ASPECT4 Logistics A Presentation of Release 9.1

ASPECT4 Logistics A Presentation of Release 9.1

ASPECT4 Logistics A Presentation of Release 9.1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

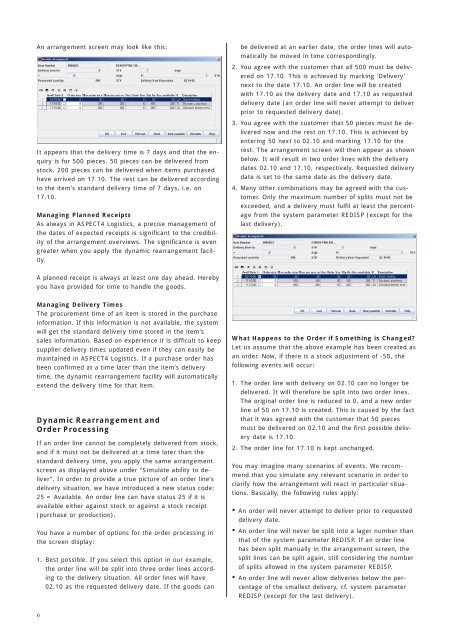

An arrangement screen may look like this:<br />

It appears that the delivery time is 7 days and that the enquiry<br />

is for 500 pieces. 50 pieces can be delivered from<br />

stock. 200 pieces can be delivered when items purchased<br />

have arrived on 17.10. The rest can be delivered according<br />

to the item’s standard delivery time <strong>of</strong> 7 days, i.e. on<br />

17.10.<br />

Managing Planned Receipts<br />

As always in <strong>ASPECT4</strong> <strong>Logistics</strong>, a precise management <strong>of</strong><br />

the dates <strong>of</strong> expected receipts is significant to the credibility<br />

<strong>of</strong> the arrangement overviews. The significance is even<br />

greater when you apply the dynamic rearrangement facility.<br />

A planned receipt is always at least one day ahead. Hereby<br />

you have provided for time to handle the goods.<br />

Managing Delivery Times<br />

The procurement time <strong>of</strong> an item is stored in the purchase<br />

information. If this information is not available, the system<br />

will get the standard delivery time stored in the item’s<br />

sales information. Based on experience it is difficult to keep<br />

supplier delivery times updated even if they can easily be<br />

maintained in <strong>ASPECT4</strong> <strong>Logistics</strong>. If a purchase order has<br />

been confirmed at a time later than the item’s delivery<br />

time, the dynamic rearrangement facility will automatically<br />

extend the delivery time for that item.<br />

Dynamic Rearrangement and<br />

Order Processing<br />

If an order line cannot be completely delivered from stock,<br />

and if it must not be delivered at a time later than the<br />

standard delivery time, you apply the same arrangement<br />

screen as displayed above under "Simulate ability to deliver".<br />

In order to provide a true picture <strong>of</strong> an order line’s<br />

delivery situation, we have introduced a new status code:<br />

25 = Available. An order line can have status 25 if it is<br />

available either against stock or against a stock receipt<br />

(purchase or production).<br />

You have a number <strong>of</strong> options for the order processing in<br />

the screen display:<br />

1. Best possible. If you select this option in our example,<br />

the order line will be split into three order lines according<br />

to the delivery situation. All order lines will have<br />

02.10 as the requested delivery date. If the goods can<br />

6<br />

be delivered at an earlier date, the order lines will automatically<br />

be moved in time correspondingly.<br />

2. You agree with the customer that all 500 must be delivered<br />

on 17.10. This is achieved by marking 'Delivery'<br />

next to the date 17.10. An order line will be created<br />

with 17.10 as the delivery date and 17.10 as requested<br />

delivery date (an order line will never attempt to deliver<br />

prior to requested delivery date).<br />

3. You agree with the customer that 50 pieces must be delivered<br />

now and the rest on 17.10. This is achieved by<br />

entering 50 next to 02.10 and marking 17.10 for the<br />

rest. The arrangement screen will then appear as shown<br />

below. It will result in two order lines with the delivery<br />

dates 02.10 and 17.10, respectively. Requested delivery<br />

date is set to the same date as the delivery date.<br />

4. Many other combinations may be agreed with the customer.<br />

Only the maximum number <strong>of</strong> splits must not be<br />

exceeded, and a delivery must fulfil at least the percentage<br />

from the system parameter REDISP (except for the<br />

last delivery).<br />

What Happens to the Order if Something is Changed?<br />

Let us assume that the above example has been created as<br />

an order. Now, if there is a stock adjustment <strong>of</strong> -50, the<br />

following events will occur:<br />

1. The order line with delivery on 02.10 can no longer be<br />

delivered. It will therefore be split into two order lines.<br />

The original order line is reduced to 0, and a new order<br />

line <strong>of</strong> 50 on 17.10 is created. This is caused by the fact<br />

that it was agreed with the customer that 50 pieces<br />

must be delivered on 02.10 and the first possible delivery<br />

date is 17.10.<br />

2. The order line for 17.10 is kept unchanged.<br />

You may imagine many scenarios <strong>of</strong> events. We recommend<br />

that you simulate any relevant scenario in order to<br />

clarify how the arrangement will react in particular situations.<br />

Basically, the following rules apply:<br />

• An order will never attempt to deliver prior to requested<br />

delivery date.<br />

• An order line will never be split into a lager number than<br />

that <strong>of</strong> the system parameter REDISP. If an order line<br />

has been split manually in the arrangement screen, the<br />

split lines can be split again, still considering the number<br />

<strong>of</strong> splits allowed in the system parameter REDISP.<br />

• An order line will never allow deliveries below the percentage<br />

<strong>of</strong> the smallest delivery, cf. system parameter<br />

REDISP (except for the last delivery).