Microstructural Evolution in a 17-4 PH Stainless Steel after Aging at ...

Microstructural Evolution in a 17-4 PH Stainless Steel after Aging at ...

Microstructural Evolution in a 17-4 PH Stainless Steel after Aging at ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I. INTRODUCTION<br />

PRECIPITATION-hardened sta<strong>in</strong>less steels are<br />

widely used as structural m<strong>at</strong>erials for chemical and<br />

power plants because of their balanced comb<strong>in</strong><strong>at</strong>ion of<br />

good mechanical properties and adequ<strong>at</strong>e corrosion resistance.<br />

<strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel is a martensitic sta<strong>in</strong>less<br />

steel conta<strong>in</strong><strong>in</strong>g approxim<strong>at</strong>ely 3 wt pct Cu and is<br />

strengthened by precipit<strong>at</strong>ion of copper <strong>in</strong> the martensite<br />

m<strong>at</strong>rix [1-8] . After a solution he<strong>at</strong>-tre<strong>at</strong>ment, this alloy<br />

is precipit<strong>at</strong>ion hardened by temper<strong>in</strong>g <strong>at</strong> about<br />

580°C for about 4 hours. Typical service temper<strong>at</strong>ures<br />

<strong>in</strong> power plant applic<strong>at</strong>ions are below 300°C, but <strong>in</strong>creases<br />

<strong>in</strong> hardness and tensile strength accompanied<br />

by embrittlement was reported <strong>at</strong> temper<strong>at</strong>ures rang<strong>in</strong>g<br />

from 300 to 400°C <strong>after</strong> long term ag<strong>in</strong>g. S<strong>in</strong>ce these<br />

m<strong>at</strong>erials have to serve for a very long period of time<br />

dur<strong>in</strong>g the life span of the plants, understand<strong>in</strong>g the<br />

embrittlement mechanism <strong>at</strong> slightly above the service<br />

temper<strong>at</strong>ure is very important.<br />

The precipit<strong>at</strong>ion sequence <strong>in</strong> <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel<br />

beg<strong>in</strong>s with form<strong>at</strong>ion of coherent copper precipit<strong>at</strong>es,<br />

which occurs dur<strong>in</strong>g the temper<strong>in</strong>g tre<strong>at</strong>ment before service.<br />

These coherent particles were reported to transform<br />

to <strong>in</strong>coherent fcc-Cu particles <strong>after</strong> long term ag<strong>in</strong>g<br />

<strong>at</strong> temper<strong>at</strong>ures around 400°C [3] . In addition, s<strong>in</strong>ce<br />

the Cr concentr<strong>at</strong>ion <strong>in</strong> <strong>17</strong>-4 <strong>PH</strong> is with<strong>in</strong> the sp<strong>in</strong>odal<br />

l<strong>in</strong>e, phase decomposition of the martensite <strong>in</strong>to the Ferich<br />

α and the Cr-enriched α’ is expected on ag<strong>in</strong>g below<br />

450°C. Much work has shown th<strong>at</strong> sta<strong>in</strong>less steels<br />

are embrittled when α’ phase precipit<strong>at</strong>es by sp<strong>in</strong>odal<br />

decomposition [11] . Such α’ embrittlement is anticip<strong>at</strong>ed<br />

<strong>in</strong> the <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel as well.<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

<strong>Microstructural</strong> <strong>Evolution</strong> <strong>in</strong> a <strong>17</strong>-4 <strong>PH</strong> Sta<strong>in</strong>less <strong>Steel</strong><br />

<strong>after</strong> Ag<strong>in</strong>g <strong>at</strong> 400°C<br />

M. MURAYAMA, Y. KATAYAMA and K. HONO<br />

The microstructure of <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel <strong>at</strong> various stages of he<strong>at</strong> tre<strong>at</strong>ment, i.e. <strong>after</strong> solution he<strong>at</strong>tre<strong>at</strong>ment,<br />

temper<strong>in</strong>g <strong>at</strong> 580°C and long term ag<strong>in</strong>g <strong>at</strong> 400°C, have been studied by <strong>at</strong>om probe field ion<br />

microscopy (APFIM) and transmission electron microscopy (TEM). The solution tre<strong>at</strong>ed specimen consists<br />

largely of martensite with a small fraction of δ-ferrite. No precipit<strong>at</strong>es are present <strong>in</strong> the martensite<br />

phase, while spherical fcc-Cu particles are present <strong>in</strong> the d-ferrite. After temper<strong>in</strong>g for 4 h <strong>at</strong> 580°C, coherent<br />

Cu particles precipit<strong>at</strong>e <strong>in</strong> the martensite phase. At this stage, the Cr concentr<strong>at</strong>ion <strong>in</strong> the martensite<br />

phase is still uniform. After 5000 h ag<strong>in</strong>g <strong>at</strong> 400°C, the martensite sp<strong>in</strong>odaly decomposes <strong>in</strong>to Fe-rich α<br />

and Cr-enriched α’. In addition, f<strong>in</strong>e particles of the G-phase (structure type D8 a , space group Fm3m )<br />

enriched <strong>in</strong> Si, Ni and Mn have been found <strong>in</strong> <strong>in</strong>tim<strong>at</strong>e contact with the Cu precipit<strong>at</strong>es. Follow<strong>in</strong>g sp<strong>in</strong>odal<br />

decomposition of the martensite phase, G-phase precipit<strong>at</strong>ion occurs <strong>after</strong> long-term ag<strong>in</strong>g.<br />

M. MURAYAMA, Researcher, and K. HONO, Head of 3rd Labor<strong>at</strong>ory,<br />

are with M<strong>at</strong>erials Physics Division, N<strong>at</strong>ional Research Institute<br />

for Metals, Tsukuba 305-0047, Japan. Y. KATAYAMA, is<br />

with Heavy Appar<strong>at</strong>us Eng<strong>in</strong>eer<strong>in</strong>g Labor<strong>at</strong>ory, Toshiba Corpor<strong>at</strong>ion,<br />

