- Page 2:

© 2002 by CRC Press LLCModeling To

- Page 5 and 6:

ContentsPrefaceAcknowledgmentsFUNDA

- Page 7 and 8:

APPLICATIONS8. MODELING OF ENGINEER

- Page 9 and 10:

The contents of this book are organ

- Page 11 and 12:

PART IFundamentals© 2002 by CRC Pr

- Page 13 and 14:

The models resulting from the model

- Page 15 and 16:

within the grasp of only a few with

- Page 17 and 18:

1.2.3 STATIC VS. DYNAMICWhen a syst

- Page 19 and 20:

Real SystemsMathematical ModelsDete

- Page 21 and 22:

through several pathways. Consequen

- Page 23 and 24:

ange of complex environmental appli

- Page 25 and 26:

APPENDIX 1.1 TYPICAL USES OF MATHEM

- Page 27 and 28:

APPENDIX 1.2 (continued)Target Audi

- Page 29 and 30:

characteristics. The system is isol

- Page 31 and 32:

formation, inferencing, testing, va

- Page 33 and 34:

system-surroundings interactions ca

- Page 35 and 36:

2.2.4 INTERPRETATION AND EVALUATION

- Page 37 and 38:

to fill in where scientific theorie

- Page 39 and 40:

Figure 2.3 Schematic of real system

- Page 41 and 42:

Table 2.1 Variables, Symbols, Dimen

- Page 43 and 44:

∴Net diffusive inflow = -EA ∂

- Page 45 and 46:

in terms of the model parameters al

- Page 47 and 48:

Figure 2.8 Model predictions vs. me

- Page 49 and 50:

variables. Deterministic systems ca

- Page 51 and 52:

e possible, and a computational met

- Page 53 and 54:

or, in matrix forma 11 a 12 a 13a 2

- Page 55 and 56:

(a)(b)Figure 3.3 (a) Setting up Sol

- Page 57 and 58:

Figure 3.5 Using MATLAB ® for solv

- Page 59 and 60:

Another method, known as the Newton

- Page 61 and 62:

and so on up tof n (x 1 , x 2 , . .

- Page 63 and 64:

c. Second-order equation with equid

- Page 65 and 66:

Figure 3.9 Solution of ODE by Mathe

- Page 67 and 68:

over the entire step, which may be

- Page 69 and 70:

Hence, the original problem is now

- Page 71 and 72:

2∂ f f i1,j1 - f i-1,j1 - f i1,j-

- Page 73 and 74:

modeling, in diagnosis and troubles

- Page 75 and 76:

For the reach x ≥ a: C S D K

- Page 77 and 78:

contaminants that do not undergo an

- Page 79 and 80:

known as an intensive property. Oth

- Page 81 and 82:

Dissolved mass in sample = dissolve

- Page 83 and 84:

Figure 4.2 Illustration of steady s

- Page 85 and 86: 4.3.2.2 Dalton’s LawDalton’s La

- Page 87 and 88: Table 4.2 Different Forms of Quanti

- Page 89 and 90: M olesoxygenHence, K a-w = = 8 - 3

- Page 91 and 92: SolutionThe flux, N, which is the d

- Page 93 and 94: Figure 4.3 Illustration of the Two-

- Page 95 and 96: where C s is the concentration of t

- Page 97 and 98: Fraction in dissolved form = f d =

- Page 99 and 100: in the air (M/L -3 ), C a is the co

- Page 101 and 102: ackward reactions can expressed in

- Page 103 and 104: 4.7.2 ELEMENTARY REACTIONSThe rate

- Page 105 and 106: excess energy. The direct photolysi

- Page 107 and 108: 4.8 MATERIAL BALANCEAs indicated in

- Page 109 and 110: SolutionLet M be the mass of chemic

- Page 111 and 112: CpHence, the final result isEXERCIS

- Page 113 and 114: APPENDIX 4.1 COMMON PARTITION COEFF

- Page 115 and 116: analyzing and modeling them. The ex

- Page 117 and 118: \5.2.2 HETEROGENEOUS REACTORSHetero

- Page 119 and 120: CC = in -(t t 0 )k C t in0 k- C

- Page 121 and 122: Worked Example 5.1A wastewater trea

- Page 123 and 124: or,C L = C 0 e -(k /u)L = C 0 e -k

- Page 125 and 126: HRT = 1 k (1 - )The overall HRT

- Page 127 and 128: The MB equation for the above syste

- Page 129 and 130: the particle surface (ML -2 T -1 ),

- Page 131 and 132: 0 = QX - Q(X - dX) - K L (aAdz)(X -

- Page 133 and 134: chemical engineering applications.

