Operating Instructions - Electric stirrer for Ultromat - ProMinent

Operating Instructions - Electric stirrer for Ultromat - ProMinent

Operating Instructions - Electric stirrer for Ultromat - ProMinent

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>ProMinent</strong> Dosiertechnik GmbHIm Schuhmachergewann 5 - 1169123 HeidelbergTelephone: +49 6221 842-0Fax: +49 6221 842-419email: info@prominent.deInternet: www.prominent.com986474, 3, en_GB© 20122

Table of contentsTable of contents1 Introduction........................................................................... 51.1 Explanation of the safety in<strong>for</strong>mation............................ 61.2 Users' qualifications...................................................... 82 Safety and responsibility....................................................... 92.1 General safety notes..................................................... 92.2 Intended use................................................................. 93 Commissioning................................................................... 103.1 Storage and transport................................................. 103.2 Construction................................................................ 103.3 Assembly.................................................................... 113.4 Sound pressure level.................................................. 113.5 Installation................................................................... 114 Repairing and maintaining the <strong>stirrer</strong>s................................ 124.1 Maintenance............................................................... 124.2 Repairs....................................................................... 125 Technical data..................................................................... 135.1 Motor data................................................................... 135.2 Materials used............................................................ 165.3 Dimensions and weights <strong>for</strong> the ULFa <strong>stirrer</strong>.............. 175.4 Dimensions and weights <strong>for</strong> the ULDa <strong>stirrer</strong>............. 185.5 Dimensions and weights <strong>for</strong> the ULPa <strong>stirrer</strong>............. 195.6 Dimensions and weights <strong>for</strong> the <strong>Ultromat</strong> ATR <strong>stirrer</strong>. 205.7 Dimensions and weights <strong>for</strong> the <strong>Ultromat</strong> MT <strong>stirrer</strong>... 215.8 Spare parts................................................................. 226 Declaration of Con<strong>for</strong>mity................................................... 247 Index................................................................................... 254

Introduction1 IntroductionThe electric <strong>stirrer</strong>s are used to mix polymer solutions in anAbout this product<strong>Ultromat</strong> ® .The <strong>stirrer</strong>s can be ordered and delivered separately, but alsotogether with an <strong>Ultromat</strong> ® .The media-contacting parts of the <strong>stirrer</strong>s are made from stainlesssteel. Media viscosities up to 1500 mPas are permissibleStirrer <strong>for</strong> <strong>Ultromat</strong> ULFa-chamber 1:Article no. Description Per<strong>for</strong>mance Propellers1030267 Stirrer 0.25 kW, 2 propellers, ULFa 400 0.25 kW 21030269 Stirrer 0.55 kW, 2 propellers, ULFa 1000 0.55 kW 21030270 Stirrer 0.75 kW, 2 propellers, ULFa 2000 0.75 kW 21030271 Stirrer 1.1 kW, 2 propellers, ULFa 4000 1.1 kW 21030272 Stirrer 2.2 kW, 2 propellers, ULFa 8000 2.2 kW 2Stirrer <strong>for</strong> <strong>Ultromat</strong> ULFa chamber 2/3:Article no. Description Per<strong>for</strong>mance Propellers1031374 Stirrer 0.18 kW, 1 propellers, ULFa 400 0.18 kW 11031375 Stirrer 0.55 kW, 1 propellers, ULFa 1000 0.55 kW 11031376 Stirrer 0.75 kW, 1 propellers, ULFa 2000 0.75 kW 11031377 Stirrer 1.1 kW, 1 propellers, ULFa 4000 1.1 kW 11031378 Stirrer 2.2 kW, 1 propellers, ULFa 8000 2.2 kW 1Stirrer <strong>for</strong> <strong>Ultromat</strong> ULDa:Article no. Description Per<strong>for</strong>mance Propellers1039149 Stirrer 0.75 kW, 1 propeller, ULDa 400 0.75 kW 11039144 Stirrer 1.1 kW, 1 propeller, ULDa 1000 1.1 kW 11039124 Stirrer 2.2 kW, 1 propeller, ULDa 2000 2.2 kW 1Stirrer <strong>for</strong> <strong>Ultromat</strong> ULPa:Article no. Description Per<strong>for</strong>mance Propellers1037003 Stirrer 0.75 kW, 1 propeller, ULPa 400 0.75 kW 11036747 Stirrer 1.1 kW, 1 propeller, ULPa 1000 1.1 kW 15

