Selecting a Rear Suspension - Chris Alston's Chassisworks

Selecting a Rear Suspension - Chris Alston's Chassisworks

Selecting a Rear Suspension - Chris Alston's Chassisworks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

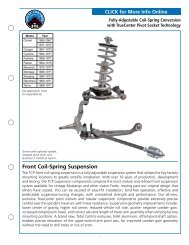

Product Tech<strong>Selecting</strong> a <strong>Rear</strong> <strong>Suspension</strong>4-LINK LENGTHSAll 4-links use top and bottom bars of unequallengths. However, some have a top bar whichis considerably shorter. These are commonlyreferred to as “unequal-length” 4-links. Thisis definitely an inferior design from the past,when chassis builders were not allowed tomodify stock frames. This style causes rapidchanges in the pinion angle and the frontintersect point. Stay away from these designs!The <strong>Chassisworks</strong> Eliminator II 4-link is themost sophisticated rear suspension available today.With its 1/2”-diameter bolt holes, the 4-linkadjustments are now much finer and, of course,there are more from which to choose. This isthe same design that we developed, tested andinstall on our 6-second Pro Modified cars.LADDER BARS vs. 4-LINKA 4-link is like anything else that’s infinitelyadjustable: If you’re not going to spend thetime it takes to get it adjusted correctly, you’rebetter off with a part that doesn’t adjust. If youwant to buy something that’s inexpensive; thatdoesn’t take a lot of real care and extra energyto install; and that basically works right outof the box, then ladder bars are for you. Ifyou want your car to go as fast as possible,and you’re willing to invest whatever energy ittakes, choose a 4-link.Neither type of suspension is perfectlysuited to all-around highway operation. To be100-percent streetable, a rear suspension mustallow the rearend to “roll” independent of thebody. This movement is necessary to smoothlytransverse potholes, speed bumps, curbs andother irregularities in the road. <strong>Chassisworks</strong>now offers ladder bars and 4-links with large,urethane-bushed rod ends which greatlyincrease the amount of rearend roll available— a real plus for Pro Street applications.Additionally, these urethane bushings willabsorb some of the road vibrations.The importance of rearend roll is greatlydiminished on smooth surfaces, of course.Typically, a 4-link allows the rearend to roll afew degrees more than ladder bars. Our newPro Street 4-link offers an unprecedentedamount of suspension travel and, consequently,an incredibly smooth ride. Incidentally, this isthe first race-type 4-link ever designed specificallyfor high-powered street cars and trucks.Beware of old-style “4-bar” designs. These areborrowed from the street-rod industry, and willnot hold up to high horsepower.One more thing: All of your chassis andsuspension components should be purchasedfrom a single source. If you buy a <strong>Chassisworks</strong>4-link or ladder bars and another company’ssubframe, you’re compromising whateverscience was designed into each system— assuming you can even get the parts to fit!Frame design has a tremendous amount to dowith the bracket design. A knowledgeablechassis builder actually designs the suspensionfirst, and then designs a frame that will hold it.LOCATERSA locater keeps the rearend from moving rightand left. Any ladder-bar or 4-link car with coilsprings has to have one. Without a locater,you couldn’t even drive the car. Only two typesare used in drag racing anymore. The morecommon is the track locater: a diagonal linkthat runs from the front of one side of thesuspension to the rear of the other side. Inchassis where clearance problems exist, orin very narrow frames, we use a wishbone,instead, to center the rearend.Some companies still offer only panhardrods, which attach to theframe and to the top of therearend. In a drag car, theframe is very narrow,making this link extremelyshort — only 12 to18 inches long.Such a short linkcauses the rearendto move right to left in the frame as much astwo inches through the suspension travel. Thepanhard rod has no place on a very narrowrear frame, but it can be used on wider rearframes. Use a track locater whenever possible.A track locater or wishbone will always keepthe rearend centered through its full travel.HOUSING FLOATERSIf you have leaf springs and want to add eitherladder bars or a 4-link, housing floaters aremandatory. The rearend attempts to pivotaround both the suspension bar and the leafspring, because they’re both attached to thehousing. Since it can’t pivot around twodissimilar-length arcs, the rearend will bind upwithout floaters. The section that the springgoes through is greased, allowing the floaterto slide on the spring — compensating forthe different arcs through which the rearendmoves. Our design also centers the rearendand permits adjustment of the ride height.Incidentally, floater sales have been ona steady decline for years — reflecting thediminished popularity of leaf springs. Eventhough <strong>Chassisworks</strong> offers the most advancedfloater made, it’s a dying part. We recommendinstalling coil springs, which do not requirefloaters.COIL SPRINGSIn the past, leaf springs were popular becauseSuper Stock rules required original-type springs;leaf-spring cars once cost less money to buildthan coil-over cars; and Chrysler Corporationdevoted lots of energy to Super Stock springtechnology. However, rule changes have madelate-model cars more popular — and those allcame with coil springs. Plus, with the adventof inexpensive coil-spring-mounting kits, costis no longer an issue. Leaf springs are muchharder to mount; they require floaters; andthey weigh so much more that it’s pointlessto continue with them. By the time you buytwo shock absorbers and floaters and buildnew top and bottom shock mounts, the pricedifference is negligible. Last but not least aresome important performance disadvantages.Our economicalcoil-spring assemblyoffers a full six inchesof suspension traveland approximately sixinches of ride-heightadjustment.Because leafsprings sit underneaththe frame,your ladder barsmust fit inboard of the frame. In a coil-springcar, you can make the bars fit under the frame— in the space that would otherwise be occupiedby leaf springs. Now the suspension hasa wider stance, so the car won’t body-roll asmuch. Moreover, you can’t get a leaf-springframe narrow enough to run big tires on anykind of skinny car. Leaf springs take up a minimumof six additional inches of frame width.So, if you’re trying to put a big tire on a narrowcar like an early Nova or Mustang, you’ll belucky to get a 14-inch slick in there, becauseyou can’t build the suspension that narrow. Youcan’t install the ladder bars a foot apart; it justdoesn’t work.Coil springs are the way to go. The onlyexception would be the guy who just wantsto put a set of ladder bars on an existing, stocktypefull frame. Anybody who’s doinga “back-half” car, with a new frame, shouldthrow the leaf springs away.LADDER-BAR ROD ENDSThe rod end at the front of a ladder bar isextremely critical. This is the one that invariablyfails because it’s the front end that’s beingbent, and that’s a real hard load to overcome.Conversely, the rear rod ends are being pulledand pushed, and will take a lot more strain inthose directions. The strength of any rod endis determined entirely by the amount of areathere is to break, and by the strength of thematerial. At a minimum, you need a 4130-type,3/4-inch-shank front rod end on a ladder bar, orit will break. We’ve gone to a 1-inch-diametershank, so the cross section is actually twice that Order: 800-722-2269 Technical Assistance/Customer Service: 916-388-0288 <strong>Chris</strong> Alston’s <strong>Chassisworks</strong> Inc., 8661 Younger Creek Drive, Sacramento, CA 95828