Yokohama 230-0045, Japan<br />

Manuscript submitted April 21, 1998.<br />

Several studies on the effect of ag<strong>in</strong>g <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less<br />

steel were carried out [3-6] . Early work by Anthony<br />

[4] proposed mechanical properties of <strong>17</strong>-4 <strong>PH</strong> are <strong>in</strong>fluenced<br />

by precipit<strong>at</strong>ion of α’ phase, but no direct evidence<br />

for α’ precipit<strong>at</strong>ion was presented. L<strong>at</strong>er, Jack<br />

and Kalish [3] observed copper precipit<strong>at</strong>ion on ag<strong>in</strong>g<br />

and correl<strong>at</strong>ed it to mechanical property changes; however,<br />

there was no mention of phase decomposition <strong>in</strong><br />

the martensite phase. More recently, Yrieix and<br />

Guttmann [10] reported th<strong>at</strong> <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel exhibits<br />

high susceptibility to ag<strong>in</strong>g embrittlement <strong>at</strong><br />

400°C, and they concluded th<strong>at</strong> it was essentially due<br />

to α’ precipit<strong>at</strong>ion. In their study, however, no microstructural<br />

observ<strong>at</strong>ion results were shown. Employ<strong>in</strong>g<br />

<strong>at</strong>om probe field ion microscopy (APFIM) and transmission<br />

electron microscopy (TEM), Miller and Burke<br />

[6] showed direct evidence for a’ precipit<strong>at</strong>ion <strong>after</strong> ag<strong>in</strong>g<br />

<strong>at</strong> 482°C. They also reported th<strong>at</strong> significant<br />

amounts of iron, nickel and manganese were conta<strong>in</strong>ed<br />

<strong>in</strong> the ε-Cu precipit<strong>at</strong>es even <strong>in</strong> the overaged condition.<br />

However, their ag<strong>in</strong>g temper<strong>at</strong>ure is r<strong>at</strong>her high compared<br />

to the service condition of <strong>17</strong>-4 <strong>PH</strong> steel.<br />

This study aimed to carry out a more complete characteriz<strong>at</strong>ion<br />

of microstructures <strong>in</strong> <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel<br />

<strong>at</strong> various stages of he<strong>at</strong> tre<strong>at</strong>ment, i.e., <strong>after</strong> solution<br />

he<strong>at</strong>-tre<strong>at</strong>ment, temper<strong>in</strong>g <strong>at</strong> 580°C for four hours, and<br />

long term ag<strong>in</strong>g <strong>at</strong> 400°C, <strong>in</strong> order to obta<strong>in</strong> a better<br />

understand<strong>in</strong>g of the embrittlement phenomena on ag<strong>in</strong>g.<br />

II. EXPERIMENTAL PROCEDURES<br />

The chemical composition of the alloy used <strong>in</strong> this<br />

study was Fe-16.5Cr-4.0Ni-3.4Cu-0.6Si-0.6Mn-0.3Nb-<br />

0.06C (wt pct) or Fe-<strong>17</strong>.5Cr-3.8Ni-2.9Cu-1.2Si-0.6Mn-<br />

0.2Nb-0.3C (<strong>at</strong>. pct). The alloy was solution he<strong>at</strong>-tre<strong>at</strong>ed<br />

<strong>at</strong> 1050°C for 1 h and subsequently w<strong>at</strong>er quenched.<br />

The solution tre<strong>at</strong>ed samples were then aged <strong>at</strong> 580°C<br />

for 4 h (temper<strong>in</strong>g). This he<strong>at</strong> tre<strong>at</strong>ment causes precipit<strong>at</strong>ion<br />

of coherent Cu precipit<strong>at</strong>es <strong>in</strong> the martensite phase

(a)<br />

(b)<br />

110<br />

110<br />

l<strong>at</strong>ed with the depth scale of the analysis, and the total<br />

depth of this analysis is estim<strong>at</strong>ed to be approxim<strong>at</strong>ely<br />

60 nm. This d<strong>at</strong>a shows th<strong>at</strong> the martensite <strong>in</strong> the solution<br />

he<strong>at</strong>-tre<strong>at</strong>ed specimen is a supers<strong>at</strong>ur<strong>at</strong>ed solid solution<br />

conta<strong>in</strong><strong>in</strong>g all solute <strong>at</strong>oms homogeneously.<br />

C. Tempered microstructure<br />

(c)<br />

100nm<br />

110<br />

011<br />

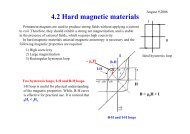

Fig. 5 (a) TEM bright field image, (b) [001] and (c) [111] SAD<br />

p<strong>at</strong>tern of the martensite phase tempered <strong>at</strong> 580°C for 4 h.<br />

Figure 5 shows a bright field TEM image of the<br />

martensite phase <strong>after</strong> ag<strong>in</strong>g for 4 h <strong>at</strong> 580°C. Brightfield<br />

image does not give any clear contrast correspond<strong>in</strong>g<br />

to f<strong>in</strong>e coherent Cu precipit<strong>at</strong>es expected <strong>in</strong> this<br />

stage. This suggests th<strong>at</strong> Cu precipit<strong>at</strong>es, if any, is still<br />

coherent and they do not cause large stra<strong>in</strong> contrast due<br />

to the small stra<strong>in</strong> field around the precipit<strong>at</strong>e. In fact,<br />

the SADP taken from a martensite l<strong>at</strong>h does not show<br />

any evidence for a secondary phase, suggest<strong>in</strong>g th<strong>at</strong><br />

there is no precipit<strong>at</strong>es with the dist<strong>in</strong>ct structure different<br />

from the bcc m<strong>at</strong>rix. Figure 6 shows 3DAP elemental<br />

mapp<strong>in</strong>g of Cu and Cr obta<strong>in</strong>ed from the martensite<br />

phase. The Cu mapp<strong>in</strong>g clearly shows th<strong>at</strong> there<br />

is a small spherical particle enriched with Cu. On the<br />

other hand, the Cr mapp<strong>in</strong>g shows th<strong>at</strong> the distribution<br />

of Cr <strong>at</strong>oms is uniform martensite phase. The Cu el-<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

emental map clearly shows th<strong>at</strong> there is Cu enriched<br />

precipit<strong>at</strong>e <strong>in</strong> this stage. As the SADP (Figure 5(b) and<br />

(c)) does not show any evidence for presence of the<br />

secondary phase, the Cu enriched precipit<strong>at</strong>e observe<br />

<strong>in</strong> the 3DAP d<strong>at</strong>a is believed to be fully coherent bcc-<br />

Cu. In order to quantify the concentr<strong>at</strong>ion of the particle,<br />

concentr<strong>at</strong>ion depth profile was measured from<br />

the selected region near the Cu-rich precipit<strong>at</strong>e as shown<br />

<strong>in</strong> Fig. 6 (c). The chemical composition of the Cu-rich<br />

precipit<strong>at</strong>es has been found to be 55 <strong>at</strong>.pct Cu, 30 <strong>at</strong>.pct<br />

