dynorbital ®SupremeAir-Powered

- Page 79 and 80:

WET SANDERS79Wet Dynafine ®Air-Pow

- Page 81 and 82:

Dynabuffer ........................

- Page 83 and 84:

BUFFERS AND POLISHERS“Two-Step

- Page 85 and 86:

BUFFERS AND POLISHERS3" Diameter Bu

- Page 87 and 88:

BUFFERS AND POLISHERS5"-8" Diameter

- Page 89 and 90:

Straight-Line Buffer.4 hp and .7 hp

- Page 91 and 92:

Pencil Grinders ...................

- Page 93 and 94:

Pencil GrindersTurbine-Driven Air M

- Page 95 and 96:

.33 hp Die GrinderRight Angle, Gear

- Page 97 and 98:

.4 hp Die GrindersStraight-Line, Ge

- Page 99 and 100:

.4 hp Die GrindersRight Angle, Fron

- Page 101 and 102:

.5 hp Die GrindersStraight-Line, Ge

- Page 103 and 104:

DIE GRINDERS.5 hp Die Grinders7° O

- Page 105 and 106:

.7 hp Die GrindersStraight-Line, Fr

- Page 107 and 108:

1 hp Die GrindersStraight-Line, Rea

- Page 109 and 110:

DIE GRINDERS1 hp Extension Grinders

- Page 111 and 112:

2" Dia. Disc Sanders.4 hp and .5 hp

- Page 113 and 114:

3" Dia. Disc Sanders.4 hp, .55 hp a

- Page 115 and 116:

DISC SANDERS4-1/2" Dia. Disc Sander

- Page 117 and 118:

DISC SANDERS4-1/2"-5" Dia. Disc San

- Page 119 and 120:

Depressed Center Wheel Grinders ...

- Page 121 and 122:

GRINDERSDepressed Center Wheel Grin

- Page 123 and 124:

GRINDERSDepressed Center Wheel Grin

- Page 125 and 126:

GRINDERSType 1 Wheel GrindersAir-Po

- Page 127 and 128:

GRINDERSCut-Off Wheel ToolsAir-Powe

- Page 129 and 130:

GRINDERSVacuum Cut-Off Wheel ToolsA

- Page 131 and 132:

DrillsAir-Powered Drills, Angle Hea

- Page 133 and 134:

DrillsAir-Powered Drills, 3/8" Chuc

- Page 135 and 136:

DRILLS AND SPECIALTY TOOLSStockade

- Page 137 and 138:

Dynadie ® IIIAir-Powered Reciproca

- Page 139 and 140:

Versatility Grinders ..............

- Page 141 and 142:

Versatility GrinderElectric Abrasiv

- Page 143 and 144:

STATIONARY MACHINESVersatility Grin

- Page 145 and 146:

STATIONARY MACHINESVersatility Grin

- Page 147 and 148:

STATIONARY MACHINESElectric Tool Po

- Page 149 and 150:

STATIONARY MACHINESWet Deburring St

- Page 151 and 152:

Portable Vacuum SystemsChoose from

- Page 153 and 154:

DUST COLLECTION SYSTEMSElectric Por

- Page 155 and 156:

Exhaust HosesMany Configurations to

- Page 157 and 158:

Overskirt ShroudsFor Dynorbital ®

- Page 159 and 160:

Accessories Intro.qxd:Layout 1 9/27

- Page 161 and 162:

2006 Ind Cat_Accessories:2006 Indus

- Page 163 and 164:

2006 Ind Cat_Accessories:2006 Indus

- Page 165 and 166:

2006 Ind Cat_Accessories:2006 Indus

- Page 167 and 168:

2006 Ind Cat_Accessories:2006 Indus

- Page 169 and 170:

2006 Ind Cat_Accessories:2006 Indus

- Page 171 and 172:

2006 Ind Cat_Accessories:2006 Indus

- Page 173 and 174:

2006 Ind Cat_Accessories:2006 Indus

- Page 175 and 176: 2006 Ind Cat_Accessories:2006 Indus

- Page 177 and 178: 2006 Ind Cat_Accessories:2006 Indus

- Page 179 and 180: 2006 Ind Cat_Accessories:2006 Indus

- Page 181 and 182: 2006 Ind Cat_Accessories:2006 Indus

- Page 183 and 184: 2006 Ind Cat_Accessories:2006 Indus

- Page 185 and 186: 2006 Ind Cat_Accessories:2006 Indus

- Page 187 and 188: 2006 Ind Cat_Accessories:2006 Indus

- Page 189 and 190: 2006 Ind Cat_Accessories:2006 Indus

- Page 191 and 192: 2006 Ind Cat_Accessories:2006 Indus

- Page 193 and 194: 2006 Ind Cat_Accessories:2006 Indus

- Page 195 and 196: 2006 Ind Cat_Accessories:2006 Indus

- Page 197 and 198: 2006 Ind Cat_Accessories copy:2006

- Page 199 and 200: 2006 Ind Cat_Accessories copy:2006

- Page 201 and 202: 2006 Ind Cat_Accessories copy:2006

- Page 203 and 204: 2006 Ind Cat_Accessories copy:2006

- Page 205 and 206: 2006 Ind Cat_Accessories:2006 Indus

- Page 207 and 208: 2006 Ind Cat_Accessories:2006 Indus

- Page 209 and 210: Coated Abrasive BeltsFor Use With P

- Page 211 and 212: ABRASIVES AND FILES 211Coated Abras

- Page 213 and 214: ABRASIVES AND FILES 213Non-Woven Ny

- Page 215 and 216: CoatedABRASIVES AND FILES 215NewEdg

- Page 217 and 218: ABRASIVES AND FILES 217Coated Abras

- Page 219 and 220: Dynastraight ®FlapperDynisherABRAS

- Page 221 and 222: DynaMitt SheetsCoatedABRASIVES AND

- Page 223 and 224: ABRASIVES AND FILES 223Bi-Metal Rec

- Page 225: PRODUCT & SAFETY INFORMATIONSafety

- Page 229 and 230: PRODUCT & SAFETY INFORMATIONMaintai

- Page 231 and 232: NUMERICAL INDEX OF TOOLS231Model Pa

- Page 233 and 234: Dynabrade ’ s Mobile Training Uni