VC2MTTaper end mill, 2 flute, Medium cut lengthy SlottingWorkmaterialCarbon steel, Alloy steel( 30HRC)Ck55, 070M55Cast iron GG25Alloy steel, Tool steelPre-hardened steel(30 45HRC)W.Nr. 1.2344(H13), X210Cr12Hardened steel(45 55HRC)W.Nr. 1.2344(H13)Small milldia.(mm)11.522.5Revolution(min -1 )16,00010,0008,0006,500Feed rate(mm/min)400400400400Depth of cut(mm)0.030.060.080.12Revolution(min -1 )12,0007,5006,0005,000Feed rate(mm/min)300300300300Depth of cut(mm)0.030.060.080.12Revolution(min -1 )10,0006,5005,0004,000Feed rate(mm/min)100100100100Depth of cut(mm)0.020.040.060.101) A high-speed spindle is recommended. When using a reduced speed, the revolution and feed rate must be reduced proportionately.2) Non-water-soluble cutting fluid is recommended.VC4MTTaper end mill, Medium cut length, 4 flutey Side millingWorkmaterialSmall milldia.(mm)3456810Depth ofcutCarbon steel, Alloy steel( 30HRC)Ck55, 070M55Cast iron GG25Revolution(min -1 )4,2003,4002,9002,5001,9001,600Feed rate(mm/min)110135170200220220Alloy steel, Tool steelPre-hardened steel(30 45HRC)W.Nr. 1.2344(H13)X210Cr12Revolution(min -1 )3,4002,7002,3002,0001,5001,300Feed rate(mm/min)95110135170170170< 0.05D< 2.5DHardened steel(45 55HRC)W.Nr. 1.2344(H13)Revolution(min -1 )2,3001,8001,5001,3001,000800Feed rate(mm/min)1) If the rigidity of the machine or the workpiece installation is very low, or chattering is generated, please reduce the revolution and the feedrate proportionately.607080100100100D:Dia.<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDERECOMM<strong>END</strong>ED CUTTING CONDITIONS FOR MIRACLE <strong>END</strong> <strong>MILLS</strong>B257

