Measure of Friction losses on Common Rail Engine

Measure of Friction losses on Common Rail Engine

Measure of Friction losses on Common Rail Engine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

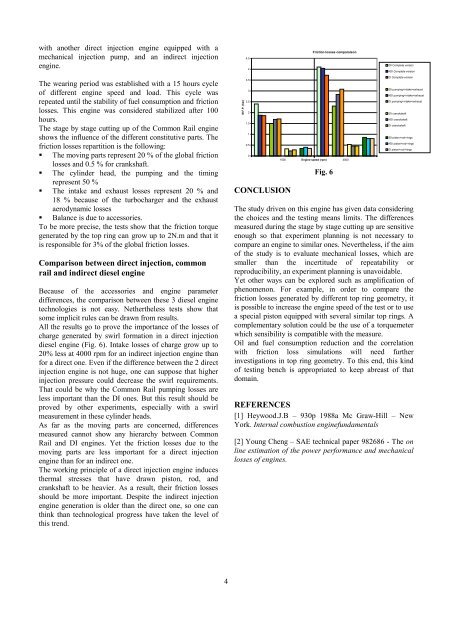

with another direct injecti<strong>on</strong> engine equipped with amechanical injecti<strong>on</strong> pump, and an indirect injecti<strong>on</strong>engine.4.54<str<strong>on</strong>g>Fricti<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>losses</str<strong>on</strong>g> comparais<strong>on</strong>IDI Complete versi<strong>on</strong>HDI Complete versi<strong>on</strong>The wearing period was established with a 15 hours cycle<str<strong>on</strong>g>of</str<strong>on</strong>g> different engine speed and load. This cycle wasrepeated until the stability <str<strong>on</strong>g>of</str<strong>on</strong>g> fuel c<strong>on</strong>sumpti<strong>on</strong> and fricti<strong>on</strong><str<strong>on</strong>g>losses</str<strong>on</strong>g>. This engine was c<strong>on</strong>sidered stabilized after 100hours.The stage by stage cutting up <str<strong>on</strong>g>of</str<strong>on</strong>g> the Comm<strong>on</strong> <strong>Rail</strong> engineshows the influence <str<strong>on</strong>g>of</str<strong>on</strong>g> the different c<strong>on</strong>stitutive parts. Thefricti<strong>on</strong> <str<strong>on</strong>g>losses</str<strong>on</strong>g> repartiti<strong>on</strong> is the following:• The moving parts represent 20 % <str<strong>on</strong>g>of</str<strong>on</strong>g> the global fricti<strong>on</strong><str<strong>on</strong>g>losses</str<strong>on</strong>g> and 0.5 % for crankshaft.• The cylinder head, the pumping and the timingrepresent 50 %• The intake and exhaust <str<strong>on</strong>g>losses</str<strong>on</strong>g> represent 20 % and18 % because <str<strong>on</strong>g>of</str<strong>on</strong>g> the turbocharger and the exhaustaerodynamic <str<strong>on</strong>g>losses</str<strong>on</strong>g>• Balance is due to accessories.To be more precise, the tests show that the fricti<strong>on</strong> torquegenerated by the top ring can grow up to 2N.m and that itis resp<strong>on</strong>sible for 3% <str<strong>on</strong>g>of</str<strong>on</strong>g> the global fricti<strong>on</strong> <str<strong>on</strong>g>losses</str<strong>on</strong>g>.Comparis<strong>on</strong> between direct injecti<strong>on</strong>, comm<strong>on</strong>rail and indirect diesel engineBecause <str<strong>on</strong>g>of</str<strong>on</strong>g> the accessories and engine parameterdifferences, the comparis<strong>on</strong> between these 3 diesel enginetechnologies is not easy. Nethertheless tests show thatsome implicit rules can be drawn from results.All the results go to prove the importance <str<strong>on</strong>g>of</str<strong>on</strong>g> the <str<strong>on</strong>g>losses</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g>charge generated by swirl formati<strong>on</strong> in a direct injecti<strong>on</strong>diesel engine (Fig. 6). Intake <str<strong>on</strong>g>losses</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> charge grow up to20% less at 4000 rpm for an indirect injecti<strong>on</strong> engine thanfor a direct <strong>on</strong>e. Even if the difference between the 2 directinjecti<strong>on</strong> engine is not huge, <strong>on</strong>e can suppose that higherinjecti<strong>on</strong> pressure could decrease the swirl requirements.That could be why the Comm<strong>on</strong> <strong>Rail</strong> pumping <str<strong>on</strong>g>losses</str<strong>on</strong>g> areless important than