Fe, 10 <strong>at</strong>. pct Cr, 5 <strong>at</strong>. pct Ni. It is seen th<strong>at</strong> Cr and Ni<br />

are rejected from the Cu-enriched particle slightly. It<br />

should also be noted th<strong>at</strong> the concentr<strong>at</strong>ion of Cu <strong>in</strong> the<br />

particle is significantly lower than th<strong>at</strong> expected from<br />

the equilibrium e-Cu.<br />

D. Ag<strong>in</strong>g for 100 h <strong>at</strong> 400°C<br />

Figure 7 (a) and (b) show 3DAP elemental mapp<strong>in</strong>g<br />

of Cu and Cr obta<strong>in</strong>ed from the martensite phase <strong>in</strong> the<br />

specimen aged for 100 h <strong>at</strong> 400°C. The Cu mapp<strong>in</strong>g<br />

shows th<strong>at</strong> a high density of Cu-rich precipit<strong>at</strong>es of approxim<strong>at</strong>ely<br />

3 nm <strong>in</strong> diameter is present. The Cr mapp<strong>in</strong>g<br />

shows th<strong>at</strong> the distribution of Cr <strong>at</strong>oms is no longer<br />

uniform and fluctu<strong>at</strong>ions of Cr concentr<strong>at</strong>ion occur.<br />

Concentr<strong>at</strong>ion depth profiles of Fe, Cr, Ni, Si and Cu<br />

were measured from a selected region cutt<strong>in</strong>g two Curich<br />

precipit<strong>at</strong>es as shown <strong>in</strong> Figure 6(c). The concentr<strong>at</strong>ion<br />

of Cu <strong>in</strong> the Cu-rich precipit<strong>at</strong>es is approxim<strong>at</strong>ely<br />

70 <strong>at</strong>. pct Cu, which is much higher than th<strong>at</strong> observed<br />

<strong>in</strong> the tempered specimen, but it is still lower than the<br />

equilibrium concentr<strong>at</strong>ion of the ε-Cu. The presence of<br />

fluctu<strong>at</strong>ions <strong>in</strong> Cr concentr<strong>at</strong>ion <strong>in</strong>dic<strong>at</strong>es th<strong>at</strong> the phase<br />

decomposition occurs <strong>in</strong> the martensite phase, and it<br />

decomposes to Fe-rich a and Cr-enriched α’ phases. The<br />

Cr concentr<strong>at</strong>ion <strong>in</strong> the α’ phase is only 25 <strong>at</strong>. pct and<br />

this is significantly lower than th<strong>at</strong> of equilibrium α’<br />

phase, suggest<strong>in</strong>g th<strong>at</strong> it is still <strong>in</strong> an <strong>in</strong>itial stage of the<br />

decomposition process. It should be noted th<strong>at</strong> there is<br />

no <strong>in</strong>dic<strong>at</strong>ion of partition<strong>in</strong>g of Ni.<br />

E. Ag<strong>in</strong>g for 5000 h <strong>at</strong> 400°C<br />

Figure 8 (a) shows a dark field image excited us<strong>in</strong>g<br />

the 1/2(110) reflection and Figures 8 (b) – (d) shows<br />

[001], [011], [111] zone SAD p<strong>at</strong>ters, respectively obta<strong>in</strong>ed<br />

from the martensite phase aged for 5000 hours<br />

<strong>at</strong> 400°C. Extra reflections <strong>in</strong>dic<strong>at</strong>e an ordered phase<br />

hav<strong>in</strong>g a cube-on-cube orient<strong>at</strong>ion rel<strong>at</strong>ionship precipit<strong>at</strong>es<br />

<strong>after</strong> prolonged ag<strong>in</strong>g. The dark field image which<br />

was taken us<strong>in</strong>g the 1/2(110) reflection shows a high<br />

density of f<strong>in</strong>e, ordered particles are dispersed <strong>in</strong> the<br />

martensite m<strong>at</strong>rix. The diffraction p<strong>at</strong>tern was found to<br />

be consistent with the G phase (structure type D8 , space a<br />

group Fm3m ) reported <strong>in</strong> aged duplex sta<strong>in</strong>less steels<br />

[23,26,27] [19] and type 308 sta<strong>in</strong>less steels .<br />

Figure 9 shows <strong>at</strong>om probe concentr<strong>at</strong>ion depth profiles<br />

obta<strong>in</strong>ed from the martensite phase <strong>in</strong> the alloy

~26nm<br />

(a) Cr<br />

(b) Cu<br />

~16nm<br />

~26nm<br />

aged for 5000 hours <strong>at</strong> 400°C. In addition to Cu-enriched<br />

precipit<strong>at</strong>es, significant fluctu<strong>at</strong>ions <strong>in</strong> Cr concentr<strong>at</strong>ion<br />

are observed. This shows th<strong>at</strong> phase decomposition<br />

occurs <strong>in</strong> the martensite phase, and the martensite<br />

decomposes to Fe-rich α and Cr-enriched α’<br />

phases. The Cr concentr<strong>at</strong>ion <strong>in</strong> the α’ phase is approxim<strong>at</strong>ely<br />

40 <strong>at</strong>. pct, which is aga<strong>in</strong> significantly lower<br />

than th<strong>at</strong> expected from thermal equilibrium (~90 <strong>at</strong>.<br />

pct). Thus, it is believed th<strong>at</strong> this stage is still <strong>in</strong> the<br />

middle of the decomposition process, and has not<br />

reached the equilibrium. The Ni concentr<strong>at</strong>ion profile<br />

does not show any tendency of partition<strong>in</strong>g of Ni to the<br />

a phase, unlike previous report by Danoix <strong>in</strong> the aged<br />

ferrite phase of duplex sta<strong>in</strong>less steel [26]. It appears<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

Fe & Cr / <strong>at</strong>. %<br />

Ni<br />

Si<br />

Cu<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

30<br />

15<br />

0<br />

30<br />

15<br />

0<br />

60<br />

40<br />

20<br />

0<br />

0 2 4 6 8 10<br />

Depth / ~nm<br />

Fig. 6 3DAP elemental mapp<strong>in</strong>g of the martensite phase aged <strong>at</strong> 580°C for 4 h. (a) The uniform distribution of Cr and (b) a f<strong>in</strong>e spherical Cu<br />

rich precipit<strong>at</strong>e is observed. (c) Concentr<strong>at</strong>ion depth profile through a Cu precipit<strong>at</strong>e.<br />