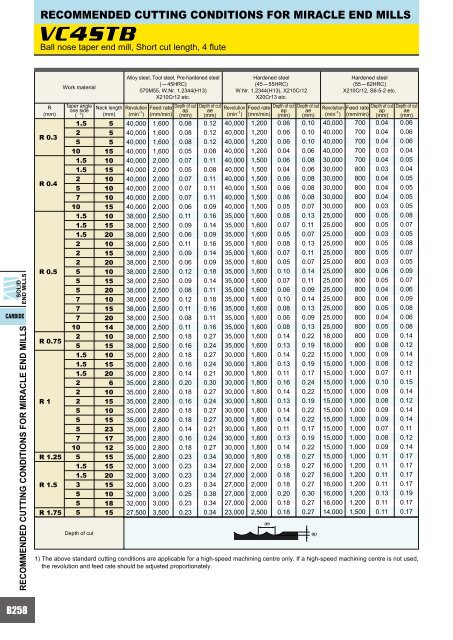

RECOMM<strong>END</strong>ED CUTTING CONDITIONS FOR MIRACLE <strong>END</strong> <strong>MILLS</strong>VC4STBBall nose taper end mill, Short cut length, 4 flute<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDERECOMM<strong>END</strong>ED CUTTING CONDITIONS FOR MIRACLE <strong>END</strong> <strong>MILLS</strong>R(mm)R 0.3R 0.4R 0.5R 0.75R 1R 1.25R 1.5R 1.75Work materialTaper angleone side( °)1.525101.51.5257101.51.51.522255577710251.51.51.522255571051.51.53555Depth of cutNeck length(mm)5551510151010101510152010152010152010152014101510152061015101523171215152015101815Alloy steel, Tool steel, Pre-hardened steel( 45HRC)070M55, W.Nr. 1.2344(H13)X210Cr12 etc.Revolution(min -1 )40,00040,00040,00040,00040,00040,00040,00040,00040,00040,00038,00038,00038,00038,00038,00038,00038,00038,00038,00038,00038,00038,00038,00038,00038,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00032,00032,00032,00032,00032,00027,500Feed rate(mm/min)1,6001,6001,6001,6002,0002,0002,0002,0002,0002,0002,5002,5002,5002,5002,5002,5002,5002,5002,5002,5002,5002,5002,5002,5002,5002,8002,8002,8002,8002,8002,8002,8002,8002,8002,8002,8002,8003,0003,0003,0003,0003,0003,500Depth of cutap(mm)0.080.080.080.050.070.050.070.070.070.060.110.090.060.110.090.060.120.090.080.120.110.080.110.180.160.180.160.140.200.180.160.180.180.140.160.180.230.230.230.230.250.230.23Depth of cutae(mm)0.120.120.120.080.110.080.110.110.110.090.160.140.090.160.140.090.180.140.110.180.160.110.160.270.240.270.240.210.300.270.240.270.270.210.240.270.340.340.340.340.380.340.34Hardened steel(45 55HRC)W.Nr. 1.2344(H13), X210Cr12X20Cr13 etc.Revolution(min -1 )40,00040,00040,00040,00040,00040,00040,00040,00040,00040,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00035,00030,00030,00030,00030,00030,00030,00030,00030,00030,00030,00030,00030,00027,00027,00027,00027,00027,00023,000Feed rate(mm/min)1,2001,2001,2001,2001,5001,5001,5001,5001,5001,5001,6001,6001,6001,6001,6001,6001,6001,6001,6001,6001,6001,6001,6001,6001,6001,8001,8001,8001,8001,8001,8001,8001,8001,8001,8001,8001,8002,0002,0002,0002,0002,0002,500aeDepth of cutap(mm)0.060.060.060.040.060.040.060.060.060.050.080.070.050.080.070.050.100.070.060.100.080.060.080.140.130.140.130.110.160.140.130.140.140.110.130.140.180.180.180.180.200.180.18Depth of cutae(mm)0.100.100.100.060.080.060.080.080.080.070.130.110.070.130.110.070.140.110.090.140.130.090.130.220.190.220.190.170.240.220.190.220.220.170.190.220.270.270.270.270.300.270.27apRevolution(min -1 )40,00040,00040,00040,00030,00030,00030,00030,00030,00030,00025,00025,00025,00025,00025,00025,00025,00025,00025,00025,00025,00025,00025,00018,00018,00015,00015,00015,00015,00015,00015,00015,00015,00015,00015,00015,00015,00016,00016,00016,00016,00016,00014,000Hardened steel(55 62HRC)X210Cr12, S6-5-2 etc.Feed rate(mm/min)7007007007007008008008008008008008008008008008008008008008008008008008008001,0001,0001,0001,0001,0001,0001,0001,0001,0001,0001,0001,0001,2001,2001,2001,2001,2001,500Depth of cutap(mm)0.040.040.040.030.040.030.040.040.040.030.050.050.030.050.050.030.060.050.040.060.050.040.050.090.080.090.080.070.100.090.080.090.090.070.080.090.110.110.110.110.130.110.11Depth of cutae(mm)0.060.060.060.040.050.040.050.050.050.050.080.070.050.080.070.050.090.070.060.090.080.060.080.140.120.140.120.110.150.140.120.140.140.110.120.140.170.170.170.170.190.170.171) The above standard cutting conditions are applicable for a high-speed machining centre only. If a high-speed machining centre is not used,the revolution and feed rate should be adjusted proportionately.B258

- Page 5:

SOLID END MILLSEND MILLS SELECTION

- Page 9 and 10:

SOLID END MILLSEND MILLS SELECTION

- Page 11 and 12:

SOLID END MILLSPRODUCT CODE DESCRIP

- Page 13 and 14:

SOLID END MILLSCOATING TECHNOLOGYCo

- Page 15 and 16:

MSTAR END MILLSMS2SSEnd mill, Short

- Page 17 and 18:

MSTAR END MILLSMS2MSExpandEnd mill,

- Page 19 and 20:

MSTAR END MILLSMS2LSEnd mill, long

- Page 21 and 22:

B0200 -0.010 -0.020.4

- Page 24 and 25:

Unit : mmOrder NumberMS2XL6D0220N05

- Page 26 and 27:

MSMHD0High power, Medium cut length

- Page 28 and 29:

MSJHD0High power, Semi long cut len

- Page 30 and 31:

MS4SC0End mill, Short cut length, 4

- Page 32 and 33:

MS4JC0End mill, Semi long cut lengt

- Page 34 and 35:

B033B210MS4XLD0160N180D0160N200D016

- Page 36 and 37:

MS2ES0End mill, 2 flute, For small

- Page 38 and 39:

MS4ECD1End mill, 4 flute, For small

- Page 40 and 41:

END MILLSMS2MB0Ball nose, Medium cu

- Page 42 and 43:

B041B2139.5°9°8.7°8.3°8°12.2°

- Page 44 and 45:

B043B2134.9°6.7°4.4°4°5.7°3.7

- Page 46:

B045B2136.8°5.9°5.2°4.6°4.2°3.

