Transition Comparison Integrated Farm Assurance V3 ... - GlobalGAP

Transition Comparison Integrated Farm Assurance V3 ... - GlobalGAP

Transition Comparison Integrated Farm Assurance V3 ... - GlobalGAP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EUREPGAP<strong>Transition</strong> <strong>Comparison</strong><strong>Integrated</strong> <strong>Farm</strong> <strong>Assurance</strong> <strong>V3</strong>.0-Mar07vs<strong>Integrated</strong> <strong>Farm</strong> <strong>Assurance</strong> V2.0-Mar05 (Poultry)V1.0-Mar07English VersionValid from March 2007©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPTRANSITION COMPARISONCPCC | LIVESTOCKENGLISH VERSIONINTRODUCTIONCode Ref.: IFA 1.0 TCVersion: V1.0-Mar07Section: IntroductionPage: 1 of 1This document is a summary of the changes from the <strong>Integrated</strong> <strong>Farm</strong> <strong>Assurance</strong> (Livestock) V2.0-Mar05 (old version) to the <strong>Integrated</strong> <strong>Farm</strong><strong>Assurance</strong> > All <strong>Farm</strong> > Livestock Base > Cattle & Sheep, Dairy, Pig, Poultry <strong>V3</strong>.0-Mar07 (new) version.1. The sheet named "Summary | Added|Deleted" contains the Control Points that were either added to the new version, or deleted from the old version.2. The sheet named "Summary | Level Change" contains the Control Points of which the levels were changed from the old to the new version.3. The All <strong>Farm</strong>, Livestock Base, Cattle & Sheep, Dairy, Pig and Poultry sheets show a detailed comparison between the new and old version.Red text indicates all modifications.In total, for Livestock (all sub-scopes) certification there are a possible 779 Control Points to comply with:Major Must Minor Must Recom. TotalAll <strong>Farm</strong> 12 22 11 45Livestock Base 66 24 13 103Cattle & Sheep 6 20 6 32Sub-total 84 66 30 180Dairy 24 25 9 58Sub-total 108 91 39 238Pig 45 24 17 86Sub-total 123 70 41 234Poultry 66 73 20 159Sub-total 144 119 44 307Total 375 280 124 779For Cattle & Sheep certification: A producer must comply with 100% of the applicable 84 Major Musts and 95% of the applicable 66 Minor Musts.For Dairy certification: A producer must comply with 100% of the applicable 108 Major Musts and 95% of the applicable 91 Minor Musts. (A Dairy producermust comply with the points for Cattle & Sheep AND Dairy).For Pig certification: A producer must comply with 100% of the applicable 123 Major Musts and 95% of the applicable 70 Minor Musts.For Poultry certification: A producer must comply with 100% of the applicable 144 Major Musts and 95% of the applicable 119 Minor Musts.©Copyright: EUREPGAP c/o FoodPLUS GmbHSpichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

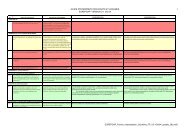

EUREPGAPTRANSITION COMPARISONCPCC | LIVESTOCKENGLISH VERSIONSUMMARY OF MODIFICATIONS OF CONTROL POINTSCode Ref.: IFA 1.0 TCVersion: V1.0-Mar07Section: Summary |Added|DeletedPage: 1 of 21. ADDED CONTROL POINTS AND COMPLIANCE CRITERIAALL FARM BASELIVESTOCK BASECLASSIFICATION POINT LEVEL CLASSIFICATION POINT LEVELControl Point, Compliance Criteria 3.2.3 Minor Must Heading LB.9 LIVESTOCK DESPATCHControl Point, Compliance Criteria 3.2.4 Minor Must Subheading LB.9.1 Identification & TraceabilityControl Point, Compliance Criteria 3.2.6 Minor Must Control Point, Compliance Criteria 9.1.1 Major MustControl Point, Compliance Criteria 3.2.7 Minor Must Control Point, Compliance Criteria 9.1.2 Major MustControl Point, Compliance Criteria 3.2.8 Minor Must Control Point, Compliance Criteria 9.1.3 Major MustControl Point, Compliance Criteria 3.4.2 Major Must Subheading LB.9.2 Loading and UnloadingControl Point, Compliance Criteria 3.5.4 Minor Must Control Point, Compliance Criteria 9.2.1 Recom.Subheading AF.3.6 Subcontractors Control Point, Compliance Criteria 9.2.2 Major MustControl Point, Compliance Criteria 3.6.1 Minor Must Control Point, Compliance Criteria 9.2.3 Major MustHeading 7.1. TRACEABILITY Control Point, Compliance Criteria 9.2.4 Major MustControl Point, Compliance Criteria 7.1 Major Must Subheading LB.9.3 Fitness of LivestockControl Point, Compliance Criteria 9.3.1 Minor MustSubheadingLB.9.4 Poultry DespatchControl Point, Compliance Criteria 9.4.1 Recom.Control Point, Compliance Criteria 9.4.2 Major MustDAIRYCLASSIFICATION POINT LEVELControl Point, Compliance Criteria 4.4 Recom.Control Point, Compliance Criteria 6.4.3 Minor Must©Copyright: EUREPGAP c/o FoodPLUS GmbHSpichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPTRANSITION COMPARISONCPCC | LIVESTOCKENGLISH VERSION2. DELETED CONTROL POINTS AND COMPLIANCE (IFA V2.0-Mar05)Code Ref.: IFA 1.0 TCVersion: V1.0-Mar07Section: Summary |Added|DeletedPage: 2 of 2CLASSIFICATION POINT LEVELControl Point, Compliance Criteria 1.1.5 Major MustControl Point, Compliance Criteria 1.2.2.2 Recom.Control Point, Compliance Criteria 1.4.1.3 Minor MustControl Point, Compliance Criteria 1.4.1.4 Minor MustControl Point, Compliance Criteria 1.4.1.5 Minor MustControl Point, Compliance Criteria 1.6.1.3 Recom.Control Point, Compliance Criteria 1.6.1.4 Minor MustControl Point, Compliance Criteria 5.2.2 Major MustControl Point, Compliance Criteria 5.7.3.4 Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbHSpichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPTRANSITION COMPARISONCPCC | LIVESTOCKENGLISH VERSIONSUMMARY OF MODIFICATIONS OF CONTROL POINTSCode Ref.: IFA 1.0 TCVersion: V1.0-Mar07Section: Summary |Level ChangePage: 1 of 13. LEVEL CHANGEALL FARM BASELIVESTOCK BASEControl Level Control LevelControl Level Control LevelPointV2.0-Mar05Point<strong>V3</strong>.0-Mar07PointV2.0-Mar05Point<strong>V3</strong>.0-Mar071.2.1.2 Recom. 2.1.1 Major Must 5.3.4 Recom. 3.4 Minor Must1.2.1.4 Minor Must 2.21 Major Must 5.8.2 Recom. 8.2 Minor Must9.1.5.3 Minor Must1.2.2.1 Recom. 2.2.2 Minor Must1.4.1.2 Recom. 3.1.2 Minor Must5.2.2 Major Must 3.2.1 Minor Must CATTLE & SHEEP1.4.2.1 Minor Must 3.2.2 Major Must Control Level Control Level1.4.2.2PointV2.0-Mar05Point<strong>V3</strong>.0-Mar075.7.3.4 Recom. 3.3.1 Minor Must 6.4.7 Recom. 4.7 Minor Must1.4.1.61.4.3.4 Minor Must 3.4.1 Major Must 6.4.9 Recom. 4.9 Minor Must1.4.4.1 Minor Must 3.5.1 Major Must5.2.2 Major Must 3.5.3 Minor Must1.5.2.2 Recom. 4.1.1 Minor Must1.5.2.31.2.3.51.5.3.3Major MustMinor MustDAIRY4.2.3 Major Must ControlPointV2.0-Mar05LevelControlPoint<strong>V3</strong>.0-Mar07Level7.2.1 Recom. 2.1 Minor Must7.2.2 Recom. 2.2 Minor Must©Copyright: EUREPGAP c/o FoodPLUS GmbHSpichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 1 of 14EUREPGAP IFA <strong>V3</strong>.0-Mar07EUREPGAP V2-0Mar05N° Control Point & Compliance Criteria Level N° Control Point & Compliance Criteria LevelALL FARM BASEAF.1 RECORD KEEPING AND INTERNAL SELF-CP 1.1 Are all records requested during the external inspection accessibleand kept for a minimum period of time of two years, unless a longerrequirement is stated in specific control points?CC 1.1 Producers keep up to date records for a minimum of two years fromthe date of first inspection, unless legally required to do so for alonger period. No N/A. (For Livestock certification, cross check withLS.3.2, PG.1.3 and PG.4.3 where documents are required for 3years)CP 1.2 Does the producer or producer group take responsibility toundertake a minimum of one internal self-assessment or producergroup internal inspection, respectively, per year against theEUREPGAP Standard?CC 1.2 There is documentary evidence that the EUREPGAP orbenchmarked standard internal self-assessment/internal producergroup inspections under responsibility of the producer/producergroup ha(s)ve been carried out and are recorded annually. No N/A.MinorMustMinorMustMajorMustMajorMust1.1.1 Are all records requested during the inspection accessible and keptfor a minimum period of time of two years unless longerrequirement stated in specific control points?1.1.1 <strong>Farm</strong>ers keep up to date records for a minimum of two years,unless legally required to do so for a longer period. Retrospectiverecords are not requested prior to application for EUREPGAPregistration. New applicants must have full records for at leastthree months prior to the date of inspection. No N/A. (Cross checkwith 5.3.2, 8.1.3 and 8.4.3, 3 years)1.1.2 Does the farmer undertake a minimum of one internal selfassessmentper year against the EUREPGAP Standard?Has the internal self-assessment been documented and recorded?1.1.31.1.2 There is documentary evidence that the EUREPGAP internal selfassessmenthas been carried out annually. No N/A.The EUREPGAP Checklist has been completed and documented.1.1.3 No N/A.MinorMustMinorMustMajorMustMajorMustCP 1.3 Are effective corrective actions taken as a result of nonconformancesdetected during the internal self-assessment orinternal producer group inspections?CC 1.3 Effective corrective actions are documented