Mono & Multi Couplers

Mono & Multi Couplers

Mono & Multi Couplers

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

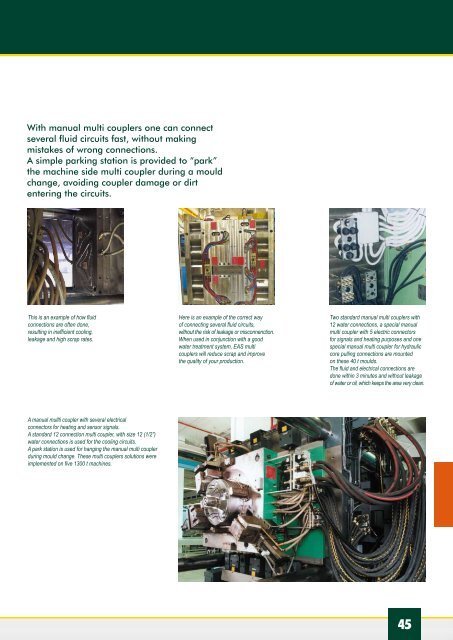

With manual multi couplers one can connectseveral fluid circuits fast, without makingmistakes of wrong connections.A simple parking station is provided to “park”the machine side multi coupler during a mouldchange, avoiding coupler damage or dirtentering the circuits.This is an example of how fluidconnections are often done,resulting in inefficient cooling,leakage and high scrap rates.Here is an example of the correct wayof connecting several fluid circuits,without the risk of leakage or misconnenction.When used in conjunction with a goodwater treatment system, EAS multicouplers will reduce scrap and improvethe quality of your production.Two standard manual multi couplers with12 water connections, a special manualmulti coupler with 5 electric connectorsfor signals and heating purposes and onespecial manual multi coupler for hydrauliccore pulling connections are mountedon these 40 t moulds.The fluid and electrical connections aredone within 3 minutes and without leakageof water or oil, which keeps the area very clean.A manual mullti coupler with several electricalconnectors for heating and sensor signals.A standard 12 connection multi coupler, with size 12 (1/2”)water connections is used for the cooling circuits.A park station is used for hanging the manual multi couplerduring mould change. These multi couplers solutions wereimplemented on five 1300 t machines.45