IntroductionArticle no. Description Per<strong>for</strong>mance Propellers1037024 Stirrer 2.2 kW, 1 propeller, ULPa 2000 2.2 kW 11037032 Stirrer 3.0 kW, 1 propeller, ULPa 4000 3.0 kW 1Stirrer <strong>for</strong> <strong>Ultromat</strong> ATR:Article no. Description Per<strong>for</strong>mance Propellers1031374 Stirrer 0.18 kW, 1 propeller, ATR 400 0.18 kW 11031375 Stirrer 0.55 kW, 1 propeller, ATR 1000 0.55 kW 11031376 Stirrer 0.75 kW, 1 propeller, ATR 2000 0.75 kW 1Stirrer <strong>for</strong> <strong>Ultromat</strong> MT:Article no. Description Per<strong>for</strong>mance Propellers1005114 Stirrer MT 140, 0.18 kW 0.18 kW 11005115 Stirrer MT 250, 0.55 kW 0.55 kW 11005116 Stirrer MT 500, 0.75 kW 0.75 kW 11005117 Stirrer MT 1000, 1.1 kW 1.1 kW 11005118 Stirrer MT 2000, 2.2 kW 2.2 kW 11007722 Stirrer MT 3000, 2.2 kW 2.2 kW 11007723 Stirrer MT 4000, 3.0 kW 3.0 kW 11.1 Explanation of the safety in<strong>for</strong>mationIntroductionThese operating instructions provide in<strong>for</strong>mation on the technicaldata and functions of the product. These operating instructions providedetailed safety in<strong>for</strong>mation and are provided as clear step-bystepinstructions.The safety in<strong>for</strong>mation and notes are categorised according to thefollowing scheme. A number of different symbols are used todenote different situations. The symbols shown here serve only asexamples.DANGER!Nature and source of the dangerConsequence: Fatal or very serious injuries.Measure to be taken to avoid this dangerDanger!– Denotes an immediate threatening danger. If this isdisregarded, it will result in fatal or very seriousinjuries.6

IntroductionWARNING!Nature and source of the dangerPossible consequence: Fatal or very serious injuries.Measure to be taken to avoid this dangerWarning!– Denotes a possibly hazardous situation. If this isdisregarded, it could result in fatal or very seriousinjuries.CAUTION!Nature and source of the dangerPossible consequence: Slight or minor injuries, materialdamage.Measure to be taken to avoid this dangerCaution!– Denotes a possibly hazardous situation. If this isdisregarded, it could result in slight or minor injuries.May also be used as a warning about materialdamage.NOTICE!Nature and source of the dangerDamage to the product or its surroundingsMeasure to be taken to avoid this dangerNote!– Denotes a possibly damaging situation. If this isdisregarded, the product or an object in its vicinitycould be damaged.Type of in<strong>for</strong>mationHints on use and additional in<strong>for</strong>mationSource of the in<strong>for</strong>mation, additional measuresIn<strong>for</strong>mation!– Denotes hints on use and other useful in<strong>for</strong>mation.It does not indicate a hazardous or damaging situation.7