and have beenimplemented. No N/AMajorMustMajorMust1.1.4 Are effective corrective actions taken as a result of nonconformancesdetected in the internal self-assessment?1.1.4 Effective corrective actions are documented and have beenimplemented. No N/AMajorMustMajorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 2 of 14AF.2 SITE HISTORY AND SITE MANAGEMENTAF.2.1 Site HistoryCP 2.1.1 Is a recording system established for each unit of production orother area/location to provide a permanent record of thelivestock/aquaculture production and/or other agronomic activitiesundertaken at those locations? Are these records kept in an orderedand up-to-date fashion?CC 2.1.1 Current records must provide a history of EUREPGAP production ofall production areas. For Crops: New applicants must have fullrecords for at least three months prior to the date of externalinspection that reference each area covered by a crop with all theagronomic activities related to EUREPGAP documentation requiredof this area; and for Livestock and Aquaculture: these records mustgo back at least one rotation. No N/AMajorMustMajorMust1.2.1.2 Is a recording system established for each unit of production orother area/location to provide a permanent record of the livestockproduction and/or other agronomic activities undertaken at thoselocations? Are these records kept in an ordered and up-to-datefashion?1.2.1.2 Current records should provide a history of production of all fields(going back at least one rotation) and buildings (going back at least5 years).Recom.Recom.CP 2.1.2 Is a reference system for each field, orchard, greenhouse, yard,plot, livestock building or other area/location used in productionestablished and referenced on a farm plan or map?CC 2.1.2 Compliance must include visual identification in the form of aphysical sign at each field/greenhouse/plot/livestock building/pen orother farm, or a farm plan or map that could be cross referenced tothe identification system. No N/A.AF.2.1 Site ManagementCP 2.2.1 Is there a risk assessment for new agricultural sites (i.e. crop,livestock or aquaculture enterprises) or existing sites only whererisks have changed, which shows the site in question to be suitablefor production, with regards to food safety, operator health, theenvironment and animal health where applicable?CC 2.2.1 A documented risk assessment must be carried out when crops,livestock or aquaculture enterprises are to be introduced onto newsites. The risk assessment must be revised to take into account anynew food safety risks. The risk assessment must take account sitehistory (crops/stocking) and consider impact of proposedenterprises on adjacent stock/crops/environment (see AF Annex 1Risk Assessment to determine when a risk assessment is needed).For Tea and Coffee certification, cross reference with TE.2.1.1 andCO.2.1.1, respectivelyMinorMustMinorMustMajorMustMajorMust1.2.1.3 Is reference system for each field, yard, plot, livestock building orother area/location used in production established and referencedon a farm plan or map?1.2.1.3 Compliance must include visual identification in the form of aphysical sign at each fields/plots/buildings/pens etc. or a farm planor map that could be cross referenced to the identification system.No N/A.1.2.1.4 Where there is a change of site (i.e. crop or livestock enterprise), isa risk assessment undertaken, taking into account the prior use ofthe land or site and all potential impacts of the production onadjacent crops, livestock production and other areas?1.2.1.4 A documented risk assessment (verbal is enough) must be carriedout when new crops or livestock enterprises are to be introducedonto existing sites or new sites are to be cropped/stocked. The riskassessment must take account of site history (crops/stocking) andconsider impact of proposed enterprises on adjacentstock/crops/environment (see EurepGAP Guidelines for RiskAssessment for new sites)MinorMustMinorMustMinorMustMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 3 of 14CP 2.2.2 Has a management plan been developed setting out strategies tominimise all identified risks, such as pollution or water tablecontamination? Are the results of this analysis recorded and used tojustify that the site in question is suitable?CC 2.2.2 A management plan that has implemented strategies to meet theobjectives of this specific control point has been developed.MinorMust1.2.2.1 Has a management plan been developed setting out strategies tominimise all identified risks, such as pollution or water tablecontamination? Are the results of this analysis recorded and usedto justify that the site in question is suitable?1.2.2.1 A management plan that has implemented strategies to meet theobjectives of this specific control point.MinorMustAF.3 WORKERS HEALTH, SAFETY AND WELFARE 1.4 WORKER HEALTH, SAFETY AND WELFAREAF.3.1 Risk Assessments 1.4.1 Woker Health and SafetyCP 3.1.1 Does the farm have a written risk assessment for safe and healthy Minorworking conditions?MustCC 3.1.1 The written risk assessment can be a generic one but it must beappropriate for conditions on the farm. The risk assessment must bereviewed and updated when changes in the organisation (e.g. otheractivities) occur. No N/A.CP 3.1.2 Does the farm have a written health, safety and hygiene policy andprocedures including issues of the risk assessment of AF.3.1.1?CC 3.1.2 The health, safety and hygiene policy must at least include thepoints identified in the risk assessment (AF.3.1.1). This could includeaccident and emergency procedures, hygiene procedures, dealingwith any identified risks in the working situation, etc.The policy must be reviewed and updated when the riskassessment changes.MinorMustMinorMustMinorMust1.4.1.1 Do farms with more than 5 workers have a full health and safetypolicy based upon a full, written risk assessment? The policy mustcover all substances and situations that may be hazardous tohealth and include all aspects of the farm. The risk assessment andpolicy must be reviewed and updated whenever any significantchanges occur and at least annually.1.4.1.1 Where there are 5 full-time or part-time workers including theowners, there must at least be a written <strong>Farm</strong> Health and Safetypolicy available. The full written risk assessment can be a genericone. N/A only where less than 5 workers.1.4.1.2 Do all farms have a full health and safety policy based upon a full,written risk assessment. The policy should cover all substancesand situations that may be hazardous to health and include allaspects of the farm. The risk assessment and policy should bereviewed and updated at least annually.1.4.1.2 On all farms there should at least be a written <strong>Farm</strong> Health andSafety policy available. The full written risk assessment can be ageneric one.Recom.Recom.MinorMustMinorMustRecom.Recom.AF.3.2 TrainingCP 3.2.1 Is there a record kept for training activities and attendees? MinorMustCC 3.2.1 A record is kept for training activities including the topic covered, thetrainer, the date and attendees. Evidence of the attendence isrequired.MinorMust5.2.2 Is evidence of the experience, qualifications and training of allworkers employed by the farmer on either a full or part-time basisheld by the farmer?5.2.2 Evidence exists of experience, qualifications and training for allworkers. Assessment at inspection of the competence of workersfor the livestock present. Visual assessment of stock. No N/A.MajorMustMajorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 4 of 14CP 3.2.2 Do all workers handling and/or administering veterinary medicines,chemicals, disinfectants, plant protection products, biocides or otherhazardous substances and all workers operating dangerous orcomplex equipment as defined in the risk assessment in AF.3.1.1have certificates of competence, and/or details of other suchqualifications?MajorMust1.4.2.11.4.2.2Are all workers adequately trained and instructed commensuratewith their activity?All workers performing tasks, including making managementdecisions and undertaking operations, which can have a significantimpact on the consumer, operator, environment and the livestock orcrop, must be competent on the basis of the following: appropriateeducation, training, acquired knowledge and/or experience(acquired knowledge and/or experience only for farms with lessthan 5 workers).Areas covered include for livestock:- Animal welfare- Appropriate medicine usage- Animal nutrition- <strong>Farm</strong> waste(The criteria above are covered in both the Pig EUREPGAPStandard clause 8.10.1 and the Poultry EUREPGAP Standardclause 9.14.1 )Areas covered include for Combinable crops:- Use of pesticides- Use of fertilizersThe above compliance criteria are referred throughout theEurepgap Combinable Crops and Fruit and Vegetables Modules.The objectives