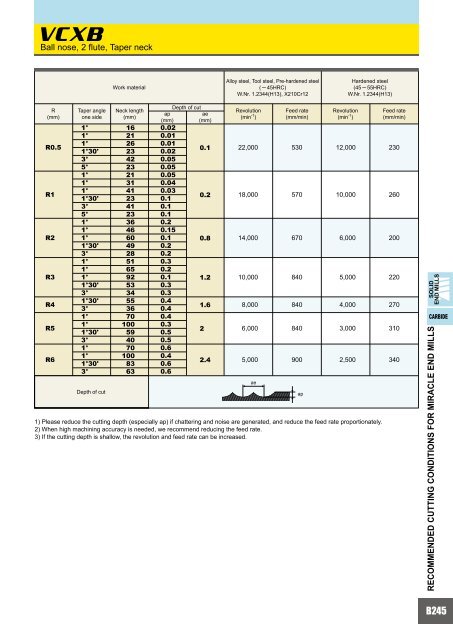

VCXBBall nose, 2 flute, Taper neckWork materialAlloy steel, Tool steel, Pre-hardened steel( 45HRC)W.Nr. 1.2344(H13), X210Cr12Hardened steel(45 55HRC)W.Nr. 1.2344(H13)R(mm)R0.5R1R2R3R4R5R6Taper angleone side1°1°1°1°30'3°5°1°1°1°1°30'3°5°1°1°1°1°30'3°1°1°1°1°30'3°1°30'3°1°1°1°30'3°1°1°1°30'3°Depth of cutNeck length(mm)162126234223213141234123364660492851659253345536701005940701008363ap(mm)0.020.010.010.020.050.050.050.040.030.10.10.10.20.150.10.20.20.30.20.10.30.30.40.40.40.30.50.50.60.40.60.6Depth of cutae(mm)0.10.20.81.21.622.4Revolution(min -1 )22,00018,00014,00010,0008,0006,0005,000aeFeed rate(mm/min)530570670840840840900apRevolution(min -1 )12,00010,0001) Please reduce the cutting depth (especially ap) if chattering and noise are generated, and reduce the feed rate proportionately.2) When high machining accuracy is needed, we recommend reducing the feed rate.3) If the cutting depth is shallow, the revolution and feed rate can be increased.6,0005,0004,0003,0002,500Feed rate(mm/min)230260200220270310340<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDERECOMM<strong>END</strong>ED CUTTING CONDITIONS FOR MIRACLE <strong>END</strong> <strong>MILLS</strong>B245

RECOMM<strong>END</strong>ED CUTTING CONDITIONS FOR MIRACLE <strong>END</strong> <strong>MILLS</strong>VC3MBBall nose end mill, Medium cut length, 3 flutey RoughingWorkmaterialR(mm)R1R2R3R4R5R6R8R10Depth ofcutAlloy steel, Tool steel, Pre-hardened steel( 45HRC)070M55, W.Nr. 1.2344(H13), X210Cr12 etc.Revolution(min -1 )32,00018,50013,00010,0008,0006,6005,0004,000%< 15° %>15°Feed rate(mm/min)3,0003,7004,0005,0005,0004,6004,0003,600Revolution(min -1 )25,00014,50010,0008,0006,5005,3004,0003,200Feed rate(mm/min)1,1701,4601,5002,0002,0001,8001,6001,440< 0.5RRevolution(min -1 )18,00011,0007,7006,0004,8004,0003,0002,400Hardened steel(45 55HRC)W.Nr. 1.2344(H13)%< 15° %>15°Feed rate(mm/min)1,4401,7601,9202,3002,2002,1001,7001,400Revolution(min -1 )16,0009,2006,4004,8003,8003,2002,4001,900< 0.2RFeed rate(mm/min)640740800920870840680550R:Radius%<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDERECOMM<strong>END</strong>ED CUTTING CONDITIONS FOR MIRACLE <strong>END</strong> <strong>MILLS</strong>y FinishingWorkmaterialR(mm)R1R2R3R4R5R6R8R10Depth ofcutAlloy steel, Tool steel, Pre-hardened steel( 45HRC)070M55, W.Nr. 1.2344(H13), X210Cr12 etc.Revolution(min -1 )32,00025,50020,00015,00012,00010,0007,5006,000%< 15° %>15°Feed rate(mm/min)3,2005,0006,1007,5007,5007,0006,0005,400Revolution(min -1 )32,00020,00015,00011,0009,0007,5005,6004,500Feed rate(mm/min)1,5002,0002,2002,7002,7002,5002,2002,000< 0.1RRevolution(min -1 )25,00017,00013,00010,0008,0006,6005,0004,000Hardened steel(45 55HRC)W.Nr. 1.2344(H13)%< 15° %>15°Feed rate(mm/min)2,0002,7003,2003,8003,7003,5002,8002,300Revolution(min -1 )20,00013,00010,0007,5006,0005,0003,7003,000< 0.06RFeed rate(mm/min)8001,0001,2001,4001,4001,3001,000900R:Radius1) % is the inclination of the machinedsurface.2) Please use VF2SB or VC4MB forworkpiece of 55HRC or above.3) If the rigidity of the machine or theworkpiece installation is very low, orchattering and noise are generated,please reduce the revolution and thefeed rate proportionately.4) When machining accuracy is important,reducing the feed rate isrecommended.Especially for finishing, lower the feedrates and/or pick feeds according tothe required accuracy.5) Cutting conditions may beconsiderably different due to theoverhang (milling depth), depth of cut,and machine tools. Please see theabove table as a standard.6) If the depth of cut is shallow, therevolution and feed rate can beincreased.B246

