BTJ 5/2011 - Baltic Press

BTJ 5/2011 - Baltic Press

BTJ 5/2011 - Baltic Press

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

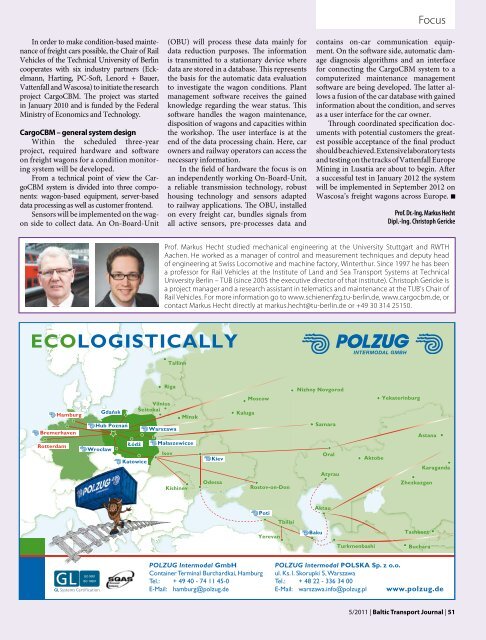

In order to make condition-based maintenanceof freight cars possible, the Chair of RailVehicles of the Technical University of Berlincooperates with six industry partners (Eckelmann,Harting, PC-Soft, Lenord + Bauer,Vattenfall and Wascosa) to initiate the researchproject CargoCBM. The project was startedin January 2010 and is funded by the FederalMinistry of Economics and Technology.CargoCBM – general system designWithin the scheduled three-yearproject, required hardware and softwareon freight wagons for a condition monitoringsystem will be developed.From a technical point of view the CargoCBMsystem is divided into three components:wagon-based equipment, server-baseddata processing as well as customer frontend.Sensors will be implemented on the wagonside to collect data. An On-Board-Unit(OBU) will process these data mainly fordata reduction purposes. The informationis transmitted to a stationary device wheredata are stored in a database. This representsthe basis for the automatic data evaluationto investigate the wagon conditions. Plantmanagement software receives the gainedknowledge regarding the wear status. Thissoftware handles the wagon maintenance,disposition of wagons and capacities withinthe workshop. The user interface is at theend of the data processing chain. Here, carowners and railway operators can access thenecessary information.In the field of hardware the focus is onan independently working On-Board-Unit,a reliable transmission technology, robusthousing technology and sensors adaptedto railway applications. The OBU, installedon every freight car, bundles signals fromall active sensors, pre-processes data andFocuscontains on-car communication equipment.On the software side, automatic damagediagnosis algorithms and an interfacefor connecting the CargoCBM system to acomputerized maintenance managementsoftware are being developed. The latter allowsa fusion of the car database with gainedinformation about the condition, and servesas a user interface for the car owner.Through coordinated specification documentswith potential customers the greatestpossible acceptance of the final productshould be achieved. Extensive laboratory testsand testing on the tracks of Vattenfall EuropeMining in Lusatia are about to begin. Aftera successful test in January 2012 the systemwill be implemented in September 2012 onWascosa’s freight wagons across Europe. Prof. Dr.-Ing. Markus HechtDipl.-Ing. Christoph GerickeProf. Markus Hecht studied mechanical engineering at the University Stuttgart and RWTHAachen. He worked as a manager of control and measurement techniques and deputy headof engineering at Swiss Locomotive and machine factory, Winterthur. Since 1997 he has beena professor for Rail Vehicles at the Institute of Land and Sea Transport Systems at TechnicalUniversity Berlin – TUB (since 2005 the executive director of that institute). Christoph Gericke isa project manager and a research assistant in telematics and maintenance at the TUB’s Chair ofRail Vehicles. For more information go to www.schienenfzg.tu-berlin.de, www.cargocbm.de, orcontact Markus Hecht directly at markus.hecht@tu-berlin.de or +49 30 314 25150. POLZUG Intermodal GmbHContainer Terminal Burchardkai, HamburgTel.: + 49 40 - 74 11 45-0E-Mail: hamburg@polzug.dePOLZUG Intermodal POLSKA Sp. z o.o.ul. Ks. l. Skorupki 5, WarszawaTel.: + 48 22 - 336 34 00E-Mail: warszawa.info@polzug.pl POLZUG_<strong>BTJ</strong>_184x118_5.indd 1 5/<strong>2011</strong> | <strong>Baltic</strong> Transport 23.09.11 Journal 12:34 | 51