Recent developments in the research of shape memory alloys

Recent developments in the research of shape memory alloys

Recent developments in the research of shape memory alloys

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

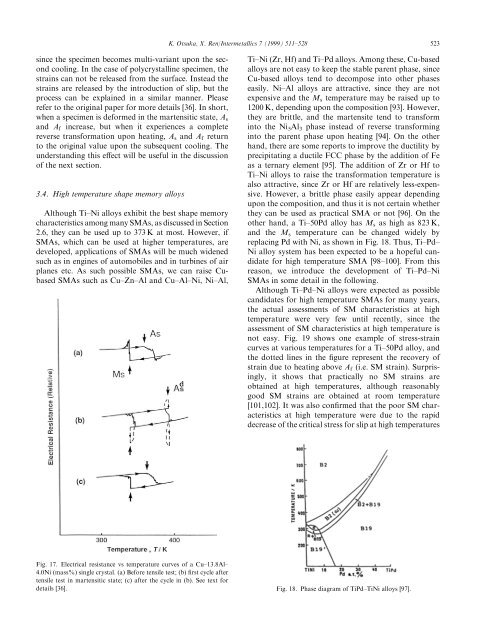

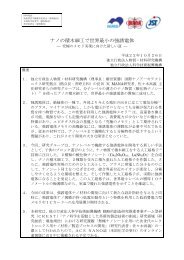

K. Otsuka, X. Ren/Intermetallics 7 (1999) 511±528 523s<strong>in</strong>ce <strong>the</strong> specimen becomes multi-variant upon <strong>the</strong> secondcool<strong>in</strong>g. In <strong>the</strong> case <strong>of</strong> polycrystall<strong>in</strong>e specimen, <strong>the</strong>stra<strong>in</strong>s can not be released from <strong>the</strong> surface. Instead <strong>the</strong>stra<strong>in</strong>s are released by <strong>the</strong> <strong>in</strong>troduction <strong>of</strong> slip, but <strong>the</strong>process can be expla<strong>in</strong>ed <strong>in</strong> a similar manner. Pleaserefer to <strong>the</strong> orig<strong>in</strong>al paper for more details [36]. In short,when a specimen is deformed <strong>in</strong> <strong>the</strong> martensitic state, A sand A f <strong>in</strong>crease, but when it experiences a completereverse transformation upon heat<strong>in</strong>g, A s and A f returnto <strong>the</strong> orig<strong>in</strong>al value upon <strong>the</strong> subsequent cool<strong>in</strong>g. Theunderstand<strong>in</strong>g this e€ect will be useful <strong>in</strong> <strong>the</strong> discussion<strong>of</strong> <strong>the</strong> next section.3.4. High temperature <strong>shape</strong> <strong>memory</strong> <strong>alloys</strong>Although Ti±Ni <strong>alloys</strong> exhibit <strong>the</strong> best <strong>shape</strong> <strong>memory</strong>characteristics among many SMAs, as discussed <strong>in</strong> Section2.6, <strong>the</strong>y can be used up to 373 K at most. However, ifSMAs, which can be used at higher temperatures, aredeveloped, applications <strong>of</strong> SMAs will be much widenedsuch as <strong>in</strong> eng<strong>in</strong>es <strong>of</strong> automobiles and <strong>in</strong> turb<strong>in</strong>es <strong>of</strong> airplanes etc. As such possible SMAs, we can raise CubasedSMAs such as Cu±Zn±Al and Cu±Al±Ni, Ni±Al,Ti±Ni (Zr, Hf) and Ti±Pd <strong>alloys</strong>. Among <strong>the</strong>se, Cu-based<strong>alloys</strong> are not easy to keep <strong>the</strong> stable parent phase, s<strong>in</strong>ceCu-based <strong>alloys</strong> tend to decompose <strong>in</strong>to o<strong>the</strong>r phaseseasily. Ni±Al <strong>alloys</strong> are attractive, s<strong>in</strong>ce <strong>the</strong>y are notexpensive and <strong>the</strong> M s temperature may be raised up to1200 K, depend<strong>in</strong>g upon <strong>the</strong> composition [93]. However,<strong>the</strong>y are brittle, and <strong>the</strong> martensite tend to transform<strong>in</strong>to <strong>the</strong> Ni 5 Al 3 phase <strong>in</strong>stead <strong>of</strong> reverse transform<strong>in</strong>g<strong>in</strong>to <strong>the</strong> parent phase upon heat<strong>in</strong>g [94]. On <strong>the</strong> o<strong>the</strong>rhand, <strong>the</strong>re are some reports to improve <strong>the</strong> ductility byprecipitat<strong>in</strong>g a ductile FCC phase by <strong>the</strong> addition <strong>of</strong> Feas a ternary element [95]. The addition <strong>of</strong> Zr or Hf toTi±Ni <strong>alloys</strong> to raise <strong>the</strong> transformation temperature isalso attractive, s<strong>in</strong>ce Zr or Hf are relatively less-expensive.However, a brittle phase easily appear depend<strong>in</strong>gupon <strong>the</strong> composition, and thus it is not certa<strong>in</strong> whe<strong>the</strong>r<strong>the</strong>y can be used as practical SMA or not [96]. On <strong>the</strong>o<strong>the</strong>r hand, a Ti±50Pd alloy has M s as high as 823 K,and <strong>the</strong> M s temperature can be changed widely byreplac<strong>in</strong>g Pd with Ni, as shown <strong>in</strong> Fig. 18. Thus, Ti±Pd±Ni alloy system has been expected to be a hopeful candidatefor high temperature SMA [98±100]. From thisreason, we <strong>in</strong>troduce <strong>the</strong> development <strong>of</strong> Ti±Pd±NiSMAs <strong>in</strong> some detail <strong>in</strong> <strong>the</strong> follow<strong>in</strong>g.Although Ti±Pd±Ni <strong>alloys</strong> were expected as possiblecandidates for high temperature SMAs for many years,<strong>the</strong> actual assessments <strong>of</strong> SM characteristics at hightemperature were very few until recently, s<strong>in</strong>ce <strong>the</strong>assessment <strong>of</strong> SM characteristics at high temperature isnot easy. Fig. 19 shows one example <strong>of</strong> stress-stra<strong>in</strong>curves at various temperatures for a Ti±50Pd alloy, and<strong>the</strong> dotted l<strong>in</strong>es <strong>in</strong> <strong>the</strong> ®gure represent <strong>the</strong> recovery <strong>of</strong>stra<strong>in</strong> due to heat<strong>in</strong>g above A f (i.e. SM stra<strong>in</strong>). Surpris<strong>in</strong>gly,it shows that practically no SM stra<strong>in</strong>s areobta<strong>in</strong>ed at high temperatures, although reasonablygood SM stra<strong>in</strong>s are obta<strong>in</strong>ed at room temperature[101,102]. It was also con®rmed that <strong>the</strong> poor SM characteristicsat high temperature were due to <strong>the</strong> rapiddecrease <strong>of</strong> <strong>the</strong> critical stress for slip at high temperaturesFig. 17. Electrical resistance vs temperature curves <strong>of</strong> a Cu±13.8Al±4.0Ni (mass%) s<strong>in</strong>gle crystal. (a) Before tensile test; (b) ®rst cycle aftertensile test <strong>in</strong> martensitic state; (c) after <strong>the</strong> cycle <strong>in</strong> (b). See text fordetails [36]. Fig. 18. Phase diagram <strong>of</strong> TiPd±TiNi <strong>alloys</strong> [97].