Coated Abrasives

Coated Abrasives

Coated Abrasives

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

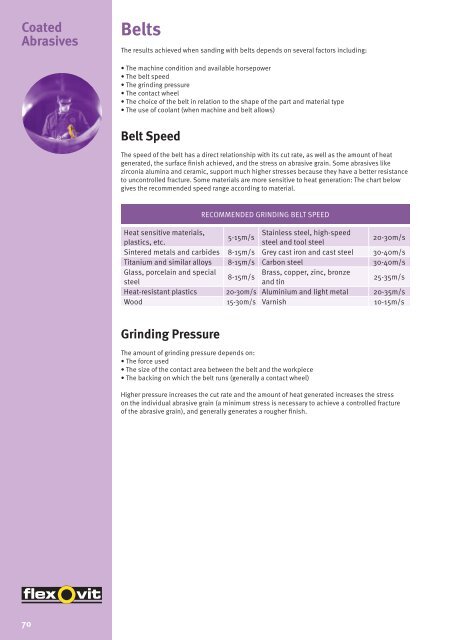

<strong>Coated</strong><strong>Abrasives</strong>BeltsThe results achieved when sanding with belts depends on several factors including:• The machine condition and available horsepower• The belt speed• The grinding pressure• The contact wheel• The choice of the belt in relation to the shape of the part and material type• The use of coolant (when machine and belt allows)Belt SpeedThe speed of the belt has a direct relationship with its cut rate, as well as the amount of heatgenerated, the surface finish achieved, and the stress on abrasive grain. Some abrasives likezirconia alumina and ceramic, support much higher stresses because they have a better resistanceto uncontrolled fracture. Some materials are more sensitive to heat generation: The chart belowgives the recommended speed range according to material.RECOMMENDED GRINDING BELT SPEEDHeat sensitive materials,Stainless steel, high-speed5-15m/splastics, etc.steel and tool steel20-30m/sSintered metals and carbides 8-15m/s Grey cast iron and cast steel 30-40m/sTitanium and similar alloys 8-15m/s Carbon steel 30-40m/sGlass, porcelain and specialBrass, copper, zinc, bronze8-15m/ssteeland tin25-35m/sHeat-resistant plastics 20-30m/s Aluminium and light metal 20-35m/sWood 15-30m/s Varnish 10-15m/sGrinding PressureThe amount of grinding pressure depends on:• The force used• The size of the contact area between the belt and the workpiece• The backing on which the belt runs (generally a contact wheel)Higher pressure increases the cut rate and the amount of heat generated increases the stresson the individual abrasive grain (a minimum stress is necessary to achieve a controlled fractureof the abrasive grain), and generally generates a rougher finish.70