Selecting a Rear Suspension - Chris Alston's Chassisworks

Selecting a Rear Suspension - Chris Alston's Chassisworks

Selecting a Rear Suspension - Chris Alston's Chassisworks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

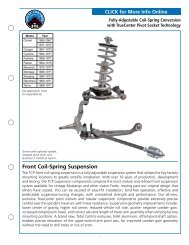

Product Tech<strong>Selecting</strong> a<strong>Rear</strong><strong>Suspension</strong><strong>Chris</strong> Alston ExplainsDrag Racing <strong>Suspension</strong>sOur popular Battle Cruiser line offers two affordable, fully adjustablestyles of rear suspension. The “double-adjustable” ladder bar isideal for e.t. brackets and street-strip applications. The 4-link isnow available with a choice of front-mount designsthat fit aftermarket rear frames (as shown)or a boxed crossmember.LADDER BARSUnlike “slapper bars” and other bolt-on devices,welded ladder bars give you a strong suspensionwith some basic adjustability. Any ladderbar that uses an adjustable front mount can beadjusted for three things. First is what we’ll callthe suspension’s “intersect point” in the chassis.When you raise or lower a ladder bar in itsfront mount, you’re actually adjusting the intersectpoint of how the drive loads are appliedin the chassis. Secondly, you can adjust pinionangle by rotating the two rod ends at the rearof the ladder bar. Finally, you can adjust thepreload in the car by setting one side differentlyfrom the other, effectively shifting weight fromone rear tire to another. Adjusting pinion angleor preload in a standard-typeladder bar requires removing the bar, thenscrewing or unscrewing the ends.What’s known as a “double-adjustable”ladder bar allows you to adjust pinion angleand preload in the front intersect point withoutremoving the bar from the car. A double-adjustablestyle is just easier to use. It has right andleft threads, so it works like a turnbuckle: Youcan loosen and rotate the adjuster withouttaking off the bar. There are two real advantagesto having the adjuster in the bottom bar,instead of the upper bar: (1) It’s easier to getto with a wrench, which solves a real problemin many cars; (2) the rod angle goes straightback and straight forward, so you can move it alot further before the spread between the twotubes gets so great that you can’t put the barback on the car.LADDER-BAR LENGTHAnyone who tells you that short-wheelbase carsneed 30-inch ladder bars, intermediatecars use 32 inches and long-wheelbase carsuse 36 inches is just showing you he doesn’tunderstand the big picture. What makes aladder bar work is dependent on where thefront mount is in relation to the car’s center ofgravity. A 32-inch ladder bar can be adjustedto have the same intersect point as a 36-inchbar in relation to the car’s center of gravity.The reason everyone uses 32-inch ladder barsis a space consideration. Bars shorter than32 inches tend to rotate the pinion angleexcessively, plus they require a front mountthat is very close to the ground.On a long-wheelbase vehicle (like a truck),the 36-inch ladder bar may be the best choice.When under-body clearance is not a factor, thelonger bar can transfer weight more easily.<strong>Chassisworks</strong>’ exclusive frontcrossmember features a tighterbend, more adjustment holes andstronger, 360-degree brackets.4-LINKSA 4-link is definitely superior to ladder bars.However, a 4-link is only superior in applicationif you are willing to invest the time it takesto sort it out. A ladder bar has two or threeadjustment holes that actually work; a 4-linkmight have 50! Actually, the 4-link doesn’thave 50 places that are better; it has perhapsthree that are better, a couple that are thesame, and a whole bunch that are worse. Youjust have a lot more possible intersect points.A tremendous amount of engineering goes intoa properly designed 4-link. There are 4-linkson the market that won’t gain you anything,because the spread on the holes and/or thebrackets themselves are improperly located.Consequently, there are lots of adjustmentsthat you can’t even get to. Email: sales@cachassisworks.com Web: cachassisworks.com <strong>Chris</strong> Alston’s <strong>Chassisworks</strong> Inc., 8661 Younger Creek Drive, Sacramento, CA 95828