of this standard/protocol should be communicatedto each workers.All workers handling and/or administering medicines, chemicals,disinfectants or other hazardous substances and all workers operatiMinorMustCC 3.2.2 Records must identify workers who carry out such tasks, and showcertificates of training or proof of competence. No N/AMajorMust1.4.2.11.4.2.2Workers to have their responsibilities and tasks identified,demonstrate competence at interview and on the basis ofinspection. For farms which do not have more than 5 full-time orpart-time workers including the owners at any time of the year,competence can be demonstrated through acquired knowledgeand/or experience only. No N/A.Workers who carry out such tasks must be identified, their recordsscrutinised for relevant national certificates, training and evidenceof competence together with authorisation to carry out tasks. NoN/AMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 5 of 14CP 3.2.3 Did all workers receive adequate health and safety training and arethey instructed according to the risk assessment in AF.3.1.1?MinorMustCC 3.2.3 Workers can demonstrate competency in responsibilities and tasksthrough visual observation. If at time of inspection there is noactivities, there must be evidence of instructions. No N/A.CP 3.2.4 Is there always an appropriate number of persons (at least oneperson) trained in first aid present on each farm whenever on-farmactivities are being carried out?CC 3.2.4 There is always at least one person trained in First Aid (within thelast 5 years) present on the farm whenever on-farm activities arebeing carried out. Applicable legislation on First Aid training must befollowed where it exists. On-farm activities include all activitiesperformed during all applicable chapters and modules .MinorMustMinorMustMinorMustCP 3.2.5 Does the farm have documented hygiene instructions? MinorMustCC 3.2.5 The hygiene instructions are visibly displayed: provided by way ofclear signs (pictures) or in the predominant language(s) of theworkforce. The instructions must at least include:- the need for hand cleaning;- the covering of skin cuts;- limitation on smoking, eating and drinking to certain areas;- notification of any relevant infections or conditions;- the use of suitable protective clothing.MinorMust1.4.2.3 The farm’s hygiene standards must be documented and adoptedby workers on farms with more than 5 workers and no poultry(specifically covered in the poultry module) Workers must receivebasic training in the farm’s hygiene requirements. Examples oftraining subjects are:- the need for hand cleaning;- the covering of skin cuts;- confinement of smoking, eating and drinking to the appropriateareas;- notification of any relevant infections or conditions;- the use of suitable protective clothing.1.4.2.3 All workers on farms with no poultry and more than 5 full-time orpart-time workers including the owners at any time of the year havereviewed and signed for the farm’s hygiene standard which mustcover subjects listed in the Control Point. Workers mustdemonstrate awareness at interview. No N/A unless less than 5workers and no poultry. Cross check with 9.9.5MinorMustMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 6 of 14CP 3.2.6 Have all persons working on the farm received basic hygienetraining according to the hygiene instructions in AF.3.2.5?MinorMustCC 3.2.6 Both written and verbal training are given as an induction trainingcourse for hygiene. Training are provided by qualified people. AllMinorMustnew workers must receive this training and confirm theirparticipation with a signature. All instructions from AF.3.2.5 must becovered in this training. All workers, including the owners andmanagers, at any time of the year have reviewed and signed for thefarm’s hygiene instructions.CP 3.2.7 Are the farm’s hygiene procedures implemented? MinorMustCC 3.2.7 Workers with according tasks demonstrate competence during theinspection. No N/A.MinorMustCP 3.2.8 Are all subcontractors and visitors aware of the relevant procedureson personal safety and hygiene?MinorMustCC 3.2.8 There is evidence that the relevant procedures on personal health,safety and hygiene are officially communicated to visitors andMinorMustsubcontractors (e. g. relevant instructions are in a visible placewhere all visitors or subcontractors can read them).AF.3.3 Hazards and First Aid 1.4.3Hazards, First Aid, Data Sheets, Protective Clothing / EquipmentCP 3.3.1 Do accident and emergency procedures exist, visually displayed,and communicated to all persons associated with the farmactivities?MinorMust5.7.3.41.4.1.6Are an accident procedure, a list of contact phone numbers and thelocation of the nearest telephone available within the immediatevicinity of the store and next to the nearest telephone?Is there an Emergency Board situated in a visible location close bythe telephone giving details of:- <strong>Farm</strong>’s map reference?- Directions from nearest fire station?- Location of fire extinguishers?- Location of water sources for fire fighting?- Location of emergency cut-offs for electricity, gas and watersupplies?- Emergency telephone number of electricity supplier?- Emergency telephone number of water supplier?Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 7 of 14CC 3.3.1 Permanent accident procedures must be clearly displayed inaccessible, and visible location(s).These instructions are available inthe predominant language(s) of the workforce and/or pictograms.The procedures must identify, if appropriate the following; E.g.:- farm's map reference or farm address- contact person(s)- location of the nearest means of communication (telephone, radio)- an up-to-date list of relevant phone numbers (police, ambulance,hospital, fire-brigade, access to emergency health care on site or bymeans of transport, electricity and water supplier);- how and where to contact the local medical services, Hospital andother emergency services.- location of fire extinguisher;- emergency exits;- emergency cut-offs for electricity, gas and water supplies.- how to report accidents or dangerous incidents.MinorMust5.7.3.41.4.1.6Accident procedure and contact telephone numbers to be availableat store and nearest telephone. Cross check with 1.4.1.1Board sited in a visible location close by the telephone andcontains all the required information.Recom.CP 3.3.2 Are potential hazards clearly identified by warning signs and placedwhere appropriate?CC 3.3.2 Permanent and legible signs must indicate potential hazards, e.g.waste pits, fuel tanks, workshops, access doors of the plantprotection product / fertiliser / any other chemical storage facilitiesas well as the treated crop etc. Warning signs must be present. NoN/A.CP 3.3.3 Is safety advice available/accesible for substances hazardous toworker health, when required?MinorMustMinorMustMinorMust1.4.3.3 Are hazards clearly identified by warning signs and placed where Minorappropriate.Must1.4.3.3 Warning signs must be present. No N/A. MinorMust1.4.3.1 Are manufacturer's data sheets or other applicable information haldfor all substances used that are hazardous to worker health?MinorMustCC 3.3.3 Information (e.g. website, tel no, data sheets, etc.) is accessible,when required, to ensure appropriate action.CP 3.3.4 Are First Aid kits present at all permanent sites and in the vicinity offield-work?CC 3.3.4 Complete and maintained first aid kits according to nationalregulations and recommendations must be available and accessibleat all permanent sites and available for transport to the vicinity of thework.MinorMustMinorMustMinorMust1.4.3.1 Data sheets or demonstrate available through agreement with aresponsible organisation must be available.1.4.3.2 Are First Aid boxes present at all permanent sites and in the vicinityof field-work?1.4.3.2 First aid box must be at all sites, contents checked, in field whereappropriate. No N/A.MinorMustMinorMustMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 8 of 14AF.3.4 Protective Clothing/EquipmentCP 3.4.1 Are workers (including subcontractors) equipped with suitableprotective clothing in accordance with legal requirements and/orlabel instructions or as authorised by a competent authority?CC 3.4.1 Complete sets of protective clothing, (e.g. rubber boots, waterproofclothing, protective overalls, rubber gloves, face masks, etc.) whichenable label instructions and/or legal requirements and/orrequirements as authorised by a competent authority to be compliedwith are available, used and in a good state of repair. This includesappropriate respiratory, ear and eye protection devices and lifejackets,where necessary.CP 3.4.2 Is protective clothing cleaned after use and stored so as to preventcontamination of the clothing or equipment?CC 3.4.2 Protective clothing is regularly cleaned, according to a scheduleadapted to the