- Page 5:

SOLID END MILLSEND MILLS SELECTION

- Page 9 and 10:

SOLID END MILLSEND MILLS SELECTION

- Page 11 and 12:

SOLID END MILLSPRODUCT CODE DESCRIP

- Page 13 and 14:

SOLID END MILLSCOATING TECHNOLOGYCo

- Page 15 and 16:

MSTAR END MILLSMS2SSEnd mill, Short

- Page 17 and 18:

MSTAR END MILLSMS2MSExpandEnd mill,

- Page 19 and 20:

MSTAR END MILLSMS2LSEnd mill, long

- Page 21 and 22:

B0200 -0.010 -0.020.4

- Page 24 and 25:

Unit : mmOrder NumberMS2XL6D0220N05

- Page 26 and 27:

MSMHD0High power, Medium cut length

- Page 28 and 29:

MSJHD0High power, Semi long cut len

- Page 30 and 31:

MS4SC0End mill, Short cut length, 4

- Page 32 and 33:

MS4JC0End mill, Semi long cut lengt

- Page 34 and 35:

B033B210MS4XLD0160N180D0160N200D016

- Page 36 and 37:

MS2ES0End mill, 2 flute, For small

- Page 38 and 39:

MS4ECD1End mill, 4 flute, For small

- Page 40 and 41:

END MILLSMS2MB0Ball nose, Medium cu

- Page 42 and 43:

B041B2139.5°9°8.7°8.3°8°12.2°

- Page 44 and 45:

B043B2134.9°6.7°4.4°4°5.7°3.7

- Page 46:

B045B2136.8°5.9°5.2°4.6°4.2°3.

- Page 49 and 50:

B0481111111111111111111111111111111

- Page 51 and 52:

MSTAR END MILLSMS2MRBExpandCorner r

- Page 53 and 54:

MSTAR END MILLSMS2XLRBCorner radius

- Page 55 and 56:

MSTAR END MILLSMS4MRBCorner radius

- Page 57 and 58:

MSTAR END MILLSMSMHDRBCorner radius

- Page 59 and 60:

MSTAR END MILLSMS2MTTaper end mill,

- Page 61 and 62:

MSTAR END MILLSMS2MTTaper end mill,

- Page 63 and 64:

MSTAR END MILLSMS4LTTaper end mill,

- Page 65 and 66:

MSTAR END MILLSMS4LTTaper end mill,

- Page 67 and 68:

MSTAR END MILLSMS4LTTaper end mill,

- Page 69 and 70:

MSTAR END MILLSMS4LTBBall nose, 4 f

- Page 71 and 72:

MSTAR END MILLSMS2MTBBall nose tape

- Page 73 and 74:

MSTAR END MILLSMS3MC aaa EEnd mill,

- Page 75 and 76:

MSTAR END MILLSMS4JC aaa EEnd mill,

- Page 77 and 78:

MSTAR END MILLSMS2MB aaa EBall nose

- Page 79 and 80:

MSTAR END MILLSMS6MH aaa E/MS8MH aa

- Page 81 and 82:

IMPACT MIRACLE END MILLSVF2SBExpand

- Page 83 and 84:

IMPACT MIRACLE END MILLSVF2SDBLBall

- Page 85 and 86:

B084VF2XLBa±0.007±0.0100 -0.029.