the DI <strong>on</strong>es. But this result should beproved by other experiments, especially with a swirlmeasurement in these cylinder heads.As far as the moving parts are c<strong>on</strong>cerned, differencesmeasured cannot show any hierarchy between Comm<strong>on</strong><strong>Rail</strong> and DI engines. Yet the fricti<strong>on</strong> <str<strong>on</strong>g>losses</str<strong>on</strong>g> due to themoving parts are less important for a direct injecti<strong>on</strong>engine than for an indirect <strong>on</strong>e.The working principle <str<strong>on</strong>g>of</str<strong>on</strong>g> a direct injecti<strong>on</strong> engine inducesthermal stresses that have drawn pist<strong>on</strong>, rod, andcrankshaft to be heavier. As a result, their fricti<strong>on</strong> <str<strong>on</strong>g>losses</str<strong>on</strong>g>should be more important. Despite the indirect injecti<strong>on</strong>engine generati<strong>on</strong> is older than the direct <strong>on</strong>e, so <strong>on</strong>e canthink than technological progress have taken the level <str<strong>on</strong>g>of</str<strong>on</strong>g>this trend.M.F.P. (bar)3.532.521.510.50CONCLUSION1500 <strong>Engine</strong> speed (rpm)4000Fig. 6DI Complete veris<strong>on</strong>IDI pumping+intake+exhaustHDI pumping+intake+exhaustDI pumping+intake+exhaustIDI cranckshaftHDI cranckshaftDI cranckshaftIDI pist<strong>on</strong>+rod+ringsHDI pist<strong>on</strong>+rod+ringsDI pist<strong>on</strong>+rod+ringsThe study driven <strong>on</strong> this engine has given data c<strong>on</strong>sideringthe choices and the testing means limits. The differencesmeasured during the stage by stage cutting up are sensitiveenough so that experiment planning is not necessary tocompare an engine to similar <strong>on</strong>es. Nevertheless, if the aim<str<strong>on</strong>g>of</str<strong>on</strong>g> the study is to evaluate mechanical <str<strong>on</strong>g>losses</str<strong>on</strong>g>, which aresmaller than the incertitude <str<strong>on</strong>g>of</str<strong>on</strong>g> repeatability orreproducibility, an experiment planning is unavoidable.Yet other ways can be explored such as amplificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g>phenomen<strong>on</strong>. For example, in order to compare thefricti<strong>on</strong> <str<strong>on</strong>g>losses</str<strong>on</strong>g> generated by different top ring geometry, itis possible to increase the engine speed <str<strong>on</strong>g>of</str<strong>on</strong>g> the test or to usea special pist<strong>on</strong> equipped with several similar top rings. Acomplementary soluti<strong>on</strong> could be the use <str<strong>on</strong>g>of</str<strong>on</strong>g> a torquemeterwhich sensibility is compatible with the measure.Oil and fuel c<strong>on</strong>sumpti<strong>on</strong> reducti<strong>on</strong> and the correlati<strong>on</strong>with fricti<strong>on</strong> loss simulati<strong>on</strong>s will need furtherinvestigati<strong>on</strong>s in top ring geometry. To this end, this kind<str<strong>on</strong>g>of</str<strong>on</strong>g> testing bench is appropriated to keep abreast <str<strong>on</strong>g>of</str<strong>on</strong>g> thatdomain.REFERENCES[1] Heywood.J.B – 930p 1988a Mc Graw-Hill – NewYork. Internal combusti<strong>on</strong> enginefundamentals[2] Young Cheng – SAE technical paper 982686 - The <strong>on</strong>line estimati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the power performance and mechanical<str<strong>on</strong>g>losses</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> engines.4