type of use and degree of soiling. Cleaning theprotective clothing and equipment includes the separate washingfrom private clothing and glove washing before removal. Dirty, tornand damaged protective clothing and equipment and expired filtercartridges should be disposed of. Single-use items (e.g. gloves,overalls, etc.) have to be disposed of after one use. All theprotective clothing and equipment including replacements filtersetc., are stored apart and physically separate from the plantprotection products/ any other chemicals which might causecontamination of the clothing or equipment in a well-ventilated area.No N/A.MajorMustMajorMustMajorMustMajorMust1.4.3.4 Is protective equipment available where necessary to all workers(including subcontractors)? Do workers wear appropriaterespiratory, ear and eye protection devices where necessary?1.4.3.4 Availability of equipment and use, where appropriate. worker todemonstrate awareness at interview. No N/A.AF.3.5 Worker Welfare 1.4.4 Worker WelfareCP 3.5.1 Is a member of management clearly identifiable as responsible forworkers health, safety and welfare?MajorMust1.4.4.1 Do all farms with more than 5 workers have a member ofmanagement who is clearly identifiable as responsible for worker,health, safety and welfare issues?CC 3.5.1 Documentation is available that demonstrates that a clearlyidentified, named member of management has the responsibility forensuring compliance with existing, current and relevant national andlocal regulations and the implementation of the policy on workershealth safety and welfare.MajorMust1.4.4.1 Where a farm has 5 full-time or part-time workers including theowners at any time during the year, (all farms for Fruit andVegetable Scope) there must be a member of managementresponsible for worker health, safety and welfare. It must bedetailed in contractual agreements with workers, where outsideworkers are employed by the farm.MinorMustMinorMustMinorMustMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 9 of 14CP 3.5.2 Do regular two way communication meetings take place betweenmanagement and workers ? Are there records from such meetings?CC 3.5.2 Records show that the concerns of the workers about health, safetyand welfare are being recorded in meetings planned and held atleast once a year between management and workers at whichmatters related to the business and worker health, safety or welfarecan be discussed openly (without fear or intimidation or retribution).The auditor is not required to make judgments about the content,accuracy or outcome of such meetings.Recom. 1.4.4.2 Are, on all farms with more than 5 workers, management of the siteencouraged to hold regular, two-way communication meetings withtheir workers where issues affecting the business or related toworker health, safety and welfare can be discussed openly? Arerecords from such meeting available as proof that management islistening to workers concerns?Recom. 1.4.4.2 Where a farm has 5 full-time or part-time workers including theowners at any time during the year, (all farms for Fruit andVegetable Scope) there should be at least two meetings a yearheld and planned between management and workers of the site, atwhich matters related to the business and worker health, safety orwelfare can be discussed openly (without fear or intimidation orretribution). Records from such meetings are kept as proof that themeetings have taken place and the concerns of the worker abouthealth safety and welfare are being recorded.The auditor is not required to make judgements about the contentaccuracy or outcome of such records.Recom.Recom.CP 3.5.3 Is there information available that provide an accurate overview overall workers of the farm?CC 3.5.3 Records demonstrate clearly an accurate overview over all workers(including seasonal workers) and subcontractors working on thefarm. Information must be available of full names, date of entry, theperiod of employment and, the regular working time and overtimeregulations. Records of all workers (also subcontractors) whichprovide the required information must be kept for the last 24 monthsfrom the date of first inspection. See AF.3.6.1 as requirement forsubcontractors.CP 3.5.4 Do workers have access to clean food storage areas, designateddining areas, hand washing facilities and drinking water?MinorMustMinorMustMinorMust5.2.2 Is evidence of the experience, qualifications and training of allworkers employed by the farmer on either a full or part-time basisheld by the farmer?5.2.2 Evidence exists of experience, qualifications and training for allworkers. Assessment at inspection of the competence of workersfor the livestock present. Visual assessment of stock. No N/A.MajorMustMajorMustCC 3.5.4 A place to store food and to eat must be available. In addition, handwashing facilities and potable drinking water must be available toworkers.MinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 10 of 14CP 3.5.5 Are on site living quarters habitable and have the basic services andfacilities?MinorMustCC 3.5.5 The living quarters for the workers on farm are habitable, have a Minorsound roof, windows and doors, and have the basic services of Mustrunning water, toilets, drains. In case of no drains, septic pits can beaccepted when proven to be hermetic.AF.3.6 SubcontractorsCP 3.6.1 When the producer makes use of subcontractors, is all the relevant Minorinformation available on farm?MustCC 3.6.1 Subcontracors must carry out an assessment (or the producer must Minordo it on behalf of the subcontractor) of compliance against the MustEUREPGAP control points relevant to the services provided on farm(inlcuding AF.3.5.3).This assessment must be available on farmduring the external inspection and the subcontractor must acceptthat EUREPGAP approved certifiers are allowed to verify theassessments through a physical inspection where there is doubt.The producer is responsible for observance of the control pointsapplicable to the tasks performed by the subcontractor by checkingand signing the assessment of the subcontractor for each task andseason contracted.AF.4 WASTE AND POLLUTION MANAGEMENT, RECYCLING AND RE-USE1.4.4.3 Are on site living quarters habitable and have the basic servicesand facilities?1.4.4.3 The living quarters for the workers on farm are habitable, soundroof, windows and doors, and have the basic services of runningwater, toilets, drains.1.5MinorMustMinorMustWASTE AND POLLUTION MANAGEMENT, RECYCLING AND RE-USEAF.4.1 Identification of Waste and Pollutants 1.5.2 Identification of Waste and PollutionCP 4.1.1 Have all possible waste products and sources of pollution beenidentified in all areas of the business?MinorMust1.5.2.21.5.2.3Have all possible waste products been identified in all areas of thebusiness?Have potential sources of pollution been identified?Recom.CC 4.1.1 All possible waste products (such as paper, cardboard, plastic, oil,etc) and sources of pollution (e.g. fertiliser excess, exhaust smoke,oil, fuel, noise, effluent, chemicals, sheep-dip, feed waste, dead ordiseased fish, algae produced during net cleaning, etc) produced bythe farm processes have been listed.MinorMust1.5.2.21.5.2.3All possible waste products (such as paper, cardboard, plastic, oil,etc) produced by the farm processes have been catalogued anddocumented.Potential sources of pollution (e.g. fertiliser excess, exhaust smoke,oil, fuel, noise, effluent, chemicals, sheep-dip, etc) have beencatalogued and documented for all the farm processes.Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 11 of 14AF.4.2 Waste and Pollution Action PlanCP 4.2.1 Is there a documented farm waste management plan to avoid orreduce wastage and pollution and avoid the use of landfill orburning, by waste recycling? Are organic wastes composted on thefarm and utilised for soil-conditioning, provided there is no risk ofdisease carry-over?CC 4.2.1 A comprehensive, current, documented plan that covers wastagereduction, pollution and waste recycling is available. Air, soil andwater contamination must be considered.Recom. 1.5.2.11.5.3.1Recom. 1.5.2.11.5.3.1Do all farms have a written <strong>Farm</strong> Waste Management Plan toprevent the contamination of the air, soil and/or water with harmfulpollutants?Is there a documented plan to avoid or reduce wastage andpollution and avoid the use of landfill or burning, by wasterecycling? Are organic wastes composted on the farm and utilisedfor soil-conditioning, provided there is no risk of disease carryover?A written farm waste management plan should be available thatconsiders air, soil and water contamination.A comprehensive, current, documented plan that covers wastagereduction, pollution and waste recycling is available.CP 4.2.2 Has this waste management plan been implemented? Recom. 