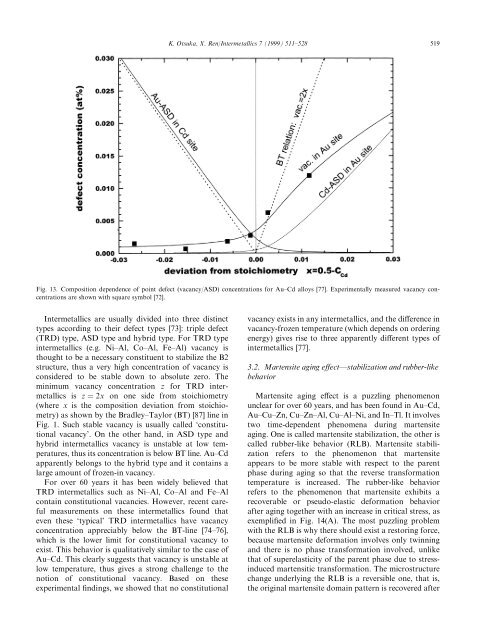

518 K. Otsuka, X. Ren/Intermetallics 7 (1999) 511±528Fig. 12. Stra<strong>in</strong>-temperature curves <strong>of</strong> Ti-±48.2Ni th<strong>in</strong> ®lm under variousconstant stresses conta<strong>in</strong><strong>in</strong>g GP zone precipitates. The specimenwas heat-treated at 745 K for 1 h, which is slightly above <strong>the</strong> crystallizationtemperature 737 K [61].this precipitation on Ti-rich side, refer to <strong>the</strong> orig<strong>in</strong>alpapers for those.Thus, it has become possible to make Ti±Ni th<strong>in</strong> ®lmswith good mechanical properties, but one problem forpractical use is <strong>the</strong> control <strong>of</strong> <strong>the</strong> composition <strong>of</strong> th<strong>in</strong>®lms [65]. S<strong>in</strong>ce it seems that <strong>the</strong> composition is di€erenteven on <strong>the</strong> same substrate and <strong>the</strong> transformationtemperature is very sensitive to composition, compositioncontrol will be an important problem <strong>in</strong> <strong>the</strong> future.Fur<strong>the</strong>rmore, for <strong>the</strong> application to micromach<strong>in</strong>es, <strong>the</strong>substrate must be Si chips. Thus, how to avoid <strong>the</strong> constra<strong>in</strong>tdue to <strong>the</strong> large di€erence <strong>in</strong> <strong>the</strong> <strong>the</strong>rmal expansioncoecient <strong>of</strong> <strong>the</strong> th<strong>in</strong> ®lm and substrate will be <strong>the</strong>second problem [65]. As <strong>the</strong> third, we expect fur<strong>the</strong>rdevelopment <strong>of</strong> applications <strong>of</strong> th<strong>in</strong> ®lms, s<strong>in</strong>ce manyapplications are not disclosed as yet [68].3. Developments <strong>in</strong> <strong>shape</strong> <strong>memory</strong> <strong>alloys</strong> <strong>in</strong> general3.1. Defect densities <strong>in</strong> <strong>in</strong>termetallicsÐare <strong>the</strong>re anyconstitutional vacancies <strong>in</strong> <strong>in</strong>termetallics?As mentioned earlier, most <strong>of</strong> SMAs are <strong>in</strong> fact<strong>in</strong>termetallic compounds (<strong>shape</strong> <strong>memory</strong> <strong>in</strong>termetallics)because <strong>the</strong>y are ordered <strong>alloys</strong> and many <strong>of</strong> <strong>the</strong>mrema<strong>in</strong> ordered near to <strong>the</strong> melt<strong>in</strong>g temperature (e.g.Ti±Ni, Au±Cd, etc.). Therefore, po<strong>in</strong>t defects we discusshere <strong>in</strong>clude both vacancy and anti-site defect (ASD).In comparison to <strong>the</strong> relatively recent knowledgeabout <strong>the</strong> role <strong>of</strong> po<strong>in</strong>t defects on mechanical properties<strong>of</strong> structural <strong>in</strong>termetallics for high temperature applications[69], <strong>the</strong> important role <strong>of</strong> po<strong>in</strong>t defects <strong>in</strong> <strong>shape</strong><strong>memory</strong> <strong>in</strong>termetallics has been widely known for manydecades, because <strong>the</strong>y strongly a€ect nearly all aspects<strong>of</strong> martensitic transformation. This is evidenced by <strong>the</strong>strong dependence <strong>of</strong> M s temperature, transformationhysteresis, and even <strong>the</strong> structure <strong>of</strong> martensite, on <strong>the</strong>concentration <strong>of</strong> po<strong>in</strong>t defects, which can be variedei<strong>the</strong>r by composition change or by heat-treatment (e.g.quench<strong>in</strong>g). For example, <strong>in</strong> many <strong>alloys</strong> (e.g. Cu±Zn, Ti±Ni, Cu±Al, Fe±Pd,...) only 1 at% change <strong>in</strong> compositionvaries <strong>the</strong> M s temperature by as much as tens <strong>of</strong> or evenover a hundred degrees. Sometimes a very small change<strong>in</strong> composition can even change <strong>the</strong> resultant martensitestructure (e.g., Au±47.5Cd and Au±49.5Cd have di€erentmartensite structure). Quench<strong>in</strong>g also gives rise tostrong change <strong>in</strong> transformation temperature and evenchange <strong>in</strong> martensite structure, as well as an <strong>in</strong>crease <strong>in</strong>transformation hysteresis. Po<strong>in</strong>t defects also play a centralrole <strong>in</strong> determ<strong>in</strong><strong>in</strong>g <strong>the</strong> puzzl<strong>in</strong>g martensite ag<strong>in</strong>ge€ect, which will be discussed <strong>in</strong> <strong>the</strong> next section.Lattice dynamics plays a key role <strong>in</strong> martensitictransformations, as manifested by frequently observedlattice s<strong>of</strong>ten<strong>in</strong>g prior to martensitic transformation[70,71] Therefore, we expect that <strong>the</strong> e€ect <strong>of</strong> po<strong>in</strong>tdefects on MT must stem from <strong>the</strong>ir <strong>in</strong>¯uence on latticedynamics through chang<strong>in</strong>g elastic constants and phononenergies, as well as anharmonic energies. A typical example<strong>of</strong> this has been given <strong>in</strong> Section 2.3, which showedhow an addition <strong>of</strong> Cu to Ti±Ni changes <strong>the</strong> elastic constantsand ultimately <strong>the</strong> structure <strong>of</strong> martensite.Despite <strong>the</strong> importance <strong>of</strong> po<strong>in</strong>t defects, quantitative<strong>in</strong>formation about <strong>the</strong>ir concentrations and compositiondependence <strong>in</strong> SMAs (<strong>in</strong>termetallics) is rare. Thismay be due to <strong>the</strong> experimental diculty <strong>in</strong> measur<strong>in</strong>gdefect concentrations. Only Au±Cd furnace-cooled b 2alloy has been measured systematically <strong>in</strong> its wholehomogeneity range (Cd=4652 at%) [72], as shown <strong>in</strong>Fig. 13. The vacancy concentration is determ<strong>in</strong>ed by acomb<strong>in</strong>ation <strong>of</strong> density measurement and x-ray latticeparameter determ<strong>in</strong>ation, and <strong>the</strong> concentrations <strong>of</strong>o<strong>the</strong>r defects (Au±ASD and Cd±ASD) are determ<strong>in</strong>edby best-®tt<strong>in</strong>g <strong>the</strong> experimental vacancy-compositionrelation with a <strong>the</strong>oretical model. A notable fact fromthis result is that vacancy concentration <strong>in</strong> slow-cooledAu-Cd is ra<strong>the</strong>r high (>10 3 ), and is extremely high onCd-rich side (10 2 ), compared with that <strong>in</strong> pure metalsor disordered <strong>alloys</strong> even <strong>in</strong> <strong>the</strong>ir quenched state. Thisfeature is common to many <strong>in</strong>termetallics with <strong>the</strong> openB2 structure.