- Page 88 and 89:

B087B2292.7°2.4°6.0°5.2°4.7°4.

- Page 90 and 91:

B089B230111111111111111111111111111

- Page 92 and 93:

VFSDEnd mill, Short cut length, 4/6

- Page 94 and 95:

VFSDRBCorner radius, Short cut leng

- Page 96 and 97:

MIRACLE END MILLSVC2SS0End mill, Ex

- Page 98 and 99:

VC2MSEnd mill, Medium cut length, 2

- Page 100 and 101:

VC2MSSS0End mill, Medium cut length

- Page 102 and 103:

VC2XLEnd mill, Short cut length, 2

- Page 104 and 105:

VC4MCSSEnd mill, Medium cut length,

- Page 106 and 107:

VC2ESBBall nose, Extra short cut le

- Page 108 and 109:

VC2SBBall nose, Short cut length, 2

- Page 110 and 111:

VC2PSBBall nose, Short cut length,

- Page 112 and 113:

VC2MBSSBall nose, Medium cut length

- Page 114 and 115:

VC2LBBall nose, Medium cut length,

- Page 116 and 117:

VC2XLBBall nose, 2 flute, Long neck

- Page 118 and 119:

B245B117VCXBaVCXB R0050T0100L016R00

- Page 120 and 121:

VC2XZBBall nose, Medium cut length,

- Page 122 and 123:

VC4MBBall nose, Medium cut length,

- Page 124 and 125:

B123B248VCPSRBa0 -0.01±0.0112.4°

- Page 126 and 127:

B125B2484.2°4.2°4.3°3.3°3.4°3.

- Page 128 and 129:

VCPSRBExpandCorner radius, Short cu

- Page 130 and 131:

VCHFRBCorner radius, Short flute le

- Page 132 and 133:

VC4SRBCorner radius, Short cut leng

- Page 134 and 135:

VCMDEnd mill, Medium cut length, 6

- Page 136 and 137:

VCMDLEnd mill, Medium cut length, 6

- Page 138 and 139:

VCMHDRBCorner radius, Medium cut le

- Page 140 and 141:

VCMHEnd mill, Medium cut length, 3

- Page 142 and 143:

VCSFPRExpandRoughing type, Short cu

- Page 144 and 145:

VC4MTTaper end mill, Medium cut len

- Page 146 and 147:

VC4STBBall nose taper end mill, Sho

- Page 148 and 149:

VC2CChamfer cutter, 2 flutee 0.0290

- Page 150 and 151:

CRN END MILLSCRN2MSEnd mill, Medium

- Page 152 and 153:

B151B263CRN2XL D0100N120S04D0100N12

- Page 154 and 155:

CRN2MBBall nose, Medium cut length,

- Page 156 and 157:

B155B2657.9°9.5°6.8°8.5°6.0°7.

- Page 158 and 159:

CRN2MRBCorner radius end mill, Medi

- Page 160 and 161:

Order NumberCRN2XLRB D0500R020N25D0

- Page 162 and 163:

DLC2MBBall nose end mill, Medium cu

- Page 164 and 165:

DC2MBNFBall nose, Medium cut length

- Page 166 and 167:

DCXBBall nose taper, Medium cut len

- Page 168 and 169:

DC2LBBall nose, long cut length, 2

- Page 170 and 171:

BRAZED TYPE END MILLSEND MILLPolycr

- Page 172 and 173:

AM2SC2 flute end mill, Short cut le

- Page 174 and 175:

AM3SS3 flute end mill, Short cut le

- Page 176 and 177:

AM4MF4 flute end mill, Medium cut l

- Page 178 and 179:

1 B177B278D1 ap L1L3 D4 R ND5AM2SCR

- Page 180 and 181:

B179B279D1 ap L1L3 D4 R ND5AM3SSRBD

- Page 182 and 183:

AMSRRoughing end mill, 3 flute, Sho

- Page 184 and 185:

CARBIDE END MILLSSEE2SEnd mill, Sho

- Page 186 and 187:

SEE4LEnd mill, Long cut length, 4 f

- Page 188 and 189:

SEG2SAEnd mill, 2 flute, Irregular

- Page 190 and 191:

VIOLET END MILLSVA2SSEnd mill, Shor

- Page 192 and 193:

VA4MC0End mill, Medium cut length,

- Page 194 and 195:

VASFPRRoughing type, Short cut leng

- Page 196 and 197: VAMRRoughing type, Medium cut lengt

- Page 198 and 199: VALRRoughing type, Long cut length,

- Page 200 and 201: VALHEnd mill, High helix, Long cut

- Page 202 and 203: MS2JSEnd mill, Semi long cut length

- Page 204 and 205: MS2XLEnd mill, Short cut length, 2

- Page 206 and 207: MSSHDHigh power, Short cut length,

- Page 208 and 209: MSMHZDEnd mill, Medium cut length,

- Page 210 and 211: MS4JCEnd mill, Semi long cut length

- Page 212 and 213: MS2ESEnd mill, 2 flute, For small a

- Page 214 and 215: MS2XLBBall nose, Short cut length,

- Page 216 and 217: MS2XLRBCorner radius end mill, Shor

- Page 218 and 219: MSMHDRBCorner radius end mill, High

- Page 220 and 221: MS4LTTaper end mill, Long cut lengt

- Page 222 and 223: MS2SB aaa EBall nose, Short cut len

- Page 224 and 225: MS3MC aaa EEnd mill, Medium cut len

- Page 226 and 227: MS4MC aaa EEnd mill, Medium cut len

- Page 228 and 229: RECOMMENDED CUTTING CONDITIONS FOR

- Page 230 and 231: VF2XLBBall nose, Long cut length, 2

- Page 232 and 233: Work materialCarbon steel, Alloy st

- Page 234 and 235: RECOMMENDED CUTTING CONDITIONS FOR

- Page 236 and 237: VC2JSEnd mill, Semi long cut length

- Page 238 and 239: VC4MCEnd mill, Medium cut length, 4

- Page 240 and 241: Ball nose, Short cut length, 2 flut

- Page 242 and 243: Ball nose, Medium cut length, 2 flu

- Page 244 and 245: VC2XZBBall nose, Medium cut length,

- Page 248 and 249: VC4MBBall nose, Medium cut length,

- Page 250 and 251: yTaper neck typeWork materialAlloy

- Page 252 and 253: VCMDEnd mill, Medium cut length, 6

- Page 254 and 255: VCMHDRBCorner radius, Medium cut le

- Page 256 and 257: VC6MHEnd mill, Medium cut length, 6

- Page 258 and 259: VC2MTTaper end mill, 2 flute, Mediu

- Page 260 and 261: R(mm)R 2R 3R 4Work materialTaper an

- Page 262 and 263: VCRCCorner rounding cutterWorkmater

- Page 264 and 265: CRN2XLEnd mill, 2 flute, Long neck,

- Page 266 and 267: CRN2XLBBall nose, Long neck, 2 flut

- Page 268 and 269: CRN2XLRBCorner radius end mill, Sho

- Page 270 and 271: DLC2MBBall nose end mill, Medium cu

- Page 272 and 273: DC2MBBall nose, Medium cut length,

- Page 274 and 275: RECOMMENDED CUTTING CONDITIONS FOR

- Page 276 and 277: AM2MR2 flute end mill, Medium cut l

- Page 278 and 279: AM4MF4 flute end mill, Medium cut l

- Page 280 and 281: AM3SSRB3 flute end mill, Corner rad

- Page 282 and 283: AMMRRoughing end mill, 3 flute, Med

- Page 284 and 285: SEE4LEnd mill, Long cut length, 4 f

- Page 286 and 287: RECOMMENDED CUTTING CONDITIONS FOR

- Page 288 and 289: VA2MBBall nose, Medium cut length,

- Page 290 and 291: VAMFPRRoughing type, Medium cut len

- Page 292 and 293: VAJRRoughing type, Semi long cut le

- Page 294: MemoB293