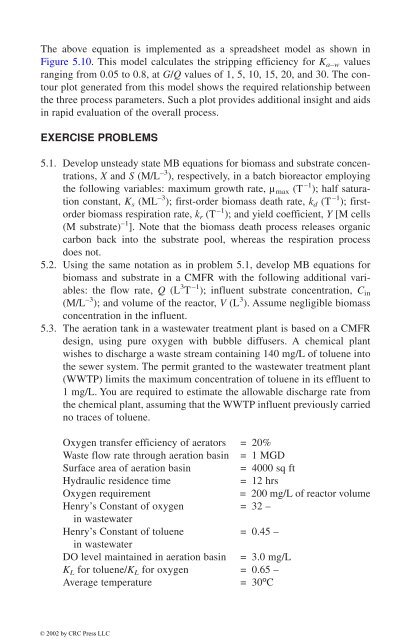

- Page 135: This expression does not provide an

- Page 139 and 140: and degradation of the natural envi

- Page 141 and 142: The solution to the above PDE gives

- Page 143 and 144: • river 2: x = 15000.5 dmay ∴u

- Page 145 and 146: These functions are valuable tools

- Page 147 and 148: this problem. Once the basic “syn

- Page 149 and 150: giving the condition Q > 4πRu for

- Page 151 and 152: directions, and the last term repre

- Page 153 and 154: SolutionTo be conservative, it may

- Page 155 and 156: zone, because the hydraulic conduct

- Page 157 and 158: 6.2.5 FLOW OF AIR AND CONTAMINANTS

- Page 159 and 160: time-dependent volumetric flow rate

- Page 161 and 162: Solution(1) The steady state concen

- Page 163 and 164: As a first step in modeling a river

- Page 165 and 166: where a 1,4 is the conversion facto

- Page 167 and 168: © 2002 by CRC Press LLCFigure 6.8

- Page 169 and 170: Figure 6.106.5 Consider the stream

- Page 171 and 172: Case 4: Pulse Source in Two Dimensi

- Page 173 and 174: End users often adapted these model

- Page 175 and 176: to further enhance the capabilities

- Page 177 and 178: are always expressed in the standar

- Page 179 and 180: know the program’s environment. M

- Page 181 and 182: typing in the equations in algebrai

- Page 183 and 184: accessed in Simulink ® models. The

- Page 185 and 186: By combining the above simple funct

- Page 187 and 188:

Concentration [mg/L]Figure 7.3 Lake

- Page 189 and 190:

saving considerable model building

- Page 191 and 192:

dependent variable, the dependent v

- Page 193 and 194:

command is used to keep the plot fr

- Page 195 and 196:

Figure 7.10 Lake problem solved wit

- Page 197 and 198:

simulation. This enables, for examp

- Page 199 and 200:

Figure 7.13 Lake problem modeled in

- Page 201 and 202:

It is hoped that the above overview

- Page 203 and 204:

APPENDIX 7.2 EXAMPLES OF TYPES OF E

- Page 205 and 206:

CHAPTER 8Modeling of EngineeredEnvi

- Page 207 and 208:

MB on dissolved oxygen: dC od xyt=

- Page 209 and 210:

© 2002 by CRC Press LLCFigure 8.1

- Page 211 and 212:

Table 8.2 SBR Model Equations Gener

- Page 213 and 214:

Figure 8.4 Predicted vs. measured C

- Page 215 and 216:

mathematical model. First, a proces

- Page 217 and 218:

Figure 8.9 Pretreatment system—ef

- Page 219 and 220:

Figure 8.11 CMFRs in series: optimi

- Page 221 and 222:

Other improvements can include alte

- Page 223 and 224:

Figure 8.15 Model of wastewater tre

- Page 225 and 226:

8.5 MODELING EXAMPLE: CHEMICAL OXID

- Page 227 and 228:

When Mathematica ® cannot find ana

- Page 229 and 230:

Figure 8.20 Chemical oxidation proc

- Page 231 and 232:

Figure 8.22 Chemical oxidation proc

- Page 233 and 234:

Figure 8.24 Chemical oxidation proc

- Page 235 and 236:

fairly large and may not be suitabl

- Page 237 and 238:

© 2002 by CRC Press LLCFigure 8.27

- Page 239 and 240:

where q is the mass of color adsorb

- Page 241 and 242:

Figure 8.29 Results of activated ca

- Page 243 and 244:

and d X = (µ - b)Xdtwhere b is the

- Page 245 and 246:

Figure 8.32 Results of bioregenerat

- Page 247 and 248:

under a set of known data, the stat

- Page 249 and 250:

MB across element on oxygen in gas

- Page 251 and 252:

Figure 8.38 Typical results of oxyg

- Page 253 and 254:

Figure 8.39 Mathematica ® script f

- Page 255 and 256:

entered as a function of x and y, u

- Page 257 and 258:

To generalize the approach, the gov

- Page 259 and 260:

Figure 8.44 Concentration in pore g

- Page 261 and 262:

modeling of a sample problem from T

- Page 263 and 264:

Figure 9.2 Lakes in series modeled

- Page 265 and 266:

Figure 9.4 Two lakes in series mode

- Page 267 and 268:

In this example, a two-compartment

- Page 269 and 270:

in the sediments, v b is the burial

- Page 271 and 272:

Figure 9.9 Algal growth modeled in

- Page 273 and 274:

Figure 9.11 Algal growth modeled in

- Page 275 and 276:

Once the basic model is constructed

- Page 277 and 278:

Figure 9.15 Graphical user interfac

- Page 279 and 280:

Figure 9.17 Contaminant transport v

- Page 281 and 282:

Figure 9.19 Contaminant transport v

- Page 283 and 284:

© 2002 by CRC Press LLCFigure 9.20

- Page 285 and 286:

Figure 9.21 Chemical equilibrium mo

- Page 287 and 288:

MB on liver:MB on bones: d P2 = k 2

- Page 289 and 290:

Table 9.3 Model Equations in ithink

- Page 291 and 292:

Figure 9.25 Problem definition for

- Page 293 and 294:

Figure 9.28 Groundwater flow visual

- Page 295 and 296:

W and the second to V, in line 6. T

- Page 297 and 298:

Figure 9.30 Three-dimensional conto

- Page 299 and 300:

VerticalDispersion CoefficientsHori

- Page 301 and 302:

configuration of the unit world pro

- Page 303 and 304:

342Chemical Mass Distribution [%]11

- Page 305 and 306:

water quality standard of 500 mg/L

- Page 307 and 308:

Hence, Q π tan-1 - 1 - UL - 1Q/

- Page 309 and 310:

Figure 9.38d Stream lines and veloc

- Page 311 and 312:

BibliographyBedient P. B., Rifai, H

- Page 313:

Nirmalakhandan, N., Jang, W., and S