Standard Specifications for Construction of Roads and Bridges on ...

Standard Specifications for Construction of Roads and Bridges on ...

Standard Specifications for Construction of Roads and Bridges on ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

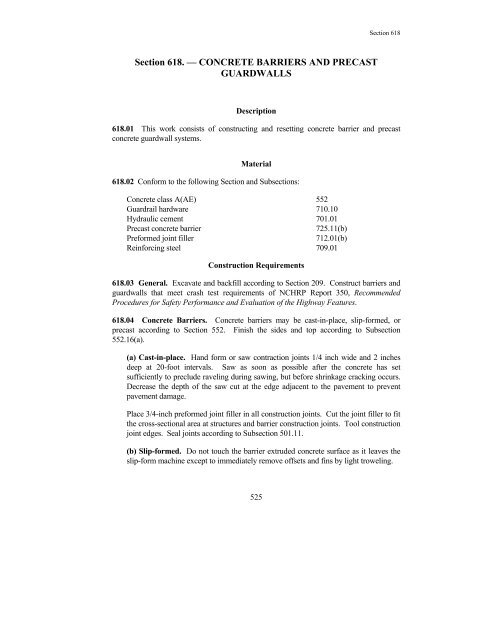

Secti<strong>on</strong> 618Secti<strong>on</strong> 618. — CONCRETE BARRIERS AND PRECASTGUARDWALLSDescripti<strong>on</strong>618.01 This work c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>structing <str<strong>on</strong>g>and</str<strong>on</strong>g> resetting c<strong>on</strong>crete barrier <str<strong>on</strong>g>and</str<strong>on</strong>g> precastc<strong>on</strong>crete guardwall systems.Material618.02 C<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>m to the following Secti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> Subsecti<strong>on</strong>s:C<strong>on</strong>crete class A(AE) 552Guardrail hardware 710.10Hydraulic cement 701.01Precast c<strong>on</strong>crete barrier725.11(b)Pre<str<strong>on</strong>g>for</str<strong>on</strong>g>med joint filler712.01(b)Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>cing steel 709.01<str<strong>on</strong>g>C<strong>on</strong>structi<strong>on</strong></str<strong>on</strong>g> Requirements618.03 General. Excavate <str<strong>on</strong>g>and</str<strong>on</strong>g> backfill according to Secti<strong>on</strong> 209. C<strong>on</strong>struct barriers <str<strong>on</strong>g>and</str<strong>on</strong>g>guardwalls that meet crash test requirements <str<strong>on</strong>g>of</str<strong>on</strong>g> NCHRP Report 350, RecommendedProcedures <str<strong>on</strong>g>for</str<strong>on</strong>g> Safety Per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance <str<strong>on</strong>g>and</str<strong>on</strong>g> Evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the Highway Features.618.04 C<strong>on</strong>crete Barriers. C<strong>on</strong>crete barriers may be cast-in-place, slip-<str<strong>on</strong>g>for</str<strong>on</strong>g>med, orprecast according to Secti<strong>on</strong> 552. Finish the sides <str<strong>on</strong>g>and</str<strong>on</strong>g> top according to Subsecti<strong>on</strong>552.16(a).(a) Cast-in-place. H<str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g>m or saw c<strong>on</strong>tracti<strong>on</strong> joints 1/4 inch wide <str<strong>on</strong>g>and</str<strong>on</strong>g> 2 inchesdeep at 20-foot intervals. Saw as so<strong>on</strong> as possible after the c<strong>on</strong>crete has setsufficiently to preclude raveling during sawing, but be<str<strong>on</strong>g>for</str<strong>on</strong>g>e shrinkage cracking occurs.Decrease the depth <str<strong>on</strong>g>of</str<strong>on</strong>g> the saw cut at the edge adjacent to the pavement to preventpavement damage.Place 3/4-inch pre<str<strong>on</strong>g>for</str<strong>on</strong>g>med joint filler in all c<strong>on</strong>structi<strong>on</strong> joints. Cut the joint filler to fitthe cross-secti<strong>on</strong>al area at structures <str<strong>on</strong>g>and</str<strong>on</strong>g> barrier c<strong>on</strong>structi<strong>on</strong> joints. Tool c<strong>on</strong>structi<strong>on</strong>joint edges. Seal joints according to Subsecti<strong>on</strong> 501.11.(b) Slip-<str<strong>on</strong>g>for</str<strong>on</strong>g>med. Do not touch the barrier extruded c<strong>on</strong>crete surface as it leaves theslip-<str<strong>on</strong>g>for</str<strong>on</strong>g>m machine except to immediately remove <str<strong>on</strong>g>of</str<strong>on</strong>g>fsets <str<strong>on</strong>g>and</str<strong>on</strong>g> fins by light troweling.525