K. Otsuka, X. Ren/Intermetallics 7 (1999) 511±528 519Fig. 13. Composition dependence <strong>of</strong> po<strong>in</strong>t defect (vacancy/ASD) concentrations for Au±Cd <strong>alloys</strong> [77]. Experimentally measured vacancy concentrationsare shown with square symbol [72].Intermetallics are usually divided <strong>in</strong>to three dist<strong>in</strong>cttypes accord<strong>in</strong>g to <strong>the</strong>ir defect types [73]: triple defect(TRD) type, ASD type and hybrid type. For TRD type<strong>in</strong>termetallics (e.g. Ni±Al, Co±Al, Fe±Al) vacancy isthought to be a necessary constituent to stabilize <strong>the</strong> B2structure, thus a very high concentration <strong>of</strong> vacancy isconsidered to be stable down to absolute zero. Them<strong>in</strong>imum vacancy concentration z for TRD <strong>in</strong>termetallicsis z ˆ 2x on one side from stoichiometry(where x is <strong>the</strong> composition deviation from stoichiometry)as shown by <strong>the</strong> Bradley±Taylor (BT) [87] l<strong>in</strong>e <strong>in</strong>Fig. 1. Such stable vacancy is usually called `constitutionalvacancy'. On <strong>the</strong> o<strong>the</strong>r hand, <strong>in</strong> ASD type andhybrid <strong>in</strong>termetallics vacancy is unstable at low temperatures,thus its concentration is below BT l<strong>in</strong>e. Au±Cdapparently belongs to <strong>the</strong> hybrid type and it conta<strong>in</strong>s alarge amount <strong>of</strong> frozen-<strong>in</strong> vacancy.For over 60 years it has been widely believed thatTRD <strong>in</strong>termetallics such as Ni±Al, Co±Al and Fe±Alconta<strong>in</strong> constitutional vacancies. However, recent carefulmeasurements on <strong>the</strong>se <strong>in</strong>termetallics found thateven <strong>the</strong>se `typical' TRD <strong>in</strong>termetallics have vacancyconcentration appreciably below <strong>the</strong> BT-l<strong>in</strong>e [74±76],which is <strong>the</strong> lower limit for constitutional vacancy toexist. This behavior is qualitatively similar to <strong>the</strong> case <strong>of</strong>Au±Cd. This clearly suggests that vacancy is unstable atlow temperature, thus gives a strong challenge to <strong>the</strong>notion <strong>of</strong> constitutional vacancy. Based on <strong>the</strong>seexperimental ®nd<strong>in</strong>gs, we showed that no constitutionalvacancy exists <strong>in</strong> any <strong>in</strong>termetallics, and <strong>the</strong> di€erence <strong>in</strong>vacancy-frozen temperature (which depends on order<strong>in</strong>genergy) gives rise to three apparently di€erent types <strong>of</strong><strong>in</strong>termetallics [77].3.2. Martensite ag<strong>in</strong>g e€ectÐstabilization and rubber-likebehaviorMartensite ag<strong>in</strong>g e€ect is a puzzl<strong>in</strong>g phenomenonunclear for over 60 years, and has been found <strong>in</strong> Au±Cd,Au±Cu±Zn, Cu±Zn±Al, Cu±Al±Ni, and In±Tl. It <strong>in</strong>volvestwo time-dependent phenomena dur<strong>in</strong>g martensiteag<strong>in</strong>g. One is called martensite stabilization, <strong>the</strong> o<strong>the</strong>r iscalled rubber-like behavior (RLB). Martensite stabilizationrefers to <strong>the</strong> phenomenon that martensiteappears to be more stable with respect to <strong>the</strong> parentphase dur<strong>in</strong>g ag<strong>in</strong>g so that <strong>the</strong> reverse transformationtemperature is <strong>in</strong>creased. The rubber-like behaviorrefers to <strong>the</strong> phenomenon that martensite exhibits arecoverable or pseudo-elastic deformation behaviorafter ag<strong>in</strong>g toge<strong>the</strong>r with an <strong>in</strong>crease <strong>in</strong> critical stress, asexempli®ed <strong>in</strong> Fig. 14(A). The most puzzl<strong>in</strong>g problemwith <strong>the</strong> RLB is why <strong>the</strong>re should exist a restor<strong>in</strong>g force,because martensite deformation <strong>in</strong>volves only tw<strong>in</strong>n<strong>in</strong>gand <strong>the</strong>re is no phase transformation <strong>in</strong>volved, unlikethat <strong>of</strong> superelasticity <strong>of</strong> <strong>the</strong> parent phase due to stress<strong>in</strong>ducedmartensitic transformation. The microstructurechange underly<strong>in</strong>g <strong>the</strong> RLB is a reversible one, that is,<strong>the</strong> orig<strong>in</strong>al martensite doma<strong>in</strong> pattern is recovered after