(c)<br />

th<strong>at</strong> Cu enriched precipit<strong>at</strong>es do not have any correl<strong>at</strong>ion<br />

with the Cr concentr<strong>at</strong>ion fluctu<strong>at</strong>ions. From the<br />

concentr<strong>at</strong>ion profile, two types of Cu precipit<strong>at</strong>es are<br />

observed. One is composed of Cu only, and the other is<br />

enriched with Ni, Si and Mn, as well. The apparent Cu<br />

concentr<strong>at</strong>ion of the l<strong>at</strong>ter is ~20 <strong>at</strong>. pct Cu. This observ<strong>at</strong>ion<br />

is similar to the solute partition<strong>in</strong>g <strong>in</strong> an ultraf<strong>in</strong>e<br />

copper-enriched zone <strong>in</strong> a neutron irradi<strong>at</strong>ed A533B<br />

submerged arc weld reported by Miller et al [13] .<br />

Figure 10 shows 3DAP elemental mapp<strong>in</strong>gs of Cr,<br />

Cu, Ni and Si. Mn cannot be mapped because the mass<br />

spectrum of Mn 2+ overlaps with th<strong>at</strong> of Fe 2+ . The Cr<br />

mapp<strong>in</strong>g shows the concentr<strong>at</strong>ion of Cr fluctu<strong>at</strong>es. The<br />

Cr enriched regions appear to be <strong>in</strong>terconnected, which<br />

Fe<br />

Cr

Fe & Cr / <strong>at</strong>. %<br />

(a)<br />

(b)<br />

Ni<br />

Si<br />

Cu<br />

Cr<br />

Cu<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

30<br />

15<br />

0<br />

30<br />

15<br />

0<br />

70<br />

50<br />

30<br />

10<br />

0<br />

~30nm<br />

0 5 10 15 20 25<br />

Depth / ~nm<br />

~9nm<br />

Fig. 7 3DAP elemental mapp<strong>in</strong>g of the martensite phase aged <strong>at</strong><br />

580°C for 4 h. (a) The phase decomposition <strong>in</strong>to Cr enriched and<br />

depleted region occur <strong>in</strong> the martensite phase. (b) F<strong>in</strong>e spherical<br />

Cu rich precipit<strong>at</strong>e. (c) Concentr<strong>at</strong>ion depth profile obta<strong>in</strong>ed from<br />

the selected region near the Cu precipit<strong>at</strong>e.<br />

is a typical fe<strong>at</strong>ure of sp<strong>in</strong>odal decomposition. The periodicity<br />

of the fluctu<strong>at</strong>ion is on the order of 3 nm. The<br />

Cu mapp<strong>in</strong>g shows th<strong>at</strong> Cu-enriched particles approxim<strong>at</strong>ely<br />

8 nm <strong>in</strong> diameter are present. In direct contact<br />

with one of the Cu particle, a Ni and Si enriched particle<br />

is observed as <strong>in</strong>dic<strong>at</strong>ed by an arrow <strong>in</strong> Figure<br />

10(b). Such f<strong>in</strong>e particles are always observed <strong>in</strong> contact<br />

with Cu precipit<strong>at</strong>es, and they are believed to be<br />

the G-phase based on the TEM observ<strong>at</strong>ion shown <strong>in</strong><br />

Figure 8. Figure 10 (c) shows concentr<strong>at</strong>ion depth profiles<br />

across the Cu precipit<strong>at</strong>e and the G-phase <strong>in</strong>di-<br />

Fe<br />

Cr<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

Fe &Cr / <strong>at</strong>.%<br />

(a)<br />

(b)<br />

110<br />

110<br />

(c) 011<br />

200<br />

(d)<br />

100nm<br />

Fig. 8 TEM (a) dark filed image, (b) [001], (c) [011] and (d) [111]<br />

SAD p<strong>at</strong>tern of the martensite phase aged 400°C for 5000 h. The<br />

dark field image was taken us<strong>in</strong>g the 1/2(011) reflection.<br />

Ni<br />

Si<br />

Mn<br />

Cu<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

30<br />

15<br />

0<br />

30<br />

15<br />

0<br />

10<br />

0<br />

30<br />

15<br />

0<br />

0 500 1000 1500<br />

Number of Atoms / x50<br />

Fig. 9 1DAP concentr<strong>at</strong>ion depth profile of the martensite phase<br />

aged <strong>at</strong> 400°C for 5000 h. Ni, Si, and Mn appear to be partitioned<br />

<strong>in</strong>to the Cu precipit<strong>at</strong>e.<br />

110<br />

011

~15nm<br />

Ni + Si Cu<br />

(a) Cr<br />

(b) Cu, Ni and Si<br />

~18nm<br />

~15nm<br />

Fe & Cr / <strong>at</strong>. %<br />

Ni<br />

Si<br />

Cu<br />

c<strong>at</strong>ed by the arrow <strong>in</strong> Figure 10 (b). The Cu precipit<strong>at</strong>e<br />

conta<strong>in</strong>s approxim<strong>at</strong>ely 95 <strong>at</strong>. pct Cu, which is close to<br />

the equilibrium concentr<strong>at</strong>ion of ε-Cu. The composition<br />

of the G-phase is approxim<strong>at</strong>ely 55 <strong>at</strong>. pct Ni, 25<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

50<br />

0<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Cu precipit<strong>at</strong>e<br />

0 2 4 6 8 10<br />

Depth / ~nm<br />

(c)<br />

G phase<br />

12 14<br />

Fig. 10 3DAP elemental mapp<strong>in</strong>g of the martensite phase aged <strong>at</strong> 400°C for 5000 h. (a) The phase decomposition <strong>in</strong>to Cr enriched and<br />

depleted region occur <strong>in</strong> the martensite phase. (b) Large dots correspond to Cu <strong>at</strong>oms and small dots to Ni and Si <strong>at</strong>oms. (c) Concentr<strong>at</strong>ion<br />

depth profile across the Cu precipit<strong>at</strong>e and the Ni-Si enriched particle obta<strong>in</strong>ed from the selected region near the Cu precipit<strong>at</strong>e (<strong>in</strong>dic<strong>at</strong>ed by<br />

arrow).<br />

Fe<br />

Cr<br />

<strong>at</strong>. pct Si, 20 <strong>at</strong>. pct Fe. In addition, Mn is also enriched<br />