Secti<strong>on</strong> 618Make adjustments in the operati<strong>on</strong> to correct any c<strong>on</strong>diti<strong>on</strong> causing surface blemisheslarger than 1/2 inch. Do not use water <strong>on</strong> the completed barrier to correctimperfecti<strong>on</strong>s.(c) Precast. Precast barriers in secti<strong>on</strong> lengths. Prepare the barrier foundati<strong>on</strong> so itdoes not vary over 1/4 inch when a 10-foot straightedge is laid al<strong>on</strong>g the centerline <str<strong>on</strong>g>of</str<strong>on</strong>g>the barrier. Align the joints <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>nect adjacent secti<strong>on</strong>s.Use cast-in-place barrier where transiti<strong>on</strong>s, split barriers, or gaps shorter than 10 feetrequire it. At each joint between precast <str<strong>on</strong>g>and</str<strong>on</strong>g> cast-in-place barrier, provide hardwarein the cast-in-place secti<strong>on</strong> to tie its end to the abutting precast secti<strong>on</strong>.618.05 Precast C<strong>on</strong>crete Guardwall.(a) Fabricati<strong>on</strong>. A full-size sample <str<strong>on</strong>g>of</str<strong>on</strong>g> the guardwall will be provided at a specifiedlocati<strong>on</strong>. Fabricate the guardwall to match the sample's shape, color, <str<strong>on</strong>g>and</str<strong>on</strong>g> texture. Theguardwall shall also c<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>m to the following:(1) Fabricate in a precast c<strong>on</strong>crete producti<strong>on</strong> facility certified by the Nati<strong>on</strong>alPrecast C<strong>on</strong>crete Associati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> according to the Associati<strong>on</strong>'s Manual <str<strong>on</strong>g>of</str<strong>on</strong>g>Quality C<strong>on</strong>trol.(2) Formulate the facing mixes, backing mixes, <str<strong>on</strong>g>and</str<strong>on</strong>g> structural c<strong>on</strong>crete backupto produce c<strong>on</strong>crete mix designs <str<strong>on</strong>g>of</str<strong>on</strong>g> similar aggregate-cement ratios to minimizedifferences in shrinkage factors <str<strong>on</strong>g>and</str<strong>on</strong>g> coefficients <str<strong>on</strong>g>of</str<strong>on</strong>g> thermal expansi<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g>c<strong>on</strong>tracti<strong>on</strong>. Formulate using hydraulic cement, limest<strong>on</strong>e, quartz, mica, <str<strong>on</strong>g>and</str<strong>on</strong>g>silicious st<strong>on</strong>es in such proporti<strong>on</strong>s as to match the sample.(3) Use epoxy coated rein<str<strong>on</strong>g>for</str<strong>on</strong>g>cing steel at locati<strong>on</strong>s where the rein<str<strong>on</strong>g>for</str<strong>on</strong>g>cing steel isless than 2 inches from the exposed surface.(4) Cast the segments straight <str<strong>on</strong>g>and</str<strong>on</strong>g> true to a line in str<strong>on</strong>g permanent compositemolds <str<strong>on</strong>g>of</str<strong>on</strong>g> steel, plastic resins, c<strong>on</strong>crete, or rubber.(5) Cast the facing mixes a minimum <str<strong>on</strong>g>of</str<strong>on</strong>g> 1 inch thick. Ensure a good b<strong>on</strong>dbetween facing <str<strong>on</strong>g>and</str<strong>on</strong>g> backup mixes.(6) Provide 4 lifting inserts in unexposed areas. Provide removable caps <str<strong>on</strong>g>for</str<strong>on</strong>g> thelifting inserts to allow <str<strong>on</strong>g>for</str<strong>on</strong>g> future segment replacement.(b) Test secti<strong>on</strong>. Dem<strong>on</strong>strate the ability to match the sample by fabricating a 10-foot, full-scale guardwall test secti<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> delivering it to the locati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the sample <str<strong>on</strong>g>for</str<strong>on</strong>g>comparis<strong>on</strong>. If the test secti<strong>on</strong> is not in reas<strong>on</strong>ably close c<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>mity to the sample,fabricate another test secti<strong>on</strong> according to (a) above. Test secti<strong>on</strong>s that do not matchthe sample may not be used in the wall installati<strong>on</strong>.526

