Avanta open vent boiler installation and service guide

Avanta open vent boiler installation and service guide

Avanta open vent boiler installation and service guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

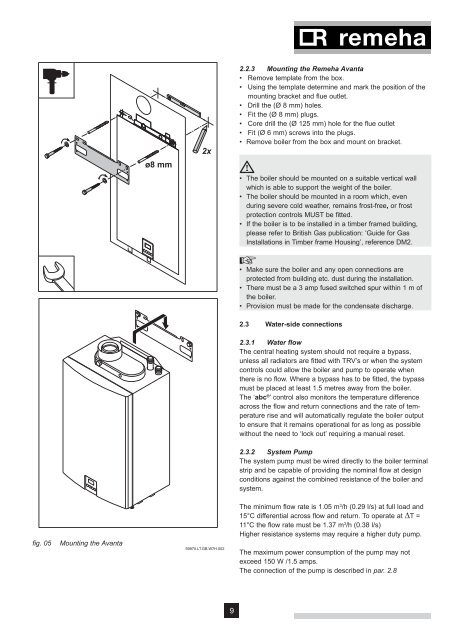

ø8 mm2x2.2.3 Mounting the Remeha <strong>Avanta</strong>• Remove template from the box.• Using the template determine <strong>and</strong> mark the position of themounting bracket <strong>and</strong> flue outlet.• Drill the (Ø 8 mm) holes.• Fit the (Ø 8 mm) plugs.• Core drill the (Ø 125 mm) hole for the flue outlet• Fit (Ø 6 mm) screws into the plugs.• Remove <strong>boiler</strong> from the box <strong>and</strong> mount on bracket.• The <strong>boiler</strong> should be mounted on a suitable vertical wallwhich is able to support the weight of the <strong>boiler</strong>.• The <strong>boiler</strong> should be mounted in a room which, evenduring severe cold weather, remains frost-free, or frostprotection controls MUST be fitted.• If the <strong>boiler</strong> is to be installed in a timber framed building,please refer to British Gas publication: ‘Guide for GasInstallations in Timber frame Housing’, reference DM2.• Make sure the <strong>boiler</strong> <strong>and</strong> any <strong>open</strong> connections areprotected from building etc. dust during the <strong>installation</strong>.• There must be a 3 amp fused switched spur within 1 m ofthe <strong>boiler</strong>.• Provision must be made for the condensate discharge.2.3 Water-side connections2.3.1 Water flowThe central heating system should not require a bypass,unless all radiators are fitted with TRV’s or when the systemcontrols could allow the <strong>boiler</strong> <strong>and</strong> pump to operate whenthere is no flow. Where a bypass has to be fitted, the bypassmust be placed at least 1.5 metres away from the <strong>boiler</strong>.The ‘abc ® ’ control also monitors the temperature differenceacross the flow <strong>and</strong> return connections <strong>and</strong> the rate of temperaturerise <strong>and</strong> will automatically regulate the <strong>boiler</strong> outputto ensure that it remains operational for as long as possiblewithout the need to ‘lock out’ requiring a manual reset.2.3.2 System PumpThe system pump must be wired directly to the <strong>boiler</strong> terminalstrip <strong>and</strong> be capable of providing the nominal flow at designconditions against the combined resistance of the <strong>boiler</strong> <strong>and</strong>system.fig. 05Mounting the <strong>Avanta</strong>59970.LT.GB.W7H.002The minimum flow rate is 1.05 m 3 /h (0.29 l/s) at full load <strong>and</strong>15°C differential across flow <strong>and</strong> return. To operate at dT =11°C the flow rate must be 1.37 m 3 /h (0.38 l/s)Higher resistance systems may require a higher duty pump.The maximum power consumption of the pump may notexceed 150 W /1.5 amps.The connection of the pump is described in par. 2.89