Introduction1.2 Users' qualificationsWARNING!Danger of injury with inadequately qualified personnel!The operator of the plant / device is responsible <strong>for</strong>ensuring that the qualifications are fulfilled.If inadequately qualified personnel work on the unit orloiter in the hazard zone of the unit, this could result indangers that could cause serious injuries and materialdamage.– All work on the unit should there<strong>for</strong>e only be conductedby qualified personnel.– Unqualified personnel should be kept away fromthe hazard zoneTrainingInstructed personnelTrained userTrained qualified personnel<strong>Electric</strong>ianCustomer Service departmentDefinitionAn instructed person is deemed to be a person who has been instructed and,if required, trained in the tasks assigned to him/her and possible dangers thatcould result from improper behaviour, as well as having been instructed in therequired protective equipment and protective measures.A trained user is a person who fulfils the requirements made of an instructedperson and who has also received additional training specific to the systemfrom <strong>ProMinent</strong> or another authorised distribution partner.A qualified employee is deemed to be a person who is able to assess thetasks assigned to him and recognize possible hazards based on his/hertraining, knowledge and experience, as well as knowledge of pertinent regulations.The assessment of a person's technical training can also be based onseveral years of work in the relevant field.<strong>Electric</strong>ians are deemed to be people, who are able to complete work on electricalsystems and recognize and avoid possible hazards independently basedon his/her technical training and experience, as well as knowledge of pertinentstandards and regulations.<strong>Electric</strong>ians should be specifically trained <strong>for</strong> the working environment inwhich the are employed and know the relevant standards and regulations.<strong>Electric</strong>ians must comply with the provisions of the applicable statutory directiveson accident prevention.Customer Service department refers to service technicians, who havereceived proven training and have been authorised by <strong>ProMinent</strong> to work onthe system.Note <strong>for</strong> the system operatorThe pertinent accident prevention regulations, as wellas all other generally acknowledged safety regulations,must be adhered to!8

Safety and responsibility2 Safety and responsibility2.1 General safety notesWARNING!Live partsPossible consequence: Fatal or very serious injuries– Measure: The device must be disconnected fromthe power supply be<strong>for</strong>e opening the housing– Isolate damaged, faulty or manipulated devicesfrom the mains in order to de-energise.WARNING!Unauthorised accessPossible consequence: Fatal or very serious injuries– Measure: Ensure that there can be no unauthorisedaccess to the deviceCAUTION!Risk of injury from the rotating propellerSlight or minor injuries.– The <strong>stirrer</strong>s must not be electrically installed, untilthey have been mounted in their operating position.– The <strong>stirrer</strong> must only be operated if it has beenensured that no danger can originate from the propellers.– Switch off the system and only then remove thescrewed cover of an inspection opening2.2 Intended useNOTICE!Intended use– Only use the <strong>stirrer</strong>s with an <strong>Ultromat</strong> ®– Any other use or modification is prohibited.– Only use the <strong>stirrer</strong>s as described in the relevant<strong>Ultromat</strong> ® operating instructions– The <strong>stirrer</strong>s should only be mounted and installedby qualified personnel9

