Mono & Multi Couplers

Mono & Multi Couplers

Mono & Multi Couplers

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

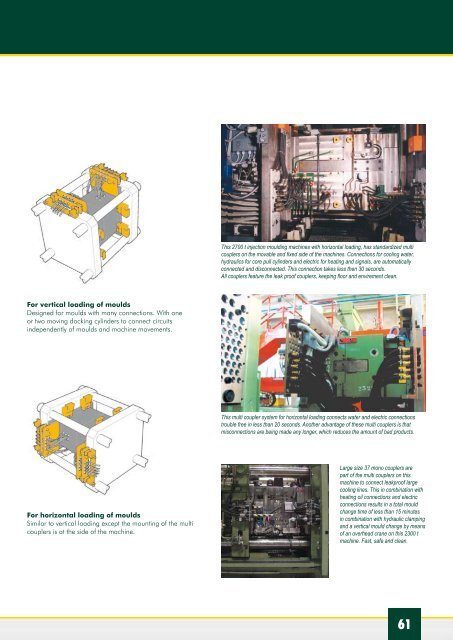

This 2700 t injection moulding machines with horizontal loading, has standardized multicouplers on the movable and fixed side of the machines. Connections for cooling water,hydraulics for core pull cylinders and electric for heating and signals, are automaticallyconnected and disconnected. This connection takes less then 30 seconds.All couplers feature the leak proof couplers, keeping floor and envirement clean.For vertical loading of mouldsDesigned for moulds with many connections. With oneor two moving docking cylinders to connect circuitsindependently of moulds and machine movements.This multi coupler system for horizontal loading connects water and electric connectionstrouble free in less than 20 seconds. Another advantage of these multi couplers is thatmisconnections are being made any longer, which reduces the amount of bad products.For horizontal loading of mouldsSimilar to vertical loading except the mounting of the multicouplers is at the side of the machine.Large size 37 mono couplers arepart of the multi couplers on thismachine to connect leakproof largecooling lines. This in combination withheating oil connections and electricconnections results in a total mouldchange time of less than 15 minutesin combination with hydraulic clampingand a vertical mould change by meansof an overhead crane on this 2300 tmachine. Fast, safe and clean.61