Measure of Friction losses on Common Rail Engine

Measure of Friction losses on Common Rail Engine

Measure of Friction losses on Common Rail Engine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

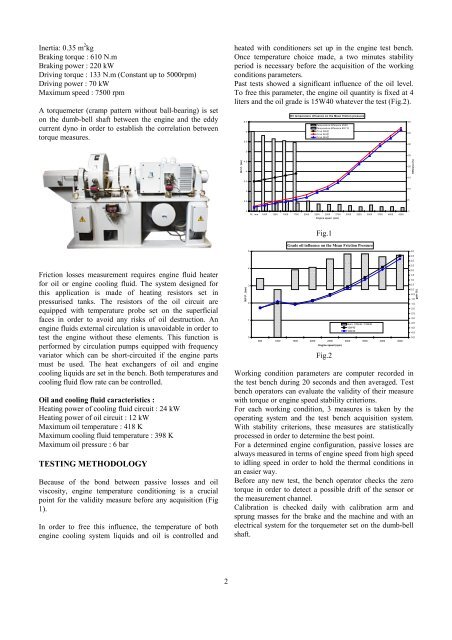

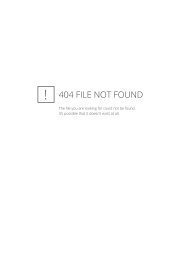

Inertia: 0.35 m 2 kgBraking torque : 610 N.mBraking power : 220 kWDriving torque : 133 N.m (C<strong>on</strong>stant up to 5000rpm)Driving power : 70 kWMaximum speed : 7500 rpmA torquemeter (cramp pattern without ball-bearing) is set<strong>on</strong> the dumb-bell shaft between the engine and the eddycurrent dyno in order to establish the correlati<strong>on</strong> betweentorque measures.heated with c<strong>on</strong>diti<strong>on</strong>ers set up in the engine test bench.Once temperature choice made, a two minutes stabilityperiod is necessary before the acquisiti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the workingc<strong>on</strong>diti<strong>on</strong>s parameters.Past tests showed a significant influence <str<strong>on</strong>g>of</str<strong>on</strong>g> the oil level.To free this parameter, the engine oil quantity is fixed at 4liters and the oil grade is 15W40 whatever the test (Fig.2).6.565.5Oil temperature influence <strong>on</strong> the Mean fricti<strong>on</strong> pressureTemperature difference 25/80Temperature difference 80/110Oil at 298캩Oil at 353캩Oil at 383캩403530525M.F.P. (bar)4.5420Difference (%)153.53102.552R□ ime 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250 3500 3750 4000 4250<strong>Engine</strong> speed (rpm)0Fig.1Grade oil influence <strong>on</strong> the Mean <str<strong>on</strong>g>Fricti<strong>on</strong></str<strong>on</strong>g> Pressure54.03.53.0<str<strong>on</strong>g>Fricti<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>losses</str<strong>on</strong>g> measurement requires engine fluid heaterfor oil or engine cooling fluid. The system designed forthis applicati<strong>on</strong> is made <str<strong>on</strong>g>of</str<strong>on</strong>g> heating resistors set inpressurised tanks. The resistors <str<strong>on</strong>g>of</str<strong>on</strong>g> the oil circuit areequipped with temperature probe set <strong>on</strong> the superficialfaces in order to avoid any risks <str<strong>on</strong>g>of</str<strong>on</strong>g> oil destructi<strong>on</strong>. Anengine fluids external circulati<strong>on</strong> is unavoidable in order totest the engine without these elements. This functi<strong>on</strong> isperformed by circulati<strong>on</strong> pumps equipped with frequencyvariator which can be short-circuited if the engine partsmust be used. The heat exchangers <str<strong>on</strong>g>of</str<strong>on</strong>g> oil and enginecooling liquids are set in the bench. Both temperatures andcooling fluid flow rate can be c<strong>on</strong>trolled.Oil and cooling fluid caracteristics :Heating power <str<strong>on</strong>g>of</str<strong>on</strong>g> cooling fluid circuit : 24 kWHeating power <str<strong>on</strong>g>of</str<strong>on</strong>g> oil circuit : 12 kWMaximum oil temperature : 418 KMaximum cooling fluid temperature : 398 KMaximum oil pressure : 6 barTESTING METHODOLOGYBecause <str<strong>on</strong>g>of</str<strong>on</strong>g> the b<strong>on</strong>d between passive <str<strong>on</strong>g>losses</str<strong>on</strong>g> and oilviscosity, engine temperature c<strong>on</strong>diti<strong>on</strong>ing is a crucialpoint for the validity measure before any acquisiti<strong>on</strong> (Fig1).In order to free this influence, the temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> bothengine cooling system liquids and oil is c<strong>on</strong>trolled andM.F.P. (bar)43210800 1000 1500 2000 2500 3000 3500 4000 4500<strong>Engine</strong> speed (rpm)Fig.2Gain: 10W40 / 15W40Working c<strong>on</strong>diti<strong>on</strong> parameters are computer recorded inthe test bench during 20 sec<strong>on</strong>ds and then averaged. Testbench operators can evaluate the validity <str<strong>on</strong>g>of</str<strong>on</strong>g> their measurewith torque or engine speed stability criteri<strong>on</strong>s.For each working c<strong>on</strong>diti<strong>on</strong>, 3 measures is taken by theoperating system and the test bench acquisiti<strong>on</strong> system.With stability criteri<strong>on</strong>s, these measures are statisticallyprocessed in order to determine the best point.For a determined engine c<strong>on</strong>figurati<strong>on</strong>, passive <str<strong>on</strong>g>losses</str<strong>on</strong>g> arealways measured in terms <str<strong>on</strong>g>of</str<strong>on</strong>g> engine speed from high speedto idling speed in order to hold the thermal c<strong>on</strong>diti<strong>on</strong>s inan easier way.Before any new test, the bench operator checks the zerotorque in order to detect a possible drift <str<strong>on</strong>g>of</str<strong>on</strong>g> the sensor orthe measurement channel.Calibrati<strong>on</strong> is checked daily with calibrati<strong>on</strong> arm andsprung masses for the brake and the machine and with anelectrical system for the torquemeter set <strong>on</strong> the dumb-bellshaft.15W4010W402.52.01.51.00.50.0-0.5-1.0-1.5-2.0-2.5-3.0-3.5-4.0-4.5-5.0gain (%)2