<strong>in</strong> the G-phase based on the 1DAP result shown <strong>in</strong> Figure<br />

9 (Mn ions can be differenti<strong>at</strong>ed from Fe <strong>at</strong>oms us<strong>in</strong>g<br />

1DAP). Accord<strong>in</strong>g to the concentr<strong>at</strong>ion depth pro-

(a)<br />

(b)<br />

G phase Cu precipit<strong>at</strong>e<br />

020 fcc<br />

011<br />

2nm<br />

Fig. 11 (a) HREM image taken <strong>at</strong> the [111] zone axis of the martensite<br />

phase <strong>in</strong> the alloy aged <strong>at</strong> 400°C for 5000 h. (b) micro-diffraction<br />

p<strong>at</strong>tern obta<strong>in</strong>ed from the region with the Moire fr<strong>in</strong>ge.<br />

file obta<strong>in</strong>ed by the conventional <strong>at</strong>om probe (Figure<br />

9), Ni, Si and Mn <strong>at</strong>oms appear to be partitioned to the<br />

Cu enriched particle <strong>in</strong>dic<strong>at</strong>ed by the dashed l<strong>in</strong>es on<br />

the left side of the figure. However, this result is probably<br />

an artifact caused by the convolut<strong>in</strong>g effect of the<br />

probe hole cover<strong>in</strong>g both Cu and G-particles because<br />

Ni, Si and Mn enrichment is not observed <strong>at</strong> the other<br />

Cu enriched region <strong>in</strong> Figure 9. In the l<strong>at</strong>ter case, the<br />

probe hole covered only the Cu particle and missed the<br />

G-phase which was adjacent to the Cu particle. These<br />

results demonstr<strong>at</strong>es th<strong>at</strong> employment of the 3DAP technique<br />

provides more accur<strong>at</strong>e d<strong>at</strong>a for characteriz<strong>in</strong>g<br />

the morphological fe<strong>at</strong>ure of f<strong>in</strong>e precipit<strong>at</strong>es embedded<br />

<strong>in</strong> the m<strong>at</strong>rix.<br />

Figure 11 (a) shows an HREM image taken along<br />

the [111] zone axis of the martensite phase <strong>in</strong> the alloy<br />

aged <strong>at</strong> 400°C for 5000 hours. In this image, fr<strong>in</strong>ge contrast<br />

hav<strong>in</strong>g a periodicity of two (011) planes is ob-<br />

bcc<br />

served. This is consistent with the fr<strong>in</strong>ge contrast expected<br />

from the G-phase (Ni X Si , X=Fe, Mn,<br />

16 6 7<br />

Si, Fm3m , a=0.406 nm). Furthermore, a small particle<br />

is observed adjacent to the G-phase, which is believed<br />

to be a Cu precipit<strong>at</strong>e. A microdiffraction p<strong>at</strong>tern taken<br />

from the region with the Moire fr<strong>in</strong>ges is shown <strong>in</strong> Figure<br />

11 (b). The [111] microdiffraction p<strong>at</strong>tern shows<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

the extra reflections near the {110} bcc reflections. The<br />

δ-spac<strong>in</strong>g calcul<strong>at</strong>ed from the extra reflections is ~0.<strong>17</strong>9<br />

nm which corresponds to the spac<strong>in</strong>g of the {020} fcc<br />

planes <strong>in</strong> fcc-Cu (0.180 nm). The orient<strong>at</strong>ion rel<strong>at</strong>ionship<br />

(OR) between the particle and the martensite almost<br />

m<strong>at</strong>ches with the K-S rel<strong>at</strong>ionship.<br />

IV. DISCUSSION<br />

This study has clarified evolution of microstructure<br />

<strong>in</strong> a <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel dur<strong>in</strong>g long term ag<strong>in</strong>g <strong>at</strong><br />

400°C. Emphasis is given to characteriz<strong>at</strong>ion of chemical<br />

fe<strong>at</strong>ures of the precipit<strong>at</strong>es which appear <strong>in</strong> the martensite<br />

phase <strong>after</strong> prolonged ag<strong>in</strong>g.<br />

The ε-Cu precipit<strong>at</strong>es have been found <strong>in</strong> the δ-ferrite<br />

<strong>after</strong> the solution he<strong>at</strong> tre<strong>at</strong>ment. The appearance<br />

of these precipit<strong>at</strong>es <strong>in</strong> the δ-ferrite was unaffected by<br />

subsequent ag<strong>in</strong>g. Rack and Kalish [3] reported similar<br />

microstructural fe<strong>at</strong>ure <strong>in</strong> δ-ferrite, but they <strong>at</strong>tributed<br />

them to NbC precipit<strong>at</strong>es. In this study, NbC were observed<br />

<strong>at</strong> martensite l<strong>at</strong>h boundaries with much larger<br />

size as shown <strong>in</strong> Figure 1, and we believe th<strong>at</strong> the f<strong>in</strong>e<br />

precipit<strong>at</strong>e <strong>in</strong> the δ-ferrite observed <strong>in</strong> the previous study<br />

as well as <strong>in</strong> this study are the ε-Cu. Precipit<strong>at</strong>ion of Cu<br />

<strong>in</strong> the Fe-Cu b<strong>in</strong>ary system has been a subject of numerous<br />

studies [14-18] , and it is well established th<strong>at</strong> the<br />

<strong>in</strong>itial Cu-enriched precipit<strong>at</strong>e is perfectly coherent with<br />

the bcc m<strong>at</strong>rix, while large overaged precipit<strong>at</strong>es have<br />

an fcc structure with the K-S OR. However, b<strong>in</strong>ary alloys<br />

were all solution he<strong>at</strong>-tre<strong>at</strong>ed <strong>in</strong> the s<strong>in</strong>gle phase<br />

ferrite region around 900°C, while the <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less<br />

steel is solution he<strong>at</strong>-tre<strong>at</strong>ed <strong>at</strong> much higher temper<strong>at</strong>ure<br />

around 1050°C. Diffusivity of Cu <strong>in</strong> the d-ferrite<br />

<strong>at</strong> this temper<strong>at</strong>ure (D Cu ~ 1 x 10 -9 cm 2 /s) is more<br />

than three orders of magnitude higher than th<strong>at</strong> <strong>in</strong> the<br />

austenite (D Cu ~ 4 x 10 -12 cm 2 /s), thus we believe th<strong>at</strong><br />