1.5.3.2 Has this waste management plan been implemented? Recom.CC 4.2.2 There are visible actions and measures on the farm that confirm thatthe objectives of the waste and pollution action plan are beingcarried out.CP 4.2.3 Are the farm and premises clear of litter and waste to avoidestablishing a breeding ground for pests and disease which couldresult in a food safety risk?CC 4.2.3 Visual assessment that there is no evidence of breeding grounds inareas of waste/litter in the immediate vicinity of the production orstorage buildings. Incidental and insignificant litter and waste on thedesignated areas are acceptable as well as the waste from thecurrent day’s work. All other litter and waste has been cleared up.Areas where produce is handled indoors are cleaned at least once aday.Recom. 1.5.3.2 There are visible actions and measures on the farm that confirmthat the objectives of the waste and pollution action plan are beingcarried out.MajorMustMajorMust1.2.3.51.5.3.31.2.3.51.5.3.3To avoid establishing a breeding ground for pests and disease, arefarms clear of litter and waste and are there adequate provisionsfor waste disposal?Are the farm and premises clear of litter and waste?Visual assessment that there is no evidence of breeding grounds inareas of waste/litter in the immediate vicinity of the production orstorage buildings.Incidental and insignificant litter and waste on the designated areasare acceptable as well as the waste from the current day’s work. Allother litter and waste has been cleared up. Areas where produce ishandled indoors are cleaned at least once a day.CP 4.2.4 Do the premises have adequate provisions for waste disposal? Recom. 1.5.3.4 Do the premises have adequate provisions for waste disposal? Recom.Recom.Recom.Recom.MajorMustMinorMustMajorMustMinorMustCC 4.2.4 The farm has designated areas to store litter and waste. Differenttypes of waste are identified and stored separately.Recom. 1.5.3.4 <strong>Farm</strong>s have designated areas to store litter and waste. Differenttypes of waste are identified and stored separately. Cross checkwith 1.2.3.5Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 12 of 14AF.5 ENVIRONMENT AND CONSERVATION 1.6 ENVIRONMENT ISSUESAF.5.1 Impact of <strong>Farm</strong>ing on the Environment and Biodiversity (crossreference1.6.1 Impact of <strong>Farm</strong>ing on the Environmentwith AB.7.5 AquacultureBase)CP 5.1.1 Does each producer have a management of wildlife andconservation plan for the enterprise that acknowledges the impactof farming activities on the environment?MinorMust1.6.1.11.6.2.11.6.2.2Does the farmer understand and assess the impact of farmingactivities on the environment?Is a key aim the enhancement of the environment and biodiversityon the farm through a conservation management plan, either as aregional activity or an individual one?Does each farmer have a management of wildlife and conservationpolicy plan for his/her enterprise?MinorMustMinorMustRecom.CC 5.1.1 There must be a written action plan which aims to enhance habitatsand increase biodiversity on the farm. This can be either a regionalactivity or individual plan, if the farm is participating in or covered byit. This includes knowledge of IPM practices, of nutrient use ofcrops, conservation sites etc.MinorMust1.6.1.11.6.2.11.6.2.2The farmer is able to demonstrate his/her knowledge andcompetence with regards to minimising the potential negativeimpact, such as nutrient loss, of the farming activity on the localenvironment.A formal conservation management plan should be implemented.There must be an action plan (verbal or written) which aims toenhance habitats and increase biodiversity on the farm.MinorMustMinorMustRecomCP 5.1.2 Has the producer considered how to enhance the environment forthe benefit of the local community and flora and fauna?CC 5.1.2 There should be tangible actions and initiatives that can bedemonstrated by the producer either on the production site or byparticipation in a group that is active in environmental supportschemes.CP 5.1.3 Is this policy compatible with sustainable commercial agriculturalproduction and does it minimise environmental impact of theagricultural activity?CC 5.1.3 The contents and objectives of the conservation plan implycompatibility with sustainable agriculture and demonstrate areduced environmental impact.Recom. 1.6.1.2 Has the farmer considered how he/she can enhance theenvironment for the benefit of the local community and flora andfauna?Recom. 1.6.1.2 There should be tangible actions and initiatives that can bedemonstrated by the farmer either on the farm or by participation ina group that is active in environmental support schemes.Recom. 1.6.2.3 Is this policy compatible with sustainable commercial agriculturalproduction and does it minimise environmental impact of theagricultural activity?Recom. 1.6.2.3 The contents and objectives of the conservation plan implycompatibility with sustainable agriculture and demonstrate areduced environmental impact.Recom.Recom.Recom.Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 13 of 14CP 5.1.4 Does the plan include a baseline audit to understand existing animal Recom. 1.6.2.4 Does the plan contemplate the undertaking of a baseline audit to Recom.and plant diversity on the farm?understand existing animal and plant diversity on the farm?CC 5.1.4 There is a commitment within the conservation plan to undertake abase line audit of the current levels, location, condition etc. of thefauna and flora on farm so as to enable actions to be planned. Referto points CO.10.1 for Coffee and TE.11.1 for Tea certification.Recom. 1.6.2.4 There is a commitment within the conservation plan to undertake abase line audit of the current levels, location, condition etc. of thefauna and flora on farm so as to enable actions to be planned.Recom.CP 5.1.5 Does the plan include action to avoid damage and deterioration ofhabitats on the farm?Recom. 1.6.2.5 Does the plan contemplate taking action to avoid damage anddeterioration of habitats on the farm?CC 5.1.5 Within the conservation plan there is a clear list of priorities and Recom. 1.6.2.5 Within the conservation plan there is a clear list of priorities andactions to rectify damaged or deteriorated habitats on the farm.actions to rectify damaged or deteriorated habitats on the farm.Refer to points CO.10.1 for Coffee and TE.11.1 for Tea certification.Recom.Recom.CP 5.1.6 Does the plan include activities to enhance habitats and increase Recom. 1.6.2.6 Does the plan contemplate the creation of an action plan to Recom.bio-diversity on the farm?enhance habitats and increase bio-diversity on the farm?CC 5.1.6 Within the conservation plan there is a clear list of priorities and Recom. 1.6.2.6 Within the conservation plan there is a clear list of priorities and Recom.actions to enhance habitats for fauna and flora where viable andincrease bio-diversity on the farm. Refer to points CO.10.1 forCoffee and TE.11.1 for Tea certification.actions to enhance habitats for fauna and flora where viable andincrease bio-diversity on the farm.AF.5.2 Unproductive Sites 1.6.3 Unproductive SitesCP 5.2.1 Has consideration been given to the conversion of unproductive Recom. 1.6.3.1 Has consideration been given to the conversion of unproductive Recom.sites (e.g. low lying wet areas, woodlands, headland strip or areasof impoverished soil) to conservation areas for the encouragementof natural flora and fauna?sites (e.g. low lying wet areas, woodlands, headland strip or areasof impoverished soil) to conservation areas for the encouragementof natural flora and fauna?CC 5.2.1 There should be a plan to convert unproductive sites into Recom. 1.6.3.1 There should be a plan to convert unproductive sites into Recom.conservation areas where viable.conservation areas where viable.AF.5.3 Energy Efficiency 1.5.1 Energy EfficiencyCP 5.3.1 Can the producer show monitoring of energy use on the farm? Recom. 1.5.1.1 Do all farms take measures to optimise energy use and minimisewaste?Recom.CC 5.3.1 Energy use records exist. For example, farming equipment shall beselected and maintained for optimum consumption of energy. Theuse of non-renewable energy sources should be kept to a minimum.(Cross reference with CO.10.2 for Coffee and TE.11.2 for Teacertification).Recom. 