Featuring: - hdgasa

Featuring: - hdgasa

Featuring: - hdgasa

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

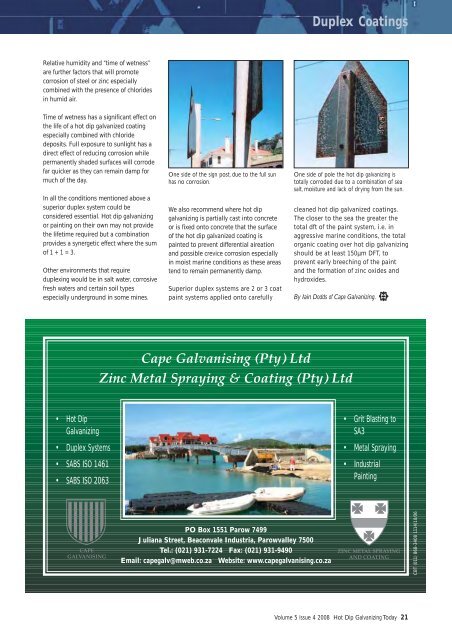

Duplex CoatingsRelative humidity and “time of wetness”are further factors that will promotecorrosion of steel or zinc especiallycombined with the presence of chloridesin humid air.Time of wetness has a significant effect onthe life of a hot dip galvanized coatingespecially combined with chloridedeposits. Full exposure to sunlight has adirect effect of reducing corrosion whilepermanently shaded surfaces will corrodefar quicker as they can remain damp formuch of the day.In all the conditions mentioned above asuperior duplex system could beconsidered essential. Hot dip galvanizingor painting on their own may not providethe lifetime required but a combinationprovides a synergetic effect where the sumof 1 + 1 = 3.Other environments that requireduplexing would be in salt water, corrosivefresh waters and certain soil typesespecially underground in some mines.One side of the sign post, due to the full sunhas no corrosion.We also recommend where hot dipgalvanizing is partially cast into concreteor is fixed onto concrete that the surfaceof the hot dip galvanized coating ispainted to prevent differential aireationand possible crevice corrosion especiallyin moist marine conditions as these areastend to remain permanently damp.Superior duplex systems are 2 or 3 coatpaint systems applied onto carefullyOne side of pole the hot dip galvanizing istotally corroded due to a combination of seasalt, moisture and lack of drying from the sun.cleaned hot dip galvanized coatings.The closer to the sea the greater thetotal dft of the paint system, i.e. inaggressive marine conditions, the totalorganic coating over hot dip galvanizingshould be at least 150µm DFT, toprevent early breeching of the paintand the formation of zinc oxides andhydroxides.By Iain Dodds of Cape Galvanizing.Cape Galvanising (Pty) LtdZinc Metal Spraying & Coating (Pty) Ltd• Hot DipGalvanizing• Grit Blasting toSA3• Duplex Systems• Metal Spraying• SABS ISO 1461• SABS ISO 2063• IndustrialPaintingCAPEGALVANISINGPO Box 1551 Parow 7499Juliana Street, Beaconvale Industria, Parowvalley 7500Tel.: (021) 931-7224 Fax: (021) 931-9490Email: capegalv@mweb.co.za Website: www.capegalvanising.co.zaZINC METAL SPRAYINGAND COATINGCBT (011) 868-3408 1114/10/06Volume 5 Issue 4 2008 Hot Dip Galvanizing Today 21