Cu precipit<strong>at</strong>ed out from the δ-ferrite dur<strong>in</strong>g cool<strong>in</strong>g<br />

<strong>after</strong> the solution he<strong>at</strong> tre<strong>at</strong>ment. Many Cu particles were<br />

observed along disloc<strong>at</strong>ions, and this would have ease<br />

the stra<strong>in</strong> contrast for precipit<strong>at</strong>ion of the fcc ε-Cu. On<br />

the other hand, no <strong>in</strong>dic<strong>at</strong>ion of presence of precipit<strong>at</strong>es<br />

are recognized <strong>in</strong> as-quenched martensite. The<br />

solubility of Cu <strong>in</strong> the austenite phase is up to 7 <strong>at</strong>. pct<br />

<strong>at</strong> 1100°C. However, the diffusivity of Cu <strong>in</strong> the austenite<br />

is orders of magnitude small than th<strong>at</strong> <strong>in</strong> the ferrite<br />

phase. Thus, the precipit<strong>at</strong>ion k<strong>in</strong>etics are much slower<br />

<strong>in</strong> the austenite phase and Cu can be quenched <strong>in</strong> the<br />

martensite phase from the solution he<strong>at</strong>-tre<strong>at</strong>ment temper<strong>at</strong>ure.<br />

After temper<strong>in</strong>g <strong>at</strong> 580°C for 4 hours, f<strong>in</strong>e Curich<br />

precipit<strong>at</strong>es were detected <strong>in</strong> the martensite phase<br />

us<strong>in</strong>g 3DAP. The Cu content <strong>in</strong> the Cu-rich precipit<strong>at</strong>es<br />

is significantly lower than the equilibrium value for ε-<br />

Cu. They reported th<strong>at</strong> the average copper concentr<strong>at</strong>ion<br />

of small precipit<strong>at</strong>es is approxim<strong>at</strong>ely 50 <strong>at</strong>. pct <strong>in</strong><br />

the earliest stage of the precipit<strong>at</strong>ion. The copper concentr<strong>at</strong>ion<br />

<strong>in</strong> the f<strong>in</strong>e, Cu-rich particles which precipit<strong>at</strong>e<br />

dur<strong>in</strong>g temper<strong>in</strong>g is <strong>in</strong> good agreement with the<br />

early study by Goodman et al. [16] . Unlike <strong>in</strong> the d-fer-

ite, these Cu-rich precipit<strong>at</strong>es observed <strong>in</strong> the martensite<br />

phase <strong>after</strong> temper<strong>in</strong>g are bcc-Cu.<br />

The martensite phase decomposes <strong>in</strong>to Fe-rich α and<br />

Cr-enriched α′ phases by the sp<strong>in</strong>odal mechanism. In<br />

addition, f<strong>in</strong>e precipit<strong>at</strong>es of the G-phase has been found<br />

<strong>in</strong> the martensite phase <strong>in</strong> direct contact with the Cu<br />

precipit<strong>at</strong>es <strong>after</strong> 5000hours ag<strong>in</strong>g <strong>at</strong> 400°C. Concentr<strong>at</strong>ion<br />

of Cr <strong>in</strong> the α′ phase is approxim<strong>at</strong>ely 25 <strong>at</strong>. pct<br />

<strong>after</strong> 100 hours, then reach 40 <strong>at</strong>. pct <strong>after</strong> 5000 hours<br />

ag<strong>in</strong>g. This concentr<strong>at</strong>ion is significantly lower than th<strong>at</strong><br />

expected from the b<strong>in</strong>odal l<strong>in</strong>e and is thought to be still<br />

<strong>in</strong> the decomposition process. S<strong>in</strong>ce no precipit<strong>at</strong>ion of<br />

the G-phase was observed <strong>after</strong> 100 hours ag<strong>in</strong>g, the<br />

<strong>in</strong>crease <strong>in</strong> yield strength up to 100 hours is <strong>at</strong>tributed<br />

to the sp<strong>in</strong>odal decomposition r<strong>at</strong>her than the form<strong>at</strong>ion<br />

of the G-phase. G-phase precipit<strong>at</strong>ion was reported<br />

<strong>in</strong> type 308 sta<strong>in</strong>less steels [9, 19] and marag<strong>in</strong>g steels [20]<br />

as a gra<strong>in</strong> boundary phase. In recent years, it was shown<br />

th<strong>at</strong> the G-phase exists <strong>in</strong> various Fe-Cr-Ni alloys as a<br />

dispersed phase <strong>in</strong> the <strong>in</strong>terior of the gra<strong>in</strong>s [21-27] . For<br />

example, Auger et al. [27] reported phase separ<strong>at</strong>ion and<br />

precipit<strong>at</strong>ion of the G-phase <strong>in</strong> the ferrite phase of duplex<br />

sta<strong>in</strong>less steel. They concluded th<strong>at</strong> the nucle<strong>at</strong>ion<br />

of the G-phase takes place <strong>at</strong> the ‘<strong>in</strong>terface’ between<br />

Cr-rich a¢ and Fe-rich a. However, <strong>in</strong> the case of the<br />

<strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel, we have found th<strong>at</strong> G-phase<br />

precipit<strong>at</strong>ion occurs <strong>in</strong> <strong>in</strong>tim<strong>at</strong>e contact with ε-Cu precipit<strong>at</strong>es<br />

<strong>after</strong> the decomposition of the martensite have<br />

progressed. This result <strong>in</strong>dic<strong>at</strong>es th<strong>at</strong> the Cu precipit<strong>at</strong>es<br />

provides heterogeneous nucle<strong>at</strong>ion sites for Gphase<br />

form<strong>at</strong>ion. One reason for this is th<strong>at</strong> the Cu/<br />

martensite <strong>in</strong>terface is a more suitable site for nucle<strong>at</strong>ion<br />

of the G-phase than the α/α’ <strong>in</strong>terface. The dark<br />

field image of the long-term aged martensite phase<br />

shows the G-phase is dispersed uniformly <strong>in</strong> the gra<strong>in</strong><br />

r<strong>at</strong>her than gra<strong>in</strong> boundary as commonly observed <strong>in</strong><br />

other sta<strong>in</strong>less steels. This suggests th<strong>at</strong> the G-phase<br />

precipit<strong>at</strong>ion itself does not contribute to the<br />

embrittlement. In fact, 80 pct of total yield strength <strong>in</strong>crease<br />

occurs before precipit<strong>at</strong>ion of the G-phase is<br />

observed (100 hours ag<strong>in</strong>g <strong>at</strong> 400°C).<br />

Our <strong>at</strong>om probe results have shown th<strong>at</strong> the <strong>at</strong>omic<br />

r<strong>at</strong>io of Ni to Si <strong>in</strong> the G-phase is 6:4. In addition, Mn<br />

and Fe are also conta<strong>in</strong>ed <strong>in</strong> the G-phase. The ternary<br />

silicide design<strong>at</strong>ed as the G-phase is known to be fcc<br />

hav<strong>in</strong>g 116 <strong>at</strong>oms <strong>in</strong> a unit cell. The l<strong>at</strong>tice parameter is<br />