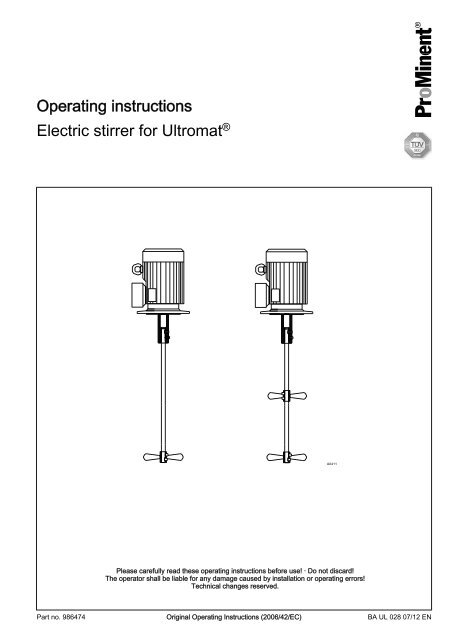

3.1 Storage and transportAmbient conditions <strong>for</strong> storage and transportationCommissioning3 CommissioningCAUTION!Risk of injury from the rotating propellerSlight or minor injuries.– The <strong>stirrer</strong>s must not be electrically installed, untilthey have been mounted in their operating position.– The <strong>stirrer</strong> must only be operated if it has beenensured that no danger can originate from the propellers.– Switch off the system and only then remove thescrewed cover of an inspection opening• Temperature: -10 °C to 50 °C• Air humidity: max. 92 % relative humidity, non-condensingAmbient conditions <strong>for</strong> operation• Temperature: -10 °C to 40 °C• Air humidity: max. 92 % relative humidity, non-condensing3.2 ConstructionStirrer construction with 1 propeller and one <strong>stirrer</strong> with 2 propellersThe <strong>stirrer</strong>s comprise the followingcomponents:Fig. 1: Stirrer with 1 propeller or 2 propellers1. <strong>Electric</strong> motor2. Coupling3. Stirrer shaft4. Propeller 25. Propeller 110

Commissioning3.3 AssemblyNOTICE!Mounting instructionThe <strong>stirrer</strong>s must only be mounted on the intendedtank flange of the <strong>Ultromat</strong> ®Ensure that cooling air can circulate freely.Mounting the <strong>stirrer</strong>1. Remove the shaft of the <strong>stirrer</strong> from the coupling2. Place the motor flange on the prepared tank flange andscrew the motor flange to the tank flange.3. Open the cover of the corresponding inspection opening4. Screw the <strong>stirrer</strong> shaft back into the coupling3.4 Sound pressure levelThe sound pressure level is < 70 dB (A), according to EN ISO11202:1997 (Acoustics - Noise emission from machinery andequipment)3.5 InstallationWARNING!Danger of an electric shock– Only an electrical technician may carry out the<strong>stirrer</strong> electrical installation!– Only install the <strong>stirrer</strong>s, if the system is disconnectedfrom the mains and secured to preventswitching back on.– Only connect the motor to the mains voltage andfrequency, which are specified on its nameplateCAUTION!Thermal overloading– The <strong>stirrer</strong> motors may be damaged by thermaloverloading– To protect the motor against overloading provideappropriate motor protection devices (e.g. motorprotection switch with thermal overcurrent trip)– Fuses do not provide motor protectionInstallation1. Connect the motor according to the wiring diagram2. Switch the system on briefly to determine the direction ofrotation of the motor (arrow on the motor housing)ðIf the motor is rotating in the incorrect direction, immediatelycompletely disconnect the system from the mainsand then connect the motor correctly.3. The inspection opening cover must now be replaced withoutfail and secured with the screw11

4.1 MaintenanceRegularlyRepairing and maintaining the <strong>stirrer</strong>s4 Repairing and maintaining the <strong>stirrer</strong>s• Regularly blow clean the motor fan and the cooling fins usingclean, oil-free compressed air– The <strong>stirrer</strong>s are otherwise maintenance free4.2 RepairsWARNING!Possibility of sudden start-upThe <strong>stirrer</strong>s can start up abruptly once they are connectedto mains voltage via the system, even if a faultalert or exists or the system is stationary (Start/Stopkey).Remove the <strong>stirrer</strong> <strong>for</strong> repair:1. Switch the main system switch to ‘Off’ and secure to preventswitching back on2. Disconnect the motor from the mains3. Remove the flange screws4. Remove the cover of the corresponding inspection opening5. Slightly lift the <strong>stirrer</strong> and release the coupling6. You can now lift the motor off in an upwards direction7. Remove the shaft with the propeller through the inspectionopening8. Refit the <strong>stirrer</strong> after repairs are concluded by following thereverse sequence9. The inspection opening cover must now be replaced withoutfail and secured with the screw12