1.5.1.1 All farms should have an energy policy (which does not necessarilyhave to be documented) and should demonstrate steps taken toensure energy efficiency to include maintenance schedules.AF.6 COMPLAINTS 1.7 COMPLAINTSCP 6.1 Is there a complaint procedure available relating to issues coveredby the EUREPGAP standard?MajorMust1.7.1 Is there a complaint form available relating to issues of compliancewith EUREPGAP standard?CC 6.1 There must be available on request, a clearly identifiable document Major 1.7.1 There must be on the farm, and available on request, a clearlyfor complaints relating to issues covered by EUREPGAP. No N/A. Mustidentifiable document for complaints relating to issues ofcompliance with EUREPGAP. No N/A.Recom.MajorMustMajorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | ALL FARMENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: All <strong>Farm</strong>Page: 14 of 14CP 6.2 Does the complaints procedure ensure that complaints areadequately recorded, studied and followed up including a record ofactions taken?CC 6.2 There are documents of the actions taken with respect to suchcomplaints regarding EUREPGAP standard deficiencies found inproducts or services. No N/A.AF.7 TRACEABILITYCP 7.1 Do all producers have a documented recall procedure to managethe withdrawal of registered products from the market?CC 7.1 All producers must have access to documented procedures whichidentify the type of event that may result in a withdrawal, personsresponsible for taking decisions on the possible withdrawal ofproduct, the mechanism for notifying customers and theEUREPGAP CB (if a sanction was not issued by the CB and theproducer or group recalled the products out of free will) andmethods of reconciling stock. The procedures must be testedannually to ensure that it is sufficient.MajorMustMajorMustMajorMustMajorMust1.7.2 Does the complaints procedure ensure that complaints areadequately recorded, studied and followed up including a record ofactions taken?1.7.2 There are documents of the actions taken with respect to suchcomplaints regarding EUREPGAP standard deficiencies found inproducts or services. No N/A.MajorMustMajorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 1 of 19EUREPGAP IFA <strong>V3</strong>.0-Mar07EUREPGAP IFA V.0-Mar05N° Control Point & Compliance Criteria Level N° Control Point & Compliance Criteria LevelLIVESTOCK BASE5 LIVESTOCK BASE MODULELB.1 SITE 5.1 SITELB.1.1 GeneralCP 1.1.1 Are farms and other facilities suitable for the intended purpose,maintained in good repair and used so as to achieve the objectivesof this standard?CC 1.1.1 There must be a visual assessment to make sure that the facilitiesare suitable for the intended purpose, maintained and in goodrepair. This include assessment of the premises for example soilstructure drainage and climate for outdoor livestock Water and feedequipment suitable for stock and type. No N/A.MinorMustMinorMust1.2.1.1 Are farms and other facilities suitable for the intended purpose,maintained in good repair and used so as to achieve the objectivesof this standard?1.2.1.1 There must be a visual assessment to make sure that the facilitiesare suitable for the intended purpose, maintained and in goodrepair. This include assessment of the premises for example soilstructure drainage and climate for outdoor livestock. Water andfeed equipment suitable for stock and type. No N/A.MinorMustMinorMustCP 1.1.2 For Livestock <strong>Farm</strong>s producing forage for own consumption andopen air livestock production, are soil maps for the farm drawn upto aid the planning of rotations and to assist in the proper andoptimal use of Crop Protection Products, fertilisers and organicmanure?CC 1.1.2 Maps showing soil types and organic fertiliser application schedule(where applicable) should be available. N/A where farms do notproduce forage or with livestock housed year round.Recom. 5.1.1Recom. 5,1,1For Livestock <strong>Farm</strong>s producing forage for own consumption andopen air livestock production, are soil maps for the farm drawn upto aid the planning of rotations and to assist in the proper andoptimal use of Crop Protection Products, fertilisers and organicmanure?Maps showing soil types and organic fertiliser application schedule(where applicable) should be available. N/A where farms do notproduce forage or with livestock housed year round.Recom.Recom.CP 1.1.3 Are all electrical installations at mains voltage inaccessible tostock, protected and earthed properly?MinorMust5.1.2 Are all electrical installations at mains voltage inaccessible tostock, protected and earthed properly?MinorMustCC 1.1.3 Visual assessment. No N/A unless no electricity. MinorMust5.1.2 Visual assessment. No N/A unless no electricity. MinorMustCP 1.1.4 Are all electrical installations undertaken by a qualified electrician Recom. 5.1.3 Are all electrical installations undertaken by a qualified electrician Recom.and appropriate records kept?and appropriate records kept?CC 1.1.4 Records/invoices denoting membership of the electrician to Recom. 5.1.3 Records/invoices denoting membership of the electrician to Recom.associations, guilds etc should be available. Simple subsequentelectrical fixture replacements (e.g. plugs, light bulbs, etc.) can bedone by the farmer if he demonstrates competence at interview.associations, guilds etc should be available. Simple subsequentelectrical fixture replacements (e.g. plugs, light bulbs, etc.) can bedone by the farmer if he demonstrates competence at interview.CP 1.1.5 Are electric fences, where used, managed so as to cause onlymomentary discomfort?CC 1.1.5 Workers to demonstrate awareness at interview. N/A where noelectric fences.Recom. 5.1.4Recom. 5.1.4Are electric fences, where used, managed so as to cause onlymomentary discomfort?Workers to demonstrate awareness at interview. N/A where noelectric fences.Recom.Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 2 of 19CP 1.1.6 Are only paints, preservatives, disinfectants and other chemicalcompounds that are approved by the respective regulatoryauthority and are suitable for use with livestock used on surfacesaccessible to livestock?CC 1.1.6 Workers to demonstrate awareness at interview. Inspect invoices,containers, and data sheets.MajorMustMajorMust5.1.5 Are only paints, preservatives, disinfectants and other chemicalcompounds that are approved by the respective regulatoryauthority and are suitable for use with livestock used on surfacesaccessible to livestock?5.1.5 Workers to demonstrate awareness at interview. Inspect invoices,containers, and data sheets. Cross check with 1.4.3.4.MajorMustMajorMustCP 1.1.7 Are all paints, preservatives, disinfectants and other chemicalcompounds stored away from livestock and feed to preventcontamination?MajorMustCC 1.1.7 Visual assessment. No N/A. MajorMustCP 1.1.8 Does the farm have formal agreement with third parties for the Majorutilisation of excess farm produced animal waste in accordance Mustwith national legislation or accepted codes of practice?CC 1.1.8 Record must be available to comply with the requirements of the Majorcontrol point.MustLB.1.2 Pest Control 1.2.3 Pest ControlCP 1.2.1 Are all entry points to buildings or equipment that may come in Minorcontact with them suitably protected to prevent, whenever Mustpractically possible, the ingress of rodents and birds?CC 1.2.1 Visual assessment. No N/A unless extensive production situations. MinorMustCP 1.2.2 Are there site plans with bait points and/or traps? MinorMustCC 1.2.2 Site plan showing bait points must exist. No N/A unless extensive Minorproduction situations.Must5.1.6 Are all paints, preservatives, disinfectants and other chemicalcompounds stored away from livestock and feed to preventcontamination?MajorMust5.1.6 Visual assessment. No N/A. MajorMust5.1.7 Does the farm have formal agreement with third parties for the Majorutilisation of excess farm produced animal waste in accordance Mustwith national legislation or accepted codes of practice?5.1.7 Record must be available to comply with the requirements of the Majorcontrol point.Must1.2.3.1 Are all entry points to buildings containing propagation material,harvested crops, livestock, feed or equipment that may come incontact with them suitably protected to prevent, whenever possible,the ingress of animal pests?MinorMust1.2.3.1 Visual assessment. No N/A unless extensive large animal Minorproduction situations.Must1.2.3.2 Are there site plans with bait points? MinorMust1.2.3.2 Site plan showing bait points must exist. No N/A unless there are Minorno baits used for pest control is justification for not using bait on Mustfarm (i.e. in extensive large animal production situations).CP 1.2.3 Are baits placed in such a manner that non-target species do nothave access?CC 1.2.3 Visual observation. Non-targeted species must not have access tothe bait. No N/A unless extensive production situations.MinorMustMinorMust1.2.3.3 Are baits placed in such a manner that non-target species do nothave access?1.2.3.3 Visual observation. Non-targeted species must not have access tothe bait.MinorMustMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 3 of 19CP 1.2.4 Are detailed records of pest control inspections and necessaryactions taken, kept?CC 1.2.4 Records of pest control inspections and follow up action plan(s).The farmer can have his own records. Inspections must take placewhenever evidence of pests present. In case of vermin must