~1.12 nm. The structure of this phase is isotypic with<br />

Th Mn (structure type D8a, space group 6 23 Fm3m ), and<br />

the ideal composition was proposed as X Ni Si , where<br />

6 16 7<br />

X is typically Ti, but can be substituted for other transition<br />

element. Consider<strong>in</strong>g the qualit<strong>at</strong>ive n<strong>at</strong>ure of the<br />

<strong>at</strong>om probe result, the determ<strong>in</strong>ed composition (55 <strong>at</strong>.<br />

pct Ni, 25 <strong>at</strong>. pct Si, 20 <strong>at</strong>. pct Fe and some Mn) is<br />

reasonably close to the ideal stoichiometry of X Ni Si 6 16 7<br />

when one allows for substitution of Mn and Fe for<br />

X [28] .<br />

In this study, partition<strong>in</strong>g of Ni <strong>in</strong> the α phase <strong>after</strong><br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

sp<strong>in</strong>odal decomposition of the martensite was not observed.<br />

This result is <strong>in</strong> contrast to the APFIM results<br />

by Danoix et al. [26] which reported th<strong>at</strong> nickel is rejected<br />

from Cr-enriched α’ phase and partitioned <strong>in</strong>to<br />

the Fe-rich α phase <strong>in</strong> the aged ferrite phase of duplex<br />

sta<strong>in</strong>less steel. In the equilibrium condition, the solubility<br />

limit of Ni <strong>in</strong> α and α’ were estim<strong>at</strong>ed to be 4.1<br />

and 0.01 <strong>at</strong>. pct, respectively, by the ThermoCalc software.<br />

Thus, Ni should partition <strong>in</strong>to the α’phase <strong>in</strong> <strong>17</strong>-<br />

4 <strong>PH</strong> as well. This suggests Ni partition<strong>in</strong>g does not<br />

occur until decomposition progresses further and the<br />

driv<strong>in</strong>g force for the partition<strong>in</strong>g reaction <strong>in</strong>creases.<br />

Similar delayed partition<strong>in</strong>g behavior was reported for<br />

Al <strong>in</strong> an Fe-Cr based alloy [29] . As the Ni concentr<strong>at</strong>ion<br />

of the duplex sta<strong>in</strong>less steel was higher than th<strong>at</strong> <strong>in</strong> <strong>17</strong>-<br />

4 <strong>PH</strong>, the driv<strong>in</strong>g force for Ni partition<strong>in</strong>g is much higher<br />

<strong>in</strong> the duplex sta<strong>in</strong>less steel. Thus the absence of concurrent<br />

partition<strong>in</strong>g of Ni with sp<strong>in</strong>odal decomposition<br />

<strong>in</strong> <strong>17</strong>-4 <strong>PH</strong> is reasonable.<br />

V. CONCLUSIONS<br />

The microstructural fe<strong>at</strong>ures of <strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less<br />

steel <strong>at</strong> various stages of he<strong>at</strong>-tre<strong>at</strong>ment has been <strong>in</strong>vestig<strong>at</strong>ed<br />

by APFIM and TEM. The ma<strong>in</strong> results are<br />

as follows:<br />

1. The fcc Cu-rich particles precipit<strong>at</strong>e <strong>in</strong> the δ-ferrite<br />

gra<strong>in</strong>s dur<strong>in</strong>g cool<strong>in</strong>g <strong>after</strong> the solution he<strong>at</strong> tre<strong>at</strong>ment.<br />

The precipit<strong>at</strong>es have the K-S orient<strong>at</strong>ion rel<strong>at</strong>ionship<br />

with the δ-ferrite m<strong>at</strong>rix.<br />

2. Temper<strong>in</strong>g <strong>at</strong> 580°C for 4 hours results <strong>in</strong> precipit<strong>at</strong>ion<br />

of coherent bcc particles <strong>in</strong> the martensite phase.<br />

The composition of the precipit<strong>at</strong>es is approxim<strong>at</strong>ely<br />

60 <strong>at</strong>. pct Cu and Cr, Ni and Si are rejected from the<br />

bcc-Cu. The Cr concentr<strong>at</strong>ion is homogeneous <strong>in</strong><br />

the martensite phase <strong>at</strong> this stage.<br />

3. After 100 hours ag<strong>in</strong>g <strong>at</strong> 400°C, evidence for<br />

sp<strong>in</strong>odal decomposition of the martensite phase <strong>in</strong>to<br />

Fe-rich a and Cr-enriched a’ phase is found. The Cr<br />

concentr<strong>at</strong>ion <strong>in</strong> the a’ phase is approxim<strong>at</strong>ely 25 <strong>at</strong>.<br />

pct, significantly lower than the equilibrium value.<br />

The concentr<strong>at</strong>ion of Cu <strong>in</strong> the Cu-enriched precipit<strong>at</strong>e<br />

is approxim<strong>at</strong>ely 70 <strong>at</strong>. pct <strong>at</strong> this stage.<br />

4. Sp<strong>in</strong>odal decomposition of the martensite phase<br />

progresses further <strong>after</strong> 5000 hours ag<strong>in</strong>g. The Cr<br />

concentr<strong>at</strong>ion of the α’ phase is 40 <strong>at</strong>. pct <strong>at</strong> this<br />

stage. The structure of the coarsened Cu precipit<strong>at</strong>es<br />

is fcc and their concentr<strong>at</strong>ion is almost 100 <strong>at</strong>. pct<br />

Cu. F<strong>in</strong>e particles of G-phase conta<strong>in</strong><strong>in</strong>g approxim<strong>at</strong>ely<br />

60 <strong>at</strong>. pct Ni, 25 <strong>at</strong>. pct Si and some Fe and<br />