Technical data5 Technical data5.1 Motor dataStirrer motor of 0.18 kW (740878)Mains supply frequency 50 Hz 60 HzPower 0.18 kW 0.18 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 1.47 / 0.84 A 1.27 / 0.73 ASpeed: 675 - 695 rpm 810-850 rpmcos φ: 0.59 0.64Motor type:K21R80K8Size:80 K8Mounting:IM V1 FF130Degree of protection: IP 55Weight:10.5 kgInsulation class:FMotor flange/hole circle:A 160 / 130 mmManufacturer:VEMStirrer motor of 0.25 kW (1021090)Mains supply frequency 50 Hz 60 HzPower 0.25 kW 0.25 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 2.15 / 1.23 A 1.86 / 1.07 ASpeed: 685 - 700 rpm 830 - 850 rpmcos φ: 0.56 0.58Motor type:K21R80G8Size:80 G8Mounting:IIM V1 FF165Degree of protection: IP 55Weight:12 kgInsulation class:FMotor flange/hole circle:A 200 / 165 mmManufacturer:VEM13

Technical dataStirrer motor of 0.55 kW (740879)Mains supply frequency 50 Hz 60 HzPower 0.55 kW 0.55 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 4.05 / 2.3 A 3.5 / 2.0 ASpeed: 690 - 700 rpm 830 - 855 rpmcos φ: 0.60 0.61Motor type:K21R90L8Size:90L8Mounting:IM V1 FF165Degree of protection: IP 55Weight:18 kgInsulation class:FMotor flange/hole circle:A 200 / 165 mmManufacturer:VEMStirrer motor of 0.75 kW (740880)Mains supply frequency 50 Hz 60 HzPower 0.75 kW 0.75 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 5.45 / 3.1 A 4.6 / 2.65 ASpeed: 700 - 710 rpm 840 – 860 rpmcos φ: 0.60 0.60Motor type:K21R100L8Size:100 L8Mounting:IIM V1 FF165Degree of protection: IP 55Weight:23 kgInsulation class:FMotor flange/hole circle:A 200 / 165 mmManufacturer:VEM14

Technical dataStirrer motor of 1.1 kW (740881)Mains supply frequency 50 Hz 60 HzPower 1.1 kW 1.1 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 5.95 / 3.4 A 5.3 / 3.05 ASpeed: 695 - 710 rpm 830 - 865 rpmcos φ: 0.67 0.71Motor type:K21R100LX8Size:100LX8Mounting:IM V1 FF215Degree of protection: IP 55Weight:28 kgInsulation class:FMotor flange/hole circle:A 250 / 215 mmManufacturer:VEMStirrer motor of 2.2 kW (740882)Mains supply frequency 50 Hz 60 HzPower 2.2 kW 2.2 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 11.0 / 6.35 A 10.3 / 5.95 ASpeed: 675 - 695 rpm 805 - 850 rpmcos φ: 0.68 0.73Motor type:K21R112MX8Size:112 MX8Mounting:IM V1 FF215Degree of protection: IP 55Weight:37 kgInsulation class:FMotor flange/hole circle:A 250 / 215 mmManufacturer:VEM15

Technical dataStirrer motor of 3.0 kW (1018470)Mains supply frequency 50 Hz 60 HzPower 3.00 kW 3.00 kWVoltage: 220 – 240 / 380 - 420 V 220 – 265 / 380 – 460 VCurrent: 13.0 / 7.4 A 13.2 / 7.6 ASpeed: 695 - 705 rpm 830 - 855 rpmcos φ: 0.75 0.73Motor type:K21R132M8Size:90L8Mounting:IM V1Degree of protection: IP 55Weight:53 kgInsulation class:FMotor flange/hole circle:A 300 / 265 mmManufacturer:VEM5.2 Materials usedUnit Material number ( AISI )Stirrer shaft 1.4301 / 1.4404Propellers 1.4571Coupling 1.430516