Product Tech<strong>Selecting</strong> a <strong>Rear</strong> <strong>Suspension</strong>4-LINK LENGTHSAll 4-links use top and bottom bars of unequallengths. However, some have a top bar whichis considerably shorter. These are commonlyreferred to as “unequal-length” 4-links. Thisis definitely an inferior design from the past,when chassis builders were not allowed tomodify stock frames. This style causes rapidchanges in the pinion angle and the frontintersect point. Stay away from these designs!The <strong>Chassisworks</strong> Eliminator II 4-link is themost sophisticated rear suspension available today.With its 1/2”-diameter bolt holes, the 4-linkadjustments are now much finer and, of course,there are more from which to choose. This isthe same design that we developed, tested andinstall on our 6-second Pro Modified cars.LADDER BARS vs. 4-LINKA 4-link is like anything else that’s infinitelyadjustable: If you’re not going to spend thetime it takes to get it adjusted correctly, you’rebetter off with a part that doesn’t adjust. If youwant to buy something that’s inexpensive; thatdoesn’t take a lot of real care and extra energyto install; and that basically works right outof the box, then ladder bars are for you. Ifyou want your car to go as fast as possible,and you’re willing to invest whatever energy ittakes, choose a 4-link.Neither type of suspension is perfectlysuited to all-around highway operation. To be100-percent streetable, a rear suspension mustallow the rearend to “roll” independent of thebody. This movement is necessary to smoothlytransverse potholes, speed bumps, curbs andother irregularities in the road. <strong>Chassisworks</strong>now offers ladder bars and 4-links with large,urethane-bushed rod ends which greatlyincrease the amount of rearend roll available— a real plus for Pro Street applications.Additionally, these urethane bushings willabsorb some of the road vibrations.The importance of rearend roll is greatlydiminished on smooth surfaces, of course.Typically, a 4-link allows the rearend to roll afew degrees more than ladder bars. Our newPro Street 4-link offers an unprecedentedamount of suspension travel and, consequently,an incredibly smooth ride. Incidentally, this isthe first race-type 4-link ever designed specificallyfor high-powered street cars and trucks.Beware of old-style “4-bar” designs. These areborrowed from the street-rod industry, and willnot hold up to high horsepower.One more thing: All of your chassis andsuspension components should be purchasedfrom a single source. If you buy a <strong>Chassisworks</strong>4-link or ladder bars and another company’ssubframe, you’re compromising whateverscience was designed into each system— assuming you can even get the parts to fit!Frame design has a tremendous amount to dowith the bracket design. A knowledgeablechassis builder actually designs the suspensionfirst, and then designs a frame that will hold it.LOCATERSA locater keeps the rearend from moving rightand left. Any ladder-bar or 4-link car with coilsprings has to have one. Without a locater,you couldn’t even drive the car. Only two typesare used in drag racing anymore. The morecommon is the track locater: a diagonal linkthat runs from the front of one side of thesuspension to the rear of the other side. Inchassis where clearance problems exist, orin very narrow frames, we use a wishbone,instead, to center the rearend.Some companies still offer only panhardrods, which attach to theframe and to the top of therearend. In a drag car, theframe is very narrow,making this link extremelyshort — only 12 to18 inches long.Such a short linkcauses the rearendto move right to left in the frame as much astwo inches through the suspension travel. Thepanhard rod has no place on a very narrowrear frame, but it can be used on wider rearframes. Use a track locater whenever possible.A track locater or wishbone will always keepthe rearend centered through its full travel.HOUSING FLOATERSIf you have leaf springs and want to add eitherladder bars or a 4-link, housing floaters aremandatory. The rearend attempts to pivotaround both the suspension bar and the leafspring, because they’re both attached to thehousing. Since it can’t pivot around twodissimilar-length arcs, the rearend will bind upwithout floaters. The section that the springgoes through is greased, allowing the floaterto slide on the spring — compensating forthe different arcs through which the rearendmoves. Our design also centers the rearendand permits adjustment of the ride height.Incidentally, floater sales have been ona steady decline for years — reflecting thediminished popularity of leaf springs. Eventhough <strong>Chassisworks</strong> offers the most advancedfloater made, it’s a dying part. We recommendinstalling coil springs, which do not requirefloaters.COIL SPRINGSIn the past, leaf springs were popular becauseSuper Stock rules required original-type springs;leaf-spring cars once cost less money to buildthan coil-over cars; and Chrysler Corporationdevoted lots of energy to Super Stock springtechnology. However, rule changes have madelate-model cars more popular — and those allcame with coil springs. Plus, with the adventof inexpensive coil-spring-mounting kits, costis no longer an issue. Leaf springs are muchharder to mount; they require floaters; andthey weigh so much more that it’s pointlessto continue with them. By the time you buytwo shock absorbers and floaters and buildnew top and bottom shock mounts, the pricedifference is negligible. Last but not