- Page 49 and 50:

B0481111111111111111111111111111111

- Page 51 and 52:

MSTAR END MILLSMS2MRBExpandCorner r

- Page 53 and 54:

MSTAR END MILLSMS2XLRBCorner radius

- Page 55 and 56:

MSTAR END MILLSMS4MRBCorner radius

- Page 57 and 58:

MSTAR END MILLSMSMHDRBCorner radius

- Page 59 and 60:

MSTAR END MILLSMS2MTTaper end mill,

- Page 61 and 62:

MSTAR END MILLSMS2MTTaper end mill,

- Page 63 and 64:

MSTAR END MILLSMS4LTTaper end mill,

- Page 65 and 66:

MSTAR END MILLSMS4LTTaper end mill,

- Page 67 and 68:

MSTAR END MILLSMS4LTTaper end mill,

- Page 69 and 70:

MSTAR END MILLSMS4LTBBall nose, 4 f

- Page 71 and 72:

MSTAR END MILLSMS2MTBBall nose tape

- Page 73 and 74:

MSTAR END MILLSMS3MC aaa EEnd mill,

- Page 75 and 76:

MSTAR END MILLSMS4JC aaa EEnd mill,

- Page 77 and 78:

MSTAR END MILLSMS2MB aaa EBall nose

- Page 79 and 80:

MSTAR END MILLSMS6MH aaa E/MS8MH aa

- Page 81 and 82:

IMPACT MIRACLE END MILLSVF2SBExpand

- Page 83 and 84:

IMPACT MIRACLE END MILLSVF2SDBLBall

- Page 85 and 86:

B084VF2XLBa±0.007±0.0100 -0.029.

- Page 88 and 89:

B087B2292.7°2.4°6.0°5.2°4.7°4.

- Page 90 and 91:

B089B230111111111111111111111111111

- Page 92 and 93:

VFSDEnd mill, Short cut length, 4/6

- Page 94 and 95:

VFSDRBCorner radius, Short cut leng

- Page 96 and 97:

MIRACLE END MILLSVC2SS0End mill, Ex

- Page 98 and 99:

VC2MSEnd mill, Medium cut length, 2

- Page 100 and 101:

VC2MSSS0End mill, Medium cut length

- Page 102 and 103:

VC2XLEnd mill, Short cut length, 2

- Page 104 and 105:

VC4MCSSEnd mill, Medium cut length,

- Page 106 and 107:

VC2ESBBall nose, Extra short cut le

- Page 108 and 109:

VC2SBBall nose, Short cut length, 2

- Page 110 and 111:

VC2PSBBall nose, Short cut length,

- Page 112 and 113:

VC2MBSSBall nose, Medium cut length

- Page 114 and 115:

VC2LBBall nose, Medium cut length,

- Page 116 and 117:

VC2XLBBall nose, 2 flute, Long neck

- Page 118 and 119:

B245B117VCXBaVCXB R0050T0100L016R00

- Page 120 and 121:

VC2XZBBall nose, Medium cut length,

- Page 122 and 123:

VC4MBBall nose, Medium cut length,

- Page 124 and 125:

B123B248VCPSRBa0 -0.01±0.0112.4°

- Page 126 and 127:

B125B2484.2°4.2°4.3°3.3°3.4°3.

- Page 128 and 129:

VCPSRBExpandCorner radius, Short cu

- Page 130 and 131:

VCHFRBCorner radius, Short flute le

- Page 132 and 133:

VC4SRBCorner radius, Short cut leng

- Page 134 and 135:

VCMDEnd mill, Medium cut length, 6

- Page 136 and 137:

VCMDLEnd mill, Medium cut length, 6

- Page 138 and 139:

VCMHDRBCorner radius, Medium cut le

- Page 140 and 141:

VCMHEnd mill, Medium cut length, 3

- Page 142 and 143:

VCSFPRExpandRoughing type, Short cu

- Page 144 and 145:

VC4MTTaper end mill, Medium cut len

- Page 146 and 147:

VC4STBBall nose taper end mill, Sho

- Page 148 and 149:

VC2CChamfer cutter, 2 flutee 0.0290

- Page 150 and 151:

CRN END MILLSCRN2MSEnd mill, Medium

- Page 152 and 153:

B151B263CRN2XL D0100N120S04D0100N12

- Page 154 and 155:

CRN2MBBall nose, Medium cut length,

- Page 156 and 157:

B155B2657.9°9.5°6.8°8.5°6.0°7.

