Fybroc Division series 1500 horizontal pumps - MHz Electronics, Inc

Fybroc Division series 1500 horizontal pumps - MHz Electronics, Inc

Fybroc Division series 1500 horizontal pumps - MHz Electronics, Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

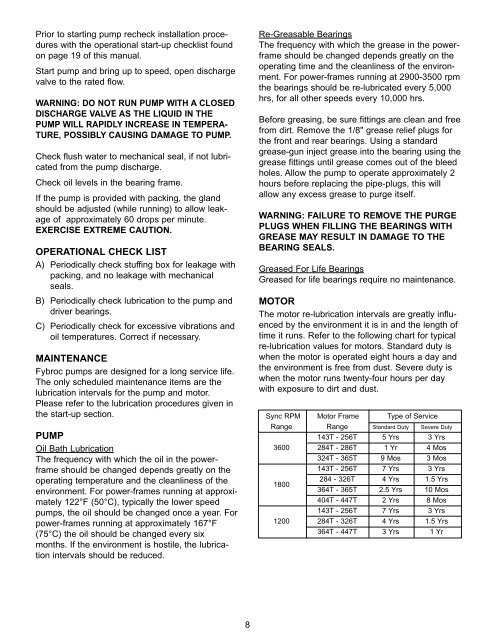

Prior to starting pump recheck installation procedureswith the operational start-up checklist foundon page 19 of this manual.Start pump and bring up to speed, open dischargevalve to the rated flow.WARNING: DO NOT RUN PUMP WITH A CLOSEDDISCHARGE VALVE AS THE LIQUID IN THEPUMP WILL RAPIDLY INCREASE IN TEMPERA-TURE, POSSIBLY CAUSING DAMAGE TO PUMP.Check flush water to mechanical seal, if not lubricatedfrom the pump discharge.Check oil levels in the bearing frame.If the pump is provided with packing, the glandshould be adjusted (while running) to allow leakageof approximately 60 drops per minute.EXERCISE EXTREME CAUTION.OPERATIONAL CHECK LISTA) Periodically check stuffing box for leakage withpacking, and no leakage with mechanicalseals.B) Periodically check lubrication to the pump anddriver bearings.C) Periodically check for excessive vibrations andoil temperatures. Correct if necessary.MAINTENANCE<strong>Fybroc</strong> <strong>pumps</strong> are designed for a long service life.The only scheduled maintenance items are thelubrication intervals for the pump and motor.Please refer to the lubrication procedures given inthe start-up section.PUMPOil Bath LubricationThe frequency with which the oil in the powerframeshould be changed depends greatly on theoperating temperature and the cleanliness of theenvironment. For power-frames running at approximately122°F (50°C), typically the lower speed<strong>pumps</strong>, the oil should be changed once a year. Forpower-frames running at approximately 167°F(75°C) the oil should be changed every sixmonths. If the environment is hostile, the lubricationintervals should be reduced.Re-Greasable BearingsThe frequency with which the grease in the powerframeshould be changed depends greatly on theoperating time and the cleanliness of the environment.For power-frames running at 2900-3500 rpmthe bearings should be re-lubricated every 5,000hrs, for all other speeds every 10,000 hrs.Before greasing, be sure fittings are clean and freefrom dirt. Remove the 1/8" grease relief plugs forthe front and rear bearings. Using a standardgrease-gun inject grease into the bearing using thegrease fittings until grease comes out of the bleedholes. Allow the pump to operate approximately 2hours before replacing the pipe-plugs, this willallow any excess grease to purge itself.WARNING: FAILURE TO REMOVE THE PURGEPLUGS WHEN FILLING THE BEARINGS WITHGREASE MAY RESULT IN DAMAGE TO THEBEARING SEALS.Greased For Life BearingsGreased for life bearings require no maintenance.MOTORThe motor re-lubrication intervals are greatly influencedby the environment it is in and the length oftime it runs. Refer to the following chart for typicalre-lubrication values for motors. Standard duty iswhen the motor is operated eight hours a day andthe environment is free from dust. Severe duty iswhen the motor runs twenty-four hours per daywith exposure to dirt and dust.Sync RPM Motor Frame Type of ServiceRange Range Standard Duty Severe Duty143T - 256T 5 Yrs 3 Yrs3600 284T - 286T 1 Yr 4 Mos324T - 365T 9 Mos 3 Mos143T - 256T 7 Yrs 3 Yrs1800284 - 326T 4 Yrs 1.5 Yrs364T - 365T 2.5 Yrs 10 Mos404T - 447T 2 Yrs 8 Mos143T - 256T 7 Yrs 3 Yrs1200 284T - 326T 4 Yrs 1.5 Yrs364T - 447T 3 Yrs 1 Yr8