least aresome important performance disadvantages.Our economicalcoil-spring assemblyoffers a full six inchesof suspension traveland approximately sixinches of ride-heightadjustment.Because leafsprings sit underneaththe frame,your ladder barsmust fit inboard of the frame. In a coil-springcar, you can make the bars fit under the frame— in the space that would otherwise be occupiedby leaf springs. Now the suspension hasa wider stance, so the car won’t body-roll asmuch. Moreover, you can’t get a leaf-springframe narrow enough to run big tires on anykind of skinny car. Leaf springs take up a minimumof six additional inches of frame width.So, if you’re trying to put a big tire on a narrowcar like an early Nova or Mustang, you’ll belucky to get a 14-inch slick in there, becauseyou can’t build the suspension that narrow. Youcan’t install the ladder bars a foot apart; it justdoesn’t work.Coil springs are the way to go. The onlyexception would be the guy who just wantsto put a set of ladder bars on an existing, stocktypefull frame. Anybody who’s doinga “back-half” car, with a new frame, shouldthrow the leaf springs away.LADDER-BAR ROD ENDSThe rod end at the front of a ladder bar isextremely critical. This is the one that invariablyfails because it’s the front end that’s beingbent, and that’s a real hard load to overcome.Conversely, the rear rod ends are being pulledand pushed, and will take a lot more strain inthose directions. The strength of any rod endis determined entirely by the amount of areathere is to break, and by the strength of thematerial. At a minimum, you need a 4130-type,3/4-inch-shank front rod end on a ladder bar, orit will break. We’ve gone to a 1-inch-diametershank, so the cross section is actually twice that Order: 800-722-2269 Technical Assistance/Customer Service: 916-388-0288 <strong>Chris</strong> Alston’s <strong>Chassisworks</strong> Inc., 8661 Younger Creek Drive, Sacramento, CA 95828

of a 3/4-inch end. Plus, it’s made from a newaerospace material with strength equivalent to4130 chromemoly.Another factor is the diameter of the ladderbar’s tubing. The bottom bar tends to flex in areal high-horsepower or heavyweight car. Our1-1/4-inch bottom bars are almost impossibleto flex. To offset their slightly heavier weight,we use two 3/4-inch-shank rod ends with1/2-inch bolts at the rear. You don’t give upany strength, because you have two rod endsback there.Even with the giant front rod end, you haveto be very careful inspecting and replacing it.When you first install the rod ends, measurethem with a caliper. If they stretch even acouple thousandths, get rid of them. They needto be inspected frequently, especially in a heavyand/or very fast car. At the absolute minimum,it’s an annual throw-away part.Some manufacturers advertise that solid rodends in the front of the ladder bar will causebinding; however, since ladder bars for raceuse do not “roll,” installing spherical rod endswould only increase the possibility of breakage— definitely a bad idea.In a solid-rod-end car, you cannot run thefront bolt that holds the rearend to the frametight, because it pinches the bracket againstthe rod end, and binds it up. If you torque this5/8-inch bolt and squeeze these brackets, therearend won’t go up and down. What it does ispromptly break a front rod end off! However,track locaters that bolt onto the front ofladder bars now require that the bolt is tight;otherwise, the locater won’t locate the rearsuspension. <strong>Chassisworks</strong> solved this problemby going to a 3/4-inch-hole bracket with aspacer set. The spacer tightens against the sideof the rod end, but it has a 3/4-inch outside,so it will pivot in the bracket — allowing youto tighten the front bolt. If you keep it greased,it’s really free and really strong.For Pro Street applications, <strong>Chassisworks</strong>has developed a huge, aerospace-alloy,billet-steel ladder-bar rod end that uses largeurethane bushings. It’s strong enough for bigblockhorsepower.4-LINK ROD ENDSSpherical-type rod ends should be used in alllinks. The rearend actually rotates, and solidrod ends don’t allow that natural movement.A 4-link with solid ends will be much stiffer,making the car difficult to hook up. For dragracing 4-links, <strong>Chassisworks</strong> offers sets of eightrod ends in either mild steel or 4130 chromemoly.The 4130 units are twice as strong, andare absolutely mandatory for vehicles makinglots of horsepower, and/or carrying a lot ofweight, and/or running huge rear tires.For Pro Street applications, <strong>Chassisworks</strong>has developed a huge, aerospace-alloy, billetsteelrod end that uses large urethane bushings.It’s strong enough for big-block horsepower.SHOCK ABSORBERSToday’s basic rear-suspension setup uses aninexpensive coil-spring kit with light-valved,OEM-type shock absorbers. Our