- Page 158 and 159:

CRN2MRBCorner radius end mill, Medi

- Page 160 and 161:

Order NumberCRN2XLRB D0500R020N25D0

- Page 162 and 163:

DLC2MBBall nose end mill, Medium cu

- Page 164 and 165:

DC2MBNFBall nose, Medium cut length

- Page 166 and 167:

DCXBBall nose taper, Medium cut len

- Page 168 and 169:

DC2LBBall nose, long cut length, 2

- Page 170 and 171:

BRAZED TYPE END MILLSEND MILLPolycr

- Page 172 and 173:

AM2SC2 flute end mill, Short cut le

- Page 174 and 175:

AM3SS3 flute end mill, Short cut le

- Page 176 and 177:

AM4MF4 flute end mill, Medium cut l

- Page 178 and 179:

1 B177B278D1 ap L1L3 D4 R ND5AM2SCR

- Page 180 and 181:

B179B279D1 ap L1L3 D4 R ND5AM3SSRBD

- Page 182 and 183:

AMSRRoughing end mill, 3 flute, Sho

- Page 184 and 185:

CARBIDE END MILLSSEE2SEnd mill, Sho

- Page 186 and 187:

SEE4LEnd mill, Long cut length, 4 f

- Page 188 and 189:

SEG2SAEnd mill, 2 flute, Irregular

- Page 190 and 191:

VIOLET END MILLSVA2SSEnd mill, Shor

- Page 192 and 193:

VA4MC0End mill, Medium cut length,

- Page 194 and 195:

VASFPRRoughing type, Short cut leng

- Page 196 and 197:

VAMRRoughing type, Medium cut lengt

- Page 198 and 199:

VALRRoughing type, Long cut length,

- Page 200 and 201:

VALHEnd mill, High helix, Long cut

- Page 202 and 203:

MS2JSEnd mill, Semi long cut length

- Page 204 and 205:

MS2XLEnd mill, Short cut length, 2

- Page 206 and 207:

MSSHDHigh power, Short cut length,

- Page 208 and 209: MSMHZDEnd mill, Medium cut length,

- Page 210 and 211: MS4JCEnd mill, Semi long cut length

- Page 212 and 213: MS2ESEnd mill, 2 flute, For small a

- Page 214 and 215: MS2XLBBall nose, Short cut length,

- Page 216 and 217: MS2XLRBCorner radius end mill, Shor

- Page 218 and 219: MSMHDRBCorner radius end mill, High

- Page 220 and 221: MS4LTTaper end mill, Long cut lengt

- Page 222 and 223: MS2SB aaa EBall nose, Short cut len

- Page 224 and 225: MS3MC aaa EEnd mill, Medium cut len

- Page 226 and 227: MS4MC aaa EEnd mill, Medium cut len

- Page 228 and 229: RECOMMENDED CUTTING CONDITIONS FOR

- Page 230 and 231: VF2XLBBall nose, Long cut length, 2

- Page 232 and 233: Work materialCarbon steel, Alloy st

- Page 234 and 235: RECOMMENDED CUTTING CONDITIONS FOR

- Page 236 and 237: VC2JSEnd mill, Semi long cut length

- Page 238 and 239: VC4MCEnd mill, Medium cut length, 4

- Page 240 and 241: Ball nose, Short cut length, 2 flut

- Page 242 and 243: Ball nose, Medium cut length, 2 flu

- Page 244 and 245: VC2XZBBall nose, Medium cut length,

- Page 246 and 247: VCXBBall nose, 2 flute, Taper neckW

- Page 248 and 249: VC4MBBall nose, Medium cut length,

- Page 250 and 251: yTaper neck typeWork materialAlloy

- Page 252 and 253: VCMDEnd mill, Medium cut length, 6

- Page 254 and 255: VCMHDRBCorner radius, Medium cut le

- Page 256 and 257: VC6MHEnd mill, Medium cut length, 6

- Page 260 and 261: R(mm)R 2R 3R 4Work materialTaper an

- Page 262 and 263: VCRCCorner rounding cutterWorkmater

- Page 264 and 265: CRN2XLEnd mill, 2 flute, Long neck,

- Page 266 and 267: CRN2XLBBall nose, Long neck, 2 flut

- Page 268 and 269: CRN2XLRBCorner radius end mill, Sho

- Page 270 and 271: DLC2MBBall nose end mill, Medium cu

- Page 272 and 273: DC2MBBall nose, Medium cut length,

- Page 274 and 275: RECOMMENDED CUTTING CONDITIONS FOR

- Page 276 and 277: AM2MR2 flute end mill, Medium cut l

- Page 278 and 279: AM4MF4 flute end mill, Medium cut l

- Page 280 and 281: AM3SSRB3 flute end mill, Corner rad

- Page 282 and 283: AMMRRoughing end mill, 3 flute, Med

- Page 284 and 285: SEE4LEnd mill, Long cut length, 4 f

- Page 286 and 287: RECOMMENDED CUTTING CONDITIONS FOR

- Page 288 and 289: VA2MBBall nose, Medium cut length,

- Page 290 and 291: VAMFPRRoughing type, Medium cut len

- Page 292 and 293: VAJRRoughing type, Semi long cut le

- Page 294: MemoB293