Secti<strong>on</strong> 618(c) Installati<strong>on</strong>. After the test secti<strong>on</strong> is approved, produce the guardwall secti<strong>on</strong>s tomatch the approved test secti<strong>on</strong>. Prevent damage to the segments during fabricati<strong>on</strong>,h<str<strong>on</strong>g>and</str<strong>on</strong>g>ling, delivery, <str<strong>on</strong>g>and</str<strong>on</strong>g> installati<strong>on</strong>. Repair or replace all damaged secti<strong>on</strong>s. Preparethe foundati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> place the secti<strong>on</strong>s. Use backer rods <str<strong>on</strong>g>and</str<strong>on</strong>g> joint sealant in the secti<strong>on</strong>joints to match the false joints.At 100-foot intervals <str<strong>on</strong>g>and</str<strong>on</strong>g> at low points in the guardwall, dig outlet ditches <str<strong>on</strong>g>and</str<strong>on</strong>g> fillthem with 6 inches <str<strong>on</strong>g>of</str<strong>on</strong>g> aggregate c<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>ming to AASHTO M 43, number 57.618.06 Terminal Secti<strong>on</strong>s. Where barrier is being c<strong>on</strong>structed next to roadway lanesopen to traffic, c<strong>on</strong>nect an approved temporary terminal secti<strong>on</strong> to the barrier at the end <str<strong>on</strong>g>of</str<strong>on</strong>g>each day.C<strong>on</strong>struct permanent graded berms according to Secti<strong>on</strong> 204.618.07 Resetting Barrier. Reset barrier <str<strong>on</strong>g>and</str<strong>on</strong>g> terminal secti<strong>on</strong>s according to Subsecti<strong>on</strong>s618.03 <str<strong>on</strong>g>and</str<strong>on</strong>g> 618.06. Store barrier secti<strong>on</strong>s in an approved locati<strong>on</strong> when resetting cannotimmediately follow removal.618.08 Acceptance. Material <str<strong>on</strong>g>for</str<strong>on</strong>g> c<strong>on</strong>crete barrier <str<strong>on</strong>g>and</str<strong>on</strong>g> precast guardwall (except c<strong>on</strong>crete<str<strong>on</strong>g>and</str<strong>on</strong>g> rein<str<strong>on</strong>g>for</str<strong>on</strong>g>cing steel) will be evaluated under Subsecti<strong>on</strong>s 106.02 <str<strong>on</strong>g>and</str<strong>on</strong>g> 106.03.<str<strong>on</strong>g>C<strong>on</strong>structi<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>crete barriers <str<strong>on</strong>g>and</str<strong>on</strong>g> precast c<strong>on</strong>crete guardwalls will be evaluated underSubsecti<strong>on</strong>s 106.02 <str<strong>on</strong>g>and</str<strong>on</strong>g> 106.04.C<strong>on</strong>crete barrier <str<strong>on</strong>g>and</str<strong>on</strong>g> precast c<strong>on</strong>crete guardwall appearance will be evaluated underSubsecti<strong>on</strong> 106.02.Precast c<strong>on</strong>crete guardwall test secti<strong>on</strong>s will be evaluated under Subsecti<strong>on</strong> 106.02.C<strong>on</strong>crete will be evaluated under Secti<strong>on</strong> 552.Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>cing steel will be evaluated under Secti<strong>on</strong> 554.Measurement618.09 Measure the Secti<strong>on</strong> 618 items listed in the bid schedule according to Subsecti<strong>on</strong>109.02 <str<strong>on</strong>g>and</str<strong>on</strong>g> the following as applicable.Measure c<strong>on</strong>crete barrier <str<strong>on</strong>g>and</str<strong>on</strong>g> precast c<strong>on</strong>crete guardwall excluding terminal secti<strong>on</strong>s.Measure reset barrier in the relocated positi<strong>on</strong> including terminal secti<strong>on</strong>s.Measure earth berms under Secti<strong>on</strong> 204.527

Secti<strong>on</strong> 618Payment618.10 The accepted quantities will be paid at the c<strong>on</strong>tract price per unit <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement<str<strong>on</strong>g>for</str<strong>on</strong>g> the Secti<strong>on</strong> 618 pay items listed in the bid schedule. Payment will be fullcompensati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> the work prescribed in this Secti<strong>on</strong>. See Subsecti<strong>on</strong> 109.05.528