havea contact number or evidence of in-house capability to controlpests.MinorMustMinorMust1.2.3.4 Are detailed records of animal pest control inspections andnecessary actions taken kept?1.2.3.4 Records of pest control inspections and follow up action plan(s).The farmer can have his own records. Inspections must take placewhenever evidence of pests present. In case of vermin must havea contact number or evidence of in-house capability to controlpests. (Cross check Pigs (8.9.1) and Poultry (9.9.11))MinorMustMinorMust1.3 Machinery and Equipment Hygiene 1.3 MACHINERY AND EQUIPMENTCP 1.3.1 Are lorries/trucks and trailers carrying crops or stock feed cleanand fit for the purpose of carrying raw materials entering into thefood chain, with particular care given to the cleanliness of dualpurpose trailers to prevent contamination?MajorMust1.3.1 Are lorries/trucks and trailers carrying crops or stock feed cleanand fit for the purpose of carrying raw materials entering into thefood chain, with particular care given to the cleanliness of dualpurpose trailers to prevent contamination?CC 1.3.1 Workers to demonstrate awareness at interview and visual Major 1.3.1 Workers to demonstrate awareness at interview and visualassessment of transport vehicles. Type of cleaning must be Mustassessment of transport vehicles. Type of cleaning must beappropriate to clean what was being previously transported. Noappropriate to clean what was being previously transported. NoN/A unless no supplement feeding of livestock on farm.N/A unless no supplement feeding of livestock on farm.CP 1.3.2 Are all bulk loaders used for loading crops or stock feed cleaned Major 1.3.2 Are all bulk loaders used for loading crops or stock feed cleanedprior to use, with particular care given to the cleanliness of dual Mustprior to use, with particular care given to the cleanliness of dualpurpose loaders, to prevent contamination?purpose loaders, to prevent contamination?CC 1.3.2 Visual assessment that bulk loaders are kept in a clean, dry and fit Major 1.3.2 Visual assessment that bulk loaders are kept in a clean, dry and fitstate to avoid harm to the goods being carried inside.Muststate to avoid harm to the goods being carried inside.CP 1.3.3 Is crop or forage conditioning equipment serviced and cleaned in Minor 1.3.3 Is crop or forage conditioning equipment serviced and cleaned inaccordance with manufacturers’ instructions and are records Mustaccordance with manufacturers’ instructions and are recordsmaintained?maintained?CC 1.3.3 Records must be available, together with manufacturers’ Minor 1.3.3 Records must be available, together with manufacturers’instructions. N/A if no relevant equipment.Mustinstructions. N/A if no relevant equipment.LB.2 WORKER HEALTH, SAFETY AND WELFARE 5.2 WORKERSCP 2.1 On livestock farms, are all workers aware of the contingency Minor 5.2.1 On livestock farms, are all workers aware of the contingencyprocedures relevant to their enterprise in the event of emergencies Mustprocedures relevant to their enterprise in the event of emergencieswhich pose a threat to human health, food safety or livestockwhich pose a threat to human health, food safety or livestockhealth and welfare? Do these contingency procedures cover thehealth and welfare? Do these contingency procedures cover theevent of failure of the feed or water supply?event of failure of the feed or water supply?MajorMustMajorMustMajorMustMajorMustMinorMustMinorMustMinorMustCC 2.1 Workers must demonstrate awareness at interview on howlivestock are guaranteed food and water within 24 hours of anemergency.MinorMust5.2.1 Workers must demonstrate awareness at interview on howlivestock are guaranteed food and water within 24 hours of anemergency.MinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 4 of 19LB.3 LIVESTOCK SOURCING, IDENTIFICATION AND TRACEABILITYCP 3.1 Do all farms with livestock enterprises maintain a movementrecord?CC 3.1 A visual inspection of a sample of records confirms that at least thefollowing are recorded: Date moved to/from farm; Numbers moved;Identification marks (tags/chips/tattoos); Address to or from whichthey have been moved. No N/A.CP 3.2 Are procedures in place to ensure all livestock, have beenborn/hatched and reared on a EurepGAP (or benchmarkedscheme) assured farm? No EurepGAP approved farms mayaccommodate both assured and non-assured livestock of the samespecies.CC 3.2 Procedures including movement records (minimum 3 years, 3months at first inspection) and EurepGAP approved despatchnotes or equivalent document containing the same information (seeEurepGAP despatch note guideline) must be in place, except forCattle and Sheep (CS.1.1) Cross-reference with PG.1.1 (Pigs) andPY.1.1 (Poultry). Records must provide address and assurancedetails of farm of origin. No N/A.CP 3.3 Are all livestock individually identified, though not necessarilyuniquely?CC 3.3 All livestock must have individual or batch identification, dependingon the livestock. Poultry may have batch ID.CP 3.4 Are procedures in place to demonstrate full traceability of livestockback to farm of birth/hatching?CC 3.4 Movement history to farm of birth/hatching is recorded, eitherindividually or as a group. Pigs and poultry may have batch/houseID.CP 3.5 Are all livestock uniquely identified (poultry may have batch ID) andare procedures in place to demonstrate full traceability back to farmof birth/hatching?CC 3.5 Unique identification of individual livestock with movement historyto farm of birth/hatching registered on a centralised database.Poultry may have batch/house ID.MajorMustMajorMustMajorMustMajorMustMajorMustMajorMustMinorMustMinorMust5.3Recom. 5.3.5Recom. 5.3.5LIVESTOCK SOURCING, IDENTIFICATION AND TRACEABILITY5.3.1 Do all farms with livestock enterprises maintain a movementrecord?5.3.1 A visual inspection of a sample of records confirms that at least thefollowing are recorded:· Date moved to/from farm.· Numbersmoved· Identification marks (tags/chips/tattoos)· Address to or fromwhich they have been moved. No N/A.5.3.2 Are procedures in place to ensure all livestock, have beenborn/hatched and reared on a EUREPGAP (or benchmarkedscheme) assured farm? No EUREPGAP approved farms mayaccommodate both assured and non-assured livestock of the samespecies.5.3.2 Procedures including movement records (minimum 3 years, 3months at first inspection) and EUREPGAP approved dispatchnotes or equivalent document containing the same information (seeEUREPGAP dispatch note guideline) must be in place, except forcattle and sheep see point 6.1.1, and poultry see point 9.1.1.Records must provide address and assurance details of farm oforigin. No N/A.5.3.3 Are all livestock individually identified, though not necessarilyuniquely (poultry may have batch ID)?5.3.3 All livestock must have individual or batch identification, dependingon the livestock.5.3.4 Are procedures in place to demonstrate full traceability of livestockback to farm of birth/hatching?5.3.4 Movement history to farm of birth/hatching is recorded. Pigs andpoultry may have batch/house ID.Are all livestock uniquely identified (poultry may have batch ID) andare procedures in place to demonstrate full traceability back to farmof birth/hatching?Unique identification of individual livestock with movement historyto farm of birth/hatching registered on a centralised database.Poultry may have batch/house ID.MajorMustMajorMustMajorMustMajorMustMajorMustMajorMustRecom.Recom.Recom.Recom.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 5 of 19CP 3.6 Is a mechanism of identification used to identify specific livestockor batches/houses of livestock requiring or having receivedtreatment (for which there is a required period of withdrawal) atleast until the withdrawal period has been completed?MajorMust5.3.6 Is a mechanism of identification used to identify specific livestockor batches/houses of livestock requiring or having receivedtreatment (for which there is a required period of withdrawal) atleast until the withdrawal period has been completed?MajorMustCC 3.6 Assessment of mechanism. No N/A. Cross-reference with LB.7.2.3 MajorMustCP 3.7 Are all livestock accompanied by a despatch note that meets the MajorEurepGAP standard and national legal requirements when being Musttransported? These despatch notes are to be used on change ofownership and on movements in excess of 20 kilometres.5.3.6 Assessment where possible and/or workers to demonstrateawareness at interview. No N/A. Cross Check with 5.7.2.35.3.7 Are all livestock accompanied by a despatch note that meets theEUREPGAP standard and national legal requirements when beingtransported? These despatch notes are to be used on change ofownership and on movements in excess of 20 kilometres.MajorMustMajorMustCC 3.7 EurepGAP approval despatch notes are correctly completed for allmovements of livestock