adjustableride-heightlower shock mount allows the homebuilder to be off a little in his calculations,and still get the car to ride where he wants.And there is some adjustment in that forperformance. Our kit uses the same coil springsthat we put in our Koni coil-over set. It’s a nice,compact unit that works well for the budgetconsciousguy. For about $230, you get acomplete set of shocks, springs, adjustableheightlower mounts and upper spring mounts.The next step up is to a true coil-over.The advantage here is mostly in the valving ofthe shock. What’s known as the single-internaladjustableKoni shock was specifically designedfor drag racing. You take it off and rotate it toadjust how hard the shock comes apart. Thisseparation, or extension, is the majority oftuning on a drag racing shock. Like anythingelse, if a shock has more adjustments, you canpossibly make it work better, because you havemore places you can put it. Internally adjustableKonis cost about $300 a pair, with springs.Our mounting kit is about $60, so the true-coiloverpackage is almost $130 more than thecoil-spring kit described above. The third stepup the “shock ladder” is the VariShock QuickSet1 externally adjustable, aluminum-bodied coilover.Since the extension setting of the shock iswhat controls a drag race car’s rear suspension,these shocks are the “best bang for your buck.”For about $420 a pair (with springs), you getthe external adjustment at two-thirds the priceof double-adjustable shocks.The ultimate drag racing shock is VariShock’sdouble-adjustable QuickSet 2. One knob at thebottom adjusts how hard the shock absorbercomes together; a second knob at the bottomsets how hard the shock pulls apart. Thesecost about twice as much as the internallySpherical rod ends (foreground)are offered in several mild-steeland chromemoly versions forcompetition 4-links. Larger, billet-steel rod ends with urethanebushings (background) areincluded with all Pro Street 4-links.adjustable SensiSet model, but we recommendthe QuickSet 2 to the racer who’s seriouslyinterested in both hooking up at launch andmaintaining high-speed stability at the big end.WHEELIE BARSThe two popular styles of wheelie bars useeither a flat bottom bar with a tubular upperbar; or tubular bars on both the bottom andtop. The flat-bottom design was a functionalwheelie bar in its day, but it’s old technologynow. It is inherently inconsistent in the way thealuminum bottom bar acts as a spring. When itgets up on the wheel, it gets some of its springby flexing the bottom bar, and some fromhaving an actual spring in the top. So you havethese two springs working together, and it’sdifficult to fine-tune and get good control.It also takes up more room under a car. In areal narrow, late-model, pro-type car, this is aserious issue. Plus, its mounting-bracket designprevents this type of wheelie bar from runningreal close to the ground, and bumper clearanceis an incredible problem on newer cars. Mostflat-type bars are also too short, so they tendto unload the tire. A 44-inch bar may be realcommon, but it’s too violent against the tireto work well. The car may not wheelstand, butyou’re not getting the optimum result, either.You want a wheelie bar at least 50 inches long.Dual-tube wheelie bars are found in all realrace cars because they’re a little lighter; theyoffer better bumper clearance; and they resultin a more solid assembly, making them easierto fine-tune. On dual-tube wheelie bars, it isimportant to “X” the top strut — not thebottom. By “X”-ing the top, you have more jackclearance. Plus, designs that only “X” on thebottom half will break the lower tube, becausethe partial “X” overloads the tube in the center.This will only happen in hard-launching, fastcars, but why take a chance?Now you must choose between a springloadedor unsprung design. On a car thatwheelstands hardly at all, you can get awaywith our unsprung version, because you’re notviolently on the bar that hard. But if you havea car that seriously wheelstands, you want thespring-loaded bar to give that extra bit ofcontrol. The difference in price is about $50.A spring-loaded bar may seem simple, but it’sactually quite sophisticated. Adjustments haveto be made very carefully. Most racers makeway too coarse of an adjustment; the way theyget a car not to wheelstand excessively is tomake it unload the tire. It’s a fine line to get thewheelie bars to delicately keep the car on theground without unloading the tire, particularlywhere it counts most: in the first 60 feet. Youneed a bar that’s very stable and lets you makefine adjustments. That’s why dual-tube, springloadedwheelie bars have become the norm forpro race cars Email: sales@cachassisworks.com Web: cachassisworks.com <strong>Chris</strong> Alston’s <strong>Chassisworks</strong> Inc., 8661 Younger Creek Drive, Sacramento, CA 95828ProductTech-004