On the CouchOn the couch withJeremie MalanJeremie Malan of Jeremie MalanArchitects was born and bred inPretoria. He attended Afrikaans HoërSeunsskool in Pretoria and alsostudied Architecture at theUniversity of Pretoria. Jeremieexplains his career choice as an“instinctive knowing” since the ageof 5. He remembers playing on thefamily farm and constructing littlehouses out of sticks and mud. Thefamily, although being farmers, hada creative streak. Jeremie’s paternalgrandmother was an artist and hisfather who, despite being principallya farmer, had a keen interest inLandscape Architecture.The Malan clan still call Pretoriahome and comprises of Maré, anartist and office interior designerwho inputs in all the firm’s buildingsfrom space planning to detail designand choices of finishes andfurniture. Cillié (26) is an architectand also works for Jeremie MalanArchitects. (He was awarded theCorobrik Best University StudentAward for 2005 and also awarded theSasol Best Young Artist Award in2006.) Phillip (22) is a commercialpilot in Namibia and pilots touriststo game lodges in desolate butwonderful parts of Southern Africa.And “laatlammetjie” Maria (10) is atprimary school and loves animals,friends, piano, theatre, art, schooland Hannah Montana!True South African architecture to me isunfortunately non-existent; butregional, historic and ethnic stylesexist. These though are far apartnot only regarding nationalsymbolism but also in the use ofmaterials and the response to site,topography, climate and the culturalbackground. I find that this multifaceted background stimulatescreative and diverse styles whichcontribute to a rich visuality.I find inspiration in well planned,accurately detailed, well proportionedand well constructed buildings suchas The Eiffel Tower, Centre Pompidou,Chapel Ronchamp, GuggenheimBilbao, Lloyds London, Sydney Operaand The Union Buildings.My company Jeremie Malan Architectsspecialises in libraries, hotels andstorage facilities (depot’s, archivesand warehouses).The professional achievement I am mostproud of is the completion of The NewNational Library of South Africa inPretoria which spanned 17 yearsfrom inception to handover. Thefirst 10 years were used todetermine suitable sites and torefine a brief for the new library. In2001 we were appointed to concludewith a proposed site and a designconcept. Thereafter ourappointment was extended to detailand construct the building whichwas completed in August 08.Hot dip galvanizing to me is a versatilemethod of utilising steel inbuildings by ensuring long lastingand good quality finish for a basematerial (steel) which is prone toproblems.We use this coating often because it ismaintenance free but also providesversatile options in the designprocess.A prime example of the application of hotdip galvanizing in one of my designs isThe New National Library of SouthAfrica. We used an external hot dipgalvanized steel structure to providesunscreen and covered walkwayelements. This allowed us toexperiment with lightweight andhighly suitable architecturalelements on the facades providingthe necessary shade but allowingthe structural freedom of a steelstructure. The hot dip galvanizedfinish provides an economicsolution for a modern, expensivefaçade.I choose to live in South Africa because Iwas born here with a family historyspanning over 300 years. I believethat this history must continue andmy contribution must not only helpsustain our country and serve itspeople but also compliment thelegacy of the many people who havelived here and who have contributedto a beautiful country.When I leave the office I go home, readthe newspaper, listen to Mozart andtalk to my family.Jeremie Malan Architects can bereached on 012 460 5388 /malanarc@mweb.co.zaThe Association wishes to thank DesereStrydom for this contribution.30 Hot Dip Galvanizing Today Volume 5 Issue 4 2008

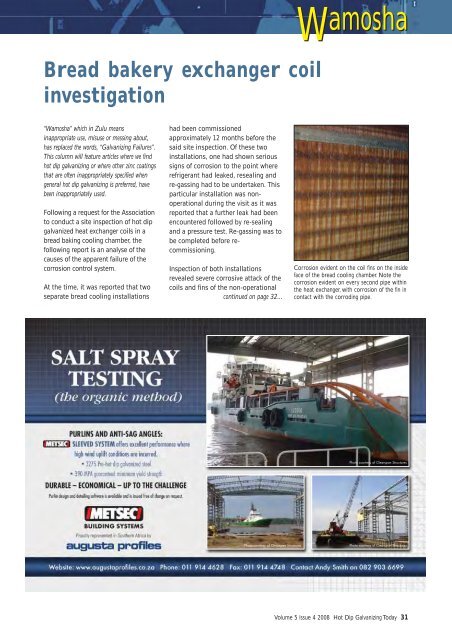

Bread bakery exchanger coilinvestigationW amosha“Wamosha” which in Zulu meansinappropriate use, misuse or messing about,has replaced the words, “Galvanizing Failures”.This column will feature articles where we findhot dip galvanizing or where other zinc coatingsthat are often inappropriately specified whengeneral hot dip galvanizing is preferred, havebeen inappropriately used.Following a request for the Associationto conduct a site inspection of hot dipgalvanized heat exchanger coils in abread baking cooling chamber, thefollowing report is an analyse of thecauses of the apparent failure of thecorrosion control system.At the time, it was reported that twoseparate bread cooling installationshad been commissionedapproximately 12 months before thesaid site inspection. Of these twoinstallations, one had shown serioussigns of corrosion to the point whererefrigerant had leaked, resealing andre-gassing had to be undertaken. Thisparticular installation was nonoperationalduring the visit as it wasreported that a further leak had beenencountered followed by re-sealingand a pressure test. Re-gassing was tobe completed before recommissioning.Inspection of both installationsrevealed severe corrosive attack of thecoils and fins of the non-operationalcontinued on page 32...Corrosion evident on the coil fins on the insideface of the bread cooling chamber. Note thecorrosion evident on every second pipe withinthe heat exchanger, with corrosion of the fin incontact with the corroding pipe.Photo courtesy of Clearspan StructuresPhoto courtesy of Clearspan StructuresPhoto courtesy of Clearspan StructuresVolume 5 Issue 4 2008 Hot Dip Galvanizing Today 31