off the farm (see EurepGAP despatch noteguideline), and evidence of compliance with any additionalapplicable legal requirements regarding despatch of livestock. SeeLB Annex 1- Despatch note. No N/AMajorMust5.3.7 EUREPGAP approval despatch notes are correctly completed forall movements of livestock off the farm (see EUREPGAP dispatchnote guideline), and evidence of compliance with any additionalapplicable legal requirements regarding dispatch of livestock. NoN/ALB.4 LIVESTOCK FEED AND WATER 5.4 LIVESTOCK FEED AND WATERLB.4.1 General 5.4.1 GeneralCP 4.1.1 Does all livestock have access to sufficient clean water, includingwhilst at pasture?MajorMust5.4.1.1 Does all livestock have access to sufficient clean water, includingwhilst at pasture? Are fouled drinking facilities cleaned? Are stepstaken to ensure supplies in extreme weather/climates?MajorMustMajorMustCC 4.1.1 Sufficient clean water must be available, fouled drinking facilitiesmust be cleaned and there must be a mechanism in place toensure supplies in extreme weather/climates. No N/A. Cross checkMajorMust5.4.1.1 Visual assessment and workers to demonstrate awareness atinterview. No N/A. Cross check with 8.4.6 and 9.2.2.MajorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 6 of 19CP 4.1.2 Has compound feed been manufactured by, and obtained from, asource approved by EurepGAP?CC 4.1.2 Where compound feed is supplied by a company that is licensedwith the relevant competent authority it must demonstrate that itcomplies with the requirements for quality assurance set byEurepGAP (see EurepGAP Compound Feed ManufacturingStandard). Compound Feed Manufacturers (CFM) approved byEUREPGAP are placed on the approved list on thewww.eurepgap.org website. The CFM used must be certifiedagainst the EUREPGAP CFM Standard OR against a standard thathas been successfully benchmarked against the EUREPGAP CFMStandard within 12 months of the producer's registration withEurepGAP. Refer to the EurepGAP Compound Feed ManufacturingStandard. No N/AMajorMustMajorMust5.4.1.2 Has purchased feed (except forage) and industry by-products beenmanufactured by, and obtained from, a source approved byEUREPGAP.5.4.1.2 Where purchased feed (except forage) is supplied by a companythat is licensed with the relevant competent authority it mustdemonstrate that it complies with the requirements for qualityassurance set by EUREPGAP.MajorMustMajorMustCP 4.1.3 Are all home-mixers of feedstuffs registered with, or approved by,the relevant competent authority?CC 4.1.3 Home-mixers must demonstrate registration (i.e. by conforming toEU Directive 95/69), or approval with the relevant competentauthority.CP 4.1.4 Are labels of the feedstuffs kept by the farmer as evidence of feedorigin and ingredient composition?CC 4.1.4 Feedstuffs labels that cover the contents of the feed must be kept.Invoice number must be registered in the production data base andthis number to be traced back to the feed batch information kept bythe feed supplier when feed bag labels are not kept after feedconsumption. No N/A unless no feedstuff supplied.MajorMustMajorMustMajorMustMajorMust5.4.1.3 Are all home-mixers of feeding stuffs registered with, or approvedby, the relevant competent authority?5.4.1.3 Home-mixers must demonstrate registration (i.e. by conforming toEU Directive 95/69), or approval with the relevant competentauthority.5.4.1.4 Are labels of the feedingstuffs kept by the farmer as evidence offeed origin and ingredient composition?5.4.1.4 Feedstuffs labels kept, that covering the contents of the feed. NoN/A unless no feedstuff supplied.MajorMustMajorMustMajorMustMajorMustCP 4.1.5 Are all purchased stock feed materials traceable to the supplier? MajorMustCC 4.1.5 All stock feed materials are traceable to the supplier. No N/A. MajorMustCP 4.1.6 Are protein elements of diets only obtained from vegetables, milk, Majoreggs or fish (fishmeal cannot be fed to ruminants).MustCC 4.1.6 Feed records demonstrate only permitted sources used. Labelling Majorto this effect or a statement from the manufacturer stating the Mustprotein origin must be kept by the farmer as evidence. No N/Aunless no feeding.5.4.1.5 Are all purchased stock feed materials traceable to the supplier? MajorMust5.4.1.5 All stock feed materials are traceable to the supplier. No N/A. MajorMust5.4.1.7 Are protein elements of diets only obtained from vegetables, milk, Majoreggs or fish (fishmeal cannot be fed to ruminants).Must5.4.1.7 Feed records demonstrate only permitted sources used. Labelling Majorto this effect or a statement from the manufacturer stating the Mustprotein origin must be kept by the farmer as evidence. No N/Aunless no feeding.©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org

EUREPGAPBENCHMARKING CROSS-REFERENCE CHECKLISTINTEGRATED FARM ASSURANCE | CPCCLIVESTOCK | LIVESTOCK BASEENGLISH VERSIONCode Ref.: IFA 3.0 BCVersion: 3.0-Mar07Section: Livestock BasePage: 7 of 19CP 4.1.7 Did enterprises which mix feed in their own machines draw up amixture protocol for the different mixtures?CC 4.1.7 Detailed records show the percentage of the components. No N/Aunless no mixing in own machinery.CP 4.1.8 Do home-mixers source, from January 2009, only certifiedEurepGAP combinable crops for mixing feed?CC 4.1.8 All combinable crops (see crop list for Combinable Crops) sourcedfor mixing feed must be EurepGAP (or equivalent) certified. No N/Aunless no mixing in own machinery.MajorMustMajorMustMajorMustMajorMust5.4.1.8 Did enterprises which mix feed in their own machines draw up amixture protocol for the different mixtures which shows thepercentage of the components?5.4.1.8 Interview answers or visual inspection of records as detailed. NoN/A unless no mixing in own machinery.5.4.1.6 Is forage fed on the farm derived from crops that were producedand certified according to the relevant EUREPGAP standard(where a standard is available)?5.4.1.6 Bought in forage is from EUREPGAP approved farms. No N/Aunless no standard available.CP 4.1.9 Is fishmeal only from sustainable and traceable sources permitted? Recom. 5.4.1.9 Is fishmeal only from sustainable and traceable sources permitted? Recom.CC 4.1.9 Feed records demonstrate only permitted sources used. Labellingto this effect or a statement from the manufacturer stating thefishmeal sustainability origin should be kept by the farmer asevidence. N/A where no feeding.Recom. 5.4.1.9CP 4.1.10 Is there a procedure to deal with residues of medicated feed? MajorMustCC 4.1.10 If medicated feed was used, there must be a separate Majorbin/compartment in which withdrawal ration is stored.MustCP 4.1.11 Is there a procedure to ensure that feeding systems are cleaned Majorregularly?MustCC 4.1.11 Visual assessment and workers to demonstrate awareness at Majorinterview. No N/A.MustFeed records demonstrate only permitted sources used. Labellingto this effect or a statement from the manufacturer stating thefishmeal sustainability origin should be kept by the farmer asevidence. N/A where no feeding.5.4.1.10 Is there a procedure to deal with residues of medicated feed? MajorMust5.4.1.10 If medicated feed was used, there must be a separate Majorbin/compartment in which withdrawal ration is stored.Must5.4.1.11 Is there a procedure to ensure that feeding systems are cleaned Majorregularly?Must5.4.1.11 Visual assessment and workers to demonstrate awareness at Majorinterview. No N/A.MustLB.4.2 Feed Records 5.4.2 Feed RecordsCP 4.2.1 Are documentary records (for example invoices) of feed suppliers Major 5.4.2.1 Do documentary records (for example invoices) of feed suppliers Majorfrom whom feed materials have been purchased available? Mustfrom whom feed materials have been purchased include the type of MustCC 4.2.1 Records, including the type of feed, quantity and date of delivery,are available for purchased feeds. No N/A unless no feeding.MajorMustfeed, quantity and date of delivery?5.4.2.1 Records as detailed are available for purchased feeds. No N/Aunless no feeding.MajorMustMajorMustMajorMustMajorMustRecom.MajorMustCP 4.2.2 Do documentary records of feed suppliers from whom compoundfeed and other animal feed material have been purchased includethe ingredients?CC 4.2.2 Labels/invoices/statements specifying ingredients are available. NoN/A unless no feeding OR if there are patent/intellectual propertyrights limitations.MinorMustMinorMust5.4.2.2 Do documentary records of feed suppliers from whom compoundfeed and other animal feed material have been purchased includethe ingredients?5.4.2.2 Labels/invoices/statements specifying ingredients are available. NoN/A unless no feeding OR if there are patent/intellectual propertyrights limitations.MinorMustMinorMust©Copyright: EUREPGAP c/o FoodPLUS GmbH,Spichernstr. 55, D-50672 Köln (Cologne); Germany | Tel: +49-221-57993-25/-66; Fax: +49-221-57993-56 | http://www.eurepgap.org