Technical data5.3 Dimensions and weights <strong>for</strong> the ULFa <strong>stirrer</strong>A0413Fig. 2: Stirrer dimensionsStirrer with 2 propellers <strong>for</strong> chamber 1 (dimensions in mm):ULFa Part no. Per<strong>for</strong>mance1. 2. 3. 4. 5. Weight400 1030267 0.25 kW 680 165 120 215 430 14 kg1000 1030269 0.55 kW 960 165 150 360 720 21 kg2000 1030270 0.75 kW 1100 165 170 395 790 26 kg4000/6000 1030271 1.1 kW 1480 215 200 595 1190 36 kg8000 1030272 2.2 kW 1540 215 220 605 1210 46 kgStirrer with 1 propeller <strong>for</strong> chambers 2+3 (dimensions in mm):ULFa Part no. Per<strong>for</strong>mance1. 2. 3. 4. 5. Weight400 1031374 0.18 kW 670 130 120 -- 430 12 kg1000 1031375 0.55 kW 960 165 170 -- 720 21 kg2000 1031376 0.75 kW 1100 165 200 -- 790 26 kg4000/6000 1031377 1.1 kW 1480 215 220 -- 1190 36 kg8000 1031378 2.2 kW 1540 215 260 -- 1210 45 kg17

Technical data5.4 Dimensions and weights <strong>for</strong> the ULDa <strong>stirrer</strong>A1101Fig. 3: Stirrer dimensionsStirrer with 1 propeller (dimensions in mm):ULDa Part no. Per<strong>for</strong>mance1. 2. 3. 4. Weight400 1039149 0.75 kW 790 165 200 480 26 kg1000 1039144 1.1 kW 1107 215 220 817 36 kg2000 1039124 2.2 kW 1407 215 260 1077 45 kg18

Technical data5.5 Dimensions and weights <strong>for</strong> the ULPa <strong>stirrer</strong>A1101Fig. 4: Stirrer dimensionsStirrer with 1 propeller (dimensions in mm):ULPa Part no. Per<strong>for</strong>mance1. 2. 3. 4. Weight400 1037003 0.75 kW 1130 165 200 830 26 kg1000 1036747 1.1 kW 1220 215 220 915 36 kg2000 1037024 2.2 kW 1610 215 260 1275 45 kg4000 1037032 3.0 kW 1760 265 310 1341 65 kg19

Technical data5.6 Dimensions and weights <strong>for</strong> the <strong>Ultromat</strong> ATR <strong>stirrer</strong>A1101Fig. 5: Stirrer dimensionsStirrer with 1 propeller (dimensions in mm):ATR Part no. Per<strong>for</strong>mance1. 2. 3. 4. Weight400 1031374 0.18 kW 670 130 120 430 12 kg1000 1031375 0.55 kW 960 165 170 720 21 kg2000 1031376 0.75 kW 1100 165 200 790 26 kg20

Technical data5.7 Dimensions and weights <strong>for</strong> the <strong>Ultromat</strong> MT <strong>stirrer</strong>A1101Fig. 6: Stirrer dimensionsStirrer with 1 propeller (dimensions in mm):MT Part no. Per<strong>for</strong>mance1. 2. 3. 4. Weight140 1005114 0.18 kW 818 130 120 610 12 kg250 1005115 0.55 kW 1211 165 170 965 21 kg500 1005116 0.75 kW 1106 165 200 835 26 kg1000 1005117 1.1 kW 1086 215 220 815 36 kg2000 1005118 2.2 kW 1607 215 260 1275 45 kg3000 1007722 2.2 kW 1707 215 260 1375 45 kg4000 1007723 3.0 kW 2174 265 310 1775 65 kg21