Mn are present <strong>in</strong> direct contact with the Cu precipit<strong>at</strong>es,<br />

suggest<strong>in</strong>g th<strong>at</strong> G-phase is heterogeneously<br />

nucle<strong>at</strong>ed <strong>at</strong> the martensite/Cu <strong>in</strong>terface.<br />

5. The <strong>in</strong>crease <strong>in</strong> hardness and yield strength of the<br />

<strong>17</strong>-4 <strong>PH</strong> sta<strong>in</strong>less steel <strong>after</strong> ag<strong>in</strong>g <strong>at</strong> 400°C is mostly<br />

caused by sp<strong>in</strong>odal decomposition of the martensite<br />

phase. G-phase precipit<strong>at</strong>ion does not appear to make

a significant contribution to the embrittlement dur<strong>in</strong>g<br />

ag<strong>in</strong>g.<br />

ACKNOWLEDGMENTS<br />

The authors thank Professor W.T. Reynolds, Jr., Virg<strong>in</strong>ia<br />

Polytechnic Institute and St<strong>at</strong>e University, for<br />

valuable discussions. This work was supported by the<br />

Frontier Research Center for Structural M<strong>at</strong>erials,<br />

NRIM.<br />

REFERENCES<br />

1. G.N. Goller and W.C. Clarke, Jr.: Iron Age, 1950, vol. 165, pp.<br />

79-83.<br />

2. G.N. Goller and W.C. Clarke, Jr.: Iron Age, 1950, vol. 165, pp.<br />

86-89.<br />

3. H.J. Rack and D. Kalish: Metall. Trans., 1974, vol. 5, pp. 1595-<br />

1605.<br />

4. K.C. Antony: J. Metall., 1963, vol. 15, pp. 922-927.<br />

5. U.K. Viswan<strong>at</strong>han, S. Banerjee and R. Krishnan: M<strong>at</strong>er. Sci.<br />

Eng., 1988, vol. A104, pp. 181-189.<br />

6. M.K. Miller and M.G. Burke: Proc. 5th Int. Smp. on the Environmental<br />

Degrad<strong>at</strong>ion of M<strong>at</strong>erials <strong>in</strong> Nuclear Power Systems<br />

- W<strong>at</strong>er Reactors, September 1991 Monterey, ed. E.P.<br />

Simonen , American Nuclear Society, La Grange Park, 1992,<br />

pp.689-695.<br />

7. H.R. Habibi-Bajguirani and M.L. Jenk<strong>in</strong>s: Phil. Mag. Lett.,<br />

1966, vol. 73, pp. 155-162.<br />

8. K. Ozbaysal and O.T. Inal: M<strong>at</strong>er. Sci. Eng., 1990, vol. A130,<br />

pp. 205-2<strong>17</strong>.<br />

9. J.M. Vitek, S.A. David, D.J. Alexander, J.R. Keiser and R.K.<br />

Nanstad: Acta Metall., 1991, vol. 39, pp. 503-516.<br />

10. B. Yrieix and M. Guttmann: M<strong>at</strong>er. Sci. Technol, 1993, vol. 9,<br />

pp. 125-134.<br />

Published <strong>in</strong> Metall. M<strong>at</strong>er. Trans. A. Vol. 30A, pp. 345-353. 1999<br />

11. W.C. Leslie: The Physical Metallurgy of <strong>Steel</strong>s, McGraw-Hill<br />

Inc., New York, 1981.<br />

12. D. Blavette, B. Deconihout, A. Bostel, J.M. Sarrau, M. Bouet<br />

and A. Menand: Rev. Sci. Instrum, 1993, vol. 64, pp. 2911-<br />

2919.<br />

13. M. K. Miller, M. G. Hether<strong>in</strong>gton and M. G. Burke: Metall.<br />

Trans. A, 1989, vol. 20A, pp. 2651-2661.<br />

14. P.J. Othen, M.L. Jenk<strong>in</strong>s and G.D.W. Smith: Phil. Mag. A, 1996,<br />

vol. 73, pp. 1-24.<br />

15. E. Hornbogen and R.C. Glenn: Trans. AIME, 1960, vol. 218,<br />

pp. 1064-1070.<br />

16. S.R. Goodman, S.S. Brenner and J.R. Low, Jr.: Metall. Trans.,<br />

1973, vol. 4, pp. 2363-2369.<br />

<strong>17</strong>. S.R. Goodman, S.S. Brenner and J.R. Low, Jr.: Metall. Trans.,<br />

1973, vol. 4, pp. 2371-2378.<br />

18. W.J. Phythian and C.A. English: J. Nucl. M<strong>at</strong>er., 1993, vol.<br />

205, pp. 162-<strong>17</strong>7.<br />

19. J.M. Vitek: Metall. Trans. A, 1987, vol. 18A, pp. 154-156.<br />

20. H.J. Rack and D. Kalish: Metall. Trans., 1971, vol. 2, pp. 3011-<br />

3020.<br />

21. W. Sha, A. Cerezo and G.D.W. Smith: Metall. Trans. A, 1993,<br />

vol. 24A, pp. 1241-1249.<br />

22. R.C. Ecob, R.C. Lobb and V.L. Kohler: J. M<strong>at</strong>er. Sci., 1987,<br />

vol. 22, pp. 2867-2880.<br />

23. M. Vr<strong>in</strong><strong>at</strong>, R. Cozar and Y. Meyzaud: Scripta Metall., 1986,<br />

vol. 20, pp. 1101-1106.<br />

24. B. Soylu and R.W.K. Honeycombe: M<strong>at</strong>er. Sci. Technol., 1991,<br />

vol. 7, pp. 137-145.<br />

25. H.M. Chung: Int. J. Pres. Ves. Pip<strong>in</strong>g, 1992, vol. 50, pp. <strong>17</strong>9-<br />

213.<br />

26. F. Danoix, P. Auger and D. Blavette: Surf. Sci., 1992, vol. 266,<br />

pp. 364-369.<br />

27. P. Auger, F. Danoix, A. Menand, S. Bonnet, J. Bourgo<strong>in</strong> and<br />

M. Guttmann: M<strong>at</strong>er. Sci. Technol., 1990, vol. 6, pp. 301-313.<br />

28. F.X. Spiegel, D. Bardos and P.A. Beck: Trans. AIME, 1963,<br />

vol. 227, pp. 575-579.<br />

29. H.G. Read, H. Murakami and K. Hono: Scripta M<strong>at</strong>er., 1997,<br />

vol. 36, pp. 355-361.