Technical data5.8 Spare partsFig. 7: Spare parts1. <strong>Electric</strong> motor2. Coupling3. Stirrer shaft4. Propeller 25. Propeller 1Stirrer with 2 propellers (ULFa):Part no. Per<strong>for</strong>mance 1 2 3 4 51030267 0.25 kW 1021090 1031395 1030655 1031394 10313941030269 0.55 kW 740879 1031398 1026267 1031396 10313961030270 0.75 kW 740880 1031398 1030664 1031397 10313971030271 1.1 kW 740881 1026256 1030666 740885 7408851030272 2.2 kW 740882 1026256 1030667 740886 740886Stirrer with 1 propeller (ULFa):Part no. Per<strong>for</strong>mance 1 2 3 4. 51031374 0.18 kW 740878 1031395 1030655 -- 10313941031375 0.55 kW 740879 1031398 1026267 -- 10313971031376 0.75 kW 740880 1031398 1030664 -- 10314001031377 1.1 kW 740881 1026256 1030666 -- 7408861031378 2.2 kW 740882 1026256 1030667 -- 74088722

Technical dataStirrer with 1 propeller (ULDa):Part no. Per<strong>for</strong>mance 1 2 3 51039149 0.75 kW 740880 1031398 1039147 10314001039144 1.1 kW 740881 1026256 1039143 7408861039124 2.2 kW 740882 1026256 1039123 740887Stirrer with 1 propeller (ULPa):Part no. Per<strong>for</strong>mance 1 2 3 51037003 0.75 kW 740880 1031398 1037000 10314001036747 1.1 kW 740881 1026256 1036746 7408861037024 2.2 kW 740882 1026256 1037001 7408871037032 3.0 kW 1018470 1037324 1037638 1018601Stirrer with 1 propeller (ATR):Part no. Per<strong>for</strong>mance 1 2 3 51031374 0.18 kW 740878 1031395 1030655 10313941031375 0.55 kW 740879 1031398 1026267 10313971031376 0.75 kW 740880 1031398 1030664 1031400Stirrer with 1 propeller (MT):Part no. Per<strong>for</strong>mance 1 2 3 51005114 0.18 kW 740878 1031395 1037281 10313941005115 0.55 kW 740879 1026265 1037283 7408841005116 0.75 kW 740880 1026265 1037382 7408851005117 1.1 kW 740881 1026256 1037321 7408861005118 2.2 kW 740882 1026256 1037001 7408871007722 2.2 kW 740882 1026256 1037323 7408871007723 3.0 kW 1018470 1037324 1037325 101860123

Declaration of Con<strong>for</strong>mity6 Declaration of Con<strong>for</strong>mityEC Declaration of Con<strong>for</strong>mityWe hereby declare,that the following designated product complies with the pertinent fundamental safety and health requirementsof the EC Directive in terms of its design and construction and in terms of the version marketed by us.This declaration loses its validity in the event of a modification to the product not agreed with us.Description of the product:<strong>Electric</strong> <strong>stirrer</strong> in the explanations special steel and PVDF<strong>for</strong> container 60 - 1000 liter and 0,02 - 0,75 kWSerial no.:Please refer to type plate on the devicePertinentEC Directives:EG - Machinery Directive(2006/42/EC)EC EMC Directive (2004/108/EC)The protection targets laid out in the low-voltage regulations2006/95/EG have, as shown in appendix I, Nr. 1.5.1of the machine regulations 2006/42/EG been adhered toApplied harmonised standardsin particular:Technical documents have beencompiled by documentationspecialists:Date / Manufacturer - Signature :Details of the signatory:15.11.2010Joachim Schall, Development DirectorFig. 8: Manufacturer's declaration24

Index7 IndexGGeneral non-discriminatory approach.................... 3LLive parts................................................................ 9Nnon-discriminatory approach.................................. 3PPolymer solutions................................................... 5Propellers............................................................... 9SSafety in<strong>for</strong>mation.................................................. 6Safety notes........................................................... 9Spare parts........................................................... 22Stainless steel........................................................ 5UUnauthorised access.............................................. 9Users' qualifications............................................... 8VViscosity................................................................. 525